April - June 2007 - Kasetsart University

April - June 2007 - Kasetsart University

April - June 2007 - Kasetsart University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>April</strong> - <strong>June</strong> <strong>2007</strong><br />

Volume 41 Number 2<br />

http://www.rdi.ku.ac.th

KASETSART JOURNAL<br />

NATURAL SCIENCE<br />

(http://www.rdi.ku.ac.th)<br />

<strong>Kasetsart</strong> Journal (Natural Science) is a peer-reviewed journal of<br />

<strong>Kasetsart</strong> <strong>University</strong> (www.ku.ac.th) which publishes original research articles on<br />

natural sciences and other topics dealing with current knowledge and advances in<br />

technology. The <strong>Kasetsart</strong> Journal (Natural Science) is issued four times per year. Articles<br />

from researchers worldwide are welcomed.<br />

EDITORS<br />

Editor-in-Chief<br />

Wanchai Chanprasert<br />

Associate Professor, Seed Science and Technology,<br />

Faculty of Agriculture, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

e-mail: agrwcc@ku.ac.th<br />

Associate Editor<br />

Amara Thongpan<br />

Associate Professor, Cell and Molecular Biology,<br />

Faculty of Science, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

EDITORIAL BOARD<br />

Roberto Bonoan<br />

Researcher, Department Manager, Soil Science,<br />

National Tobacco Administration, Department of<br />

Agricualture, Philippines<br />

Korchoke Chantawarangul<br />

Assistant Professor, Civil Engineering, Faculty of<br />

Engineering, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Parnjit Damrongkulkamjorn<br />

Assistant Professor, Electrical Engineering, Faculty of<br />

Engineering, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Praparat Hormchan<br />

Associate Professor, Entomology, Faculty of<br />

Agriculture, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Kanapol Jutamanee<br />

Associate Professor, Plant Physiology, Faculty of<br />

Science, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Onanong Naivikul<br />

Professor, Cereal Chemistry and Technology, Faculty of<br />

Agro-Industry, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Eiji Nawata<br />

Associate Professor, Tropical Agriculture, Kyoto<br />

<strong>University</strong>, Japan<br />

Saran Petpiroon<br />

Associate Professor, Marine Ecology and Pollution,<br />

Faculty of Fisheries, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Witoon Prinyawiwatkul<br />

Professor, Food Science and Technology, Louisiana State<br />

<strong>University</strong> and LSU Agricultural Center, USA<br />

Hathairat Rimkeeree<br />

Assistant Professor, Product Development, Faculty of<br />

Agro-Industry, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

U Ravi Sangakkara<br />

Professor, Crop Ecology, Faculty of Agriculture,<br />

<strong>University</strong> of Peradeniya, Sri Lanka<br />

Uthaiwan Sangwanit<br />

Lecturer, Forest Resources, Faculty of Forestry,<br />

<strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Thongchai Suwonsichon<br />

Associate Professor, Food Science, Faculty of Agro-<br />

Industry, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Aree Thankijjanukij<br />

Associate Library Director, Agricultural Information<br />

Management, <strong>Kasetsart</strong> <strong>University</strong><br />

Satoru Tsuchikawa<br />

Assistant Professor, Near Infrared Spectroscopy and<br />

Agricultural Science, Graduate School of<br />

Bioagricultural Sciences, Nagoya <strong>University</strong>, Japan<br />

Sirichai Wongnarkpet<br />

Assistant Professor, Veterinary Epidemiology, Faculty<br />

of Veterinary Medicine, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Kenji Yamane<br />

Associate Professor, Floriculture and Horticulture,<br />

Faculty of Agriculture, Utsunomiya <strong>University</strong>, Japan<br />

MANAGING EDITORS<br />

Orawan Wongwanich<br />

Senior Researcher, <strong>Kasetsart</strong> <strong>University</strong> Research and<br />

Development Institute, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Somporn Maneeprasopsuk<br />

Researcher, <strong>Kasetsart</strong> <strong>University</strong> Research and<br />

Development Institute, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

EDITORIAL ADVISORY BOARD<br />

Gerald T. Baker<br />

Professor, Entomology, Mississippi State <strong>University</strong>, USA<br />

A. Bruce Bishop<br />

Professor, Civil and Environmental Engineering, Utah State<br />

<strong>University</strong>, USA<br />

Samakkee Boonyawat<br />

Associate Professor, Forest Resource Management, Faculty of<br />

Forestry, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Delores Chambers<br />

Assistant Professor, Food Science, College of Human Ecology,<br />

Kansas State <strong>University</strong>, USA<br />

Edgar Chambers<br />

Professor, Food Science, College of Human Ecology, Kansas State<br />

<strong>University</strong>, USA<br />

Angsumarn Chandrapatya<br />

Professor, Entomology, Faculty of Agriculture, <strong>Kasetsart</strong> <strong>University</strong>,<br />

Thailand<br />

Mauricio A. Elzo<br />

Professor, Animal Breeding and Genetics, <strong>University</strong> of Florida,<br />

USA<br />

John Hampton<br />

Professor, Seed Science and Technology, Lincoln <strong>University</strong>,<br />

New Zealand<br />

Parichat Hongsprabhas<br />

Assistant Professor, Food Science, Faculty of Agro-Industry,<br />

<strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Sathaporn Jittapalapong<br />

Associate Professor, Veterinary Parasitology, Faculty of Veterinary<br />

Medicine, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Helen H. Keenan<br />

Professor, Environmental Science, <strong>University</strong> of Strathclyde,<br />

Scotland<br />

Saichol Ketsa<br />

Professor, Postharvest Technology, Faculty of Agriculture,<br />

<strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Jumras Limtrakul<br />

Professor, Physical Chemistry, Faculty of Science, <strong>Kasetsart</strong><br />

<strong>University</strong>, Thailand<br />

Chitochi Miki<br />

Professor, Structural Engineering, Tokyo Institute of Technology,<br />

Japan<br />

Larry Miller<br />

Professor, Agricultural Education College of Food, Agriculture and<br />

Environment, Ohio State <strong>University</strong>, USA<br />

Tadashi Miyata<br />

Professor, Entomology, Nagoya <strong>University</strong>, Japan<br />

Punpiti Piamsa-nga<br />

Assistant Professor, Computer Engineering, Faculty of Engineering,<br />

<strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Wiroj Rujopakarn<br />

Professor, Transportation Engineering, Faculty of Engineering,<br />

<strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Ed Sarobol<br />

Associate Professor, Crop Physiology, Faculty of Agriculture,<br />

<strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Narongrit Sombatsompop<br />

Professor, Polymer Processing, School of Energy and Materials,<br />

King Mongkut’s <strong>University</strong> of Technology Thonburi, Thailand<br />

Peerasak Srinives<br />

Professor, Plant Breeding, , Faculty of Agriculture at Kamphaeng<br />

Saen, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

Rungsit Suwanmankha<br />

Professor, Weed Science, Faculty of Agriculture, <strong>Kasetsart</strong><br />

<strong>University</strong>, Thailand<br />

Chanvit Vajrabukka<br />

Professor, Animal Science, Physiology, Animal Behavior, Faculty<br />

of Agriculture, <strong>Kasetsart</strong> <strong>University</strong>, Thailand<br />

PUBLISHER<br />

The <strong>Kasetsart</strong> Journal (Natural Science) is published by <strong>Kasetsart</strong> <strong>University</strong> Research<br />

and Development Institute (KURDI), <strong>Kasetsart</strong> <strong>University</strong>, Bangkok, Thailand<br />

EDITORIAL OFFICE<br />

<strong>Kasetsart</strong> <strong>University</strong> Research and Development Institute (KURDI), <strong>Kasetsart</strong><br />

<strong>University</strong>, Chatuchak, Bangkok 10900, Thailand<br />

TEL 66 (2) 5795548; FAX 66 (2) 5611474<br />

e-mail: kj_rdi@ku.ac.th

KASETSART JOURNAL<br />

NATURAL SCIENCE<br />

The publication of <strong>Kasetsart</strong> <strong>University</strong><br />

VOLUME 41 <strong>April</strong> - <strong>June</strong> <strong>2007</strong> NUMBER 2<br />

Changing in TSS, TA and Sugar Contents and Sucrose Synthase Activity in Ethephon-Treated<br />

‘Pattavia’ Pineapple Fruit<br />

...................... Ngarmnij Chuenboonngarm, Niran Juntawong, Arunee Engkagul,<br />

.............................................................. Wallop Arirob and Surin Peyachoknakul 205<br />

Phylogenetic Analysis of Thai Amomum (Alpinioideae: Zingiberaceae) Using AFLP Markers<br />

............. Wittaya Kaewsri, Yingyong Paisooksantivatana, Uamporn Veesommai,<br />

............................................................. Wichan Eiadthong and Srunya Vajrodaya 213<br />

Prediction of Sweet Corn Seeds Field Emergence under Wet Soil Condition<br />

............................................ Vichai Wongvarodom and Wikanate Rangsikansong 227<br />

Modifying Controlled Deterioration for Evaluating Field Weathering Resistance of Soybean<br />

.............................................Ye Changrong, Prapa Sripichitt, Sunanta Juntakool,<br />

....................................................................Vipa Hongtrakul and Arom Sripichitt 232<br />

Composite Line Method for the Development of Early Generation Hybrids<br />

of Maize (Zea mays L.)<br />

................. Nguyen Phuong, Krisda Samphantharak and Vatcharee Lertmongkol 242<br />

Anther Culture of BC 1F 1 (KDML105//IRBB5/KDML105) Hybrid to Produce Bacterial Blight<br />

Resistance Doubled Haploid Rice<br />

................................. Supanyika Sengsai, Surin Peyachoknagul, Prapa Sripichitt,<br />

.......................................................... Amara Thongpan and Pradit Pongtongkam 251<br />

Novel PCR Primers for Specific Detection of Xanthomonas citri subsp. citri the Causal Agent<br />

of Bacterial Citrus Canker<br />

Udomsak Lertsuchatavanich, Ampaiwan Paradornuwat, Junlapark Chunwongse,<br />

....................................................... Norman W. Schaad and Niphone Thaveechai 262<br />

Soil-to-Plant Transfer of Radiocaesium in Thailand<br />

................................................Thitika Thammavech and Teerasak Veerapaspong 274<br />

