A New Innovative Automobile Concept in the Compact Car Class

A New Innovative Automobile Concept in the Compact Car Class

A New Innovative Automobile Concept in the Compact Car Class

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

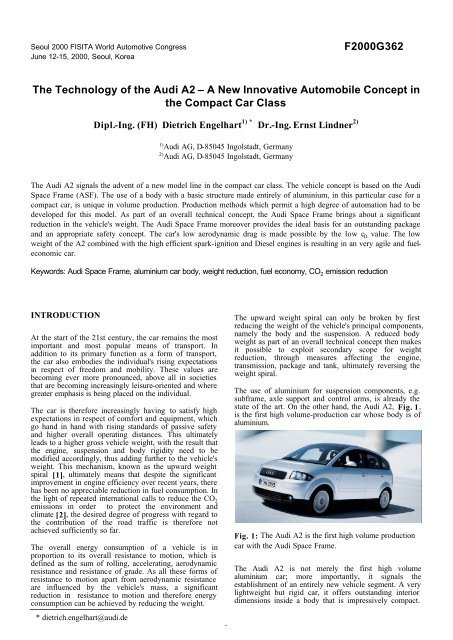

Seoul 2000 FISITA World Automotive CongressJune 12-15, 2000, Seoul, KoreaF2000G362The Technology of <strong>the</strong> Audi A2 – A <strong>New</strong> <strong>Innovative</strong> <strong>Automobile</strong> <strong>Concept</strong> <strong>in</strong><strong>the</strong> <strong>Compact</strong> <strong>Car</strong> <strong>Class</strong>Dipl.-Ing. (FH) Dietrich Engelhart 1) * Dr.-Ing. Ernst L<strong>in</strong>dner 2)1) Audi AG, D-85045 Ingolstadt, Germany2) Audi AG, D-85045 Ingolstadt, GermanyThe Audi A2 signals <strong>the</strong> advent of a new model l<strong>in</strong>e <strong>in</strong> <strong>the</strong> compact car class. The vehicle concept is based on <strong>the</strong> AudiSpace Frame (ASF). The use of a body with a basic structure made entirely of alum<strong>in</strong>ium, <strong>in</strong> this particular case for acompact car, is unique <strong>in</strong> volume production. Production methods which permit a high degree of automation had to bedeveloped for this model. As part of an overall technical concept, <strong>the</strong> Audi Space Frame br<strong>in</strong>gs about a significantreduction <strong>in</strong> <strong>the</strong> vehicle's weight. The Audi Space Frame moreover provides <strong>the</strong> ideal basis for an outstand<strong>in</strong>g packageand an appropriate safety concept. The car's low aerodynamic drag is made possible by <strong>the</strong> low c D value. The lowweight of <strong>the</strong> A2 comb<strong>in</strong>ed with <strong>the</strong> high efficient spark-ignition and Diesel eng<strong>in</strong>es is result<strong>in</strong>g <strong>in</strong> an very agile and fueleconomiccar.Keywords: Audi Space Frame, alum<strong>in</strong>ium car body, weight reduction, fuel economy, CO 2 emission reductionINTRODUCTIONAt <strong>the</strong> start of <strong>the</strong> 21st century, <strong>the</strong> car rema<strong>in</strong>s <strong>the</strong> mostimportant and most popular means of transport. Inaddition to its primary function as a form of transport,<strong>the</strong> car also embodies <strong>the</strong> <strong>in</strong>dividual's ris<strong>in</strong>g expectations<strong>in</strong> respect of freedom and mobility. These values arebecom<strong>in</strong>g ever more pronounced, above all <strong>in</strong> societiesthat are becom<strong>in</strong>g <strong>in</strong>creas<strong>in</strong>gly leisure-oriented and wheregreater emphasis is be<strong>in</strong>g placed on <strong>the</strong> <strong>in</strong>dividual.The car is <strong>the</strong>refore <strong>in</strong>creas<strong>in</strong>gly hav<strong>in</strong>g to satisfy highexpectations <strong>in</strong> respect of comfort and equipment, whichgo hand <strong>in</strong> hand with ris<strong>in</strong>g standards of passive safetyand higher overall operat<strong>in</strong>g distances. This ultimatelyleads to a higher gross vehicle weight, with <strong>the</strong> result that<strong>the</strong> eng<strong>in</strong>e, suspension and body rigidity need to bemodified accord<strong>in</strong>gly, thus add<strong>in</strong>g fur<strong>the</strong>r to <strong>the</strong> vehicle'sweight. This mechanism, known as <strong>the</strong> upward weightspiral [1], ultimately means that despite <strong>the</strong> significantimprovement <strong>in</strong> eng<strong>in</strong>e efficiency over recent years, <strong>the</strong>rehas been no appreciable reduction <strong>in</strong> fuel consumption. In<strong>the</strong> light of repeated <strong>in</strong>ternational calls to reduce <strong>the</strong> CO 2emissions <strong>in</strong> order to protect <strong>the</strong> environment andclimate [2], <strong>the</strong> desired degree of progress with regard to<strong>the</strong> contribution of <strong>the</strong> road traffic is <strong>the</strong>refore notachieved sufficiently so far.The overall energy consumption of a vehicle is <strong>in</strong>proportion to its overall resistance to motion, which isdef<strong>in</strong>ed as <strong>the</strong> sum of roll<strong>in</strong>g, accelerat<strong>in</strong>g, aerodynamicresistance and resistance of grade. As all <strong>the</strong>se forms ofresistance to motion apart from aerodynamic resistanceare <strong>in</strong>fluenced by <strong>the</strong> vehicle's mass, a significantreduction <strong>in</strong> resistance to motion and <strong>the</strong>refore energyconsumption can be achieved by reduc<strong>in</strong>g <strong>the</strong> weight.