Mine to Market March-April 2012 - Mount Isa Mines

Mine to Market March-April 2012 - Mount Isa Mines

Mine to Market March-April 2012 - Mount Isa Mines

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

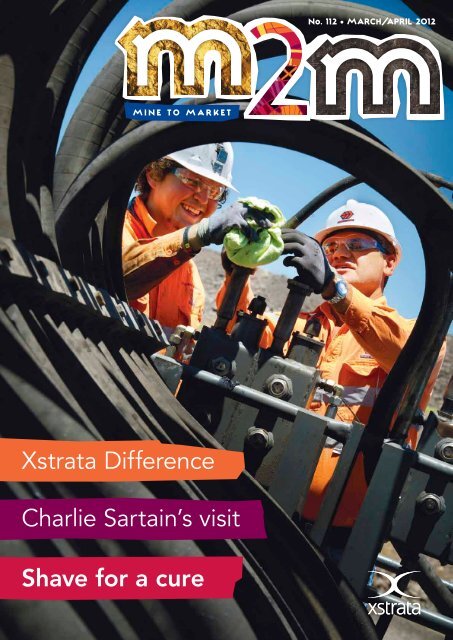

No. 112 • MARCH/APRIL <strong>2012</strong>MINE TO MARKETXstrata DifferenceCharlie Sartain’s visitShave for a cure

No. 112 • MARCH/APRIL <strong>2012</strong>21 24OperationsXstrata Difference . . . . . . . . . . . . . . . . . . . . . 1Charlie Sartain’s visit . . . . . . . . . . . . . . . . . . . 2<strong>Mount</strong> Margaret Mining Project advancing . 3MICO shafts . . . . . . . . . . . . . . . . . . . . . . . . 11MICO continuous Improvement project. . . 11Simply Outstanding . . . . . . . . . . . . . . . . . . 12Xstrata Technology leading the way . . . . . . 20Bowen Ram Car . . . . . . . . . . . . . . . . . . . . . 20Up CloseMike Westerman . . . . . . . . . . . . . . . . . . . . . . 9SafetySafety innovation award . . . . . . . . . . . . . . . . 5Our S<strong>to</strong>riesJames Windisch – Zinc . . . . . . . . . . . . . . . . 10Kate McCutcheon – EHM . . . . . . . . . . . . . . 15Shaun Byrnes – Copper . . . . . . . . . . . . . . . 22Bob Griffin – Townsville . . . . . . . . . . . . . . . . 27EnvironmentEHM TED expanded . . . . . . . . . . . . . . . . . . . 5St Joseph’s Primary School . . . . . . . . . . . . . 26HealthDon’t let the flu bugknock you out . . . . . . . . . . . . . . . . . . . . . . . 28CommunityHis<strong>to</strong>ric rail ambulance back on display . . . . 4EHM operations recovered from rain . . . . . . 5Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>sSchool Bursary Program <strong>2012</strong> . . . . . . . . . . . 8<strong>Mount</strong> <strong>Isa</strong>’s oral health building . . . . . . . . . 16Crime prevention . . . . . . . . . . . . . . . . . . . . 18Award winning flying doc<strong>to</strong>rbase officially opens . . . . . . . . . . . . . . . . . . 21<strong>Isa</strong> Library lives on . . . . . . . . . . . . . . . . . . . . 23The Smith Family graduation ceremony . . . 23Shave for a cure . . . . . . . . . . . . . . . . . . . . . 24Our peopleTwenty, thirty forty years… . . . . . . . . . . . . . . 630 Years and many miles<strong>to</strong>nes . . . . . . . . . . . 7His<strong>to</strong>ry in the making . . . . . . . . . . . . . . . . . . 7Vacation Students visit our operation . . . . . 13Campbell clan return underground . . . . . . 13Welcome new apprentices . . . . . . . . . . . . . 14Xstrata Graduate Programwelcomes 48 new graduates . . . . . . . . . . . 17QRC Resources Awards for Women . . . . . . 19NoticesXstrata Super . . . . . . . . . . . . . . . . . . . . . . . . 14Announcements, In Memoriam,Accommodation, For Sale . . . . . . . . . . . . . 29Calendar . . . . . . . . . . . . . . . . . . . . . . . . . . . 29From the COO’sThe health and safety of our workforcecontinues <strong>to</strong> be our key focus in <strong>2012</strong>, withour efforts and commitment <strong>to</strong> providing aninjury-free safe work environment supportedby a strong safety performance in <strong>March</strong>.Since the acquisition of <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s byXstrata in 2003, we have made considerableimprovements in our safety performance. In <strong>March</strong><strong>2012</strong> North Queensland Copper Operationsachieved a miles<strong>to</strong>ne, recording no medicaltreatment, restricted work or lost time injuries atany of our operations. A Total Recordable InjuryFrequency Rate of 5.4 is an 82.2% improvementfrom 2004 figures. The improvement in this safetymeasure demonstrates that it is achievable for theworkplace <strong>to</strong> be free of recordable injuries.This performance also supports our SafetyLeadership Program which reinforces theeffectiveness of a risk based approach <strong>to</strong> preparingfor work. When we consider; ‘what we are about<strong>to</strong> do?’, ‘what could go wrong?’, ‘what we canpersonally do <strong>to</strong> prevent it going wrong?’ and ‘arewe right <strong>to</strong> start?’, our performance demonstratesthat all accidents are preventable.Steve de KruijffChief Operating OfficerXstrata CopperNorth QueenslandXstrata North Queensland is also committed<strong>to</strong> the sustainability of north Queensland andcurrently has more than $1.6 billion expansionprojects underway or in planning <strong>to</strong> expand ourmining operations in the region. But the potentialcan only be reached with a dedicated approach <strong>to</strong>addressing the state-wide pressures that industrygrowth is putting on communities.While we continue <strong>to</strong> grow our operations innorth Queensland, our priority will be <strong>to</strong> continue<strong>to</strong> employ locally and relocate new employees andtheir families <strong>to</strong> the north west where possible.However, <strong>to</strong> successfully achieve this goal, we need<strong>to</strong> work closely with local stakeholders <strong>to</strong> ensurethe quality and availability of housing is addressed.It is only fair that our new recruits <strong>to</strong> the north westare able <strong>to</strong> access the facilities and infrastructurethey would expect <strong>to</strong> find in other regional cities.The socio-economic development of <strong>Mount</strong> <strong>Isa</strong>and the region is vital <strong>to</strong> maintaining a sustainablecommunity through infrastructure development.We look forward <strong>to</strong> a year of positive growthfor the communities where we operate.Brian HearneChief Operating OfficerXstrata Zinc AustraliaOn the coverGary Birch – IndigenousTraineeship Coordina<strong>to</strong>rXstrata s<strong>to</strong>ck priceXstrata is listed on the Londonand Zurich s<strong>to</strong>ck exchanges.£11.02As at 16 <strong>April</strong> <strong>2012</strong>. Xstratashare price on the London S<strong>to</strong>ckExchange (XTA.L)Contact the edi<strong>to</strong>rInput from all Xstrata NorthQueensland operationsis invited. Any articles,innovations, achievements,ideas or suggestions arevery welcome. Pleasecontact Lara Lavers, XstrataCommunity Relations on email:llavers@xstratacopper.com.auor phone: (07) 4744 2955.The Xstrata Ethics LineThe Xstrata Ethics Line is anindependently run, confidentialfacility providing employees andstakeholders with a means forreporting breaches of Xstrata’sBusiness Principles, policiesor prevailing legislation. Toaccess this line please visitwww.xstrataethics.com orfreecall: 1800 987 310

OperationsXstratadifferenceFrom looking at the frontcover of this edition of <strong>Mine</strong><strong>to</strong> <strong>Market</strong>, you will havenoticed the fresh look of thepublication, which is a part ofXstrata’s ‘new look and feel’.Throughout the publication, you willappreciate the new layout changes whichhave been implemented, along withadvanced colour and tapestry artwork.New features of the magazine willalso see a focus on bringing the personals<strong>to</strong>ries and journeys of our employees <strong>to</strong>the reader.This is just one of the ways we arecommunicating <strong>to</strong> our people throughtelling their s<strong>to</strong>ries as well as our own,and bringing <strong>to</strong> life what is important <strong>to</strong>us at Xstrata.Our internet sites have also undergonea make-over with user-friendly updates.mine <strong>to</strong> market1