Beta-carotene, Mimosine and Quality of Leucaena Silage Kept at Different Duration<br />

............................ Wanna Angthong, Boonlom Cheva-Isarakul, Somkid Promma<br />

................................................................................ and Boonserm Cheva-Isarkul 282<br />

Effects of Natural Mineral Soils on Body Weight and Liver Minerals of Black Head Somali<br />

Sheep in Ethiopia<br />

.................................... Sisay Tilahun, Pravee Vijchulata, Pornsri Chairatanayuth<br />

.............................................................................. and Suwapong Swasdiphanich 288<br />

Protoplast Isolation and Culture of Aquatic Plant Cryptocoryne wendtii De Wit<br />

.................. Kanchanaree Pongchawee, Uthairat Na-Nakorn, Siranut Lamseejan,<br />

.......................................................... Supawadee Poompuang and Salak Phansiri 300

Anti HSV-1 Activity of Spirulina platensis Polysaccharide<br />

.... Nattayaporn Chirasuwan, Ratana Chaiklahan, Marasri Ruengjitchatchawalya<br />

.......................................................... Boosya Bunnag and Morakot Tanticharoen 311<br />

Taura Syndrome Virus Disease in Farm-Reared Penaeus monodon in Thailand<br />

.................................................................... Chalor Limsuwan and Niti Chuchird 319<br />

Optimization of Docosahexaenoic Acid (DHA) Production and Improvement of Astaxanthin<br />

Content in a Mutant Schizochytrium limacinum Isolated from Mangrove Forest in Thailand<br />

.................... Wassana Chatdumrong, Wichien Yongmanitchai, Savitree Limtong<br />

...................................................................... and Wanchai Worawattanamateekul 324<br />

Cloning, Expression, Purification and Biological Activities of Recombinant Mouse Interleukin-2<br />

in E. coli M15<br />

........... Sanchai Chantajorn, Ratchanee Hongprayoon and Thaweesak Songserm 335<br />

Production and Partial Characterization of Chitosanases from a Newly Isolated Bacillus cereus<br />

..... Sutee Wangtueai, Wanchai Worawattanamateekul, Mathana Sangjindavong,<br />

.............................................. Nuanphan Naranong and Sarote Sirisansaneeyakul 346<br />

Application of Pectin Coating in the Production of Vitamin Fortified Rice<br />

..................................................... Lalita Chatiyanont and Phaisan Wuttijumnong 356<br />

The effects of starter cultures on biogenic amine and free amino acid contents<br />

in Nham during Fermentation<br />

......... Sasithorn Limsuwan, Wonnop Visessanguan and Jirasak Kongkiattikajorn<br />

Product Development System in Pattern Construction System, Standard Body Measurement<br />

and Suitable Fitting Allowance for Thai Ladies Brand in Fashion Industry<br />

................................................................................. Foengfurad Mungtavesinsuk 373<br />

A Nonlinear Optimization Problem for Determining Safety Stocks in a Two-Stage<br />

Manufacturing System<br />

.............................................................................................Parthana Parthanadee 380<br />

Design and Implementation of a Framework for .NET-based Utility Computing Infrastructure<br />

............................................. Thanapol Rojanapanpat* and Putchong Uthayopas 394

<strong>Kasetsart</strong> J. (Nat. Sci.) 41 : 205 - 212 (<strong>2007</strong>)<br />

Changing in TSS, TA and Sugar Contents and Sucrose Synthase<br />

Activity in Ethephon-Treated ‘Pattavia’ Pineapple Fruit<br />

Ngarmnij Chuenboonngarm 1 , Niran Juntawong 2 *, Arunee Engkagul 3 ,<br />

Wallop Arirob 2 and Surin Peyachoknakul 4<br />

ABSTRACT<br />

Exogenous ethylene increases endogenous ethylene which plays a crucial role on ripening in<br />

climacteric fruits. Although pineapple is a non-climacteric fruit, ethylene released from ethephon is<br />

effectively used to hasten the harvesting period. Effects from the use of a high concentration of ethephon<br />

on eating quality, fruit size and the reduction in harvesting period have been reported. In this paper, the<br />

effect of a low concentration of ethephon on pineapple fruit quality and sucrose synthase (SuSy) activity<br />

was investigated. Field experiment was arranged in split plot design. In the main plot, two levels of<br />

ethephon concentrations, i.e. 0 and 500 mg/l, were used by spraying at 110 days after forcing (DAF)<br />

fruits. The sub plot was harvesting time, i.e. 5 times of one-week intervals from 124 to 152 DAF. We<br />

found that the total soluble solid (TSS) was significantly increased in most of harvesting-treated fruits<br />

while the titratable acid (TA) was significantly increased at 131 DAF of harvesting-treated fruits. Only<br />

at 131 DAF harvesting time, the glucose content and SuSy activity of ethephon-treated fruits were<br />

significantly reduced and return to the control level afterward. However, ethephon had no effect on the<br />

fructose and sucrose contents at all harvesting times. In conclusion, fruit quality with shortening of<br />

harvesting time could be improved by applying 500 mg/l ethephon at 110 DAF since TSS content which<br />

is one of the parameter predicting eating quality of pineapple was increased without decreasing fruit<br />

quality.<br />

Key words: ‘Pattavia’ pineapple, ethephon, total soluble solid (TSS), titratable acidity (TA), sucrose<br />

synthase<br />

INTRODUCTION<br />

Ethephon is one of the most effective<br />

inflorescence forcing agents in pineapple [Ananas<br />

comosus L. (Merr.)] that is widely used presently<br />

(Bartholomew et al., 2003). Its function is to<br />

stimulate the respiration rate of fruit while<br />

chlorophyll remains in shell (Dull et al., 1967).<br />

Moreover, it accelerates the ripening process and<br />

concentrates the harvest peak (Chalermglin, 1979;<br />

Smith, 1991). In other non-climacteric fruit such<br />

as pepper, exogenous ethylene promotes and<br />

increases a cellulase activity (Ferrarese et al.,<br />

1995).<br />

1 Bioscience Interdisciplinary Graduate Program, Faculty of Science, <strong>Kasetsart</strong> <strong>University</strong>, Bangkok 10900, Thailand.<br />

2 Department of Botany, Faculty of Science, <strong>Kasetsart</strong> <strong>University</strong>, Bangkok 10900, Thailand.<br />

3 Department of Biochemistry, Faculty of Science, <strong>Kasetsart</strong> <strong>University</strong>, Bangkok 10900, Thailand.<br />

4 Department of Genetics, Faculty of Science, <strong>Kasetsart</strong> <strong>University</strong>, Bangkok 10900, Thailand.<br />

* Corresponding author, e-mail: fscinrj@ku.ac.th<br />

Received date : 19/06/06 Accepted date : 06/10/06

206<br />

To achieve the high fruit quality, high<br />

total soluble solid (TSS) at the range of 12-14%<br />

and relatively low titratable acidity (TA) of citric<br />

acid at the range of 0.4-0.6% in pineapple flesh<br />

are recommended for pineapple production in<br />

Thailand (Thongtham, 1983). Though TSS and<br />

TA are eating quality prediction parameters, TSS<br />

is the only parameter suitable as a year-round index<br />

(Bartolome et al., 1995). Bartolome et al. (1996)<br />

found that TSS in pineapples was positively<br />

correlated with total sugars. Beside reflecting fruit<br />

quality, TA also indicates the sourness. In<br />

pineapples, TA is reported as citric acid, not malic<br />

acid. It varies primarily with fruit developmental<br />

stages but does not relatively respond to short-term<br />

environmental changes, while the malic acid varies<br />

with environmental changes especially the light<br />

(Singleton and Gortner, 1965).<br />

Many factors including ethephon have<br />

affected pineapple fruit quality (Bartholomew et<br />

al., 2003). An application time and the quantity<br />

of ethephon have influences on the quality of fruit.<br />

Too early application causes the reduction in size<br />

and weight of crown and fruit, whereas low TSS<br />

and high TA contents are also found (Audinay,<br />

1970; Chalermglin, 1979). TSS is highly<br />

correlated with test-panel eating quality (Smith,<br />

1988) and with total sugars (Bartoleme et al.,<br />

1996). In pineapple fruits, fructose, sucrose, and<br />

glucose play important roles in flavor<br />

characteristics and are major sugars which vary<br />

according to the stage of fruit development.<br />

Sucrose content is lowest in the flesh during the<br />

early stage of fruit growth but rapidly increases at<br />

6 weeks before harvest and becomes predominant<br />

in mature fruit. In the early stage, glucose is<br />

slightly higher than fructose and remains relatively<br />

constant through development while fructose<br />

slightly increases at 2 weeks before harvest (Chen<br />

and Paull, 2000). The changes in total sugar<br />

contents are affected by the developmental stage<br />

of fruits, climates, and varieties (Bartoleme et al.,<br />

1996), nevertheless the change of each sugar<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2)<br />

