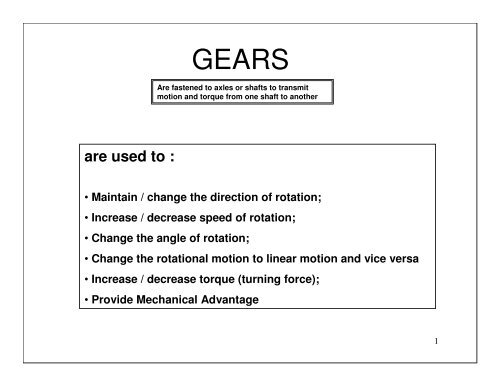

are used to : - Tegnologie

are used to : - Tegnologie

are used to : - Tegnologie

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Pawl and ratchetA ratchet mechanism is based on a wheelthat has teeth cut out of it and a pawl thatfollows as the wheel turns. Studying thediagram you will see that as the ratchetwheel turns and the pawl falls in<strong>to</strong> the 'dip'between the teeth. Ratchets <strong>are</strong> <strong>used</strong>widely in lifting equipment <strong>to</strong> lock themotion and prevent reverse rotation whenthe input force is remove. Ratchets canalso be <strong>used</strong> <strong>to</strong> drive a motion in onedirection and allow free-wheeling in thereverse direction.Chain and sprocketA chain is made up of a series of links withthe links held <strong>to</strong>gether with steel pins. Thisarrange makes a chain a strong, long lastingway of transmitting rotary motion from onegear wheel <strong>to</strong> another.Chain drive has one main advantage over atraditional gear train. Only two gear wheelsand a chain <strong>are</strong> needed <strong>to</strong> transmit rotarymotion over a distance. With a traditional geartrain, many gears must be arranged meshingwith each other in order <strong>to</strong> transmit motion.4

Changing the direction of motion (1)Adjacent gears on a gear trainrotate in opposite directions.Notice how the driver rotatesclockwise while the followerrotates anticlockwise.The addition of a third gear(idler) makes the followerand driver rotate in the samedirection.7

Meshed GearsThe diagram below shows five meshed gears. The first gear that the force is applied iscalled the driver gear. Notice that the arrows show how the gears <strong>are</strong> turning. Every othergear is turning clockwise. The very last gear is the driven gear. All of the gears in between<strong>are</strong> called idlers.8

Sizes of gearsGear ratio= Comparing the size of gearsThe gear ratio of a gear train can be determined by:1) Dividing the number of teeth on the follower, by the number of teeth on the driver.Gear Ratio =No. teeth on follower (output)No. teeth on driver (input)Gear Ratio =No. teeth on follower (output)No. teeth on driver (input)In this gear train the driver has 15 teethwhile the follower has 5 teeth.5Gear Ratio =15Gear Ratio = 1 : 3=139

2) Dividing the diameter of the follower, by the diameter of the driver.Gear Ratio =Diameter of follower (output)Diameter of driver (input)Gear Ratio =Diameter of follower (output)Diameter of driver (input)In this gear train the driver has adiameter of 18 cm while thefollower has a diameter of 6 cm.6Gear Ratio =18Gear Ratio = 1 : 3=1310

Big DriverSmall Driver11

ExercisesLook at the image on the left. Gear "B"has 36 teeth and gear "A" has 12.Calculate the gear ratio of this gear train if"B" is the driver.Look at the image on the left. Gear "B" has12 teeth and gear "A" has 24.Calculate the gear ratio of this gear train if"B" is the driver.The hand drill on the left usesintermeshing bevel gears. Gear "A" has80 teeth while gear "B" has 16.Which one is the driver?Calculate the gear ratio.12

Calculate the gear ratios of these gear trains13

Gear ratios and simple gear trainsWhat is the Gear ratioof the Gear Train ABC ?14

Gear ratios and compound gear trainsWhat is the Gear ratioof the Gear Train ABCD ?The ratio of the two gears on the same axis is not taken in<strong>to</strong> account.Gear C is the output <strong>to</strong> Gear A. Gear D is the output <strong>to</strong> gear B.15