<strong>Mount</strong> MargaretMining ProjectadvancingOur <strong>Mount</strong> Margaret Mining(MMM) Project has beengaining momentum in recentmonths with significantprogress having been madeon all aspects of the project.OperationsSteve Holland – Field Officer Geology,processing drill core at the E1 North deposit.Road works are underway for a culvert crossingon the Ernest Henry Mining Lease.Our mining lease for the East-West haul road was granted on16 February <strong>2012</strong> and haul roadconstruction is expected <strong>to</strong>commence in <strong>April</strong>.John Twomey – MMM ProjectDirec<strong>to</strong>r, said it was an exciting timewith construction of the haul road about<strong>to</strong> commence.“The East-West haul road will link theE1 deposits <strong>to</strong> Ernest Henry Mining wherethe ore will be processed through ourexisting concentra<strong>to</strong>r,” John said.“We are looking forward <strong>to</strong> gettingconstruction works underway as it will markan important miles<strong>to</strong>ne for the project.”Meanwhile, our drilling team hascompleted in-fill drilling on the E1 mininglease at both the E1 North and Eas<strong>to</strong>pen pit locations <strong>to</strong> confirm the exten<strong>to</strong>f mineralisation.Drilling is currently progressing atthe E1 South site.Mat Clifford – Senior <strong>Mine</strong> Geologist,says the drillers have completed 20 holesand drilled around 4,000 metres in <strong>to</strong>talso far.“We have been working closely with ourcontrac<strong>to</strong>r Depco <strong>to</strong> ensure we achieve ourtargets safely,” Mat said.“We’re pleased <strong>to</strong> report we’vecompleted all works <strong>to</strong> date with noincidents having been recorded.”Civil works are expected <strong>to</strong> commenceon the E1 mining lease in <strong>April</strong> or May,with the construction of access roadsand infrastructure pads for offices andcrib rooms, maintenance areas, explosivebatching plants and services sheds.“The beginning of infrastructureconstruction will be another significantmiles<strong>to</strong>ne for the project since we’ll reallybe able <strong>to</strong> see some physical progress,”John said.For more information on the project,please refer <strong>to</strong> the MMM Project FactSheet on our website:www.ernesthenrymining.com.auOn 29 June 2011, XstrataCopper announced that it hadacquired the E1 and Monakoffcopper tenements near ErnestHenry Mining (EHM) fromExco Resources Ltd.The E1 and Monakoff coppertenements are located 8 kilometreseast and 21 kilometres southrespectively of EHM and <strong>to</strong>getherform our <strong>Mount</strong> Margaret Mining(MMM) Project.Our MMM Project incorporatesthe development of five small openpit mines, including three at theE1 tenement (known as E1 North,E1 South and E1 East) and two atthe Monakoff tenement (known asMonakoff and Monakoff East).mine <strong>to</strong> market3

His<strong>to</strong>ric rail ambulanceback on displayCommunityAfter 10 years in s<strong>to</strong>rage,Cloncurry’s his<strong>to</strong>ric railambulance is back on displayat Mary Kathleen MemorialPark thanks <strong>to</strong> a project run by theCloncurry His<strong>to</strong>rical Society with supportfrom Ernest Henry Mining (EHM).In late 2010, we provided $30,000 <strong>to</strong>the Cloncurry His<strong>to</strong>rical Society for theconstruction of a new display facility <strong>to</strong>house the rail ambulance and other localrailway memorabilia.The new facility was officially openedon 18 <strong>March</strong> this year and around 50community members watched on as MylesJohns<strong>to</strong>n – EHM General Manager, cut theribbon with assistance from Wayne Tapp –Cloncurry His<strong>to</strong>rical Society President, andCouncillor Colin Ferguson.“It’s a strong part of Cloncurry’shis<strong>to</strong>ry as it was converted<strong>to</strong> rail especially for use in theCloncurry district, so it‘s justgreat <strong>to</strong> have it back on displayfor everyone <strong>to</strong> appreciate– <strong>to</strong>urists and the community.”Gail Wipaki – Secretary of the CloncurryHis<strong>to</strong>rical Society and Mary KathleenMemorial Park Manager, was extremelyhappy <strong>to</strong> see the rail ambulance back ondisplay.“The rail ambulance servicedthe Cloncurry area during medicalemergencies between 1954 and 1971when roads were impassable during wetweather,” Gail said.“It was on display at Mary KathleenMemorial Park from the mid 1980’s until2002 when it was moved <strong>to</strong> the CloncurryAirport for s<strong>to</strong>rage since the shed it hadbeen housed in was badly damagedby termites.”Pictured from <strong>to</strong>p right (clockwise):Louise Waters looks at rail memorabiliain the new rail his<strong>to</strong>ry display facility.Myles Johns<strong>to</strong>n – Ernest Henry MiningGeneral Manager, cuts the ribbon <strong>to</strong> officiallyopen the new rail his<strong>to</strong>ry display facility atMary Kathleen Memorial Park with Wayne Tapp– Cloncurry His<strong>to</strong>rical Society President (left) andCouncillor Colin Ferguson (right).Around 50 community members attended theopening of the new rail his<strong>to</strong>ry display facility.Roderick Macnamara with the his<strong>to</strong>ric railambulance.4 mine <strong>to</strong> market

EHM operations recoveredfrom significant rain eventOur Ernest Henry Miningoperations are back <strong>to</strong> normalafter a significant amount ofrainfall caused some downtimein late January.When 178 millimetres of rain fell in a24 hour period on 27 and 28 January, wetemporarily suspended our undergroundand surface operations <strong>to</strong> ensure the safetyof our employees, in line with our standardoperating procedure for handling extremeweather events.EHM TED expandedOn 5 <strong>March</strong> <strong>2012</strong>, we completedan expansion of our TailingsEvaporation Dam (TED) atErnest Henry Mining <strong>to</strong> increaseits capacity in line with thenew Environmental Authorityconditions issued by theDepartment of Environment andResource Management.The TED is a purpose-built basinformed by a perimeter of embankmentwalls, with its primary function being <strong>to</strong>Operating resumed in most areas within24 hours of the rain event, but floodingcaused some damage <strong>to</strong> critical processingequipment in our concentra<strong>to</strong>r, making itimpossible <strong>to</strong> re-start.Myles Johns<strong>to</strong>n – General Manager,Ernest Henry Mining, said despite theunfortunate weather event, it gave usthe chance <strong>to</strong> perform a maintenanceshutdown earlier than expected.“We <strong>to</strong>ok the opportunity <strong>to</strong>commence a maintenance shutdown inour concentra<strong>to</strong>r on 1 February that hadbeen planned <strong>to</strong> commence later in themonth so we could reduce the amount ofdowntime in the plant,” Myles said.“The shutdown went well and once allworks were completed we recommencedfull concentra<strong>to</strong>r operations on 6 February.“All teams responded well <strong>to</strong> the rainevent, prioritising safety whilst working <strong>to</strong>minimise downtime.“I’m pleased <strong>to</strong> say we don’t expectimpacts on our <strong>2012</strong> production profile aswe plan <strong>to</strong> make up any shortfall resultingfrom this event throughout the remainderof the year.”contain decant water from our tailingss<strong>to</strong>rage facility so it can be evaporated.Our TED was originally designed <strong>to</strong>contain a one in every 10 year 72 hourrainfall event, however can now containa one in every 100 year 72 hour rainfallevent.The embankment walls of the TEDhave been expanded using approximately480,000 <strong>to</strong>nnes of material, increasing thes<strong>to</strong>rage capacity of the facility by 4,350mega litres (ML) <strong>to</strong> a <strong>to</strong>tal of 7,000ML.SafetySafetyinnovationawardCongratulations <strong>to</strong> HastingsDeering who won our 2011Quarter Four InnovationAward at Ernest HenryMining (EHM) with its Cat 793haul truck work platform.The awards are held each quarter<strong>to</strong> recognise and reward personnelfor identifying and implementingan innovative solution for a process,cost, environmental, health, safety,community issue or risk.The haul truck work platformwas designed and fabricated byMark Zilm – Workshop Fitter, andDorian Stringer – Boilermaker, andprovides an easy and safe platformfor workers <strong>to</strong> stand on whenperforming maintenance tasks onthe rear of a Cat 793 engine.Previously, workers would climbover the engine and reach down<strong>to</strong> conduct maintenance work, butwith the use of the platform, they’veimproved their ergonomic position,reducing the risk of sprains, strainsand falls.The platform also provides aplace <strong>to</strong> safely s<strong>to</strong>re <strong>to</strong>ols duringa job.The Concentra<strong>to</strong>r’s metallurgyteam was awarded runner-up for itscreation of a SAG (Semi Au<strong>to</strong>genousGrinding) Mill Trumpet Platformwhich provides a flat working surfacefor workers <strong>to</strong> stand on whenperforming maintenance tasks insidethe SAG Mill.A contrac<strong>to</strong>r from Hastings Deering kneels onthe work platform which won the Quarter FourInnovation Award, <strong>to</strong> perform maintenancetasks on the engine of a Cat 793 haul truck.mine <strong>to</strong> market5