content in ethephon-treated pineapple fruits has<br />

not been reported.<br />

In a sink organ, sugar accumulation is<br />

related to the presence of sucrose metabolizing<br />

enzymes. One of them is sucrose synthase (SuSy)<br />

(Taiz and Zeiger, 1998) which reversibly converts<br />

sucrose and UDP to fructose and UDP-glucose.<br />

SuSy is important in cell metabolism not only in<br />

sink strength (Nguyen-Quoc and Foyer, 2001) but<br />

also in cell wall synthesis (Nakai et al., 1999; Ruan<br />

et al., 2003), and starch synthesis (D / Aoust et al.,<br />

1999). Furthermore, it accumulates sucrose in<br />

edible tissue of satsuma mandarin fruit (Komatsu<br />

et al., 2002) and saves ATP in glycolysis pathway<br />

(Huber and Azakawa, 1986). Chen and Paull<br />

(2000) reported that in pineapple fruits SuSy<br />

activity was higher at young stage, lower at 6<br />

weeks before harvest, and then constant till<br />

harvesting time. The change of SuSy activity in<br />

ethephon treated fruit has also not been reported.<br />

The objective of this work is to answer the question<br />

if ethephon could increase TSS, TA, sugar content<br />

and SuSy activity in pineapple fruit.<br />

MATERIALS AND METHODS<br />

Plant and fruit materials<br />

Field-grown ‘Pattavia’ pineapple<br />

[Ananas comosus L. (Merr.) cv. smooth cayenne]<br />

planted at Sam Praya district, Petchburi Province,<br />

Thailand, were used. Forcing of pineapple<br />

inflorescence was done in the evening of<br />

November 18, 2002, by spraying 50 ml of 250<br />

mg/l ethephon (a.i. 48% w/v) including 3% (w/v)<br />

urea on shoot. The experimental design used in<br />

this study was split plot design. Main plot was<br />

ethephon concentration of 0 and 500 mg/l by<br />

spraying 50 ml volume per fruit at the age of 110<br />

days after forcing (DAF). Pineapple fruit at this<br />

age is pointed-eyes stage 3 according to the Dole<br />

Company, Thailand, which is the last stage of<br />

pointed-eyes pineapple (immature) and thereafter<br />

the eyes will become flatted. Sub-plot was

harvesting time which started from 124 DAF until<br />

152 DAF. Three replications, 8 fruits each, were<br />

analyzed.<br />

Fruit samples were brought to laboratory<br />

and cut transversely into 3 sections after the size<br />

and weight of crowns and fruits were measured.<br />

Only the flesh of the middle section was used in<br />

this study. A half of the flesh was crushed and the<br />

juice was then used for determination of TSS and<br />

TA. The other half, sliced into small pieces, was<br />

used for the determination of the sugar content<br />

and sucrose synthase activity. These sliced fleshes<br />

of 8 fruits were pooled together as one of three<br />

replications at each harvesting time. The tissues<br />

were then frozen immediately in liquid nitrogen<br />

and stored at -80°C until use.<br />

Soluble sugar content<br />

TSS was determined from extracted juice<br />

using hand sugar refractometer. Soluble sugars in<br />

the form of sucrose, fructose and glucose were<br />

extracted following the method of Chen and Paull<br />

(2000). After extraction, the solution was filtered<br />

through a 0.45 mm filter, and 20 ml was injected<br />

and analyzed with HPLC by using a Waters 2690<br />

Separation Model instrumented with a Waters 410<br />

Differential Refractometer detector, employing a<br />

Sugar-PAK I (Waters Associates, Milford, USA)<br />

column of stainless steel (300 mm length × 6.5<br />

mm internal diameters). The eluting buffer was<br />

0.1 mM calcium EDTA and the flow rate was 0.5<br />

ml/min. Experiments were performed at 90°C.<br />

Soluble sugars were quantified by comparing the<br />

peak areas with external sucrose, glucose and<br />

fructose standard solutions (Sigma Co., Ltd.).<br />

Titratable acidity<br />

TA was analyzed from extracted juice<br />

after the determination of TSS contents and<br />

reported as citric acid according to AOAC (1990).<br />

Sucrose synthase determination<br />

Sucrose synthase (SuSy) in frozen flesh<br />

tissue was extracted as described by Chen and<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2) 207<br />

Paull (2000). The extracted solution was desalted<br />

by Hitrap ® Desalting column (Amersham<br />

Biosciences) and 50 µl of desalted mixture was<br />

used to determine the enzymatic activity in<br />

synthesis direction according to the method of<br />

Hubbard et al. (1989), as modified by Chen and<br />

Paull (2000).<br />

Statistical analysis<br />

All data were analyzed the variance<br />

(ANOVA) using statistical analysis software of<br />

IRRISTAT version 93-3.<br />

RESULTS AND DISCUSSION<br />

The last harvesting time in this study<br />

(152 DAF) was planned to coincide with<br />

commercial harvesting time. The commercial<br />

harvesting index for cannery fruit industry is<br />

apparent when fruits reach full-size and the shell<br />

color at the basal portion starts to change. The<br />

effects of ethephon and harvesting time on fruit<br />

quality, sugar content and SuSy activity after<br />

treating at 110 DAF are shown in Table 1.<br />

Ethephon concentration did not reduce the size and<br />

weight of the crowns and fruits. The crowns and<br />

fruits continued to develop after the treatment and<br />

the crowns reached a full-size one week (138 DAF)<br />

before the fruits did (145 DAF). Maximum growth<br />

of the crowns indicated that the fruits were nearly<br />

ready for harvest (Paull and Reyes, 1996). The<br />

concentration of ethephon plays a significant role<br />

in increasing the mean of TSS contents (11.02°<br />

Brix) when compared with the mean of untreated<br />

fruits (8.90°Brix). The mean of TA and sugar<br />

contents including SuSy activity did not change,<br />

compared with untreated fruits. The harvesting<br />

time at 145 DAF provided the highest TA, TSS<br />

and sucrose contents of 0.62% citric acid, 12.16°<br />

Brix and 54.12 g/kg FW, respectively (P

208<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2)<br />

Table 1 Effects of ethephon concentrations and harvesting times on fruit quality, sugar content and sucrose synthase activity after treated at 110 days<br />

after forcing (DAF).<br />

Crown Fruit Flesh<br />

Width Length Weight Width Length Weight TA1/ TSS2/ Sucrose Glucose Fructose SuSy activity<br />

_____(cm)_____ (g) _____(cm)_____ (g) (%citric (°Brix) ________(g/kg FW)________ (mmole/h/<br />

acid) g FW)<br />

Ethephon<br />

concentration<br />

0 mg/l 12.6 12.6 140.8 11.0 14.0 882.4 0.54 8.90b 31.07 14.78 11.61 2.374<br />

500 mg/l 11.6 11.1 127.1 11.3 14.1 922.9 0.59 11.02a 43.20 13.42 11.40 1.717<br />

Harvesting time<br />

124 DAF 11.4b 9.8b 124.8 11.5 14.2 846.2b 0.42c 8.08b 20.90d 14.46 10.86 2.297<br />

131 DAF 11.3b 10.4b 114.4 10.7 13.4 760.4b 0.52b 8.78b 23.46cd 13.96 10.43 1.984<br />

138 DAF 13.5a 13.4a 139.4 10.8 13.8 849.8b 0.58ab 8.48b 37.08bc 15.22 12.02 1.964<br />

145 DAF 12.2ab 13.0a 143.3 11.8 15.0 1149.8a 0.62a 12.16a 54.12a 14.50 13.08 2.127<br />

152 DAF 12.1ab 12.7a 147.9 11.1 13.8 906.7b 0.67a 12.30a 50.13ab 12.34 11.12 1.864<br />

Ethephon<br />

concentration ns ns ns ns ns ns ns * ns ns ns ns<br />

Harvesting time * ** ns ns ns ** ** ** ** ns ns ns<br />

Ethephon<br />

concentration X ns ns ns ns ns ns * * ns * ns *<br />

Harvesting time<br />

Mean followed by the same letter within the same column are not significantly different at the 5% level according to LSD. Symbols * and ** indicate significance at the 0.05 and 0.01 levels<br />

analyzed by DMRT, ns indicates no significant.<br />

1/ TA = Tritratable acidity<br />

2/ TSS = Total soluble solid

y Chen and Paull (2000). Figure 1 also showed<br />

that sucrose content was low in immature fruit and<br />

the highest content was achieved at 145 DAF while<br />

glucose and fructose contents were relatively<br />

constant during fruit growth as reported by Chen<br />

and Paull (2000).<br />

The interaction of ethephon<br />

concentration with harvesting time significantly<br />

affected TA, TSS and glucose contents at P

210<br />

were higher than that of the untreated fruits (Figure<br />

2B). The exogenous ethylene which was<br />

suggested to increase the lipoxygenase activity by<br />

Yu et al. (2003) might change the permeability of<br />

the membrane and cause the increase of TSS in<br />

these mature fruits. From the results on high TSS<br />

(13.53°Brix) and TA (0.6% citric acid) contents<br />

measured at 145 DAF, the treated fruits which are<br />

in the range of high eating-quality fruit<br />

(Bartholomew et al., 2003) could be harvested one<br />

week earlier. Chalermglin (1979) also reported<br />

that after applying 1,500 mg/l of ethephon at 112<br />

DAF, the treated fruits could be harvested 11 days<br />

TA (%citric acid)<br />

Glucose content (g/kg FW)<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0<br />

a<br />

a a<br />

a<br />

b<br />

a<br />

a<br />

b<br />

a<br />

(A)<br />

a<br />

(C)<br />

a<br />

124 131 138 145 152 DAF<br />

a<br />

124 131 138 145 152 DAF<br />

a<br />

a<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2)<br />

a<br />

a a a<br />

a<br />

a<br />

earlier than those of the control. However, TA was<br />

found to be inereased in treated fruits while fruit<br />

size was reduced and TSS was unchanged. This<br />

study indicates that the application of 500 mg/l<br />

ethephon to 110 DAF fruits hastened the<br />

harvesting time without reducing fruit quality.<br />

Figure 2 also showed SuSy activities<br />

which were affected by a significant interaction<br />

between ethephon concentration and harvesting<br />

time. When harvested at 131 DAF, the SuSy<br />

activity of the treated fruits was significantly lower<br />

than that of the untreated fruits. Chen and Paull<br />

(2000) suggested that the low SuSy activity in<br />

Figure 2 Changes in tritratable acidity (TA) (A), total soluble solid (TSS) (B) and glucose contents (C)<br />

and sucrose synthase activity (D) in pineapple fruits flesh at various harvesting times after<br />

treated with 500 mg/l ethephon ( ) and without ethephon ( ) at 110 days after forcing<br />

(DAF). Error bars represent standard error of the means of three replications. Bars with the<br />

same letter assigned are not significantly different at 0.05 probability level.<br />