What is the Gear ratios of these Gear Trains?16

Speed of rotationThe Velocity ratio of a pair of gearsis the inverse of the Gear ratioVelocity ratio= Comparing the rotational speed of gearsVelocity Ratio =Velocity (rpm) of outputVelocity (rpm) of inputVelocity Ratio =VR =240 rpm120 rpm21VR = 2 : 117

a 20-<strong>to</strong>oth follower will turn threetimes as fast as a 60-<strong>to</strong>oth driver.(Speed ratio: 3 : 1)a 60-<strong>to</strong>oth follower will turn once forevery three turns of a 20-<strong>to</strong>oth driver.(Speed ratio: 1 : 3)This gear train can be <strong>used</strong> <strong>to</strong>increase speed and decrease force.= Gearing upThis gear train can be <strong>used</strong> <strong>to</strong>decrease speed and increase force.= Gearing downGearing up means the followerturns faster than the driver.Gearing down means the followerturns slower than the driver.18

Working out revolutions per minute ( rpm )If A revolves at 120 rpm,what is the rpm of B ?19

Working out revolutions per minute ( rpm )If A revolves at 120 rpm,what is the rpm of B ?20

Working out revolutions per minute ( rpm )If A revolves at 60 rpm,what is the rpm of B ?21

Working out revolutions per minute ( rpm )If A revolves at 60 rpm,what is the rpm of B ?22

To summarize:This gear train will increase speedand decrease force.This gear train will decrease speedand increase force. 23

Question 1For every revolution of the drivergear calculate the number ofturns of the followerQuestion 3The input gear is connected <strong>to</strong> a mo<strong>to</strong>r that rotates at 3000 rpm.Calculate the two possible velocity ratios.Calculate the two possible output speeds.Question 2The hand drill on theright usesintermeshing bevelgears. Gear "A" has 80teeth while gear "B"has 16.Calculate the numberof turns the drill bit willcomplete if the handleis turned through 2complete rotations?Question 4Complete the gear system, <strong>to</strong> allow the output shaft <strong>to</strong> rotate at400 rpm and in the same direction as the input shaft.Indicate the number of teeth on each gear <strong>used</strong> in your solution.24

Question 1Two gears <strong>are</strong> <strong>used</strong> in a gear train. The radiusof the driving gear is 20 cm. The radius of thedriven gear is 10 cm. What is the velocity ratioof the system?If the driving wheel makes 60 revolutions perminute, calculate how many revolutions thedriven wheel makes each minute.Question 3A driving gear has a diameter of 36 cm. Thedriven gear travels at three times the numberof revolutions of the driving gear. Find thediameter of the driven gear.The driving gear in question turns at 100 rpm.Find the speed of rotation (rpm) of the drivengear.Question 2The driving gear of a gear system has 42 teethand the driven gear has 21 teeth. Calculate thevelocity ratio of the gear system.If the driving gear makes 120 revolutions perminute, calculate how many revolutions thedriven gear makes each minute.Question 4Find the velocity ratio of a gear train in whichthe driving gear has a diameter of 32 cm andthe driven gear has a diameter of 8 cm.Question 5A gear system has 60 teeth on the driving gearand 20 teeth on the driven gear. Calculate thevelocity ratio of the gear system.25

BicyclesMany machines usegears. A very goodexample is a bicycle whichhas gears that make iteasier <strong>to</strong> cycle, especiallyup hills. Bicycles normallyhave a large gear wheelwhich has a pedalattached and a selectionof gear wheels of differentsizes, on the back wheel.When the pedal isrevolved the chain pullsround the gear wheels atthe back.26

First time out, gears can be intimidating.Especially if mechanical gizmos do notweigh heavily in your background. AndBike gears <strong>are</strong> gizmos in every sense ofthe word.I'm going <strong>to</strong> talk about gears as "hard"or "easy" instead of "big" or "small".This is because "Big Gears" meansdifferent things, depending on where thegear is. A Big Gear in in back (at therear wheel) is an easier gear. A BigGear in front (at the pedals) is a hardergear.A hard gear is difficult <strong>to</strong> pedal, but yougo farther and faster with every turn ofthe crank.An easy gear is, well, easier <strong>to</strong> pedal,but you go slow, and each turn of thecranks only moves the bike a little ways.27