* dietrich.engelhart@audi.de1The upward weight spiral can only be broken by firstreduc<strong>in</strong>g <strong>the</strong> weight of <strong>the</strong> vehicle's pr<strong>in</strong>cipal components,namely <strong>the</strong> body and <strong>the</strong> suspension. A reduced bodyweight as part of an overall technical concept <strong>the</strong>n makesit possible to exploit secondary scope for weightreduction, through measures affect<strong>in</strong>g <strong>the</strong> eng<strong>in</strong>e,transmission, package and tank, ultimately revers<strong>in</strong>g <strong>the</strong>weight spiral.The use of alum<strong>in</strong>ium for suspension components, e.g.subframe, axle support and control arms, is already <strong>the</strong>state of <strong>the</strong> art. On <strong>the</strong> o<strong>the</strong>r hand, <strong>the</strong> Audi A2, Fig. 1,is <strong>the</strong> first high volume-production car whose body is ofalum<strong>in</strong>ium.Fig. 1: The Audi A2 is <strong>the</strong> first high volume productioncar with <strong>the</strong> Audi Space Frame.The Audi A2 is not merely <strong>the</strong> first high volumealum<strong>in</strong>ium car; more importantly, it signals <strong>the</strong>establishment of an entirely new vehicle segment. A verylightweight but rigid car, it offers outstand<strong>in</strong>g <strong>in</strong>teriordimensions <strong>in</strong>side a body that is impressively compact.

Its standards of soundproof<strong>in</strong>g, seat<strong>in</strong>g comfort andequipment moreover satisfy <strong>the</strong> high expectations ofpresent-day and future customers [3].AUDI SPACE FRAME ASF®The Audi Space Frame of <strong>the</strong> A2, Fig. 2, is a light alloybody, which consists of 22% alum<strong>in</strong>ium cast<strong>in</strong>gs, 18%alum<strong>in</strong>ium profiles and 60% alum<strong>in</strong>ium panels.The whole body is constructed of curved and straightalum<strong>in</strong>ium extruded sections. With<strong>in</strong> this frame structure,every element performs an <strong>in</strong>tegral, support<strong>in</strong>g role. Thecorners and nodes, which have to bear high loads,<strong>in</strong>corporate complex diecast elements that are jo<strong>in</strong>ed to<strong>the</strong> extruded sections. As seamless, enclosed hollowprofiles, <strong>the</strong> extruded sections are very rigid. Because <strong>the</strong>flanges that are commonplace <strong>in</strong> steel bodies are largelyunnecessary here, <strong>the</strong> space that is freed up can be put tooptimum use <strong>in</strong> vary<strong>in</strong>g <strong>the</strong> cross-section of <strong>the</strong> profile.By means of ribbed panels and tailored blanks, <strong>the</strong> rigidityof <strong>the</strong> diecast elements is precisely matched to <strong>the</strong> forces<strong>in</strong>troduced from <strong>the</strong> eng<strong>in</strong>e and suspension mounts. Inresponse to <strong>the</strong> need for high buckl<strong>in</strong>g strength, <strong>the</strong>alum<strong>in</strong>ium walls are thicker than <strong>the</strong>ir steel equivalents bya factor of approximately 1.4. In conjunction with <strong>the</strong>thicker alum<strong>in</strong>ium panels, <strong>the</strong> alum<strong>in</strong>ium body isextremely strong and exhibits a high energy absorptioncapacity when deformed <strong>in</strong> a collision.In <strong>the</strong> front structure, <strong>the</strong> longitud<strong>in</strong>al member comprisesa vacuum diecast element consist<strong>in</strong>g of two shell halves,and an extruded section bolted <strong>in</strong>to it. This easy-to-repairdesign is <strong>the</strong> basis of <strong>the</strong> car's low <strong>in</strong>suranceclassification. With <strong>in</strong>tegral eng<strong>in</strong>e mounts, subframeconnections and locat<strong>in</strong>g po<strong>in</strong>ts for <strong>the</strong> car jack, this is amultifunctional large-size component.Fig. 2: The A2 Audi Space Frame ASF.Thanks to <strong>the</strong> ASF, <strong>the</strong> A2 represents a high standard oflightweight design. This means that its static torsionalrigidity <strong>in</strong> relation to tare weight is high. Through <strong>the</strong>functionally optimized use of material, <strong>the</strong> A2's ASFachieves torsional rigidity values that are significantlyabove <strong>the</strong> figures for competitor models <strong>in</strong> this class. Thedynamic strength of <strong>the</strong> ASF, aga<strong>in</strong> high, guaranteesoutstand<strong>in</strong>g vibrational comfort.On <strong>the</strong> A2, <strong>the</strong> use of <strong>the</strong> ASF body means that <strong>the</strong>weight is over 40 % lower than that of a comparable steelbody. The reduction of <strong>the</strong> body weight as part of anoverall technical concept also makes it possible to exploitsecondary scope for reduc<strong>in</strong>g <strong>the</strong> weight of <strong>the</strong> eng<strong>in</strong>e,transmission, suspension and tank. The A2 1.4 l TDI, forexample, is around 230 kg lighter than <strong>the</strong> average ofvehicles with comparable <strong>in</strong>terior dimensions, Fig. 3.Tare weight [kg]14001300120011001000900800700Fig. 3: A2 1.4l TDI vehicle tare weight comparison.PRODUCTIONComparison Vehiclesaverage value- 230 kgA2 1.4l TDIWith <strong>the</strong> Audi A8 Alum<strong>in</strong>ium technology was firstimplemented on a production vehicle by Audi <strong>in</strong> 1994 [4].The challenge for <strong>the</strong> A2 was above all to manufacturealum<strong>in</strong>ium vehicle bodies on a large scale. In contrast to<strong>the</strong> large A8, where manual processes are still used tosome extent, automated processes had to be adoptedthroughout on <strong>the</strong> A2. Its production facilities are gearedup to an annual output of around 60,000 units. The A2'sASF has undergone fur<strong>the</strong>r ref<strong>in</strong>ement compared with <strong>the</strong>design used on <strong>the</strong> A8. In particular, <strong>the</strong> A2 has a largenumber of straight profiles and fewer cast nodes, which,however, entail a high degree of <strong>in</strong>tegration.The A2's side section, for example, consists of a s<strong>in</strong>glesection of deep-drawn sheet alum<strong>in</strong>ium extend<strong>in</strong>g from<strong>the</strong> lower edge of <strong>the</strong> w<strong>in</strong>dscreen to <strong>the</strong> tail lights. The A-post, on which <strong>the</strong> h<strong>in</strong>ges of <strong>the</strong> front doors are mounted,is made from a s<strong>in</strong>gle section of diecast alum<strong>in</strong>ium.Whereas <strong>the</strong> B-post on <strong>the</strong> A8 still comprises six separatesections, much larger diecast components are used on <strong>the</strong>A2. This br<strong>in</strong>gs <strong>the</strong> obvious advantage that fewer partsneed to be handled and jo<strong>in</strong>ed toge<strong>the</strong>r <strong>in</strong> <strong>the</strong> productionprocess. Fur<strong>the</strong>r advantages are <strong>the</strong> greater dimensionalaccuracy and <strong>the</strong> absence of jo<strong>in</strong>ts. A large number offunctions can moreover be <strong>in</strong>tegrated <strong>in</strong>to <strong>the</strong> largecast<strong>in</strong>gs, such as re<strong>in</strong>forc<strong>in</strong>g panels or ribs, which had tobe attached <strong>in</strong> a separate process on <strong>the</strong> A8.In order to reduce production time still fur<strong>the</strong>r, allpr<strong>in</strong>cipal extruded sections on <strong>the</strong> A2 such as <strong>the</strong> sideroof frame are calibrated <strong>in</strong> a hydroform<strong>in</strong>g plant beforeassembly, significantly reduc<strong>in</strong>g <strong>the</strong> need for bend<strong>in</strong>g andmill<strong>in</strong>g operations. In <strong>the</strong> hydroform<strong>in</strong>g plant, <strong>the</strong>preshaped components are <strong>in</strong>serted <strong>in</strong> a two-piece die,where perfect dimensional accuracy is achieved underhigh hydraulic pressure. The very low tolerances that canbe obta<strong>in</strong>ed by means of this technology permit <strong>the</strong> use of2

laser weld<strong>in</strong>g, which is much faster and erodes <strong>the</strong>material less than electric -arc weld<strong>in</strong>g. Less auxiliarymaterial is needed <strong>in</strong> laser weld<strong>in</strong>g than <strong>in</strong> conventionalweld<strong>in</strong>g processes, but <strong>the</strong> result<strong>in</strong>g welds are strongerand <strong>the</strong> vehicle body exhibits greater rigidity. In totalaround 30 metres of weld seams are produced by thismethod on every vehicle body. MIG weld<strong>in</strong>g is also usedto a considerable degree <strong>in</strong> <strong>the</strong> production process, <strong>in</strong>particular for <strong>the</strong> T-jo<strong>in</strong>ts on <strong>the</strong> welded platform. Spotweld<strong>in</strong>g, on <strong>the</strong> o<strong>the</strong>r hand, is no longer used. Robots jo<strong>in</strong>toge<strong>the</strong>r o<strong>the</strong>r body sections, such as <strong>the</strong> rear panel, bymeans of about 