Non-Slam Nozzle Check Valve 02-07 - Enertech - Curtiss Wright ...

Non-Slam Nozzle Check Valve 02-07 - Enertech - Curtiss Wright ...

Non-Slam Nozzle Check Valve 02-07 - Enertech - Curtiss Wright ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

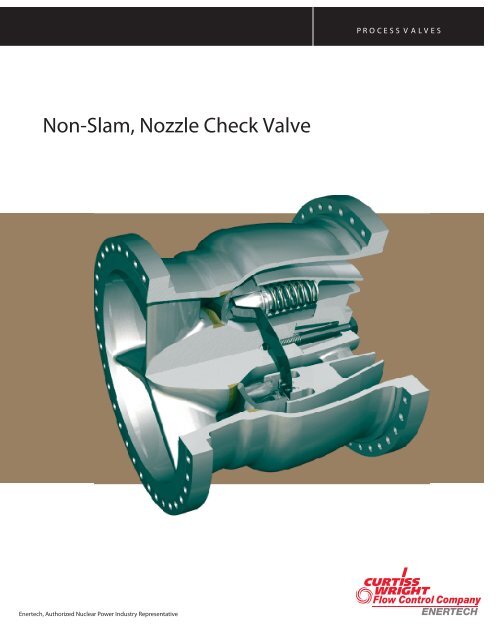

P R O C E S S V A L V E SNON-SLAM, NOZZLE CHECK VALVEPRODUCT OFFERINGDRV-BDISCHELICAL SPRINGCENTRAL TIE BOLTSPRING HOLDERFLOW DIFFUSERRADIAL GUIDEVALVE BODYTRAPEZOID WASHERThe DRV-B <strong>Nozzle</strong> <strong>Check</strong> is a large bore valve for use in compressor and pumping stations from 12 in.(300 mm) through 68 in. (1700 mm) diameter. In this size range ENTECH incorporates the use of anannular ring design which outperforms other nozzle check valve designs. By utilizing the doughnutshaped annular disc, ENTECH <strong>Nozzle</strong> <strong>Check</strong>s are able to minimize the weight (mass) of the disc and hasthe ability to go from fully open to fully closed in a fraction of a second.The DRV-B design also provides:• <strong>Non</strong>-<strong>Slam</strong> Closure• Metal Seating• Extremely Quick Closure• Spring Loaded disc design allows mounting in any orientation• Low Pressure Loss• No Scheduled Maintenance• Tight Shut-offSizes and Ratings• Size 12 in. (300 mm) through 68 in. (1700 mm)• ANSI/ASME Classes 150 through 2500• API 3000 through 10,000• Face-to-Face API 6D, Manufacturers Standard• End Connections ANSI/ASME flanges are standard,weld end or other flange end configurations can be provided upon request• Other sizes and pressure classes on request4