Highest gear: (downhill) is the largestfront gear and the smallest back gear.GR = 4 : 1VR = 1 : 4Lowest gear: (uphill) that is the smallestfront gear and the largest back gear.GR = 2 : 1VR = 1 : 2The smaller the follower -more speed & less force= Gearing upThe bigger the follower -less speed & more force= Gearing downGearing up means thefollower turns faster.Gearing down means thefollower turns slower.28

Question 1 Question 2If the pedal gear revolves once how manytimes will the sprocket gear revolve?If the diameter of the wheel, including the tyre,is 700 mm, how far will the bicycle move forone revolution of the pedals, for a Gear Ratioof 40 : 20 ?29

Changing the angle of motionBevel gears, intermesh and change the plane inwhich force is applied and rotary motion takesplace.They <strong>are</strong> <strong>used</strong> <strong>to</strong> transmit rotary motion and<strong>to</strong>rque where the bevel gear shafts <strong>are</strong> at rightangles (90 degrees) <strong>to</strong> each other.The worm and worm wheel also transmit<strong>to</strong>rque and rotary motion through a 90°angle.30

Changing the direction of motion (2)This gearing system is called a rack and pinion. Rotary motion is changed in<strong>to</strong> linear motion and vice versaIf the pinion rotates ina fixed position therack moves in a linearmotion.If the rack remainsstationary therotating pinionmoves along therack in a linearmotion.31

Movement of the rack & pinionNote: the teeth on gears must mesh perfectly, therefore, for every<strong>to</strong>oth that the pinion rotates, one <strong>to</strong>oth of the rack will move linearly.A pinion with 24 teeth rotates at 4 rpm; how far (in meters) willthe rack move in 2 minutes? The rack has 2 teeth per cm.The solution <strong>to</strong> this problem needs some initiative and logic. There<strong>are</strong> no formal equations <strong>to</strong> solve the problem.If you know how many teeth is moved on the rack in 2 minutes, youcan easily calculate the distance in meter; thus:So, the rack will move 192 teeth in 2 minutes. At 2 teeth per cm, the following can be calculated:32

DRAWING GEARSIt would be very difficult <strong>to</strong> draw gears if you had <strong>to</strong> draw all the teethevery time you wanted <strong>to</strong> design a gear system. For this reason agear can be represented by drawing two circles.33

The Wheel Although they may seem very different, wheels and gears <strong>are</strong> closelyrelated <strong>to</strong> levers. The wheel is essentially a rotating lever. Think of the diagram of thelever above as being bent in<strong>to</strong> a circle. The center of the circle is the fulcrum. In mathwe call this the center point.Wheel "A" is a circle. It is larger than wheel "B". The black circle. You will notice that"A" is larger than "B". The diameter of "A" is larger than "B". If you rotate "B"(theaxle) it will move wheel "A". Since "B" is smaller than "A" and moves in a smallercircle than "A" you will use very little input you get a large output. The large ratio ofthe wheel radius <strong>to</strong> the axle radius is what makes it easy <strong>to</strong> turn the wheel at it's rim.34

Torque(Moment of force)= a turning forceTorque (T) = Force x DistanceDepends on the amount of force and the perpendicular distance from thework-line of the force <strong>to</strong> the fulcrum, which in this case will be the centre of thegear. When working with gears, this perpendicular distance is equal <strong>to</strong> theradius of the gear. The direction of <strong>to</strong>rque is said <strong>to</strong> be either clockwise or anticlockwise.A wheel is really a lever so the import things <strong>to</strong> know <strong>are</strong> thesize of the force and the distance from the fulcrum.Most people know from experience that it is easier <strong>to</strong> turnsomething, as the effort gets further away from the centre ofrotation.A spanner is a good example. It is easier <strong>to</strong> tighten and loosenthe bolt if you push or pull the spanner right at the end.35