1800 punch rivets.strength and specific deformation behaviour with a verylow weight.In an front offset crash, <strong>the</strong> Audi Space Frame's frontlongitud<strong>in</strong>al members absorb <strong>the</strong> bulk of <strong>the</strong> deformationenergy, whereas <strong>the</strong> beam structures beh<strong>in</strong>d <strong>the</strong>m form<strong>the</strong> strong passenger cell and barely susta<strong>in</strong> deformation.Deformation of <strong>the</strong> longitud<strong>in</strong>al member follows a def<strong>in</strong>edpattern, from <strong>the</strong> front extruded section to <strong>the</strong> rearalum<strong>in</strong>ium cast<strong>in</strong>g. Energy absorption via <strong>the</strong> longitud<strong>in</strong>almembers ensures that <strong>the</strong> passenger cell rema<strong>in</strong>s largelyfree from deformation, Fig. 5.PACKAGE AND VARIABILITYThe objective of <strong>the</strong> package's design was to create an<strong>in</strong>novative spatial concept allow<strong>in</strong>g passengers to f<strong>in</strong>d ancomfortable seat<strong>in</strong>g position, <strong>in</strong> conjunction withcompact exterior dimensions, Fig. 4.Its basis was created by <strong>the</strong> transverse eng<strong>in</strong>e pr<strong>in</strong>cipleand space-sav<strong>in</strong>g axle concepts.Inside, <strong>the</strong> ergonomics of <strong>the</strong> A2 are optimized; whichmeans that <strong>the</strong> position of <strong>the</strong> front seats conveys afeel<strong>in</strong>g of spaciousness. At <strong>the</strong> rear, <strong>the</strong> contour of <strong>the</strong>car's floor <strong>in</strong>corporates a recess, <strong>the</strong> so-called "SpaceFloor", permitt<strong>in</strong>g rear passengers to sit upright <strong>in</strong> ancomfortable seat<strong>in</strong>g position. In general <strong>the</strong> slightly raisedposition of <strong>the</strong> front and rear seats also enhancesoccupant comfort.Fig. 5: Euro-NCAP 64km/h front offset crash,simulation of structural deformation.Full-size airbags for <strong>the</strong> driver and front passenger andside airbags <strong>in</strong> <strong>the</strong> seat backs, Fig. 6, <strong>in</strong> conjunction withseat belts that are fitted with belt tensioners and forcelimit<strong>in</strong>g devices, provide added occupant protection. Headairbags (Sideguard system) are available as an optionalfeature.Fig. 4: A2 Package.When <strong>the</strong> concept was elaborated, considerableimportance was also attached to <strong>in</strong>terior variability. Theavailability of 4- and 5-seater versions reflects <strong>the</strong>diversity of customer requirements. With <strong>the</strong> rear seats'multiple folded constellations, <strong>in</strong>clud<strong>in</strong>g scope for <strong>the</strong>irremoval entirely from <strong>the</strong> car, <strong>the</strong> A2 offers a wide rangeof different layouts, with a luggage capacity rang<strong>in</strong>g from390 to 1140 litres.THE SAFETY CONCEPTThe safety concept is based substantially on <strong>the</strong> AudiSpace Frame. The Audi Space Frame is a highly effectivethree-dimensional beam structure that comb<strong>in</strong>es highFig. 6: Safety concept.3

With<strong>in</strong> <strong>the</strong> vehicle concept <strong>the</strong> sills are relatively high,with <strong>the</strong> result that <strong>the</strong> position of <strong>the</strong> seats <strong>in</strong> a sideimpact collision is above <strong>the</strong> area most commonlyaffected by <strong>in</strong>trusion, provid<strong>in</strong>g a very high standard ofsafety. The strong door impact members, <strong>in</strong> conjunctionwith <strong>the</strong> B-post tak<strong>in</strong>g <strong>the</strong> form of a large-size ribbedcast<strong>in</strong>g and side airbags fitted as standard, reduce <strong>the</strong>load on <strong>the</strong> car's occupants. The structure with a roofframe designed for maximum rigidity <strong>in</strong> addition affordsvery good protection <strong>in</strong> a rollover.The Audi Space Frame is likewise beneficial <strong>in</strong> a rear-endcrash. The sturdy structure formed by <strong>the</strong> longitud<strong>in</strong>aland cross-members at floor level permits effective energyabsorption and braces <strong>the</strong> impact forces <strong>in</strong> a forwarddirection. Energy is absorbed <strong>in</strong> a highly effective mannerthanks to <strong>the</strong> fold<strong>in</strong>g-dent behaviour of <strong>the</strong> extrudedsections of <strong>the</strong> rear longitud<strong>in</strong>al members. The cast<strong>in</strong>g <strong>in</strong>front