P R O C E S S V A L V E SNON-SLAM, NOZZLE CHECK VALVEQUALITY ASSURANCECameron management operates a high level quality control program to ensure that all ENTECHproducts are designed and manufactured to the highest standards available using the latest technology.The Cameron Quality Assurance program encompasses our entire operation, from order entry to finalinspection and delivery.Cameron's Six Sigma lean manufacturing philosophy and the standard warranty which covers theproduct for 12 months after installation or 18 months after shipment, whichever occurs first, assure thatthe design, materials and workmanship of all ENTECH products result in years of dependable operation.SPECIFICATIONS AND COMPLIANCE:ISO 9001-2000, API 6D, GOST R, PED/CE, API 6A.FACE-TO FACE DIMENSIONSDRV-ZSize Manufacture’s Standard API 6Din. (mm) ASME 150-900 ASME 1500 ASME 150 ASME 300 ASME 600 ASME 900 ASME 15001 (25) 3.937 (100) 7.087 (180) - - - - -2 (50) 4.724 (120) 7.874 (200) 7.99 (203) 10.51 (267) 11.50 (292) 14.49 (368) 14.49 (368)3 (80) 7.087 (180) 7.874 (200) 9.49 (241) 12.52 (318) 14.<strong>02</strong> (356) 15.00 (381) 18.50 (470)4 (100) 9.449 (240) 7.874 (200) 11.50 (292) 14.<strong>02</strong> (356) 17.01 (432) 17.99 (457) 21.50 (546)5 (125) 11.811 (300) 9.449 (240) - - - - -6 (150) 13.780 (350) 13.780 (350) 14.<strong>02</strong> (356) 17.52 (445) 22.01 (559) 24.<strong>02</strong> (610) 27.76 (705)8 (200) 17.717 (450) 17.717 (450) 19.49 (495) 20.98 (533) 25.98 (660) 29.<strong>02</strong> (737) 32.76 (832)10 (250) 19.685 (500) 19.685 (500) 24.49 (622) 24.49 (622) 30.98 (787) 32.99 (838) 39.<strong>02</strong> (991)DRV-BSize Manufacture’s Standard API 6Din. (mm) ASME 150-300 ASME 600 ASME 900 ASME 150 ASME 300 ASME 600 ASME 900 ASME 150012 (300) 13.780 (350) 14.764 (375) 17.323 (440) 27.52 (699) 27.99 (711) 32.99 (838) 37.99 (965) 44.49 (1130)14 (350) 15.945 (405) 17.323 (440) 17.323 (440) 30.98 (787) 32.99 (838) 35.00 (889) 40.51 (1<strong>02</strong>9) 49.49 (1257)16 (400) 17.913 (455) 19.685 (500) 18.504 (470) 34.<strong>02</strong> (864) 34.<strong>02</strong> (864) 39.<strong>02</strong> (991) 44.49 (1130) 54.49 (1384)18 (450) 20.472 (520) 22.244 (565) 20.866 (530) 38.50 (978) 38.50 (978) 42.99 (1092) 47.99 (1219) 60.51 (1537)20 (500) 22.441 (570) 24.606 (625) 23.425 (595) 38.50 (978) 40.00 (1016) 47.01 (1194) 52.01 (1321) 65.51 (1664)24 (600) 26.969 (685) 29.331 (745) 33.465 (850) 50.98 (1295) 52.99 (1346) 55.00 (1397) - -28 (700) 31.496 (800) 34.252 (870) 34.449 (875) 57.01 (1448) 59.<strong>02</strong> (1499) 62.99 (1600) - -30 (750) 33.661 (855) 36.614 (930) 36.417 (925) 60.00 (1524) 62.76 (1594) 65.00 (1651) - -32 (800) 35.827 (910) 38.976 (990) 38.386 (975) - - - - -36 (900) 40.551 (1030) 44.094 (1120) 46.850 (1190) 77.01 (1956) 82.01 (2083) 82.01 (2083) - -40 (1000) 44.685 (1135) 48.819 (1240) - - - - - -42 (1050) 47.047 (1195) 51.181 (1300) - - - - - -48 (1200) 53.740 (1365) 58.465 (1485) - - - - - -56 (1400) 62.992 (1600) 68.110 (1730) - - - - - -60 (1500) 67.323 (1710) 73.031 (1855) - - - - - -DRV-BK Consult factory for Face-To-Face Dimensions.6

P R O C E S S V A L V E SNON-SLAM, NOZZLE CHECK VALVESTANDARD MATERIALS OF CONSTRUCTIONSEAT(outer)SCREWRADIAL GUIDESEAT(inner)OPENCLOSEDVALVE DISCOPENCLOSEDCENTRALTIE BOLTSEATDIFFUSERVALVE BODYHELICAL SPRINGGUIDE BUSHINGDIFFUSERVALVE BODYVALVE DISCHELICAL SPRINGDescription Standard Carbon Steel Low Temperature Carbon Steel Stainless Steel<strong>Valve</strong> Body ASTM A216 WCC / ASTM A105 ASTM A352 LCC ASTM A351 CF8M / 316 Stainless SteelDiffuser ASTM A216 WCC / ASTM A105 ASTM A352 LCC ASTM A351 CF8M / 316 Stainless Steel<strong>Valve</strong> Disc ASTM A351 CF8M / 316 Stainless Steel ASTM A351 CF8M / 316 Stainless Steel ASTM A351 CF8M / 316 Stainless SteelSeat* 316 Stainless Steel 316 Stainless Steel 316 Stainless SteelHelical Spring Alloy X-750 Alloy X-750 Alloy X-750Radial Guide** Alloy X-750 Alloy X-750 Alloy X-750Screw** ASTM A193 B8M ASTM A320 B8M ASTM A193 B8MCentral Tie Bolt** ASTM A193 B7M ASTM A320 L7M ASTM A193 B8MGuide Bushing Gr. 630 Stainless Steel Gr. 630 Stainless Steel -* 12 in. (300 mm) and larger valves use inlaid seats as standard.** 12 in. (300 mm) and larger only.Other materials available upon request to meet specific service requirements. Cameron reserves the right to substitute equivalent materials.All materials comply with NACE MR0175.7

P R O C E S S V A L V E STRADEMARK INFORMATIONREQUEST FOR QUOTES CAN BE SENT VIAMail To:<strong>Enertech</strong>, a business unit of <strong>Curtiss</strong>-<strong>Wright</strong> Flow Control Company2950 Birch StreetBrea, CA 92821 USAPhone: 714-528-2301Fax: 714-528-0128http://enertech.cwfc.com8

P R O C E S S V A L V E S

P R O C E S S V A L V E S