TSS (°Brix)<br />

SuSy Activity (µmole/h/g FV)<br />

18<br />

16<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

4<br />

3.5<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

a<br />

b b<br />

a<br />

a<br />

a a<br />

124 131 138 145 152 DAF<br />

a<br />

a<br />

b<br />

(B)<br />

a<br />

124 131 138 145 152 DAF<br />

(D)<br />

a<br />

b<br />

a<br />

a<br />

a a<br />

b<br />

a<br />

a

pineapple fruit allowed the accumulation of<br />

sucrose. However, we found that the low SuSy<br />

activity in harvested fruits treated at 131 did not<br />

enhance the sucrose accumulation (no significant<br />

interaction of sucrose was found, Table 1).<br />

Therefore, the SuSy activity was not related to the<br />

accumulation of sucrose in pineapples which is in<br />

contrast to the activity in non-climacteric, satsuma<br />

mandarin fruits (Komatsu et al., 2002). The<br />

decrease of SuSy activity of harvested fruits treated<br />

at 131 DAF might be resulted from the increase<br />

in respiration rate which increases the amount of<br />

ATP in cells. Therefore, SuSy activity which<br />

involves in energy-saving pathway of glycolysis<br />

(Huber and Akazawa, 1986) should be decreased.<br />

SuSy is an important enzyme for synthesizing<br />

UDP-glucose, the cellulose precursor (Nakai et al.,<br />

1999). Thus, exogenous ethylene enhances a<br />

cellulase activity (Ferrarese et al., 1995) which<br />

leads to high production of UDP-glucose that may<br />

act as a negative feedback to the SuSy activity.<br />

The exact mechanisms of the SuSy activity as well<br />

as the effect of ethylene on SuSy activity have still<br />

not been well-defined.<br />

CONCLUSION<br />

We conclude that the ethephon at the rate<br />

of 500 mg/l spraying at 110 DAF could increase<br />

TSS in pineapple fruit, but not TA, sugar contents<br />

and SuSy activity, and the treated fruits could be<br />

harvested at 145 DAF without the decrease of fruit<br />

size and weight.<br />

ACKNOWLEDGEMENTS<br />

The work was partially supported by<br />

Thesis and Dissertation Support Fund, Graduate<br />

School, <strong>Kasetsart</strong> <strong>University</strong>. Special thank to<br />

Assoc. Prof. Dr. Napavarn Noparatnaraporn for<br />

her suggestion in preparation of this manuscript.<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2) 211<br />

LITERATURE CITED<br />

AOAC. 1990. Official Methods of Analysis. Vol.<br />

II, 15 th ed., Association of Official Analytical<br />

Chemists, Inc., Arlington, Virginia.<br />

Audinay, A. 1970. Trial on the artificial control<br />

of ripening of pineapples with ethrel. Fruits<br />

25: 757.<br />

Bartholomew D.P., E. Malezieux, G.M. Sanewski<br />

and E. Sinclair. 2003. Inflorescence and fruit<br />

development and yield, pp. 167-202. In D.P.<br />

Bartholomew, R.E. Paull and K.G. Rohrbach<br />

(eds.). The Pineapple: Botany, Production<br />

and Uses. CABI Publishing, U.K.<br />

Bartolome A.P., P. Ruperez and C. Fuster. 1995.<br />

Pineapple fruit: morphological characteristic<br />

chemical composition and sensory analysis of<br />

Red Spanish and Smooth Cayenne cultivars.<br />

Food Chemistry 53: 75-79.<br />

Bartolome A.P., P. Ruperez and C. Fuster. 1996.<br />

Changes in soluble sugars of two pineapple<br />

fruit cultivars during frozen storage. Food<br />

Chemistry 56: 163-166.<br />

Chalermglin P. 1979. Effect of ethephon on<br />

maturation and some fruit characteristics<br />

of pineapple. MS dissertation. <strong>Kasetsart</strong><br />

<strong>University</strong>, Bangkok.<br />

Chen, C.-C. and R.E. Paull. 2000. Sugar<br />

metabolism and pineapple flesh translucency.<br />

J. Amer. Soc. Hort. Sci. 125: 558-562.<br />

D / Aoust, M.-A., S. Yelle and B. Nguyen-Quoc.<br />

1999. Antisense inhibition of tomato fruit<br />

sucrose synthase decreases fruit setting and<br />

the sucrose unloading capacity of young fruit.<br />

Plant Cell 11: 2407-2418.<br />

Dull, G.G., R.E. Young and J.B. Biale. 1967.<br />

Respiratory patterns in fruit of pineapple,<br />

Ananas comosus detached at different stages<br />

of development. Physiol. Plant. 20: 1059-<br />

1065.<br />

Ferrarese, L., L. Trainotti, P. Moretto, de L.P.<br />

Polverino, N. Rascio and G. Casaeoro. 1995.<br />

Differential ethylene-inducible expression of

212<br />

cellulase in pepper plants. Plant Mol. Biol.<br />

29: 735-747.<br />

Holcroft, D.M. and A.A. Kader. 1999. Controlled<br />

atmosphere-induced changes in pH and<br />

organic acid metabolism may affect color of<br />

stored strawberry fruit. Postharvest Biol.<br />

Technol. 17: 19-32.<br />

Hubbard, N.L., S.C. Huber and D.M. Pharr. 1989.<br />

Sucrose phosphate synthase and acid invertase<br />

as determinants of sucrose concentration in<br />

developing muskmelon (Cucumis melo L.)<br />

fruits. Plant Physiol. 91: 1527-1534.<br />

Huber, S.C. and T. Akazawa. 1986. A novel<br />

sucrose synthase pathway for sucrose<br />

degradation in culture sycamore cells. Plant<br />

Physiol. 81: 1008-1013.<br />

Komatsu, A., T. Moriguchi, K. Koyame, M. Omura<br />

and T. Akihama. 2002. Analysis of sucrose<br />

synthase genes in citrus suggests different<br />

roles and phylogenetic relationships. J. Exp.<br />

Bot. 53: 61-71.<br />

Nakai, T., N. Tonouchi, T. Konishi, Y. Kojima, T.<br />

Tsuchida, F. Yoshinaga, F. Sakai and T.<br />

Hayashi. 1999. Enhancement of cellulose<br />

production by expression of sucrose synthase<br />

in Acetobacter xylinum. PNAS 96: 14-18.<br />

Nguyen-Quoc, B. and C.H. Foyer. 2001. A role<br />

for ‘futile cycles’ involving invertase and<br />

sucrose synthase in sucrose metabolism of<br />

tomato fruit. J. Exp. Bot. 52: 881-889.<br />

Ruan, Y.-L., D.J. Llewellyn and R.T. Furbank.<br />

2003. Suppression of sucrose synthase gene<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2)<br />

expression represses cotton fiber cell<br />

initiation, elongation, and seed development.<br />

Plant Cell 15: 952-964.<br />

Singleton, V.L. and W.A. Gortner. 1965. Chemical<br />

and physical development of pineapple fruit<br />

II. Carbohydrate and acid constituents. J.<br />

Food Sci. 30: 19-23.<br />

Smith, L.G. 1988. Indices of physiological<br />

maturity and eating quality in Smooth<br />

Cayenne pineapples. 2. Indices of eating<br />

quality. Queensl. J. Agric. Animal Sci. 45:<br />

219-228.<br />

. 1991. Effects of ethephon on ripening<br />

and quality of freshmarket pineapples.<br />

Austral. J. Exp. Agric. 31: 123-127.<br />

Taiz, L. and E. Zeiger. 1998. Plant Physiology,<br />

2 nd ed., Sinaver Associates, Inc., Publishers,<br />

Sunderland. 792 p.<br />

Thongtham, J. 1983. Pineapple and Pineapple<br />

Industry in Thailand. <strong>Kasetsart</strong> <strong>University</strong><br />

Press, Bangkok.<br />

Ulrich, R. 1970. Organic acids, pp. 89-118. In<br />

A.C. Hulme (ed.). The Biochemistry of<br />

Fruits and Their Products, Vol 1. Academic<br />

Press, London.<br />

Yu, Z., C. Kun-Song, C. Qing-Jun, Z. Shang-Long<br />

and R. Yi-Ping. 2003. Effects of<br />

acetylsalicylic acid (ASA) and ethylene<br />

treatments on ripening and softening of<br />

postharvest kiwifruit. Acta Bot. Sinica 45:<br />

1447-1452.

<strong>Kasetsart</strong> J. (Nat. Sci.) 41 : 213 - 226 (<strong>2007</strong>)<br />

Phylogenetic Analysis of Thai Amomum (Alpinioideae: Zingiberaceae)<br />

Using AFLP Markers<br />

Wittaya Kaewsri 1 *, Yingyong Paisooksantivatana 1 , Uamporn Veesommai 1 ,<br />

Wichan Eiadthong 2 and Srunya Vajrodaya 3<br />

ABSTRACT<br />

The AFLP technique was used to assess the genetic relationships among 45 zingiberaceous<br />

plants including 40 collections of Amomum and 5 outgroup taxa: Alpinia, Etlingera 1, Etlingera 2,<br />

Elettaria and Geostachys. Cluster analysis using unweighted pair group method with arithmetic mean<br />

(UPGMA), based on AFLP data from 122 polymorphic bands generated with five primer combinations,<br />

was performed. The grouping of accessions of most species corresponded with their fruit morphological<br />

characteristics and were found to be consistent with previous studies. The species of Thai Amomum<br />

were classified into 3 groups based on AFLP markers: A. aculeatum group, A. biflorum group, and A.<br />

dealbatum group. The genetic relationships among genus Amomum and other genera in the tribe<br />

Alpinioideae are still incompletely understood.<br />

Key words: phylogenetic, Amomum, AFLP, Thailand<br />

INTRODUCTION<br />

Amomum Roxb. is one of the largest<br />

genera in the ginger family (Zingiberaceae) with<br />

about 150-180 species. As currently recognized,<br />

Amomum occurs from the Himalayas through<br />

Southeast Asia, Northern Australia and extends<br />

into the central Pacific and is widely distributed<br />

in Southeast Asia (Kiew, 1982; Smith, 1985).<br />

Sirirugsa (2001) estimated about 15-20 species to<br />

be found in Thailand. Plants of Amomum are<br />

generally evergreen herbs inhabiting wet forests<br />

in light gaps and at forest margins (Sakai and<br />

Nagamasu, 1998). Many species are used as<br />

medicine, spice, condiment and vegetable. Even<br />

though the plants from this genus have been long<br />

utilized, the identification is still confusing because<br />

of the absence of a comprehensive work on the<br />

genus and the much confused taxonomic problems.<br />

These bring about many changes in their<br />

taxonomic status.<br />

Four species of Amomum were first<br />

recognized by Linnaeus (1753) including: A.<br />

cardamomum, A. zingiber, A. zerumbet and A.<br />

grana-paradisi. These species have since been<br />

transferred to Elettaria Maton, Zingiber Boehm<br />

and Aframomum K. Schum. by Burtt and Smith<br />

(1972). Baker (1892), classified Amomum into 5<br />

sections; Geanthus, Achasma, Hornstedtia,<br />

Euamomum and Cenolophon based on<br />

1 Department of Horticulture, Faculty of Agriculture, <strong>Kasetsart</strong> <strong>University</strong>, Bangkok 10900, Thailand.<br />