of <strong>the</strong>se is designed such that it susta<strong>in</strong>s m<strong>in</strong>imumdeformation, to keep <strong>the</strong> fuel tank protected. Thedeformation of specifically only <strong>the</strong> rear section meansthat <strong>the</strong> passenger cell protects <strong>the</strong> occupants veryeffectively <strong>in</strong> a rear-end collision, too.AERODYNAMICSAudi’s new aero-acoustic w<strong>in</strong>d tunnel was used for <strong>the</strong>aerodynamic test<strong>in</strong>g of this model. With <strong>the</strong> road surfacemov<strong>in</strong>g at <strong>the</strong> w<strong>in</strong>d speed be<strong>in</strong>g simulated, and thanks to<strong>the</strong> rotation of <strong>the</strong> vehicle wheels, <strong>the</strong> boundaryconditions that prevail <strong>in</strong> reality can also be simulated, sothat realistic measurements are obta<strong>in</strong>ed.The good aerodynamic performance has been achievedby def<strong>in</strong><strong>in</strong>g <strong>the</strong> vehicle's fundamental characteristics at anearly stage:The range of eng<strong>in</strong>es, Table 1, currently <strong>in</strong>cludes a 1.4 lspark-ignition eng<strong>in</strong>e and two Diesel eng<strong>in</strong>es withdisplacements of 1.2 l and 1.4 l. These eng<strong>in</strong>es are sharedwith o<strong>the</strong>r cars built by <strong>the</strong> VW Group, and have beenadopted on <strong>the</strong> A2 with slight modifications.1.4L 55 KW SPARK-IGNITION ENGINEThe 1.4 l eng<strong>in</strong>e has an output of 55 kW at 5000 rpm anddevelops a torque of 126 Nm at 3800 rpm.This eng<strong>in</strong>e, designed for low weight and fuelconsumption, has an alum<strong>in</strong>ium diecast crankcase withcast-<strong>in</strong> grey cast iron l<strong>in</strong>ers. The eng<strong>in</strong>e is fitted with ashell-type plastic <strong>in</strong>take manifold and an exhaust systemmade entirely from sta<strong>in</strong>less steel.The two camshafts, which each operate two valves viafrictionally-optimized tim<strong>in</strong>g gear with roller cam follower,are mounted <strong>in</strong> <strong>the</strong> two-piece cyl<strong>in</strong>der head. The eng<strong>in</strong>echarge cycle has been designed for an ample torquecharacteristic.The frictionally optimized eng<strong>in</strong>e is an ideal basis for lowfuel consumption. The A2 1.4 l recorded fuelconsumption of 6.0 l/100 km over <strong>the</strong> MVEG II cycle.The low fuel consumption is partly attributable to <strong>the</strong> lowidle speed of 680 m<strong>in</strong> -1 . CO2 emissions are only 144g/km. The EU 4 emission standard is fulfilled <strong>in</strong> particularthanks to <strong>the</strong> <strong>in</strong>clusion of a primary catalytic converter <strong>in</strong><strong>the</strong> front pipe.• Short rounded front structure• Flat, <strong>in</strong>cl<strong>in</strong>ed w<strong>in</strong>dscreen that flows cont<strong>in</strong>uously <strong>in</strong>to<strong>the</strong> arched roof• Relatively high, aerodynamically effective fastback• Optimized exterior rear mirrorsThe aerodynamic f<strong>in</strong>e-tun<strong>in</strong>g, such as <strong>the</strong> measures to <strong>the</strong>underbody, has produced low c D values. A dragcoefficient of c D = 0.28 has been measured for <strong>the</strong> basicversions with <strong>the</strong> two 1.4 litre eng<strong>in</strong>es, and of c D = 0.25for <strong>the</strong> 1.2 l TDI.The aerodynamic drag, which is proportionally c D * A, isrelatively low, particularly on <strong>the</strong> A2 1.2 l TDI, at 0.544.Unlike o<strong>the</strong>r vehicle concepts, Fig 7, <strong>the</strong> A2's lowaerodynamic drag is achieved by reduc<strong>in</strong>g <strong>the</strong> dragcoefficient, and not <strong>the</strong> cross-sectional area. Theergonomics of <strong>the</strong> A2 are consequently much better thanfor comparison vehicles.ENGINES AND PERFORMANCEFig. 7: Cross-sectional area and c D value comparison.1.4 l 55 kW DIESEL ENGINEThe follow<strong>in</strong>g features are mak<strong>in</strong>g <strong>the</strong> 1.4l 55 kW TDIDiesel eng<strong>in</strong>e particularly suitable for use on <strong>the</strong> A2:• Inl<strong>in</strong>e 3-cyl<strong>in</strong>der eng<strong>in</strong>e as a spacesav<strong>in</strong>g, weightoptimizedpower unit for transverse <strong>in</strong>stallation,4

