M/V Cayo Largo - DTOP

M/V Cayo Largo - DTOP

M/V Cayo Largo - DTOP

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

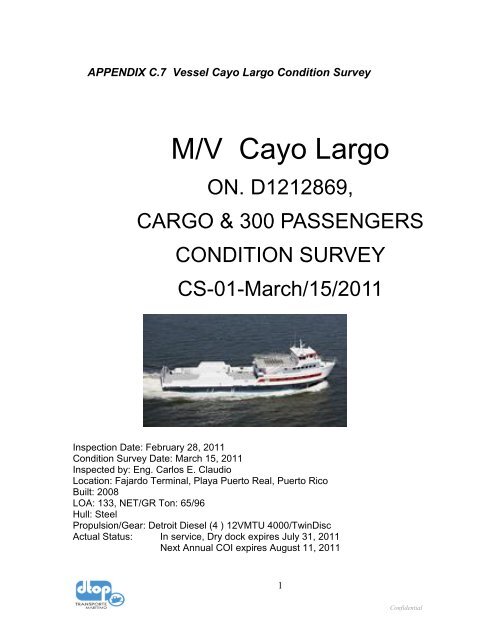

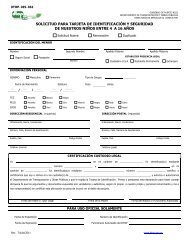

APPENDIX C.7 Vessel <strong>Cayo</strong> <strong>Largo</strong> Condition SurveyM/V <strong>Cayo</strong> <strong>Largo</strong>ON. D1212869,CARGO & 300 PASSENGERSCONDITION SURVEYCS-01-March/15/2011Inspection Date: February 28, 2011Condition Survey Date: March 15, 2011Inspected by: Eng. Carlos E. ClaudioLocation: Fajardo Terminal, Playa Puerto Real, Puerto RicoBuilt: 2008LOA: 133, NET/GR Ton: 65/96Hull: SteelPropulsion/Gear: Detroit Diesel (4 ) 12VMTU 4000/TwinDiscActual Status: In service, Dry dock expires July 31, 2011Next Annual COI expires August 11, 20111Confidential

Index:Scope of WorkAnalysisCondition Survey Report2Confidential

Scope of Work:The purpose of this report is to present actual operating conditions ofM/V <strong>Cayo</strong> <strong>Largo</strong> as per owner’s instruction after a visual inspection ofon board equipment.Pictures and comments report presentation of outstanding items to becorrect in way to maintain vessel in operating conditions.Analysis and recommendations on immediate and long termsmaintenance projections included.3Confidential

Analysis:Vessel in good condition with some maintenance work to be accomplished.Steering system oil overflow is been a continuous problem on this vessel. Review existingdesign to determine problem and correct to optimum operating conditions.Under water propulsion system inspection will be required.4Confidential

Condition Report SurveyVessel: <strong>Cayo</strong> <strong>Largo</strong>Report Date: March 15, 2011Inspection Date:.February 28, 2011Report: Condition Survey, CS-01-Sept/15/2011By: Carlos E. ClaudioLocation – Main Deck:Welding existing bitt, stbd amidships by passenger boarding gate.Engine removal inserts plates gasket materials repairs (4 ea.)Location - Void Space No. 1, (Bow Thruster):Open for inspection.Location - Void Space No. 2, (Auxiliary Machinery):Open for inspection.Location - Void Space No. 4(fwd ballast):Clean sand residues.Location - Void Space No. 5 (Aft Ballast):Ballast tank full with water, high water alarm sensor hanging from deck.Location - Void Space No. 5 (Mufflers Space) at port and stbd sides:Ventilate and certify safe for entry for inspection.Water and exhaust black stain throughout space and air discharge grill presence.Location – Transom:Renew port side stern fender.5Confidential

Location - Void Space No. 6, (Lazarette/Steering Compartment)Steering pumps oil overflow leaks, clean bilges and repair as required for proper operation.Missing light fixture. Inspect Carrier Bearings bolts since they not look aligned.Steering Pump PortSteering Pump StbdForward bulkheadForward bulkhead bilgesRudder carrier bearings bolts inspectionCarrier Bering bolts6Confidential

Location - Engine Room:Packing Box No. No. 1 (port-out) add packing and adjustPacking Box No. No. 2 (port-in) add packing and adjustPacking Box No. No. 3 (stbd-in) adjustPacking Box No. No. 4 (stbd-out) adjust.Packing Box bilge pump system reinstallation.Packing/Bearing No. 1 Packing/Bearing No. 2Packing/Bearing No. 3 Packing/Bearing No. 47Confidential

Main Propulsion Engine No. 1 (port-out) pump oil leaksMain Propulsion Engine No. 2 (port-in) sea water coolant, pump oil leaksMain Propulsion Engine No. 3 (stbd-in) pump oil leaksMain Propulsion Engine No. 4 (stbd-out) pump oil leaks correctBilges heavy oily residue, scrape, wash, and maintain.Main Propulsion Engines oil centrifugal filter oil leaks correct8Confidential

Main Engine No. 3, 4 Exhaust Flexible connections open for inspection.Main Engine No. 4 Main Engine No. 3Exhaust Flex Connector No. 4 (outbd)Exhaust Flex Connector No. 3 (outbd)9Confidential

Exhaust piping penetrations into after bulkhead open for inspection, new gaskets.Main Engine No. 1Main Engine No.2Main Engine No. 3 Main Engine No. 410Confidential

Bilge pump water seal renew and suction union connection leaks repair.Bilge Pump water leakBilge Pump connectionBilge Pump water sealBilge Pump union connectorMain Engines Deck Inserts gasket repairs to avoid water leaks into Engine Room.Main Engines inserts aboveMain Engines inserts above11Confidential

Main Propulsion Engines pre lube pumps maintain and relocate.Pre lube Pump No. 1 Pre lube Pump No. 2Pre lube Pump No. 3 Pre lube Pump No. 4Power Generator No.1, 2 (port & stbd) clean and maintain.Power generators12Confidential

Bow thruster oil tank sight glass bottom fitting leak repair.Oil sight glassAir intakes fans deflection assemblies install to avoid direct sea water spray into main engines.Ventilation fanSewage pump maintain.Location - Pilot House:Rudder angle indicator calibrate by technician to attest the accuracyFire Detection Panel service by technician and certification of proper operation.13Confidential