2 Department of Forest Biology, Faculty of Forestry, <strong>Kasetsart</strong> <strong>University</strong>, Bangkok 10900, Thailand.<br />

3 Department of Botany, Faculty of Science, <strong>Kasetsart</strong> <strong>University</strong>, Bangkok 10900, Thailand.<br />

* Corresponding author, e-mail: wittayakaewsri@yahoo.com<br />

Received date : 30/03/06 Accepted date : 3/10/06

214<br />

morphological characteristics of spike, labellum<br />

and anther crest. Schumann (1904) used the<br />

characteristics of anther crest and classified<br />

Amomum into 2 sections and 4 series. Section<br />

Geanthus was divided into 2 series, series<br />

Oliganthae and Polyanthae, distinguished by the<br />

absence of an anther crest. Section Euamomum<br />

was comprised of series Lobulatae and Integrae,<br />

characterized by an anther crest. Gagnepain (1906)<br />

separated Amomum into 3 groups based on the<br />

characteristics of floral morphology such as anther<br />

crest and lateral staminode. Loesener (1930)<br />

classified Amomum into 2 main groups using<br />

anther crest, Lobulatae and Integrae.<br />

Xia et al. (2004) investigated the<br />

phylogenetic status of Amomum using ITS and<br />

matK DNA sequence data. They indicated that<br />

Amomum as currently defined is polyphyletic with<br />

three major groups of species (A. villosum Group,<br />

A. tsao-ko Group and A. maximum Group) that do<br />

not correspond with any previously recognized<br />

sectional classification of the genus. They also<br />

mentioned that some morphological characters<br />

such as anther crest and fruit type could be useful<br />

for classification.<br />

The AFLP technique has been used to<br />

study genetic diversity and phylogenetic<br />

relationships in a wide range of plant species;<br />

Lubberstedt et al. (2000) studied relationships<br />

among early European maize inbreds, Garcia-<br />

Mass et al. (2000) used AFLP marker for<br />

measuring genetic diversity in melon, Abdalla et<br />

al. (2001) used AFLP marker for estimating<br />

genetic relationships across a wide range of<br />

taxonomic levels and for analyzing the<br />

evolutionary and historical development of cotton<br />

cultivars at the genomic level, Larson et al. (2001)<br />

studied AFLP variation in agamospermous and<br />

dioecious bluegrasses of western North America,<br />

Mizumoto et al. (2003) used AFLP for studying<br />

the diversity of nuclear and chloroplast genome<br />

in wild einkorn wheat (Triticum urartu).<br />

Because the relationships within genus<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2)<br />

Amomum and other genera in tribe Alpinioideae<br />

are still incompletely understood, a more detailed<br />

analysis using other molecular techniques is<br />

necessary. Knowledge of the genetic relationships<br />

among them is essential to the classification of<br />

the genus. This study was intended to determine<br />

genetic relationships among species of the<br />

Amomum genus occurring in Thailand using AFLP<br />

markers.<br />

MATERIALS AND METHODS<br />

Plant materials<br />

Forty accessions of Amomum and 5<br />

accessions of outgroup taxa: Alpinia, Elettaria,<br />

Etlingera 1, Etlingera 2 and Geostachys were used<br />

in this study (Table 1). All plant materials were<br />

grown and kept at Department of Horticulture,<br />

<strong>Kasetsart</strong> <strong>University</strong>, Bangkok, Thailand.<br />

DNA isolation and AFLP analysis<br />

Total genomic DNAs were extracted<br />

from 100 mg fresh young leaves using Qiagen<br />

DNeasy ® Plant Mini kit (Qiagen GmbH, Hilden,<br />

Germany).<br />

AFLP analysis was performed following<br />

the method of Vos et al. (1995) with minor<br />

modifications. From each sample, 2 templates<br />

were prepared by digesting 20-50 ng DNA with<br />

the restriction enzyme combination EcoRI-MseI<br />

and by ligating the corresponding oligonucleotide<br />

adaptors in a total volume of 10 µl. Preselective<br />

PCR amplification with primers corresponding to<br />

adaptor core sequences (E+A and M+C) was<br />

performed in a 10 µl reaction containing 3 µl of<br />

AFLP template. PCR contained 10X PCR buffer,<br />

0.5 µmol/L of each primer, 1 µmol/L of each dNTP,<br />

and 1 U Taq DNA polymerase (Fermentas,<br />

Lithuania) and was performed using a Biosystems<br />

Mod. Gene Amp ® PCR system 9700 (Biosystems,<br />

Montgomeryville, PA). PCR conditions consisted<br />

of 1 cycle of 5 min at 50°C, 1 cycle of 3 min at<br />

94°C, 24 cycles of 30 s at 94°C, 24 cycles of 1

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2) 215<br />

Table 1 List of Thai Amomum accessions and outgroup taxa used in AFLP study.<br />

Accessions Species Collected number Collected places(provinces)<br />

1 A. aculeatum Roxb. Kaewsri-02 Kanchanaburi<br />

2 A. biflorum Jack Kaewsri-52 Chanthaburi<br />

3 A. dealbatum Roxb. Kaewsri-110 Chiang Mai<br />

4 A. koenigii 1 Kaewsri-03 Kanchanaburi<br />

5 A. koenigii 2 Kaewsri-29 Nakhon Nayok<br />

6 A. micranthum Ridl. Kaewsri-63 Chanthaburi<br />

7 A. repoense Gagnep. Kaewsri-64 Chanthaburi<br />

8 A. rivale1* Kaewsri-04 Kanchanaburi<br />

9 A. rivale2* Kaewsri-23 Kanchanaburi<br />

10 A. cf. rivale Kaewsri-33 Kanchanaburi<br />

11 A. siamense Craib Kaewsri-14 Tak<br />

12 A. testaceum 1 Kaewsri-15 Tak (Cultivated)<br />

13 A. testaceum 2 Kaewsri-16 Tak (Cultivated)<br />

14 A. testaceum 3 Kaewsri-17 Tak (Cultivated)<br />

15 A. testaceum 4 Kaewsri-96 Tak (Cultivated)<br />

16 Amomum cf. testaceum Kaewsri-86 Chumphon<br />

17 A. uliginosum1 Kaewsri-30 Nakhon Nayok<br />

18 A. uliginosum2 Kaewsri-92 Tak<br />

19 A. uliginosum3 Kaewsri-32 Trat<br />

20 A. cf. villosum1 Kaewsri-12 Tak (Cultivated)<br />

21 A. cf. villosum2 Kaewsri-13 Tak<br />

22 Amomum sp.1 Kaewsri-01 Kanchanaburi<br />

23 Amomum sp.2 Kaewsri-10 Kanchanaburi<br />

24 Amomum sp.3 Kaewsri-19 Prachuap Khiri Khan<br />

25 Amomum sp.4 Kaewsri-22 Kanchanaburi<br />

26 Amomum sp.5 Kaewsri-24 Kanchanaburi<br />

27 Amomum sp.6a Kaewsri-113 Chiang Mai<br />

28 Amomum sp.6b Kaewsri-88 Tak<br />

29 Amomum sp.7 Kaewsri-27 Uthai Thani<br />

30 Amomum sp.8 Kaewsri-35 Ranong<br />

31 Amomum sp.9 Kaewsri-38 Ranong<br />

32 Amomum sp.10 Kaewsri-50 Sakon Nakhon<br />

33 Amomum sp.11 Kaewsri-68 Chumphon<br />

34 Amomum sp.12 Kaewsri-70 Chumphon<br />

35 Amomum sp.13 Kaewsri-81 Ranong<br />

36 Amomum sp.14 Kaewsri-94 Tak<br />

37 Amomum sp.15 Kaewsri-108 Chiang Mai<br />

38 Amomum sp.16 Kaewsri-111 Chiang Mai<br />

39 Amomum sp.17a Kaewsri-134 Nan<br />

40 Amomum sp.17b Kaewsri-138 Nan<br />

41 Alpinia nigra - Cultivated at KU<br />

42 Elettaria cardamomum - Tak<br />

43 Etlingera littoralis - Kanchanaburi<br />

44 Etlingera pavieana - Chanthaburi<br />

45 Geostachys sp. - Nakhon Nayok<br />

The number 1, 2, 3 or 4 of each species = Amomum’s specimens that were collected from different places.

