Separator's Digest 2004/1 - GEA Westfalia Separator Group

Separator's Digest 2004/1 - GEA Westfalia Separator Group

Separator's Digest 2004/1 - GEA Westfalia Separator Group

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

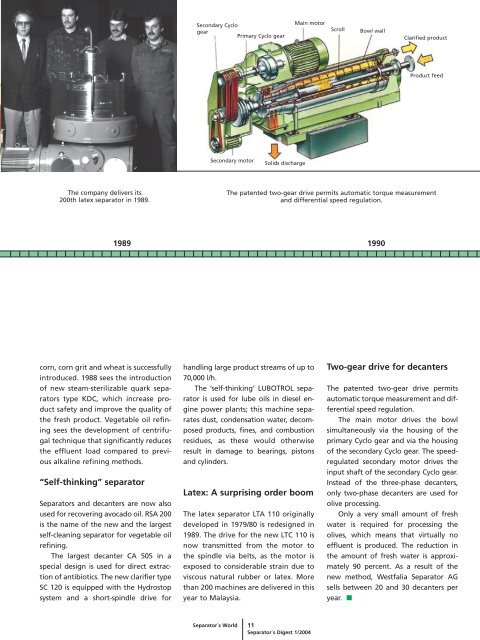

Secondary CyclogearPrimary Cyclo gearMain motorScrollBowl wallClarified productProduct feedSecondary motorSolids dischargeThe company delivers its200th latex separator in 1989.The patented two-gear drive permits automatic torque measurementand differential speed regulation.1989 1990corn, corn grit and wheat is successfullyintroduced. 1988 sees the introductionof new steam-sterilizable quark separatorstype KDC, which increase productsafety and improve the quality ofthe fresh product. Vegetable oil refiningsees the development of centrifugaltechnique that significantly reducesthe effluent load compared to previousalkaline refining methods.“Self-thinking” separator<strong>Separator</strong>s and decanters are now alsoused for recovering avocado oil. RSA 200is the name of the new and the largestself-cleaning separator for vegetable oilrefining.The largest decanter CA 505 in aspecial design is used for direct extractionof antibiotics. The new clarifier typeSC 120 is equipped with the Hydrostopsystem and a short-spindle drive forhandling large product streams of up to70,000 l/h.The ’self-thinking’ LUBOTROL separatoris used for lube oils in diesel enginepower plants; this machine separatesdust, condensation water, decomposedproducts, fines, and combustionresidues, as these would otherwiseresult in damage to bearings, pistonsand cylinders.Latex: A surprising order boomThe latex separator LTA 110 originallydeveloped in 1979/80 is redesigned in1989. The drive for the new LTC 110 isnow transmitted from the motor tothe spindle via belts, as the motor isexposed to considerable strain due toviscous natural rubber or latex. Morethan 200 machines are delivered in thisyear to Malaysia.Two-gear drive for decantersThe patented two-gear drive permitsautomatic torque measurement and differentialspeed regulation.The main motor drives the bowlsimultaneously via the housing of theprimary Cyclo gear and via the housingof the secondary Cyclo gear. The speedregulatedsecondary motor drives theinput shaft of the secondary Cyclo gear.Instead of the three-phase decanters,only two-phase decanters are used forolive processing.Only a very small amount of freshwater is required for processing theolives, which means that virtually noeffluent is produced. The reduction inthe amount of fresh water is approximately90 percent. As a result of thenew method, <strong>Westfalia</strong> <strong>Separator</strong> AGsells between 20 and 30 decanters peryear. ■<strong>Separator</strong>´s World11<strong>Separator</strong>´s <strong>Digest</strong> 1/<strong>2004</strong>