Twenty, thirty,forty years …Anniversary dinners were held for <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s employeescelebrating 20, 30 and 40 years service during February and<strong>March</strong> at the heritage listed Casa Grande.MICOcelebrating20, 30 and40 yearsservice with <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>sBack row from left <strong>to</strong> right: Steve deKruijff, Dave Joseph (30 years), BarryGarner (30 years), Joseph Emblen (30years), Callaghan McCarthy (30 years) andMike Westerman.Front row from left <strong>to</strong> right:Lee Montgomery (20 years), Mark Smith(30 Years), Chris<strong>to</strong>pher Pitt (30 Years),Colin Munns (40 years) and Alan McGill(30 years).ZINCcelebrating 20,30 and 40 yearsservice with<strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>sBack row from L <strong>to</strong> R: Richard Bawden(30 years), Joe Golling, Vance Martin (20years), Bryant Schwengler, Regan Twible(20 years) and Scott Ezzy.Front row from L <strong>to</strong> R: Bernard Forde(20 years), Leslie Bannah (40 years), SharonCrossland (40 years), Allan Marshall (30years) and Simon Bulgarelli (20 years).Pho<strong>to</strong>graphy by Roslyn Budd www.outbackpho<strong>to</strong>graphics.com.au6 mine <strong>to</strong> market

In each edition of <strong>Mine</strong> <strong>to</strong> <strong>Market</strong>, wewill bring you an up close and personalchat with one of the General Manager’sfrom our business.In this edition, we will introduce you <strong>to</strong> Mike Westerman – GeneralManager <strong>Mount</strong> <strong>Isa</strong> Copper Operations.Mike WestermanGeneral Manager <strong>Mount</strong> <strong>Isa</strong> Copper OperationsWhere did you grow up?I was born in Port Hedland, WesternAustralia and spent most of mychildhood in the Pilbara region.Prior <strong>to</strong> 1974 we lived on the land andwhen it was time <strong>to</strong> go <strong>to</strong> school my familymoved <strong>to</strong> a little salt mining <strong>to</strong>wn calledUseless Loop (real name) and then back <strong>to</strong>the Pilbara <strong>to</strong> work in mining.What attracted you <strong>to</strong> work in mining?After living and schooling in a mining<strong>to</strong>wn, it seemed like a natural progressionthat I would end up there <strong>to</strong>o. Afterfinishing Year 10 I got an apprenticeship asan Electrical Fitter, however the apprenticemaster convinced me <strong>to</strong> attend boardingschool and complete Year 12.From there I studied MiningEngineering in Kalgoorlie and have workedin mining ever since.How long have youbeen workingfor Xstrata?I have beenworking forXstrata forfour-anda-halfyears.However prior <strong>to</strong> Xstrata acquiring <strong>Mount</strong><strong>Isa</strong> <strong>Mine</strong>s Ltd (MIM) in 2003, I did workfor <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s for three years, aswell as four years at McArthur River in theNorthern Terri<strong>to</strong>ry.Prior <strong>to</strong> becoming General ManagerMICO, what did you do?Over my career I’ve held a wealthof positions. In 2000 I was MiningSuperintendent at X41 Copper <strong>Mine</strong>, in2003 I became the <strong>Mine</strong> Manager of theGreater Paraburdoo Operations for RioTin<strong>to</strong> and in 2007, prior <strong>to</strong> moving back<strong>to</strong> <strong>Mount</strong> <strong>Isa</strong>, I was the General Manager,Ernest Henry Mining.So why Xstrata?In 2007, there was an opportunity <strong>to</strong>lead the Ernest Henry Mining Operationthrough a particularly difficult stage of theopen pit and <strong>to</strong> provide support for a newfeasibility study in<strong>to</strong> underground mining.A number of my previous workcolleagues, who I have a great deal ofrespect for, had gone through thetransition from MIM <strong>to</strong> Xstrata andwere working in <strong>Mount</strong> <strong>Isa</strong> andErnest Henry.“I still remember thegenuine excitementand praise they had forhow Xstrata conductedbusiness. Ultimately, thisconvinced me that Ineeded <strong>to</strong> be part of it. “What does General Manager MICOmean <strong>to</strong> you?This is an extremely challenging role. Thereare currently 1,500 Xstrata employeesthat work for MICO, as well as up <strong>to</strong> 300contrac<strong>to</strong>rs. This makes it one of thelargest General Manager roles in ourbusiness. Therefore, <strong>to</strong> be successful it’svital <strong>to</strong> have good people supporting you.Fortunately we have a number of goodpeople within MICO that are passionateabout the company and about the <strong>to</strong>wn.Although we’ve already been operatingfor almost 90 years, I believe that we oweit <strong>to</strong> the community and the workforce<strong>to</strong> make this a successful and sustainableoperation for as long as we can.For me personally, I am proud <strong>to</strong> bepart of this operation and would like <strong>to</strong>see us continue <strong>to</strong> adapt <strong>to</strong> meet futurechallenges.What is the most challenging part ofyour role?The overall size of the operations canpresent many challenges, and just gettingaround seeing people is difficult. Therenever seems <strong>to</strong> be enough time in the day.With any mine that has been aroundso long, we are always running in<strong>to</strong>unexpected and unplanned issues. There isa high degree of variability that we need <strong>to</strong>deal with and this is always challenging.In addition <strong>to</strong> your role at Xstrata, youare also appointed <strong>to</strong> the Mining Safety& Health Advisory Committee, whatdoes that involve?This is a tripartite (Industry, Unions,Government) committee that advises theState Minister on matters relating <strong>to</strong> Safetyand Health in mining. I am the industryrepresentative on this committee, andoverall, I think that we achieve a balancedapproach <strong>to</strong> advise.What do you enjoy most about living in<strong>Mount</strong> <strong>Isa</strong>?One of the other reasons that I came back<strong>to</strong> north west Queensland is for the countrylifestyle. Most of the country areas in otherstates seem <strong>to</strong> cater predominantly formining or <strong>to</strong>urism and you don’t get a lo<strong>to</strong>f genuine country people or activitiesliving in these areas.In <strong>Mount</strong> <strong>Isa</strong> we are able <strong>to</strong> have ourhorses close <strong>to</strong> home and this really keepsus busy on the weekends. The kids are allinvolved in team sports, which tends <strong>to</strong>keep them active and there are plenty ofgood formal events that my wife attendsevery year.I think that we’re spoilt for choice in<strong>Mount</strong> <strong>Isa</strong>.mine <strong>to</strong> market9

MICO ContinuousImprovement projectThe Conveyance Rope Protec<strong>to</strong>r in operationMICOshaftsAt Xstrata, we encourage ouremployees <strong>to</strong> continuallybring new ideas <strong>to</strong> the tableon how we can improveour operations.Troy Goodman – Fitter, Shafts andHoisting at Xstrata Copper, has done justthat with his invention of the ConveyanceRope Protec<strong>to</strong>r, designed for errormanagement when cutting and burningropes on conveyances.The Conveyance Rope Protec<strong>to</strong>r is acylindrical tube (50mm long), fabricatedand complete with hinges and tag line.Glen Allen – Superintendent ShaftsMaintenance, said Troy’s invention hadmany safety benefits and extended the lifeof equipment.“It’s very efficient way of controllingcutting and burning hazards when workingaround conveyance attachments andropes,” Glen said.John (Sid) Edwards – Acting Supervisor (right),presenting Troy Goodman with a $250 voucherfor his invention.Copper Concentra<strong>to</strong>rEmbraces CIPaul Radulovic – PlantMetallurgist at the CopperConcentra<strong>to</strong>r, is one of manyMICO employees whose CI ideawas successfully implementedin<strong>to</strong> our operations in 2011.Paul’s Slag ChangeoverRecovery Improvement ControlValve has improved slag metalrecovery by au<strong>to</strong>mating controlchangeover and removinghuman error.As a Continuous ImprovementChampion, Paul believes MICO’sCI initiative has improved theCopper Concentra<strong>to</strong>r’s safety,production, environment andfinancial performances.Continuous Improvement Champion – Paul Radulovic – Plant Metallurgist at the Copper Concentra<strong>to</strong>rIntroduced in early 2011, <strong>Mount</strong> <strong>Isa</strong> Copper Operation’s (MICO) ContinuousImprovement (CI) program is designed <strong>to</strong> ensure the continued sustainabilityof our operations.Based on two components, including Operational Excellence and CI, theprogram is based around ensuring we constantly achieve our targets, and arealways striving <strong>to</strong> find new and improved methods of the way we do things.Steve Gillam – Continuous Improvement Advisor at MICO Business Supportsaid the CI project was developed <strong>to</strong> harness ideas from within MICO’s workforce.“We were confident that a lot of ideas existed within the workforce, however,there wasn’t a process in place <strong>to</strong> capture them,” Steve said.“As such, MICO’s CI department was formed <strong>to</strong> assist in collecting andimplementing ideas from our employees.”The program is designed <strong>to</strong> enhance our business by making improvementsin areas such as safety, production, environmental and financial performances.“Almost 300 ideas were received from the workforce last year and giventhat the CI culture is a new concept at MICO, we were very pleased with theworkforce’s response,” Steve said.A large number of these ideas were successfully implemented after beingreviewed using an Idea Ratings Matrix which evaluated completed ideasaccording <strong>to</strong> the time <strong>to</strong> implement the idea, cost of the project, value creationand success of the project.Employees responsible for these implemented ideas each received giftvouchers varying in value up <strong>to</strong> $250.All MICO employees are encouraged <strong>to</strong> submit CI ideas. Workers canapproach their supervisor with their suggestion, contact any of the CI team,or submit the form available on the Intranet under the CI hotlink.mine <strong>to</strong> market11