• it fulfils <strong>the</strong> emission standards currently <strong>in</strong> force,while ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g <strong>the</strong> advantageous fuel consumptionof <strong>the</strong> direct-<strong>in</strong>jection pr<strong>in</strong>ciple,• Low-cost, durable eng<strong>in</strong>e concept.cyl<strong>in</strong>der eng<strong>in</strong>e blocks can be manufactured on <strong>the</strong> sameproduction l<strong>in</strong>e.For a high standard of ref<strong>in</strong>ement, a balanc<strong>in</strong>g shaft isdriven <strong>in</strong> conjunction with <strong>the</strong> oil pump via a cha<strong>in</strong> drivewith a hydraulic tension<strong>in</strong>g element. The balanc<strong>in</strong>g shaftis mounted <strong>in</strong> a diecast alum<strong>in</strong>ium ladder frame bolted to<strong>the</strong> bear<strong>in</strong>g pedestals <strong>in</strong> <strong>the</strong> eng<strong>in</strong>e block.Table 1: Eng<strong>in</strong>e and vehicle dataThe rated output of 55 kW laid down <strong>in</strong> <strong>the</strong> specificationsis achieved at an eng<strong>in</strong>e speed of 4000 rpm. The highpressurefuel <strong>in</strong>jection assures efficient mixturepreparation, with <strong>the</strong> result that peak torque of 195 Nm isachieved as low down as 2200 rpm.A key feature of this eng<strong>in</strong>e is <strong>the</strong> new high-pressure fuel<strong>in</strong>jection system, which permits <strong>in</strong>jection pressures of upto 2050 bar. A precisely metered, separate pilot <strong>in</strong>jectionprocess, which reduces combustion noise and nitrogenoxide emissions, is achieved with this <strong>in</strong>jection system.To reach <strong>the</strong> objective, <strong>the</strong> pump-<strong>in</strong>jector units were<strong>in</strong>corporated directly <strong>in</strong>to <strong>the</strong> cyl<strong>in</strong>der head. The pump<strong>in</strong>jectorelements are driven by <strong>the</strong> camshaft via <strong>the</strong> rollerrocker arm by means of additional lift<strong>in</strong>g cams.In view of <strong>the</strong> high cyl<strong>in</strong>der pressures, <strong>the</strong> cyl<strong>in</strong>dercrankcase is made from grey cast iron. As <strong>the</strong> eng<strong>in</strong>eblock has <strong>the</strong> same design features (distance betweencyl<strong>in</strong>der axes 88 mm; bore 79.5 mm) as <strong>the</strong> 4-cyl<strong>in</strong>dereng<strong>in</strong>e blocks of <strong>the</strong> new Golf DI eng<strong>in</strong>es, <strong>the</strong> 3- and 4-1.2l 45 kW DIESEL ENGINEThe Diesel eng<strong>in</strong>e with two-valve technology has adisplacement of 1.2 l (bore: 86.4 mm, stroke: 76.5 mm)and a compression ratio of 19.5 : 1. An overheadcamshaft driven by a too<strong>the</strong>d belt controls <strong>the</strong> valves viabucket-type tappets. To reduce free <strong>in</strong>ertial forces, <strong>the</strong>three-cyl<strong>in</strong>der eng<strong>in</strong>e has a base-mounted balanc<strong>in</strong>g shaftrotat<strong>in</strong>g <strong>in</strong> <strong>the</strong> oil sump. Both <strong>the</strong> cyl<strong>in</strong>der head and <strong>the</strong>eng<strong>in</strong>e block of this Diesel eng<strong>in</strong>e are made fromalum<strong>in</strong>ium. This measure helps to keep <strong>the</strong> eng<strong>in</strong>e's dryweight down to approximately 100 kg.The key to this eng<strong>in</strong>e's high level of efficiency is onceaga<strong>in</strong> a pump-<strong>in</strong>jector direct fuel <strong>in</strong>jection system. Theturb<strong>in</strong>e geometry of <strong>the</strong> exhaust turbocharger withcharge-air cool<strong>in</strong>g is variable, thus fur<strong>the</strong>r reduc<strong>in</strong>gemissions and fuel consumption.The eng<strong>in</strong>e achieves its maximum power output of 45kW at 4000 rpm. Maximum torque of 140 Nm is availableacross an eng<strong>in</strong>e speed range of 1800 to 2400 rpm.5

The A2 1.2l TDI has a stop-start drivetra<strong>in</strong> managementsystem, which switches off <strong>the</strong> eng<strong>in</strong>e when <strong>the</strong> car isstand<strong>in</strong>g at traffic lights or <strong>in</strong> a tailback and <strong>the</strong> footbrakeis held down for more than three seconds. As soon as <strong>the</strong>brake is released, <strong>the</strong> eng<strong>in</strong>e starts aga<strong>in</strong>.TRANSMISSIONSThe transmissions were developed for <strong>the</strong> specificrequirements of <strong>the</strong> eng<strong>in</strong>es:• A lightweight 5-speed manual gearbox withmagnesium cas<strong>in</strong>g has been chosen for <strong>the</strong> 1.4l55 kW spark-ignition eng<strong>in</strong>e.• The higher-torque 1.4l 55 kW Diesel eng<strong>in</strong>e has are<strong>in</strong>forced 5-speed manual gearbox with aconventional alum<strong>in</strong>ium cas<strong>in</strong>g.