216<br />

min at 56°C, and 24 cycles of 1 min at 72°C,<br />

followed by an extension of 5 min at 72°C.<br />

Amplification products were diluted in 100 µl<br />

deionized H 2O and 2 µl were used for selective<br />

amplification in a total volume of 10 µl containing<br />

1 µmol/L of 10X PCR Buffer, 5 µmol/L of Especific<br />

primer extended by 3 selective<br />

neucleotides (Table 2), 5 µmol/L of M-specific<br />

primer extended by 3 selective nucleotides (Table<br />

2), 1 U of Taq DNA polymerase (Fermentas,<br />

Lithuania) and 1 µmol/L of each dNTPs. PCR was<br />

performed using a touchdown protocol with initial<br />

denaturation of a cycle of 30 s at 94°C, 30 s at 65°<br />

C (decreasing the temperature by 1°C after each<br />

cycle until 57°C) and 1 min at 72°C, followed by<br />

30 cycles of 30 s at 94°C, 30 s at 56°C and 1 min<br />

at 72°C with a final extension of 4 min at 72°C.<br />

Following amplification, 10 µl of formamide<br />

loading dye was added to the PCR products. The<br />

products were electrophoresed on 8% nondenaturing<br />

polyacrylamide gel. The bands were<br />

visualized using silver stain.<br />

Data analysis<br />

Each accession was scored (1) for<br />

presence and (0) for absence of each polymorphic<br />

band. AFLP bands within accessions were scored<br />

as missing if they were poorly resolved on the gel<br />

or if the template DNA did not amplify well.<br />

Similarity coefficient was calculated on the basis<br />

of Dice similarity coefficients (Dice, 1945) and is<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2)<br />

written as<br />

Cjk = 2a/(2a+b+c)<br />

In which Cjk is similarity coefficient, a<br />

is number of AFLP markers present in both j and<br />

k accessions, b is number of AFLP markers present<br />

only in j accessions and c is number of AFLP<br />

markers present only in k accessions. The<br />

similarity matrix was subjected to cluster analysis<br />

by the unweighted pair-group method with<br />

arithmetic mean (UPGMA) and a dendrogram was<br />

created using the NTSYS-pc version 2.01d<br />

program (Rohlf, 1997).<br />

RESULTS<br />

Five informative AFLP primer<br />

combinations generated a total of 364 reproducible<br />

amplification fragments across all species of<br />

Amomum, among which 122 bands were<br />

polymorphic (Table 2). The number of amplified<br />

AFLP bands per primer pair varied from 66 to 81<br />

with an average of 72.8 bands. The average<br />

number of polymorphic bands detected was 24.4<br />

per primer combination. The fragment sizes were<br />

determined by comparing each one with the<br />

standard DNA ladder, ranging from about 140 to<br />

726 base pairs (bp). Two primer combinations (E-<br />

AGG, M-CAA (Figure 2) and E-ACC, M-CAA)<br />

produced 30 polymorphic bands, a relatively<br />

higher numbers of polymorphisms compared to<br />

the other primers used in this study.<br />

Table 2 AFLP primer pairs and their number of amplified and polymorphic bands for phylogenetic<br />

study of Thai Amomum.<br />

Primer combinations Amplified bands No. of polymorphic bands<br />

(EcoRI+3/MseI+3)<br />

E-AGG, M-CAA 81 30<br />

E-ACC, M-CTA 73 17<br />

E-ACC, M-CAA 66 30<br />

E-AGC, M-CTC 74 25<br />

E-AGG, M-CTC 70 20<br />

Total 364 122<br />

Mean 72.8 24.4

Cluster analysis<br />

Cluster analysis using UPGMA<br />

(unweighted pair group method with arithmetic<br />

mean) was performed to examine genetic<br />

relationships among Thai Amomum species. A<br />

dendrogram was produced from the UPGMA<br />

cluster analysis of genetic similarity (GS) matrix<br />

for 45 accessions, 40 accessions of Amomum<br />

species and 5 accessions of out taxa, based on<br />

AFLP markers varied from 43% to 88% with a<br />

total average genetic similarity of 74.5% (Table<br />

3). Two main clusters (A and B) were separated<br />

at 57% GS. The A cluster was separated into 2<br />

groups: C and D, at 58% genetic similarity. The D<br />

group is subdivided into 2 subgroups (I and II) at<br />

59% GS while the B Cluster generated 2 groups<br />

(E and F) at 59% GS (Figure 3).<br />

The A cluster is characterized by spiny<br />

fruit (rarely smooth fruit). The C group contains<br />

Amomum koenigii 1, A. koenigii 2, A.uliginosum<br />

1, Amomum sp.9, Etlingera littoralis, A.<br />

aculeatum, Amomum sp.12 and Geostachys sp.<br />

while D group is divided into two subgroups (I<br />

and II). Subgroup (I) consists of A. testaceum 1,<br />

A. testaceum 2, A. testaceum 3 and Amomum cf.<br />

testaceum. Subgroup (II) consists of A. testaceum<br />

4, A. cf. villosum2, Amomum sp.5, Amomum sp.7,<br />

A. uliginosum2, A. cf. villosum1, A. rivale1, A.<br />

micranthum, A. rivale2, A. cf.rivale, Amomum sp.<br />

8, Amomum sp.4, A. biflorum and Amomum sp.13.<br />

The B cluster is characterized by smooth, ridged<br />

or wing fruit (rarely spiny fruit). This cluster<br />

contains E and F groups. The E group consists<br />

Amomum sp.16, Amomum sp.3, Amomum sp.2,<br />

Amomum sp.17a, A. siamense, Amomum sp.6b,<br />

Amomum sp.6a, Elettaria cardamomum, Amomum<br />

sp.17b, A.dealbatum, Amomum sp.15, Amomum<br />

sp.10 and Alpinia nigra. The F group contains<br />

Amomum sp.1, Amomum sp.14, A. repoense, and<br />

Etlingera pavieana. Regarding the out group taxa;<br />

Alpinia nigra, Elettaria cardamomum and<br />

Etlingera pavieana were inserted in B group while<br />

Etlingera littoralis and Geostachys sp. were placed<br />

in A group.<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2) 217<br />

DISCUSSION<br />

In this study, 40 accessions of Thai<br />

Amomum species were fingerprinted including 5<br />

outgroup taxa. One hundred twenty two<br />

polymorphic AFLP markers were produced from<br />

five primer combinations. UPGMA cluster<br />

analysis (Rohlf, 1997) with genetic similarity of<br />

57% separated Amomum into 2 main clusters: A<br />

consists of C and D groups and B consists of E<br />

and F groups (Figure 1).<br />

Regarding the C group, A. koenigii 1 and<br />

A.koenigii 2 were collected from Kanchanaburi<br />

and Nakhon Nayok provinces, respectively. It is<br />

clear that both collections are closely related<br />

(74%), even though the peduncular lengths vary<br />

greatly. The plants from Nakhon Nayok have a<br />

much shorter peduncle than those found in<br />

Kanchanaburi. The variation in phenotype could<br />

be caused by differences in their respective<br />

habitats. The placement of this species is similar<br />

to morphological analysis that placed it in spiny<br />

fruit group. This result is confirmation of the<br />

paraphyletic relationship between A.koenigii and<br />

the spiny fruit species (A. uliginosum and A.<br />

aculeatum). A.aculeatum and Amomum sp.12 are<br />

placed together at 90% GS. These closely related<br />

species are similar in leafy stem but differ in<br />

peduncular length, colour and size of labellum.<br />

From the results, the species Amomum sp.12<br />

should be established as a new variety. However,<br />

this is difficult to decide from only a single plant.<br />

More collections are needed to solve this problem.<br />

D group is divided into two subgroups (I<br />

and II). Subgroup D (I) consists of A. testaceum<br />

1, A. testaceum 2, A. testaceum 3 and Amomum<br />

cf. testaceum. Regarding A. testaceum species<br />

complex, the dendrogram suggests that this species<br />

can be separated into at least three varieties;<br />

especially A. testaceum 4 which was isolated from<br />

the group. The placement of A. testaceum is rather<br />

close to the spiny fruit species (Amomum sp.1 and<br />

Amomum sp.14). This result does agree with Xia<br />

et al. (2004) whose work was based on ITS and

218<br />

MatK genes. They placed A.testaceum among the<br />

spiny fruit species of A.villosum group. A possible<br />

explanation for this was a paraphyletic origin of<br />

A. testaceum complex. Although its morphological<br />

characteristics are different, its genotype is close<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2)<br />

to spiny fruit species. The Amomum cf. testaceum<br />

that was collected from Chumphon is also placed<br />

in this group. Its leafy stem is similar to A.<br />

testaceum but dif fers in its hairiness on the lower<br />

surface of leaves.<br />

Figure 1 Some species of Amomum used in AFLP study.<br />

A. A. aculeatum Roxb. B. A. biflorum Jack C. A. dealbatum Roxb.<br />

D. A.koenigii Gmelin. E. A. repoense Pierre ex Gagnep. F. A. rivale Ridl.<br />

G. A. testaceum Ridl. H. A. uliginosum K?nig ex Retz. I. A. siamense Craib

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2) 219<br />

Figure 2 AFLP fingerprint of Thai Amomum species and out-groups using E-AGG, M-CAA primer pair. 1. A. koenigii1 , 2. A. koenigii 2, 3. Amomum<br />

sp.16, 4. A. testaceum1, 5. A. testaceum 2, 6. A. testaceum 3, 7. A. testaceum 4, 8. Amomum sp.1, 9. A. aculeatum Roxb., 10. Amomum sp.12,<br />

11. A. rivale1, 12. A. rivale2, 13. A.cf. villosum1, 14. A. cf. villosum2, 15. Amomum sp.4, 16. Amomum sp.5, 17. Amomum sp.7, 18. A.<br />

uliginosum1, 19. A. uliginosum2, 20. A. uliginosum3, 21. A Amomum cf. rivale., 22. Amomum sp.17a, 23. Amomum sp.8, 24. Amomum sp.10,<br />

25. A. biflorum Jack , 26. A. micranthum Ridl., 27. Amomum sp.11, 28. Amomum sp.13, 29. none use, 30. none use, 31. A. siamense Craib,32.<br />

.Amomum sp.3, 33. Amomum sp.2, 34. Amomum sp.6b, 35. A. uliginosum4, 36. Amomum sp.17b, 37. A. repoense Gagnep., 38. Amomum sp.6a,<br />

39. none use, 40. Amomum sp.14, 41. Amomum sp.15, 42. A. dealbatum Roxb., 43. Elettaria cardamomum, 44. Etlingera littoralis, 45.<br />

Etlingera pavieana, 46. Alpinia nigra, 47. Geostachys sp., 48.Amomum cf. testaceum and M=φXHinfI

220<br />

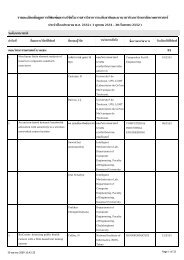

Table 3 Dice’s coefficient of similarity matrix from AFLP fingerprints of 40 accessions of Amomom and 5 outgroup taxa.<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22<br />