Simply outstandingFour of our employees had theiroutstanding work rewarded in thequarterly Finance and AdministrationDepartment Staff Recognition Awards on30 January at <strong>Mount</strong> <strong>Isa</strong>’s Red Earth Hotel.Karen Read – General ManagerFinance and Administration,said the awards recognisethe achievements of ourmost unassuming quiet achievers – theaccountants, office coordina<strong>to</strong>rs, clerksand administrative staff who are vital inensuring our operations run smoothly.“The Finance and AdministrationDepartment Staff Recognition Awards area long running initiative, and our way ofsaying ‘thanks’ <strong>to</strong> the unheralded, hardworkingemployees,” Karen said.Award recipients were chosen from apool of 15 nominees acknowledged fortheir professional excellence, achievementsin cus<strong>to</strong>mer service and commitment <strong>to</strong>safety and training.Katelin Hovi – Financial Services Officer,won The Cus<strong>to</strong>mer Focus award for herinvaluable contribution <strong>to</strong> the accountsteam and exemplary service provided <strong>to</strong>the contracts department in the processingof contrac<strong>to</strong>r and supplier payments.Lenny Buttle – Copper Concentra<strong>to</strong>rS<strong>to</strong>reperson, <strong>to</strong>ok out the Pride ofWorkmanship award for maintainingthe s<strong>to</strong>re he is responsible for in animmaculate manner, along with theuncompromising support he provides<strong>to</strong> the Copper Concentra<strong>to</strong>r.Dave Warner – TelecommunicationsSuperintendent, <strong>to</strong>ok out the SustainableDevelopment award for his commitment<strong>to</strong> the safety of our employees and theimpressive standard he applies <strong>to</strong> his RiskControl Evaluations.Pictured above from left: Mick Fahey – <strong>Isa</strong> Distribution Centre Yard Receiving Coordina<strong>to</strong>r,Karen Read – General Manager Finance and Administration, Katelin Hovi – Financial ServicesOfficer and Dave Warner – Telecommunications SuperintendentMick Fahey – <strong>Isa</strong> Distribution CentreYard Receiving Coordina<strong>to</strong>r, won theTraining title for his enthusiasm andcommitment <strong>to</strong> implementing the IDCforklift driver training programs.“I would like <strong>to</strong> congratulate ourwinners and thank all of the awardnominees for their dedication <strong>to</strong> thecompany,” Karen said.Award recipients received$100 dinner vouchers in recognitionof their achievements.“The Finance and AdministrationDepartment Staff RecognitionAwards are a long runninginitiative, and our way of saying‘thanks’ <strong>to</strong> the unheralded,hard-working members of staffwho play key such roles withinour business,” Karen said.“I would like <strong>to</strong> congratulateour winners and thank all ofthe award nominees for theirdedication <strong>to</strong> the company,”12 mine <strong>to</strong> market

Vacation studentsvisit our operationsCampbellclan returnundergroundAfter living in Ireland for the past 41 years,Martin Campbell returned <strong>to</strong> his olds<strong>to</strong>mping ground at <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s withhis brother Joe in <strong>March</strong>.In 1968, the pair <strong>to</strong>ok five days <strong>to</strong> navigate theroad-trip from Sydney <strong>to</strong> <strong>Mount</strong> <strong>Isa</strong> in search of the“big money” they heard could be made working inthe mines.Joe stayed for 31 years with <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>sworking as a Plate Layer, while Martin stayed for threeyears working as a De<strong>to</strong>na<strong>to</strong>r Crimper (draft miner).Since departing in 1971, Martin hadn’t been back<strong>to</strong> the mine, let alone Australia, after he returned <strong>to</strong>his homeland in Northern Ireland 41 years ago.That was until <strong>March</strong> <strong>2012</strong> when he made his firsttrip back <strong>to</strong> Australia in nearly four decades – and hewas eager <strong>to</strong> take a trip down memory lane and goback underground with his brother Joe.Joe, 71, retired <strong>to</strong> Brisbane in 1999 after morethan three decades working for <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s, buthe also returned <strong>to</strong> help with the construction of HardTimes <strong>Mine</strong> at Outback at <strong>Isa</strong> many years ago.Joe’s son Tyrone, an Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>semployee, <strong>to</strong>ok the pair, along with their otherbrother Stevie and his wife Sheila for a <strong>to</strong>ur of theunderground operations at R62.Vacation Work Program students from Xstrata <strong>Mount</strong> <strong>Isa</strong><strong>Mine</strong>s and Ernest Henry Mining <strong>to</strong>ok the opportunity <strong>to</strong><strong>to</strong>ur our operations in February.Ernest Henry Mining’s 15 vacation students visitedXstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s, experiencing what it would be like <strong>to</strong> workat one of the largest underground mining operations in the world.The 86 vacation students based at Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s alsogot the opportunity <strong>to</strong> get a closer look of the operations at ErnestHenry <strong>Mine</strong> during their 12 week vacation work program.Pictured above from <strong>to</strong>p:Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s vacation students get a firsthand look at the ErnestHenry <strong>Mine</strong> operationsXstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s vacation students take a <strong>to</strong>ur of Ernest Henry <strong>Mine</strong>Ernest Henry Mining’s vacation students visited Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s on10 February where they experienced what it would be like <strong>to</strong> work at one ofthe largest underground mining operations in the world.Joe, Martin, Sheila and Stevie Campbell before headingunderground at R62mine <strong>to</strong> market13

Welcome newapprenticesGive yourfinances a freecheck-up!Xstrata <strong>Mount</strong> Is <strong>Mine</strong>s welcomed 58 promisingnew apprentices in January as part of its <strong>2012</strong>apprenticeship intake.The apprentices will spend the year at the XstrataSkills Centre in <strong>Mount</strong> <strong>Isa</strong> as part of their apprenticeship program,with the remainder of the four year apprenticeship spent rotatingthrough different work areas <strong>to</strong> maximise their exposure <strong>to</strong> themining industry.In addition <strong>to</strong> the training delivered at the Xstrata Skills Centreand on the job training, apprentices are also required <strong>to</strong> attendallocated blocks of study at the local <strong>Mount</strong> <strong>Isa</strong> TAFE several timesthroughout their second, third and fourth year.The group is made up of 16 electrical fitter mechanics, 2 radiotechnicians, 2 refrigeration mechanics, 4 au<strong>to</strong> electricians, 14diesel fitters, 12 fitter and turners, and 8 boilermakers.Dave Watson – Superintendent of the Xstrata Skills Centre, saidan overwhelming number of applications were received this yearfor the apprenticeship program, with the majority of applicantsinterested in electrical or diesel fitting.“We received 700 applications for the <strong>2012</strong> intake ofapprentices, which was double the number of applicants from theprevious year,” said Dave.“Xstrata runs one of the largest apprenticeship programsin north Queensland with on-site training and tailored trainingcourses, allowing apprentices <strong>to</strong> develop specific skills in order <strong>to</strong>increase their expertise and competency.“Seventy per cent of the group is from <strong>Mount</strong> <strong>Isa</strong>, which isgreat because the program is providing real employment andskills opportunities for people living in the region.”Of the 58 apprentices selected, there are eight females madeup of 5 electricians, 1 radio tech, 1 au<strong>to</strong> electrician, and 1 fitterand turner. Fifteen of the apprentices have also come throughthe school based programs from previous years and we are alsoassisting Ernest Henry Mining <strong>to</strong> train a mechanical apprentice.In addition <strong>to</strong> the apprenticeship program, Xstrata is alsoemploying 20 School Based Trainees who will undertake aCertificate 2 in Surface Extraction Operations. This programis designed <strong>to</strong> give the students an understanding of what isinvolved in each trade as well as get them ready and qualified<strong>to</strong> work on site.Apprentices started work on 30 January.14 mine <strong>to</strong> marketIn life we often consult experts <strong>to</strong> help us, for example <strong>to</strong>keep our health in order we visit a doc<strong>to</strong>r, or <strong>to</strong> keep ourcars in good shape we see a mechanic. And, just like werefer <strong>to</strong> these experts, it’s important <strong>to</strong> ensure that ourfinances get the expert attention they deserve.While getting financial advice may seem daunting orexpensive, the truth is it can be very cost effective and may bea great way <strong>to</strong> ensure that your hard earned money is workinghard for you. To help get the ball rolling, Momentum WealthSolutions* is offering you a free Financial Fitness consultation.These one-hour consultations give you the opportunity <strong>to</strong>speak with a Licensed Financial Adviser about financial <strong>to</strong>picssuch as:• budgeting;• reducing debt;• tax effective investment strategies;• the best ways <strong>to</strong> invest your money;• creating a short-term or long-term financial plan;• super savings; and• transition <strong>to</strong> retirement strategies.Best of all, this consultation is free! The Advisers will be visitingseveral sites on different dates, but it’s important <strong>to</strong> make abooking so you don’t miss out!LOCATION<strong>Mount</strong> <strong>Isa</strong>BrisbaneTownsvilleCloncurryDATE30th May, 31st May, 1st June14th May, 16th May, 18th May21st May, 22nd MayContact HR for datePlease note that the first Financial Fitness discussion is free,but any further meetings and advice with the Financial Adviseror Financial Advice Service will be at your expense. Any feescharged are agreed in consultation with your financial adviserbefore your specific financial goals are examined.Did you know?If you’re a member of Xstratasuper you can accessfree, phone-based general advice about your super?Or if you require more personalised advice, we can put youin <strong>to</strong>uch with a Licensed Financial Adviser, and the initialconsultation is free! To get general or personal advice,call a Member Services Consultant on 1300 55 7586.*Momentum Financial Advice service is delivered by GWM AdviserServices (GWMAS) Limited (ABN 96 002 071 749) trading as MomentumFinancial Advice AFSL 230692.