• In view of <strong>the</strong> eng<strong>in</strong>e's high efficiency, <strong>the</strong> A2 1.2lTDI is supplied with an automised, five-speedmechanical gearbox with alum<strong>in</strong>ium cas<strong>in</strong>g. Inconjunction with its Economy program, whichconsistently strives to establish <strong>the</strong> lowest possibleshift<strong>in</strong>g speeds, and a high overall ratio for fueleconomy, it is able to operate at <strong>the</strong> best specific fuelconsumption <strong>in</strong> any given situation.The 1.4l TDI accelerates from 0 to 100 km/h <strong>in</strong> 12.3 s,and reaches <strong>the</strong> same top speed of 173 km/h as with <strong>the</strong>A2 1.4l Thanks to its pump-<strong>in</strong>jector technology, <strong>the</strong> 1.4lTDI achieves fuel consumption of only 4.3 litres ofDiesel fuel per 100 km. Compared to similar vehicles <strong>the</strong>A2 1.4l TDI has approximately 13% up to 53% less fuelconsumption, Fig. 9. Its CO 2 emissions are 116 g/kmand it satisfies <strong>the</strong> EU 3 emission standard.The 1.2l TDI achieves fuel consumption of only 2.99l/100 km for <strong>the</strong> MVEG cycle, accelerat<strong>in</strong>g from 0 to 100km/h <strong>in</strong> 14.8 seconds and is reach<strong>in</strong>g a top speed of 168km/h [5].Relative fuel consumption for MVEG-cycle [%]160%150%140%130%120%110%100%90%80%4,3 l/100 km3 4 5 6Comparison Vehicles10A2 1,4l TDI1 2 7 8 9Fig. 9: Fuel consumption for <strong>the</strong> A2 1.4l TDI.VEHICLE PERFORMANCE / FUEL CONSUMP-TIONAfter 12.0 seconds <strong>the</strong> A2 1.4l is accelerated from 0 to100 km/h. This is an outstand<strong>in</strong>g low value <strong>in</strong> comparisonto similar cars, Fig 8.1817161514comparison vehiclesSERVICE MODULEThe A2 has a new functional feature that also has <strong>the</strong>double role of a design element: <strong>the</strong> service module, Fig.10. The conventional radiator grille has been replaced bya fold<strong>in</strong>g cover beh<strong>in</strong>d which <strong>the</strong> oil dipstick and <strong>the</strong> filleropen<strong>in</strong>gs for eng<strong>in</strong>e oil and washer fluid are to be found.It is now no longer necessary to open <strong>the</strong> eng<strong>in</strong>ecompartment lid to check <strong>the</strong> eng<strong>in</strong>e oil level and to topup oil or washer fluid.If more extensive servic<strong>in</strong>g work <strong>in</strong>volv<strong>in</strong>g access to <strong>the</strong>eng<strong>in</strong>e compartment is required, <strong>the</strong> eng<strong>in</strong>e cover –known as <strong>the</strong> "front top" – can easily be removed byreleas<strong>in</strong>g <strong>the</strong> quick-act<strong>in</strong>g coupl<strong>in</strong>gs.1312A2 1,4l TDIA2 1,4l1140 45 50 55 60 65 70 75 80Eng<strong>in</strong>e Power [kW]Fig. 8: Acceleration from 0 to 100 km/h.The driver gets an agile feel<strong>in</strong>g up to a top speed of 173km/h. The fuel consumption never<strong>the</strong>less is 6,0 litres per100 km. The emission standard EU IV is satisfied and <strong>the</strong>CO 2 emissions are 144g/km.Fig. 10: A2 Service Module.6

ENVIRONMENTIn order to achieve also environmental objectivesespecially such as <strong>the</strong> reduction of CO 2 emissions, it isessential to view <strong>the</strong> broader context. Therefore it has tobe focused on <strong>the</strong> entire life-cycle of <strong>the</strong> car, from itsproduction, through its operation, to its ultimate recycl<strong>in</strong>g.As <strong>the</strong> bulk of <strong>the</strong> energy required throughout <strong>the</strong> lifetimeof a vehicle is consumed dur<strong>in</strong>g its operation,consumption-cutt<strong>in</strong>g measures focus<strong>in</strong>g on resistance tomotion, such as <strong>the</strong> reduction of <strong>the</strong> vehicle's weight, areparticularly significant. On <strong>the</strong> Audi A2, measures aim<strong>in</strong>g<strong>in</strong> this direction were implemented systematically through<strong>the</strong> use of <strong>the</strong> Audi Space Frame body and <strong>the</strong> lowconsumptioneng<strong>in</strong>es. The bigger amount of energyrequired for <strong>the</strong> <strong>in</strong>itial Alum<strong>in</strong>ium Space Frameproduction <strong>in</strong> comparison to a conventional steel body isalready compensated after a driv<strong>in</strong>g distance ofapproximately 85.000 km.The tare weight of <strong>the</strong> Audi A2 (with 1.4 l, 55 kW sparkignitioneng<strong>in</strong>e) is only 895 kg, thanks to <strong>the</strong> use ofmodified weightsav<strong>in</strong>g materials such as alum<strong>in</strong>ium,magnesium