1 A. koenigii 1 1.00<br />

2 A. koenigii 2 0.71 1.00<br />

3 Amomum sp. 16 0.58 0.57 1.00<br />

4 A. testaceum 1 0.56 0.54 0.45 1.00<br />

5 A. testaceum 2 0.56 0.51 0.47 0.78 1.00<br />

6 A. testaceum 3 0.57 0.57 0.51 0.78 0.88 1.00<br />

7 A. testaceum 4 0.50 0.55 0.47 0.59 0.62 0.64 1.00<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2)<br />

8 Amomum sp. 1 0.64 0.60 0.60 0.50 0.53 0.57 0.60 1.00<br />

9 A. aculeatum 0.59 0.65 0.60 0.66 0.63 0.64 0.56 0.61 1.00<br />

10 Amomum sp. 12 0.58 0.63 0.57 0.64 0.62 0.60 0.60 0.64 0.90 1.00<br />

11 A. rivale 1 0.63 0.63 0.61 0.65 0.67 0.68 0.61 0.68 0.65 0.61 1.00<br />

12 A. rivale 2 0.57 0.59 0.65 0.57 0.55 0.63 0.65 0.67 0.60 0.59 0.76 1.00<br />

13 A. cf. villosum 1 0.54 0.56 0.51 0.57 0.52 0.52 0.64 0.52 0.61 0.57 0.65 0.60 1.00<br />

14 A. cf. villosum 2 0.50 0.53 0.43 0.53 0.53 0.53 0.73 0.53 0.58 0.59 0.56 0.64 0.75 1.00<br />

15 Amomum sp. 4 0.61 0.63 0.58 0.68 0.68 0.71 0.64 0.60 0.67 0.64 0.80 0.74 0.71 0.62 1.00<br />

16 Amomum sp. 5 0.57 0.60 0.53 0.60 0.58 0.60 0.65 0.57 0.66 0.65 0.64 0.67 0.77 0.83 0.68 1.00<br />

17 Amomum sp. 7 0.53 0.55 0.52 0.62 0.68 0.64 0.69 0.59 0.60 0.66 0.67 0.67 0.65 0.70 0.75 0.71 1.00<br />

18 A. uliginosum 1 0.67 0.83 0.61 0.57 0.56 0.59 0.53 0.60 0.68 0.64 0.63 0.60 0.60 0.51 0.63 0.64 0.55 1.00<br />

19 A. uliginosum 2 0.53 0.57 0.47 0.65 0.68 0.65 0.69 0.57 0.62 0.64 0.64 0.67 0.71 0.74 0.77 0.74 0.94 0.58 1.00<br />

20 A. uliginosum 3 0.53 0.52 0.57 0.57 0.56 0.54 0.63 0.62 0.56 0.58 0.67 0.64 0.67 0.64 0.69 0.65 0.75 0.58 0.74 1.00<br />

21 Amomum cf.rivale 0.55 0.57 0.69 0.59 0.57 0.62 0.63 0.64 0.62 0.58 0.72 0.85 0.62 0.64 0.78 0.68 0.66 0.61 0.67 0.67 1.00<br />

22 A.momum sp.17a 0.53 0.52 0.58 0.53 0.51 0.48 0.53 0.56 0.60 0.60 0.63 0.56 0.60 0.48 0.60 0.53 0.60 0.50 0.57 0.58 0.60 1.00

Table 3 (Continued)<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23<br />

23 Amomum sp. 8 0.55 0.57 0.66 0.57 0.57 0.59 0.61 0.62 0.59 0.55 0.77 0.85 0.65 0.62 0.77 0.67 0.63 0.61 0.66 0.69 0.92 0.60 1.00<br />

24 Amomum sp. 10 0.55 0.50 0.63 0.54 0.53 0.48 0.57 0.59 0.57 0.58 0.60 0.57 0.60 0.53 0.60 0.51 0.53 0.58 0.58 0.61 0.63 0.61 0.66<br />

25 A. biflorum Jack 0.58 0.58 0.61 0.65 0.65 0.68 0.61 0.65 0.60 0.61 0.71 0.71 0.59 0.56 0.69 0.64 0.67 0.64 0.67 0.67 0.71 0.55 0.71<br />

26 A. micranthum Ridl. 0.53 0.54 0.62 0.61 0.60 0.63 0.71 0.63 0.63 0.62 0.73 0.75 0.63 0.63 0.64 0.61 0.64 0.57 0.64 0.67 0.76 0.56 0.74<br />

27 Amomum sp. 11 0.50 0.54 0.51 0.64 0.69 0.64 0.71 0.60 0.55 0.57 0.62 0.67 0.61 0.67 0.68 0.71 0.81 0.59 0.81 0.73 0.70 0.53 0.65<br />

28 Amomum sp. 13 0.54 0.67 0.65 0.67 0.61 0.63 0.60 0.60 0.66 0.64 0.73 0.75 0.60 0.60 0.71 0.61 0.68 0.64 0.68 0.70 0.78 0.56 0.78<br />

29 A. siamense Craib 0.54 0.62 0.57 0.58 0.60 0.57 0.54 0.55 0.60 0.64 0.70 0.57 0.58 0.55 0.62 0.58 0.59 0.64 0.59 0.64 0.60 0.60 0.65<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2) 221<br />

30 Amomum sp. 3 0.52 0.53 0.61 0.53 0.51 0.53 0.55 0.64 0.56 0.52 0.63 0.51 0.51 0.48 0.60 0.47 0.57 0.55 0.55 0.61 0.53 0.52 0.57<br />

31 Amomum sp. 2 0.50 0.53 0.66 0.51 0.51 0.50 0.57 0.67 0.51 0.49 0.60 0.56 0.48 0.47 0.57 0.43 0.53 0.53 0.50 0.58 0.57 0.50 0.55<br />

32 Amomum sp. 6b 0.58 0.60 0.58 0.54 0.53 0.51 0.53 0.60 0.57 0.58 0.67 0.60 0.57 0.60 0.63 0.60 0.60 0.57 0.58 0.64 0.63 0.64 0.64<br />

33 A. uliginosum 4 0.59 0.67 0.65 0.58 0.58 0.58 0.60 0.57 0.63 0.62 0.65 0.64 0.60 0.58 0.67 0.64 0.62 0.74 0.62 0.62 0.68 0.57 0.67<br />

34 Amomum sp.17b 0.57 0.56 0.60 0.57 0.63 0.58 0.62 0.69 0.63 0.60 0.68 0.64 0.63 0.52 0.65 0.60 0.60 0.62 0.62 0.59 0.64 0.64 0.67<br />

35 A. repoense Gagnep. 0.53 0.52 0.58 0.50 0.54 0.54 0.55 0.70 0.56 0.52 0.58 0.59 0.57 0.54 0.57 0.51 0.52 0.52 0.55 0.63 0.63 0.64 0.63<br />

36 Amomum sp. 6a 0.59 0.54 0.60 0.50 0.47 0.47 0.45 0.55 0.60 0.57 0.59 0.53 0.50 0.43 0.53 0.49 0.56 0.51 0.54 0.51 0.54 0.60 0.54<br />

37 Amomum sp. 14 0.53 0.53 0.57 0.55 0.57 0.53 0.64 0.67 0.57 0.60 0.65 0.66 0.57 0.61 0.57 0.61 0.59 0.56 0.57 0.60 0.64 0.48 0.62<br />

38 Amomum sp. 15 0.57 0.54 0.56 0.57 0.58 0.55 0.56 0.57 0.61 0.57 0.70 0.66 0.66 0.55 0.65 0.58 0.54 0.54 0.59 0.62 0.67 0.68 0.70<br />

39 A. dealbatum Roxb. 0.61 0.64 0.57 0.56 0.57 0.62 0.52 0.70 0.60 0.53 0.63 0.60 0.64 0.54 0.67 0.57 0.55 0.64 0.60 0.60 0.66 0.60 0.67<br />

40 Elettaria cardamomum 0.65 0.56 0.60 0.44 0.52 0.53 0.51 0.74 0.57 0.62 0.62 0.58 0.53 0.50 0.51 0.50 0.56 0.57 0.54 0.59 0.53 0.62 0.56<br />

41 Etlingera littoralis 0.69 0.63 0.64 0.56 0.56 0.59 0.52 0.60 0.59 0.60 0.60 0.62 0.60 0.57 0.60 0.64 0.58 0.71 0.58 0.60 0.63 0.57 0.64<br />

42 Etlingera pavieana 0.58 0.58 0.57 0.54 0.57 0.54 0.57 0.71 0.64 0.63 0.67 0.54 0.51 0.47 0.61 0.50 0.58 0.55 0.58 0.61 0.55 0.61 0.53<br />

43 Alpinia nigra 0.52 0.55 0.55 0.53 0.53 0.50 0.60 0.56 0.56 0.50 0.61 0.50 0.62 0.56 0.61 0.56 0.55 0.52 0.60 0.58 0.55 0.49 0.58<br />

44 Geostachys sp. 0.57 0.60 0.59 0.55 0.57 0.53 0.60 0.64 0.69 0.65 0.64 0.57 0.61 0.58 0.65 0.61 0.59 0.67 0.62 0.65 0.65 0.60 0.62<br />

45 Amomum cf. testaceum 0.53 0.49 0.61 0.70 0.70 0.68 0.58 0.57 0.60 0.60 0.63 0.67 0.47 0.53 0.63 0.56 0.53 0.49 0.53 0.55 0.67 0.57 0.66