KateMcCutcheon’ss<strong>to</strong>ryEHM“I am a strong advocate for women pursuing professional careers inthe mining industry. When I was at school a career in the resourcesindustry for women was not encouraged or promoted, I provideparticular emphasis on highlighting the exciting opportunities acareer in the industry can provide <strong>to</strong> women.”Receiving runner-up in the GenderDiversity section highlights thatthe work I continually pursue <strong>to</strong>open up many women’s eyesand minds <strong>to</strong> the endless opportunitiesthat exist in the mining industry isbeing recognised.As a Mining Engineer at Ernest HenryMining’s <strong>Mount</strong> Margaret project I amalways challenged and put <strong>to</strong> the test: in2011 with completing the Ernest Henrypit and now in <strong>2012</strong> bringing the <strong>Mount</strong>Margaret Project online.Being a part of the project executionteam at <strong>Mount</strong> Margaret, my role involvesmine design and scheduling, infrastructureand waste dump designs as well as settingup engineering systems such as drill andblast parameters and mine planningsystems. Once production commencesmy role will transition in<strong>to</strong> a medium termplanning role where I’ll be responsible forproduction schedules and quarterly plans.I’ve recently returned from a three monthsecondment at Xstrata Zinc’s HandlebarHill Open Cut operations in <strong>Mount</strong> <strong>Isa</strong> <strong>to</strong>complete my 12 months on machineryrequired for the Quarry Managers Ticket.While my job at <strong>Mount</strong> Margaret keepsme busy, on my days off I regularly attendresource industry related conferences,workshops and network events <strong>to</strong> not onlyshare my own experiences in the resourcesindustry but <strong>to</strong> also encourage otherwomen and students <strong>to</strong> consider a careerin the industry.A career achievement <strong>to</strong> date wouldbe presenting at the AusIMM NewLeaders Conference about managingblast interactions between open pit andunderground operations at EHM. Thiswas a chance <strong>to</strong> share my technicalknowledge about my work experiencesand <strong>to</strong> demonstrate <strong>to</strong> students and youngprofessionals that graduates can providemajor input in<strong>to</strong> mining operations andhave their ideas implemented.I have been an engineering ambassadorat the University of New South Waleswhich entailed promoting engineering <strong>to</strong>students at careers fairs, schools and beenthe face of UNSW Engineering on theundergraduate prospectus.I’m also currently studying my Mastersin Geotechnical Engineering whilstworking full-time. This has been a grea<strong>to</strong>pportunity <strong>to</strong> continue updating myknowledge while networking with othersin the resources industry. I am on track <strong>to</strong>complete my Masters coursework at theend of this year.Through sharing my experiences atUniversity, my role as a graduate and nowas an Engineer I hope that my experiencescan influence other women <strong>to</strong> considercareers in the resources industry asI would like <strong>to</strong> see more women intechnical roles.”“Recognition at therecent QueenslandResources CouncilResource Awards forWomen was a grea<strong>to</strong>pportunity <strong>to</strong> meetwith successfulpeople in theminerals industry.”mine <strong>to</strong> market15

Xstrata graduate programwelcomes 48 new graduatesThis year’s intake of the Xstrata Graduate Program saw48 graduates commence at our <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s operations.The Graduate Program is designed <strong>to</strong> provideprofessional development opportunities <strong>to</strong> individualswho have come straight out of university. The twoyearprogram provides a constant learning experienceas they convert theory in<strong>to</strong> practical hands-on work.This year’s intake of graduates was selected from over2500 applicants, with the graduates ageing between 21 and49 and 35 per cent being female.Mining Engineers and Geologists make up the majority ofthe graduates, who came from all over Australia, with 45 percent from Queensland universities.The program also includes one student from theUnited Kingdom.The Graduate Program ties in well with the Vacationand Scholarship Programs <strong>to</strong> help develop students in<strong>to</strong>potential leaders in the mining industry.Sue Wicks – Human Resources Advisor, Xstrata <strong>Mount</strong><strong>Isa</strong> <strong>Mine</strong>s, responsible for coordinating the Graduate andVacation programs, said that 15 of the current graduateintake had taken part in our Vacation Program.Louise Faint, Belinda Wong,Ashleigh Job , Julia Miller“The number of graduates thathave transitioned from ourVacation Program provides apositive sign that our program issuccessfully assisting Xstrata <strong>to</strong>recruit high calibre graduates,“Sue said.Steve de Kruijff – Xstrata Copper North QueenslandChief Operating Officer, officially welcomed thegraduates, with the event attended by General Managersand Managers from Xstrata Copper and Xstrata Zinc.Maurice Nyilimana, Liam Giudes,Samuel Dudley, Lauren Raggatt.Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>’s <strong>2012</strong> graduatesmine <strong>to</strong> market17

CommunityCrime prevention<strong>Mine</strong> <strong>to</strong> <strong>Market</strong> ispleased <strong>to</strong> announcethe commencemen<strong>to</strong>f a new crimepreventionpartnership with theQueensland PoliceService. In a regularfeature for themagazine, <strong>Mine</strong> <strong>to</strong><strong>Market</strong> will provideinformation from<strong>Mount</strong> <strong>Isa</strong> police,covering crime andother policing issuesin the area.<strong>Mount</strong> <strong>Isa</strong> District Crime PreventionCoordina<strong>to</strong>r Sergeant Glen Arrold saidActing Detective Sergeant MichaelPage initiated the partnership <strong>to</strong> helpcommunicate with mine industry workerswho may be able <strong>to</strong> assist police withreducing crime in the community.“We have such a large variety ofworkers, locals and FIFO’s on the mine site,and getting messages of crime prevention<strong>to</strong> them can be difficult,” Acting DetectiveSergeant Page said. “The <strong>Mine</strong> <strong>to</strong> <strong>Market</strong>articles will ensure that mining industrymembers are up-<strong>to</strong>-date with crime andpolicing issues around the <strong>to</strong>wn and withinthe work place.”Locking doors and windows‘Lock it or lose it’ – that’s the messagefrom police. Despite heavy mediacoverage, police continually receivecomplaints of break and enters andstealing from vehicles. In the majority ofthese reported offences, vehicles andproperty were left unsecured. This leavesyou and your property vulnerable <strong>to</strong>opportunistic crime. Unlocked vehiclesand homes are being targeted, andwhen dealing with offenders, police haveestablished that offenders will by-passa locked house or car and look for anunsecured home or car <strong>to</strong> break in<strong>to</strong>.“Almost 80% of break and enters andstealing from vehicles involved unlockedproperty recently: People need <strong>to</strong> lock upand not become victims of crime,” saidSergeant Arrold.Police have noticed an increase ininformation being received from thepublic about the suspicious behaviourof possible offenders. The community iscongratulated for looking out for eachother, including vigilance when it comes<strong>to</strong> their neighbours and workplaces. Policeencourage the public <strong>to</strong> be on the lookoutfor crime in the community and continue<strong>to</strong> report any suspicious behaviour <strong>to</strong>police. The more information we get, thehigher the success rate we will have ins<strong>to</strong>pping this type of crime.If you see something suspiciouscall <strong>Mount</strong> <strong>Isa</strong> Police Station on4744 1111, Crime S<strong>to</strong>ppersanonymously on 1800 333 000,or for non-urgent matters, thinkPolicelink on 131 444.18 mine <strong>to</strong> market

