Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

04<br />

Production today<br />

and tomorrow<br />

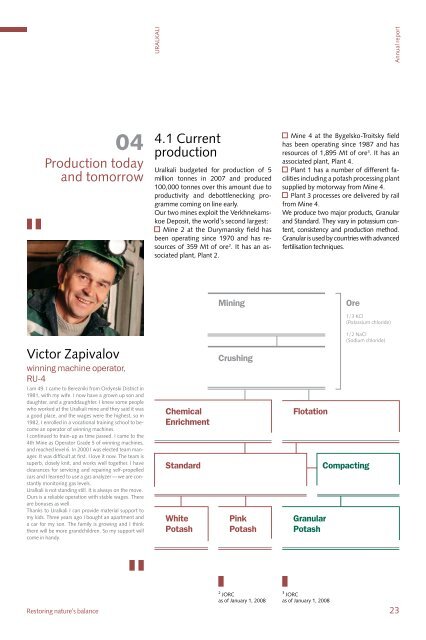

Victor Zapivalov<br />

winning machine operator,<br />

ru-4<br />

i am 49. i came to Berezniki from ordynski District in<br />

1981, with my wife. i now have a grown up son and<br />

daughter, and a granddaughter. i knew some people<br />

who worked at the uralkali mine and they said it was<br />

a good place, and the wages were the highest, so in<br />

1982, i enrolled in a vocational training school to become<br />

an operator of winning machines.<br />

i continued to train-up as time passed. i came to the<br />

4th Mine as operator Grade 5 of winning machines,<br />

and reached level 6. in 2000 i was elected team manager.<br />

it was difficult at first. i love it now. The team is<br />

superb, closely knit, and works well together. i have<br />

clearances for servicing and repairing self-propelled<br />

cars and i learned to use a gas analyzer — we are constantly<br />

monitoring gas levels.<br />

uralkali is not standing still. it is always on the move.<br />

ours is a reliable operation with stable wages. There<br />

are bonuses as well.<br />

Thanks to uralkali i can provide material support to<br />

my kids. Three years ago i bought an apartment and<br />

a car for my son. The family is growing and i think<br />

there will be more grandchildren. So my support will<br />

come in handy.<br />

Restoring nature’s balance<br />

uRAlkAli<br />

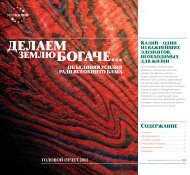

4.1 current<br />

production<br />

uralkali budgeted for production of 5<br />

million tonnes in <strong>2007</strong> and produced<br />

100,000 tonnes over this amount due to<br />

productivity and debottlenecking programme<br />

coming on line early.<br />

our two mines exploit the Verkhnekamskoe<br />

Deposit, the world’s second largest:<br />

Mine 2 at the Durymansky field has<br />

been operating since 1970 and has resources<br />

of 359 Mt of ore 2 . it has an associated<br />

plant, Plant 2.<br />

Chemical<br />

Enrichment<br />

Standard<br />

White<br />

Potash<br />

Pink<br />

Potash<br />

Annual report<br />

Mine 4 at the Bygelsko-Troitsky field<br />

has been operating since 1987 and has<br />

resources of 1,895 Mt of ore 3 . it has an<br />

associated plant, Plant 4.<br />

Plant 1 has a number of different facilities<br />

including a potash processing plant<br />

supplied by motorway from Mine 4.<br />

Plant 3 processes ore delivered by rail<br />

from Mine 4.<br />

We produce two major products, Granular<br />

and Standard. They vary in potassium content,<br />

consistency and production method.<br />

Granular is used by countries with advanced<br />

fertilisation techniques.<br />

Mining Ore<br />

Crushing<br />

2 JoRc<br />

as of January 1, 2008<br />

Flotation<br />

Granular<br />

Potash<br />

3 JoRc<br />

as of January 1, 2008<br />

1/3 kcl<br />

(Potassium chloride)<br />

1/2 Nacl<br />

(Sodium chloride)<br />

Compacting<br />

23