To understand <strong>to</strong>rque you need <strong>to</strong> know the words we use<strong>to</strong> describe circles.•The circumference is outside of the circle.•The radius is a straight line from the centre <strong>to</strong> thecircumference.•A tangent is a straight line that <strong>to</strong>uches the circumference.•The angle between a tangent and the radius is always 90degrees.The force acts in a straight lineWe always think of the force acting in a straight line andat the outside of the circular pathway.The angle between the force and the radius is always 90degrees.The <strong>to</strong>rque or turning force is equal <strong>to</strong> the size of theforce and the radius of the rotation. Simple mathematicsis <strong>used</strong> <strong>to</strong> find the <strong>to</strong>rque.Torque = Force x radius of rotation (distance)This explains why you should hold the end of thespanner rather than somewhere near the centre.36

Discuss the use of <strong>to</strong>rquein these pictures:37

Gear <strong>to</strong>rque rules:Torque is a turning force: Torque = force x distanceIncreasing <strong>to</strong>rqueWhen the driven gear has more teeththan the driver gear the <strong>to</strong>rque isincreased at the output.Decreasing <strong>to</strong>rqueWhen the driven gear has fewer teeththan the driver gear the <strong>to</strong>rque isreduced at the output.38

A big driver will reduce <strong>to</strong>rque andincrease speed of the follower.A small driver will increase <strong>to</strong>rqueand reduce speed of the follower.When we work with simple gear trains, the force transmitted from one gear <strong>to</strong> the next is the same.39

A simple gear train consists of two gears, gear A and gear B. The diameter of theinput gear A is 20 cm and a force of 5N is transmitted <strong>to</strong> gear B. What must thediameter of output gear B be so that it produces a <strong>to</strong>rque of 1.75 Nm. Draw adiagram of the gears.40

Look at the drill on the right.The input gear rotatesthrough a distance of 32cm.A output gear of the drillrotates a distance of 4 cm.What force is exerted by thedrill bit if a force of 40N wasapplied <strong>to</strong> the gear train?41

Mechanical AdvantageWhen two gears <strong>are</strong> meshed, as in thediagram on the right, they act in a similarfashion <strong>to</strong> levers. Each gear <strong>to</strong>oth can beregarded as the end of a lever with thefulcrum placed at the centre of the gear. Thelonger lever "A" is, the greater the force thatis applied <strong>to</strong> the shaft of the follower.We can make lever "A" longer by usinggears with a greater number of teeth.We can also make lever "B" smaller,therefore increasing the force exerted at theend of the lever.Gears do not only increase speed andchange the direction of motion but canmultiply turning forces.42

Mechanical AdvantageMA =Output TorqueInput TorqueMechanical advantage (MA) is the fac<strong>to</strong>r bywhich a mechanism multiplies the force put in<strong>to</strong> it.Because the force that is transmitted from one gear <strong>to</strong>the next is the same, the MA is <strong>used</strong> <strong>to</strong> comp<strong>are</strong> theoutput <strong>to</strong>rque <strong>to</strong> the input <strong>to</strong>rque of the whole system.Given the following simple gear train, determine the MAfor the system if the radius for A is 0.6 m, B is 0.3 m, C is0.8 m, and D is 0.2 m. A force of 10 N is transmitted.From the above we can see that the <strong>to</strong>rque of the idler gearshave no influence on the mechanical advantage. Thereforewe only have <strong>to</strong> calculate the <strong>to</strong>rque for gears A and D.43

Question 1Look at the imageon the left of thegears of a winebottle opener.What type of gearsystem is this?Is this simplemachine a forcemultiplier orspeed multiplier?How does thismachine make iteasy <strong>to</strong> uncorkthe wine bottle?Question 3Look at the eggbeater.Will this type of gearingproduce speed or forcemultiplication. Explain.Question 2 Question 4Determine the MA for Gear train AB.A force of 5 N is transmitted.Determine the MA for Gear train ABC. A forceof 12 N is transmitted.44