Queensland Resources CouncilResources awards for WomenOur RAW womenFour of our employees, includingone school-based trainee, havebeen recognised for their hard workand continued leadership at theQueensland Resources Council’s ResourcesAwards for Women ceremony held inBrisbane on Thursday 8 <strong>March</strong> <strong>2012</strong>.Michele Todd – Xstrata Zinc Open PitProduction Supervisor at Handlebar HillOpen Cut, was the winner of the Opera<strong>to</strong>rcategory, while Bryony Andrew – <strong>Mount</strong><strong>Isa</strong> Copper Operations DevelopmentManager, received a highly commended inthe Overall Category.The Junior Award was won by ourschool-based trainee Caitlyn Gardner,while Kate McCutcheon – MiningEngineer at Ernest Henry Mining, receivedthe runner-up award for the GenderDiversity category.The awards, which coincide withInternational Women’s Day, recognise thecontribution and achievement of women inthe resources sec<strong>to</strong>r and promote genderdiversity within the mining industry.Brian Hearne – Chief Operating Officer,Xstrata Zinc Australia, said Michele wasthe first woman <strong>to</strong> be appointed as asupervisor within our open pit operationsand her recognition as Queensland’s <strong>to</strong>pfemale opera<strong>to</strong>r this year is well deserved.“Michele leads a team that worksreliably and safely, and is also a wellregarded member of the <strong>Mount</strong> <strong>Isa</strong>community – we congratulate her on hersuccess,” Brian said.Steve de Kruijff – Chief OperatingOfficer, Xstrata Copper NorthQueensland, said it was important <strong>to</strong>celebrate the achievements of womenwho have built successful careers in themale-dominated industry.“These awards provide us with theopportunity <strong>to</strong> highlight the hard work anddedication many women, who are enteringthe resource industry, bring <strong>to</strong> the job eachday,” Steve said.“Our Junior Awards recipient CaitlynGardner is an excellent example of howwe can continue <strong>to</strong> men<strong>to</strong>r, develop andprovide opportunities <strong>to</strong> women of all agesin the resource sec<strong>to</strong>r.“Women contribute <strong>to</strong> not only thediversity of our workplace but also bringa different perspective <strong>to</strong> many tasks,including operational, undertaken in theworkplace on a daily basis which add value<strong>to</strong> the resource industry as a whole.”We would like <strong>to</strong> congratulate allemployees who nominated for the QRCawards and thank them for their dedication<strong>to</strong> the company and the mining industry.Our four employees attended theQRC’s International Women’s Daybreakfast on 8 <strong>March</strong> in Brisbane <strong>to</strong>accept their awards.Opera<strong>to</strong>r Award – Michele Todd, Xstrata ZincHandlebar Hill Open Pit <strong>Mine</strong>The Opera<strong>to</strong>r Category was won by XstrataZinc’s Michele Todd who has been workingat Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s for more than sixyears, first at Black Star Open Pit and now atHandlebar Hill Open Pit where Michele leadsa team of around 15 opera<strong>to</strong>rs as a productionsupervisor. As an Indigenous Australian,Michelle is inspired and motivated <strong>to</strong> providea better future for herself and her family.Michele is the first female <strong>to</strong> hold a productionsupervisor role at our open pit operations.Junior Award – Caitlyn Gardner,<strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>sCaitlyn Gardner, a school-based trainee atXstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s, received the JuniorAward for her enthusiasm and determination <strong>to</strong>complete an Au<strong>to</strong> Electrician Apprenticeshipfollowing her Year 12 studies, as well as herpassion for the resource industry. Caitlyn’sdedication and commitment was also evidentduring her work experience at Xstrata,achieving excellent and above averagecompetency in all assessable attributes.Gender Diversity Champion – Runner upKate McCutcheon, Ernest Henry MiningXstrata Copper’s Kate McCutcheon from ErnestHenry Mining received the runner-up award forthe Gender Diversity Champion category forher ongoing commitment <strong>to</strong> be an ambassador<strong>to</strong> all women, and for her passion <strong>to</strong> influenceother women <strong>to</strong> consider careers in theresources industry.Overall Award – highly commended BryonyAndrew, <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>sBryony Andrew, who is Xstrata <strong>Mount</strong> <strong>Isa</strong>Copper Operations Development Manager,received a highly commended for the OverallAward for her key role in the undergroundoperations and development at XstrataCopper’s <strong>Mount</strong> <strong>Isa</strong> Copper Operations. Aspart of Bryony’s role as Development Manager,she is ultimately responsible for more than300 underground employees. Bryony is alsoa men<strong>to</strong>r and role model <strong>to</strong> a number ofgraduate students at Xstrata Copper. Bryonyis the first ever female operational manager atXstrata’s <strong>Mount</strong> <strong>Isa</strong> Copper Operations.mine <strong>to</strong> market19

XstrataTechnologyleadingthe wayOperationsRobotic Cathode StrippingMachine – “the first of its kindin the world” – outlines theprogressive, forward-thinkingfrom Xstrata TechnologyMore than a year of trials and testingfrom Xstrata Technology (XT) culminatedin the installation and commissioning ofa new Robotic Cathode StrippingMachine (RCSM) at Lady Annie <strong>Mine</strong>in December 2011.The RCSM – a joint project between XT,Mesco and CST Mining – is the first of itskind in the world.John Doolan – General ManagerTankhouse Technology at XT, said theTownsville team played an important rolein manufacturing the RCSM.Robotic Cathode Stripping Machine“This has been the culmination ofseveral years of development and trialworks carried out with the robots byXT personnel in Townsville, led by OlaEriksson – Tankhouse Engineering andManufacturing Manager,” John said.“The concept has been successfullydeveloped, trialled and patented by XT,giving us another ‘first’ in the world ofCopper Tankhouse Technology.”The use of robots in stripping machineshas been around for many years, and wasfirst introduced <strong>to</strong> the industry by XT’sCanadian technology group, when therobots were used for material handling only.“Our Townsville engineers saw theopportunity <strong>to</strong> take this <strong>to</strong> the next levelso they developed a machine that usesthe robots <strong>to</strong> not only pick and place thecathode plates, but also strip and handlethe copper cathode deposit from themotherplate,” John said.The RCSM is now in production at LadyAnnie <strong>Mine</strong> and is capable of operating ata capacity of 114 cathodes per hour.The RCSM uses two 600kg payloadrobots with patented end-of-arm <strong>to</strong>olingfor cathode plate handling and stripping.“Congratulations and special thanksmust go <strong>to</strong> all involved,” John said.Bowen Ram CarUser-friendly: The upgraded Ram Car at BowenCoke Works has been a welcome addition atthe Bowen Coke Works.After 34 years of operation,the Ram Car at Bowen CokeWorks has been replaced withan advanced model.The original Ram Car was originally asecond hand purchase in 1977, bought<strong>to</strong> push the charge of coking coal out ofthe 52 ovens at the end of the three-daycooking cycle.The project of replacing the Ram Carcommenced as the operations at BowenCoke Works continue <strong>to</strong> work <strong>to</strong>wards asafer working environment, and ensuringreliable production.One of the primary aims of the projectwas <strong>to</strong> eliminate regular issues such asbroken bearing housings, the Ram Carbeing pushed off the railway track, andthe spillage of coke when the ram bladeretracts from the oven.In September 2011, the initial assemblyof the Ram Car began at the TownsvilleCopper Refinery (CRL).In December 2011, the Ram Car wasmobilised <strong>to</strong> Bowen Coke for a trial fitting,and then commissioned over two weeks.Delivery of the Ram Car was an earlyChristmas present for the Bowen Coketeam, said Bruce Coles – SuperintendentXstrata Zinc Bowen Coke.“The new ram car is much safer andmore reliable <strong>to</strong> operate,” Bruce said.“As with all new equipment there is aperiod of adjustment, but the new car issmoother, quieter and more comfortable<strong>to</strong> operate. Once the opera<strong>to</strong>rs becomemore accus<strong>to</strong>med <strong>to</strong> operating the newmachine it will be much more efficient.”A new owners manual has also beendeveloped <strong>to</strong> provide in-depth operatingand maintenance instructions for trainingpurposes, due <strong>to</strong> the car having newfeatures, and in the event of a randomfailure, set procedures are in place.Huge thanks must be given <strong>to</strong> JustinRemmer and staff at CRL whom assistedwith this project across the projects life.20 mine <strong>to</strong> market