and plastics. Accord<strong>in</strong>g to <strong>the</strong> materialsclassification of VDA guidel<strong>in</strong>e 231, <strong>the</strong> overall proportionof <strong>the</strong> weightsav<strong>in</strong>g materials alum<strong>in</strong>ium/ magnesium/polymers is 52%. The proportion of steel and ferrousmaterials is about 34% by weight.With regard to <strong>the</strong> more and more em<strong>in</strong>ent air pollutionproblem, <strong>the</strong> A2 vehicle concept, Fig. 11, represents anadequate technical solution, because <strong>the</strong> amount of CO 2emissions for this vehicle concept is on a very low level.The Audi A2 is a sophisticated, progressive andresponsible vehicle, which satisfies <strong>the</strong> ris<strong>in</strong>g expectationsof <strong>the</strong> <strong>in</strong>dividual customer, while meet<strong>in</strong>g <strong>the</strong> <strong>in</strong>creas<strong>in</strong>glychalleng<strong>in</strong>g requirements of society and <strong>the</strong> legislative.ACKNOWLEDGMENTWe thank <strong>the</strong> colleagues of <strong>the</strong> Audi A2 Team, who allsupported <strong>the</strong> success of this sophisticated project.The collegues of <strong>the</strong> plant and of <strong>the</strong> Alum<strong>in</strong>iumTechnical Centre <strong>in</strong> Neckarsulm also merit our thanks for<strong>the</strong>ir expertise which provided <strong>the</strong> very basis for volumeproduction of <strong>the</strong> Audi A2.The ASF body's large cast<strong>in</strong>gs as well as <strong>the</strong> extrudedsections and alloy panels, made from <strong>the</strong> same alloy, canbe cut away completely without undue effort, allow<strong>in</strong>g<strong>the</strong>se special alum<strong>in</strong>ium alloys to be recycled separately.Follow<strong>in</strong>g <strong>the</strong>ir removal, <strong>the</strong> cast<strong>in</strong>gs can be used <strong>in</strong> <strong>the</strong>production of new cast-alloy components.Along with <strong>the</strong> rise <strong>in</strong> <strong>the</strong> number of vehicles with a highalum<strong>in</strong>ium content such as <strong>the</strong> Audi A2, <strong>the</strong> world's firstvolume-production car with an all-alum<strong>in</strong>ium body, <strong>the</strong>supply of secondary alum<strong>in</strong>ium from scrap vehicles willoutstrip demand for primary alum<strong>in</strong>ium. In anticipation offuture developments <strong>in</strong> <strong>the</strong> field of scrap-vehiclerecycl<strong>in</strong>g, Audi has established <strong>the</strong> basis for effectiverecycl<strong>in</strong>g of alum<strong>in</strong>ium by provid<strong>in</strong>g scope for <strong>the</strong>segregation of cast and wrought alloys through suchtechniques as fillet<strong>in</strong>g and new cut detection methods.CONCLUSIONThe expertise <strong>in</strong> alum<strong>in</strong>ium technology that Audi AG hasacquired over <strong>the</strong> past decade was an essential basis forbuild<strong>in</strong>g <strong>the</strong> world's first alum<strong>in</strong>ium car, <strong>the</strong> Audi A2, ona large scale.The use of <strong>the</strong> ASF alum<strong>in</strong>ium body and <strong>the</strong> exploit<strong>in</strong>g ofsecondary weight reduction measures is result<strong>in</strong>g <strong>in</strong> alower vehicle weight that is used to <strong>the</strong> customer'sbenefit. The low weight of <strong>the</strong> A2, comb<strong>in</strong>ed with highlyefficient eng<strong>in</strong>es, results <strong>in</strong> a particularly agile, low fuelconsumptionvehicle concept. The A2's <strong>in</strong>teriordimensions are never<strong>the</strong>less generous, and its variabilityclearly above-average.Fig. 11: The very low CO 2 emissions of <strong>the</strong> A2 are oneof <strong>the</strong> important technical highlights.REFERENCES[1] Kaiser, M.: Alum<strong>in</strong>ium as a body <strong>in</strong> white material, 6.Aachener Kolloquium Fahrzeug- und Motorentechnik,1997[2] Radiative Forc<strong>in</strong>g of Climate Change. The 1994Report of <strong>the</strong> Scientific Assessment Work<strong>in</strong>g Group ofIPCC, 1995.[3] Der neue Audi A2, Special edition ATZ/MTZ, ISSN0001-2785, March 2000.[4] Paefgen,F.-J.; Leitermann, W.: Audi Space FrameASF. E<strong>in</strong> neues Pkw Rohbaukonzept <strong>in</strong> Alum<strong>in</strong>ium, VDIReport 1134, 1994.[5] Engelhart, D.; Mödl, C.: The Development of <strong>the</strong> AudiA2, a new Vehicle <strong>Concept</strong> <strong>in</strong> <strong>the</strong> <strong>Compact</strong> <strong>Car</strong> <strong>Class</strong>,VDI Report Nr. 1505, 19997