222<br />

Table 3 (Continued)<br />

24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45<br />

24 Amomum sp. 10 1.00<br />

25 A. biflorum Jack 0.60 1.00<br />

26 A. micranthum Ridl. 0.62 0.67 1.00<br />

27 Amomum sp. 11 0.57 0.73 0.63 1.00<br />

28 Amomum sp. 13 0.64 0.74 0.75 0.64 1.00<br />

29 A. siamense Craib 0.65 0.57 0.58 0.57 0.64 1.00<br />

30 Amomum sp. 3 0.69 0.58 0.57 0.51 0.64 0.60 1.00<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2)<br />

31 Amomum sp. 2 0.66 0.58 0.57 0.53 0.60 0.57 0.88 1.00<br />

32 Amomum sp. 6b 0.69 0.55 0.60 0.53 0.65 0.82 0.63 0.58 1.00<br />

33 A. uliginosum 4 0.59 0.65 0.66 0.57 0.74 0.64 0.60 0.57 0.62 1.00<br />

34 Amomum sp. 17b 0.70 0.70 0.58 0.67 0.63 0.63 0.62 0.64 0.65 0.52 1.00<br />

35 A. repoense Gagnep. 0.71 0.61 0.68 0.57 0.60 0.54 0.61 0.58 0.60 0.54 0.62 1.00<br />

36 Amomum sp. 6a 0.62 0.56 0.57 0.52 0.60 0.67 0.57 0.57 0.71 0.52 0.66 0.56 1.00<br />

37 Amomum sp. 14 0.54 0.70 0.66 0.61 0.64 0.52 0.60 0.64 0.47 0.61 0.60 0.59 0.43 1.00<br />

38 Amomum sp. 15 0.67 0.65 0.67 0.57 0.64 0.60 0.54 0.53 0.65 0.58 0.72 0.64 0.69 0.55 1.00<br />

39 A. dealbatum Roxb. 0.64 0.63 0.54 0.56 0.59 0.59 0.61 0.63 0.64 0.59 0.74 0.66 0.60 0.57 0.70 1.00<br />

40 Elettaria cardamomum 0.60 0.57 0.63 0.49 0.53 0.66 0.59 0.59 0.68 0.55 0.61 0.67 0.69 0.53 0.61 0.59 1.00<br />

41 Etlingera littoralis 0.55 0.67 0.54 0.57 0.59 0.62 0.55 0.57 0.60 0.71 0.62 0.58 0.53 0.60 0.53 0.69 0.60 1.00<br />

42 Etlingera pavieana 0.64 0.63 0.59 0.56 0.59 0.60 0.63 0.63 0.57 0.54 0.67 0.69 0.59 0.64 0.60 0.63 0.57 0.52 1.00<br />

43 Alpinia nigra 0.67 0.55 0.56 0.54 0.59 0.56 0.61 0.57 0.58 0.54 0.54 0.61 0.54 0.54 0.53 0.60 0.51 0.49 0.64 1.00<br />

44 Geostachys sp. 0.70 0.64 0.64 0.57 0.64 0.67 0.65 0.62 0.70 0.63 0.71 0.62 0.57 0.60 0.64 0.62 0.64 0.54 0.64 0.57 1.00<br />

45 Amomum cf. testaceum 0.60 0.64 0.65 0.62 0.65 0.51 0.53 0.60 0.55 0.54 0.59 0.63 0.53 0.54 0.65 0.57 0.53 0.55 0.57 0.44 0.54 1.00

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2) 223<br />

Figure 3 Dendrogram depicting the genetic relationship of 45 accessions of Amomum based on AFLP<br />

fingerprint, using similarity coefficient by DICE, clustering with UPGMA.

224<br />

Subgroup D (II) consists of A. testaceum<br />

4, A. cf. villosum, Amomum sp.5, Amomum sp.7,<br />

A. uliginosum 2, Amomum sp.11, A. uliginosum 3,<br />

A. villosum 1, A. rivale 1, A. micranthum, A. rivale<br />

2, A. cf. rivale, Amomum sp.8, Amomum sp.4 and<br />

Amomum sp.13. All members have spiny fruit and<br />

leafy stem less than 1.50 m tall. Regarding<br />

uliginosum 2 and 3 which were collected from Tak<br />

province, they were separated from A. uliginosum<br />

1 and 4 (from Nakhon Nayok and Ranong<br />

provinces, respectively). Their morphological<br />

characteristics differ from the ones in C group in<br />

its shorter leafy stem and smaller inflorescence.<br />

A possible explanation for this is that their<br />

morphological characteristics were the result of<br />

long time adaptation in the surrounding habitats<br />

which resulted in two ecotypes of A. uliginosum.<br />

B cluster consists of E and F groups. It<br />

is characterized by smooth, ridged or winged fruit<br />

(rarely spiny fruit).<br />

E and F groups include Amomum sp.16,<br />

Amomum sp.3, Amomum sp.2, Amomum sp.17a,<br />

A. siamense, Amomum sp.6b, Amomum sp.6a,<br />

Amomum sp. 17b, A. dealbatum, Amomum sp. 15,<br />

Amomum sp. 10, Elettaria cardamomum, Alpinia<br />

nigra, Amomum sp. 1, Amomum sp.14, A. repoense<br />

and Etlingera pavieana.<br />

The dendrogram suggests the placement<br />

of smooth fruit (Amomum sp.16) between spiny<br />

and winged fruit. Similar to the result of Amomum<br />

sp.1 and 10 both of which are spiny fruit but were<br />

placed among winged fruit species. Amomum<br />

sp.17a and 17b from Nan province are similar in<br />

their morphology but were placed in different<br />

clusters. More study is needed to properly identify<br />

the position of these species. A.siamense with fruit<br />

longitudinally ridged is also placed in this group.<br />

This species should be closely related to winged<br />

fruit species. Although the cluster is not completely<br />

separated from the others, all winged fruit species<br />

are clearly placed. Therefore, the results have the<br />

tendency to be consistent with the A.maximum<br />

group of Xia et al. (2004).<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2)<br />

The outgroup taxa (Alpinia, Elettaria,<br />

Etlingera and Geostachys) are placed among<br />

Amomum species. The result indicates a closer<br />

relationship among them and the spiny fruit species<br />

of Amomum. This result is similar to Xia et al.<br />

(2004) who found that Etlingera littoralis was<br />

placed in the clade of A.villosum group. The results<br />

then confirmed that Etlingera is related to the<br />

genus Amomum. Furthermore, some species of<br />

Alpinia, Elettaria and Geostachys are also closely<br />

related to the genus Amomum.<br />

Twenty-six representives of Thai<br />

Amomum can be classified into 3 groups by using<br />

AFLP evidence: A. aculeatum, A. biflorum and A.<br />

dealbatum groups.<br />

The A. aculeatum group consists of 4<br />

species: A. koenigii, A. uliginosum, A. aculeatum<br />

and Amomum sp. 12. Species in this group have<br />

smooth and spotted or spiny fruit, anther crest 3<br />

lobes, leafy stem stout and usually more than 1.5<br />

m tall.<br />

The A. biflorum group contains 10<br />

species: A. testaceum, Amomum cf. villosum,<br />

Amomum sp.4, Amomum sp.5, Amomum sp.7,<br />

Amomum sp.8, A.rivale, A. micranthum, Amomum<br />

sp.11 and Amomum sp.13. All members of this<br />

group are defined by smooth or spiny fruit. Most<br />

species of this group are spiny fruit. In the case of<br />

smooth fruit, its fruit shape is usually globular and<br />

fruit colour is white or pale brown. The leafy stem<br />

is usually slender and shorter than 1.5 m.<br />

The A. dealbatum group contains 12<br />

species of Amomum: A. dealbatum, A. repoense,<br />

A. siamense, Amomum sp.1, Amomum sp.2,<br />

Amomum sp.3, Amomum sp.6, Amomum sp.10,<br />

Amomum sp.14, Amomum sp.15, Amomum sp.16<br />

and Amomum sp.17. The species in this group are<br />

characterized by winged, ridged or smooth fruit<br />

(rarely spiny fruit and 3 lobes) and entire, round<br />

or truncate anther crest.

CONCLUSION<br />

AFLP markers classified Thai Amomum<br />

species into three groups (A. aculeatum group, A.<br />

biflorum group, and A. dealbatum group) which<br />

correspond to the fruit and leafy stem<br />

characteristics.<br />

ACKNOWLEDGEMENTS<br />

The authors are thankful to the curators<br />

of Bangkok Herbarium (BK) and Forest<br />

Herbarium (BKF) for their kind permission and<br />

suggestion during this study. Also, this work was<br />

supported by the TRF/BIOTEC Special Program<br />

for Biodiversity Research and Training grant<br />

T_14009.<br />

LITERATURE CITED<br />

Abdalla, A.M, O.U.K. Reddy and K.M. El-Zik.<br />

2001. Genetic diversity and relationships of<br />

diploid and tetraploid cottons revealed using<br />

AFLP. Theor. Appl. Genet. 102: 222-229.<br />

Baker, J.G. 1892. Scitamineae, pp. 198-264. In<br />

J. D. Hooker. Flora of British India vol.VI.<br />

L. Reeve & Co., London.<br />

Burtt, B.L. and R.M. Smith. 1972. Key species in<br />

the taxonomic history of Zingiberaceae. Note<br />

RBG. Edinb. 31: 177-227.<br />

Dice, L.R. 1945. Measures of the amount of<br />

ecological association between species.<br />

Ecology 26: 297-302.<br />

Gagnepain, F. 1906. Du Muséum. Bulletin de La<br />

Societé Botanique de France. 53: 136-145.<br />

Garcia-Mass, J., M. Oliver and H. Gomez-<br />

Paniagua. 2000. Comparing AFLP, RAPD and<br />

RFLP markers for measuring genetic diversity<br />

in melon. Theor. Appl. Genet. 101: 860-864.<br />

Kiew, K. Y. 1982. The genus Elettariopsis<br />

(Zingiberaceae) in Malaya. Notes RBG<br />

Edinb. 42: 295-314.<br />

Larson, S.R., B.L. Waldron, S.B. Monsen, L.St.<br />

<strong>Kasetsart</strong> J. (Nat. Sci.) 41(2) 225<br />

John, A.J. Palazzo, C.L. McCracken and R.D.<br />

Harrison. 2001. AFLP Variation in<br />

agamospermous and dioecious bluegrasses of<br />

Western North America. Crop Sci. 41: 1300-<br />

1305.<br />

Linnaeus, C. 1753. Monandria. In Species<br />

Plantarum-A facsimile of the first edition.<br />

London, Bernard Quaritch Ltd. 560 p.<br />

Loesener, T. 1930. Zingiberaceae (Amomum),<br />

pp.599-602. In A. Engler and K. Prantl, ed.<br />

Die Naturlichen Pflanzenfamilien, Leipzig,<br />

E. Haberland.<br />

Lubberstedt, T., A. E. Melchinger, C. DuBle, M.<br />

Vuylsteke and M. Kuiper. 2000. Relationships<br />

among early European maize inbreds: IV.<br />

Genetic diversity revealed with AFLP markers<br />

and comparison with RFLP, RAPD, and<br />

pedigree data. Crop Sci. 40: 783-791.<br />

Mizumoto, K., S. Hirosawa, C. Nakamura and S.<br />

Takumi. 2003. Nuclear and chloroplast<br />

genome genetic diversity in the wild einkorn<br />

wheat, Triticum urartu, revealed by AFLP and<br />