Award winning Flying Doc<strong>to</strong>rbase officially opensCommunityThe Royal Flying Doc<strong>to</strong>r Service (RFDS), Queensland Section,officially opened its redeveloped <strong>Mount</strong> <strong>Isa</strong> Base onSaturday 25 February with thanks <strong>to</strong> a $2 million contributionfrom Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s.The new multi-million dollar buildingis the first of its kind for the RFDSand gives the organisation thecapacity <strong>to</strong> provide new mentalhealth, nutrition and other allied healthservices <strong>to</strong> the <strong>Mount</strong> <strong>Isa</strong> region.The new base’s outstanding design hasalso been recognised, recently taking outthe title of the Walter and Oliver TunbridgeAward for Building of the Year in the NorthQueensland Regional Architectural Awards.RFDS Queensland Section ChiefExecutive Officer Nino Di Marco saidthe new building was an investment ina growing demand for services.“This is a purpose-built complexwith room for expansion andgrowth of RFDS programs in the<strong>Mount</strong> <strong>Isa</strong> region,” Nino said.Brian Hearne – Xstrata Zinc AustraliaChief Operating Officer, said communityresearch had shown a real need for theservices provided by the RFDS.“Last year, our Community AttitudesSurvey conducted in <strong>Mount</strong> <strong>Isa</strong> found thehighest priority issue of concern <strong>to</strong> theparticipants was the need for improvedcommunity services and facilities,”Brian said.“This includes health servicesparticularly in the area of mental health.“These areas are therefore a majorfocus of our future planning for theXstrata Community Program inNorth Queensland.”Steve de Kruijff – Xstrata Copper NorthQueensland Chief Operating Officer saidthe $2 million commitment by Xstrata<strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s had a dual benefit forXstrata’s workforce and the community.“We fully appreciate the importanceof the RFDS and their services particularlywhen emergencies unfortunately occur. Thisis a good example of how our industry cansupport the growth of communities,”Steve said.Nino also thanked the <strong>Mount</strong> <strong>Isa</strong> businessesand suppliers who worked on the complex.As well as housing RFDS employees, thenew base now has the capacity <strong>to</strong> providemental health and social and emotionalwellbeing services onsite with severaldedicated patient consultation rooms formingpart of the new development.Pictured above:Top: The redeveloped <strong>Mount</strong> <strong>Isa</strong> RFDS BaseFrom left: Kalkadoon elder Uncle Clive Samundertaking a traditional Smoking Ceremony at theRFDS base openingRFDS his<strong>to</strong>ry on the boardwalk at the new baseBrian Hearne – Chief Operating Officer, Xstrata ZincAustralia (left); Mark Gray – Chairman of the RFDSQueensland section Board; and Steve de Kruijff– Chief Operating Officer, Xstrata Copper NorthQueenslandmine <strong>to</strong> market21

Shaun Byrnes’s<strong>to</strong>ryOur People“As apprentices we allhave something unique<strong>to</strong> bring <strong>to</strong> the table, andthis diversity means myworkmates are alwayschallenging me <strong>to</strong> thinkdifferently – that’s thebest thing about workingat Xstrata.”This year, 34-year-old Shaun Byrnescourageously embarked on a newcareer adventure. Driven by hislove of machines and passion fortinkering with “big boys <strong>to</strong>ys” <strong>Mount</strong> <strong>Isa</strong>Golf Clubs’s former Head Greenkeeperenlisted in Xstrata <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>sapprenticeship program. For this matureagediesel fitting apprentice, shifting gearsis turning out <strong>to</strong> be quite the career move.“Starting again from the beginningwhen you’re in your 30’s can be prettyscary, but where else do you get anopportunity <strong>to</strong> jump on the mining boombandwagon and get paid <strong>to</strong> receive aqualification that will serve you for life. I’mgrabbing this opportunity with both handsand not letting go!”I’m the kind of person that loves theoutdoors and doing something thatchallenges me every day. The miningindustry appealed <strong>to</strong> me because it’salways changing, and <strong>to</strong> succeed in thisindustry you have <strong>to</strong> be able <strong>to</strong> thinkcreatively <strong>to</strong> find simple solutions <strong>to</strong>complex problems. Plus, the size andscope of the machines are beyondanything a diesel fitter would encounter inany other industry!I worked with a lot of machinerythrough my job at the golf club, so I knewthe basics of engine mechanics and how<strong>to</strong> use different types of manual <strong>to</strong>ols. It’sgoing <strong>to</strong> be awesome working on the flee<strong>to</strong>f mega-machines we have, especiallydown in the Black Star Pit. I’m dying <strong>to</strong>get my hands dirty working on one ofour 200 <strong>to</strong>nne CAT dump truck engines.I’ve even heard talk of a Leibherr R9800excava<strong>to</strong>r floating around one of Xstrata’slocal operations; two 1,492 kilowatt, 2000horse power V16 engines moving over 800<strong>to</strong>nnes of metal. That’s my idea of heaven.When I finish I want <strong>to</strong> start out in theworkshops doing rebuilds, and then I’dlove <strong>to</strong> experience working underground.It doesn’t matter how old you are, howmuch experience you have or whetheryou’re a man or a woman. As apprenticeswe all have something unique <strong>to</strong> bring<strong>to</strong> the table, and this diversity means myworkmates are always challenging me <strong>to</strong>think differently – that’s the best thinkabout working at Xstrata.”22mine <strong>to</strong> market

<strong>Isa</strong> librarylives on<strong>Mount</strong> <strong>Isa</strong> City Library has a newtemporary home thanks <strong>to</strong> Xstrata afterwe handed the keys <strong>to</strong> Rotary House <strong>to</strong><strong>Mount</strong> <strong>Isa</strong> City Council in <strong>March</strong>.To accommodate the library, RotaryHouse underwent extensive renovationswhich included structural repairs <strong>to</strong>the building exterior, electrical repairsand upgrades, installation of internalpartitioning, refit of the bathrooms, andinternal and external painting.Steve de Kruijff – Chief OperatingOfficer Xstrata Copper North Queensland,emphasised the importance of ensuringthe library re-opened for the <strong>Mount</strong> <strong>Isa</strong>community.“A library is a vital community resourcethat helps shape our future generations,”Steve said.“With <strong>Mount</strong> <strong>Isa</strong>’s library closed due <strong>to</strong>extensive s<strong>to</strong>rm damage, we are happy <strong>to</strong>be able <strong>to</strong> offer the council a temporarylocation, free of charge, so the libraryservices can recommence.Steve praised Xstrata’s hard workingteam for delivering the renovations on atight timeframe.“Our Building Services team havedone a fantastic job and have undertakenextensive renovations which have broughtRotary House up <strong>to</strong> speed with thelibrary’s requirements.“The project has also involved ourIndigenous Trainees who played a vitalrole in clearing the property, installing anirrigation system, landscaping the lawn andrepatching the driveways,” he said.Around $100,000 has been invested byXstrata in<strong>to</strong> Rotary House <strong>to</strong> accommodatea safe and pleasant modern facility forour community.External Affairs and Planning Manager, Ross Thompson assists Smith Family CEO, Dr Lisa O’Brien inhanding out graduation certificates.The Smith FamilyGraduation CeremonyCommunityIn <strong>March</strong>, Xstrata Copper NorthQueensland’s Corporate Affairsteam attended The Smith FamilyGraduation Ceremony in Brisbane<strong>to</strong> celebrate the achievements ofgraduating high school and tertiaryLearning for Life students.The Learning for Life programsupports disadvantaged children andyoung people through their education,from pre-school and primary school, <strong>to</strong>high school and on <strong>to</strong> tertiary studies ifthey choose.The Smith Family has been a valuedpartner of ours through the XstrataCommunity Program Queensland (XCPQ)since 2008, and we were proud <strong>to</strong>sponsor the event.Our initial threeyear partnershipwith the SmithFamily assistedmore than 450disadvantagedQueensland school children and theirfamilies in gaining greater access <strong>to</strong>educational opportunities.Last year, we extended ourpartnership for a further two years <strong>to</strong>support the development of greatercomputer literacy among 240 studentsin Queensland.In particular, this new partnership ishelping disadvantaged Queenslandersby enabling students <strong>to</strong> gain competencyin operating a personal computer,conducting online research, personalbanking, preparing a resume and jobapplications, preparing for job interviewsand using email.Caption (L <strong>to</strong> R): Steve de Kruijff – Chief OperatingOfficer Xstrata Copper North Queensland(left), Astrid Hancock – Library Coordina<strong>to</strong>r andCouncillor John Molony – Mayor of <strong>Mount</strong> <strong>Isa</strong>, startstacking books in the temporary library facility.The Xstrata CopperNorth QueenslandCorporate Affairsteam accepts agift from the SmithFamily CEO forXstrata Copper’scontributions.mine <strong>to</strong> market23

