positive vs negative iteration in design - Lean Construction Institute

positive vs negative iteration in design - Lean Construction Institute

positive vs negative iteration in design - Lean Construction Institute

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

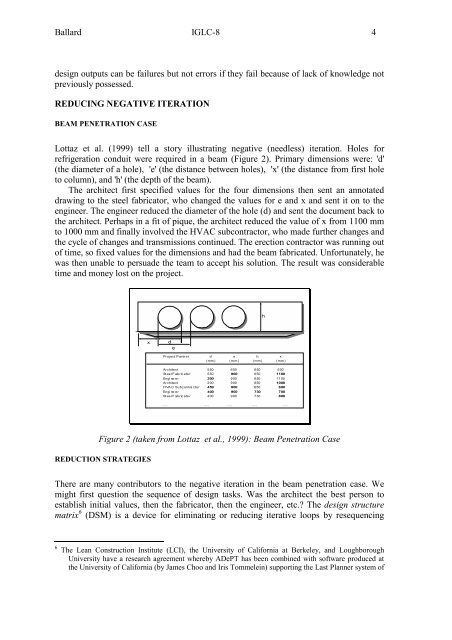

Ballard IGLC-8 4<strong>design</strong> outputs can be failures but not errors if they fail because of lack of knowledge notpreviously possessed.REDUCING NEGATIVE ITERATIONBEAM PENETRATION CASELottaz et al. (1999) tell a story illustrat<strong>in</strong>g <strong>negative</strong> (needless) <strong>iteration</strong>. Holes forrefrigeration conduit were required <strong>in</strong> a beam (Figure 2). Primary dimensions were: 'd'(the diameter of a hole), 'e' (the distance between holes), 'x' (the distance from first holeto column), and 'h' (the depth of the beam).The architect first specified values for the four dimensions then sent an annotateddraw<strong>in</strong>g to the steel fabricator, who changed the values for e and x and sent it on to theeng<strong>in</strong>eer. The eng<strong>in</strong>eer reduced the diameter of the hole (d) and sent the document back tothe architect. Perhaps <strong>in</strong> a fit of pique, the architect reduced the value of x from 1100 mmto 1000 mm and f<strong>in</strong>ally <strong>in</strong>volved the HVAC subcontractor, who made further changes andthe cycle of changes and transmissions cont<strong>in</strong>ued. The erection contractor was runn<strong>in</strong>g outof time, so fixed values for the dimensions and had the beam fabricated. Unfortunately, hewas then unable to persuade the team to accept his solution. The result was considerabletime and money lost on the project.hxdeProject Partner d e h x(mm) (mm) (mm) (mm)Architect 550 650 650 500Steel Fabricato r 550 900 650 1100Engi ne er 200 900 650 1100Architect 200 900 650 1000H VA C Subc ontra ctor 450 800 650 600Engi ne er 400 900 730 700Steel Fabricato r 400 900 730 800..... ..... ..... ..... .....Figure 2 (taken from Lottaz et al., 1999): Beam Penetration CaseREDUCTION STRATEGIESThere are many contributors to the <strong>negative</strong> <strong>iteration</strong> <strong>in</strong> the beam penetration case. Wemight first question the sequence of <strong>design</strong> tasks. Was the architect the best person toestablish <strong>in</strong>itial values, then the fabricator, then the eng<strong>in</strong>eer, etc.? The <strong>design</strong> structurematrix 6 (DSM) is a device for elim<strong>in</strong>at<strong>in</strong>g or reduc<strong>in</strong>g iterative loops by resequenc<strong>in</strong>g6 The <strong>Lean</strong> <strong>Construction</strong> <strong>Institute</strong> (LCI), the University of California at Berkeley, and LoughboroughUniversity have a research agreement whereby ADePT has been comb<strong>in</strong>ed with software produced atthe University of California (by James Choo and Iris Tommele<strong>in</strong>) support<strong>in</strong>g the Last Planner system of