Reducing speed and increasing <strong>to</strong>rqueWorm gearThe worm is always the driver.The worm gear gives the highest decrease in speedand the highest increase in <strong>to</strong>rque. This is becausethe number of teeth for the worm is one.If the wheel of a worm gear system has 36 teeth, what will thegear ratio, velocity ratio, and mechanical advantage be?The gear ratio will then be:45

Answers p 12:46

Answers p 13:47

Answers p 16:48

Answers p 24:49

Answers p 25:50

Answers p 29:51

Answers p 41:52

Answers p 44:53

1. Bevel Gears:a. Have teeth parallel <strong>to</strong> each other.b. Change the direction of motion by 90°.c. Change the direction of motion by 45°.d. Change the direction of motion by 180°.5. To increase the speed of a robot:a. Increase the gear ratio on the mo<strong>to</strong>r outputb. Increase the gear ratio on the mo<strong>to</strong>r inputc. Decrease the gear ratio on the mo<strong>to</strong>r outputd. Decrease the gear ratio on the mo<strong>to</strong>r input.2. When a large gear turns a smaller geara. The RPM of the smaller gear is faster than the large gear.b. The RPM of the smaller gear is slower than the large gear.c. The RPM of both gears is the same.3. When more than one set of gears <strong>are</strong> <strong>used</strong> <strong>to</strong>gether,they <strong>are</strong> calleda. A complex gear train.b. A compound gear train.c. A bevel gear train.d. A one-way gear train.4. When more than one set of gears <strong>are</strong> <strong>used</strong> <strong>to</strong>gether, thegear ratio for the entire train is computed by:a. Multiplying the gear ratios of each set <strong>to</strong>getherb. Dividing the gear ratio of the first set by the gear ratio of thelast set.c. Dividing the gear ratio of the last set by the gear ratio of thefirst set.d. Adding the gear ratios of each set <strong>to</strong>gether6. Idler gears:a. Can affect the <strong>to</strong>tal gear ratio.b. Can affect the rotational direction of the output gear.c. Can affect the <strong>to</strong>tal power available at the outputgear.d. Can affect the rotational speed at the output gear7. A worm gear is special because:a. It turns rotational motion in<strong>to</strong> straight-line motionb. The direction of motion is not changed.c. It can only be located on the input axle.d. They provide a very small gear ratio8. The gear set that changes rotational motion in<strong>to</strong>straight line motion is called:a. Worm gear setb. Bevel gear setc. Spur gear setd. Rack and pinion gear set54

9. Besides bevel gears, which other type of gearcan change the direction of motion by 90°:a. Worm and spur gearsb. Rack and pinionc. Spur gearsd. Rack and worm gears10. Where the teeth of a gear set, composed ofdifferent sized gears, mesh:a. The rotational speed is the sameb. The rotational speed of the idler gear is slowerc. The rotational speed of the smaller gear is fasterd. The direction of rotation is the same11. The larger the velocity ratio of a gear train:a. The greater the speedb. The greater the forcec. The greater the <strong>to</strong>rqued. The less the speed.12. Gearing down your bicycle <strong>to</strong> increase its<strong>to</strong>rque will:a. Slow the bicycle downb. Speed the bicycle upc. Increase its forced. Decrease its force13. The input gear is 12 teeth, output 36teeth. What is the gear ratio ?a. 1:2b. 1:3c. 3:1d. 3:414. A gear that is <strong>used</strong> <strong>to</strong> change direction iscalled…….. ?a. Idlerb. Driverc. Multiplierd. Driven15. What type of gear has only one <strong>to</strong>oth?a. Compound gear trainsb. Worm gearsc. Bevel gearsd. Worm gears or bevel gears16 . A gear train has two gears. The drivenis 90mm wide and the driver is 30mmwide. What is the VR?a. 1 : 3b. 3 : 1c. 1 : 60d. 60 : 15516. a15. b14. a13. c12. c11. a10. c9. a8. d7. d6. b5. a4. c3. b2. a1. bAnswersp. 54 - 55