Shave for a cureCommunityDuring <strong>March</strong>, Xstrata<strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>s (MIM)and Ernest Henry Mining(EHM) employees raisedmore than $33,000 bybravely shaving theirheads and colouringtheir locks in suppor<strong>to</strong>f the LeukaemiaFoundation’s World’sGreatest Shave.Departments from all over ourMIM operations dug deep on15–17 <strong>March</strong> <strong>to</strong> donate for thecharity, resulting in some fantasticfundraising outcomes.In <strong>to</strong>tal, XMIM raised over $22,500 – anoutstanding achievement.At EHM, more than $10,000 was raisedfor the Leukaemia Foundation, doublingthe targeted amount of $5,000.The World’s Greatest Shave raisesfunds for the Leukaemia Foundation’simportant work – providing free practicaland emotional support <strong>to</strong> people withblood cancer and their families, as well asinvesting millions in research.Since 1998, over a million people haveshaved or coloured their hair, raising inexcess of $120 million.Thank you <strong>to</strong> everyone whoparticipated in our fundraising efforts thisyear. Your support is greatly appreciated.EHM: Good sport Jason “Cluffy” Cluff– Underground Infrastructure MaintenanceSupervisor, was brave enough <strong>to</strong> colour hisentire body blue.Jenaya S<strong>to</strong>rey – Social Club Secretaryand organiser of our involvement in theWorld’s Greatest Shave, said there’s been alot of effort and support <strong>to</strong>wards this yearsfundraising for the Leukaemia Foundation.“Last year we raised $2,000so we’re extremely happy <strong>to</strong>have exceeded our target of$5,000 set by the LeukaemiaFoundation,” Jenaya said.“Part of the funds raised stay in northwest Queensland which helps <strong>to</strong> ensurethat leukaemia patients and their familieshave access <strong>to</strong> world-class supportservices and that vital research in<strong>to</strong> acure continues. From the 41,000 nightsof free accommodation provided by thefoundation during 2010–2011 <strong>to</strong> regionalpatients undergoing treatmentin Townsville or Brisbane, more than1,200 nights for patients were from northwest Queensland.”“Thanks <strong>to</strong> everyone who sacrificedtheir locks and looks and <strong>to</strong> everyonewho contributed funds for a muchneeded cause.”24 mine <strong>to</strong> market

MIM: On the morning changeover atXstrata Copper’s R62 platform, employees<strong>to</strong>ok enjoyment in their colleagues partingways with their precious hair.Don Healy – Long Term PlanningMining Maintenance at Xstrata Copper,was the first <strong>to</strong> have his locks cut.“It’s a very good cause, and that sort ofmoney is pretty good for a haircut.”Like most people, Don has beenaffected by loved ones who have sufferedfrom cancer – his father died of liver cancer,and his wife’s uncle died of lymphoma.The new look might even become apermanent fixture on Don’s head, proudlysaying he might not even grow it back.Don’s colleague, Tony Campbell –Superintendent for Maintenance Services,was the next in line for a trim.“I’ve got a couple of family memberswith cancer and I’m getting right behindMovember <strong>to</strong>o,” Tony said.Luke Crick – Senior Technical Advisorfor Planning and Reliability for MobileMaintenance, was given the job of cuttingDon and Tony’s hair, but after his dutieswere finished, in true spirit of the concept,Luke himself was talked in<strong>to</strong> losinghis locks.Pictured above:Brendan Callaghan – Sustainable DevelopmentManager, was ‘branded’ with the Ernest HenryMining logo as part of our fundraising effortsfor the World’s Greatest ShaveAround 30 people <strong>to</strong>ok part in our shave andcolour events held for the World’s GreatestShave during <strong>March</strong> at Ernest Henry MiningGlen Zahner – Pipe Fitter at the Zinc LeadConcentra<strong>to</strong>r, half way through his receivinghis new ‘do’Heine Madarang, Daniel Stroud , Kerry Bowerand Sylvia Ka<strong>to</strong>naBert Bragg, Supervisor Conver<strong>to</strong>rs at theCopper Smelter, surrenders <strong>to</strong> the clippers ofJohn Fapani, Secondary Smelting OperationsSuperintendentMatt Dawson, Operations and Maintenancecoordina<strong>to</strong>r at the Zinc Lead Concentra<strong>to</strong>r,bravely gives up his eyebrows for a great causeGraham Guy, Procurement Supervisor at IDC,accessories his new hair perfectlyHazel Myles, Magazine Keeper, GFM C crewlooking very brightBeau McCormick – Operations Supervisor atthe Zinc Lead Concentra<strong>to</strong>r, prepares <strong>to</strong> bebrave and shaveDon Healy, Luke Crick, Tony CampbellBlack Star Open Cut employees enjoy a BBQprior <strong>to</strong> the shave kicking offPaul Radulovic, Plant Metallurgist at theCopper Concentra<strong>to</strong>r, gets ready <strong>to</strong> saygoodbye <strong>to</strong> his long locksJames Jacobson says goodbye <strong>to</strong> his dreadsas Bryant Schwengler, General Manager OpenCut Mining, manoeuvres the clippersEarly stages of Hayden Jones’ haircutThe Contracts and Supply team show off theirnew ‘do’sDonovan Forbes, Paste Plant Supervisor atGFM prepares <strong>to</strong> say goodbye <strong>to</strong> his 25 yearold mo and Donovan Forbes’ new look!mine <strong>to</strong> market25

St Joseph’s PrimarySchool studentswith Jessica Ernst– Southern GulfCatchments CommunityEnvironment ProjectOfficer, and Father MickLowcock from the GoodShepherd ParishSchool Group withKalkadoon Elder, UncleClive SamSt Joseph’s Primary SchoolBush Tucker Garden<strong>Mount</strong> <strong>Isa</strong>’s St Joseph’sPrimary Schoolstudents now havean EnvironmentallySustainable conscience and a green thumbthanks <strong>to</strong> a 12 month, $10,000 programled by Southern Gulf Catchments andfunded by the Xstrata Community ProgramNorth Queensland (XCPNQ).Southern Gulf Catchments has beenworking with St Joseph’s Primary Schoolon an Environmental Sustainability project<strong>to</strong> give students an understanding andappreciation of the environment.The project focuses on issues such asglobal warming, water protection, healthand nutrition, and energy efficiency withthe aim of encouraging a natural passion instudents <strong>to</strong> serve and protect the earth.An important part of the project wasthe design and establishment of a “BushTucker” garden which commenced inOc<strong>to</strong>ber 2011. With the help and suppor<strong>to</strong>f Kalkadoon elders, Endemic Plants<strong>Mount</strong> <strong>Isa</strong>, and the teachers and staff ofSt Joseph’s Primary School, the gardenwas established with native plants andbushes carefully planted and nurturedby the students.Jessica Ernst – CommunityEnvironmental Project Officer withSouthern Gulf Catchments, said the BushTucker garden has been a rewardingproject for the students.“We’re very grateful <strong>to</strong> Xstrata forhelping us <strong>to</strong> bring this program <strong>to</strong>St Joseph’s students and <strong>to</strong> see the“We’re very grateful <strong>to</strong>Xstrata for helping us <strong>to</strong>bring this program <strong>to</strong>St Joseph’s students and <strong>to</strong>see the Bush Tucker gardencome <strong>to</strong> fruition,” Jessica said.Bush Tucker garden come <strong>to</strong> fruition,”Jessica said.Nathan Pike – General ManagerSustainable Development, XstrataCopper North Queensland said Xstrata’spartnership with Southern Gulf Catchmentshas been delivering successful outcomes.“We are delighted <strong>to</strong> support SouthernGulf Catchments with our partnershipof almost $500,000 over two years,and we look forward <strong>to</strong> working withthem <strong>to</strong> continue improving <strong>Mount</strong> <strong>Isa</strong>’ssustainability,” he said.26 mine <strong>to</strong> market

Bob Griffin’ss<strong>to</strong>ryTownsville“There’s always a new project on thehorizon, and having the opportunity<strong>to</strong> develop my skills and expand myexperience has been the key driver in mycareer – that’s what keeps me motivated.”In a career that spans 35 years andcounting, there’s not a whole lot ourTownsville Port Operations ActingTraining Coordina<strong>to</strong>r Bob Griffin hasn’texperienced. For Bob, working at Xstrata’sTownsville Port means there’s alwayssomething <strong>to</strong> look forward <strong>to</strong>.“Over the years I’ve been here therehave been so many developments andinnovations throughout the Port facility.It’s fantastic because it means I’ve had theopportunity experience and learn all aboutthe different aspects of our operations.”I started out in my career way back in‘76. I was a member of the loading crewat the Copper Refinery (CRL) Tank House.Back then, everything was done manually;there were no au<strong>to</strong>mated machines <strong>to</strong>load and strip the cells. It was hard, hotwork; the anodes were lifted in<strong>to</strong> the cellsby crane in bundles of ten and had <strong>to</strong> bespaced out by hand – it was a differenttime. Nowadays, our machines are sealedand our cabins are air conditioned – it’spretty luxurious in comparison!I look at the environment we workin <strong>to</strong>day and it amazes me how muchtechnology has improved our business.Not just in terms of productivity, but thesafety of our operations.I remember when we started rolling ou<strong>to</strong>ur new ISA Process technology in the late‘70s. In the early days, I guess we wereworried about what the technology wouldmean for us – would we be replaced withmachines? During the transition, I movedaround working for <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>ssubsidiary business Townsville Transportand Services (TTS). One day I wouldbe unloading rail wagons of lead slabsfrom <strong>Mount</strong> <strong>Isa</strong> and transporting coppercathode, copper cake and billet fromCRL <strong>to</strong> the docks for export, and the nextI’d be transporting frozen meat from theStuart and Ross River meatworks <strong>to</strong> SuterPier or working in the North QueenslandWool s<strong>to</strong>re. Looking back, while thetransition <strong>to</strong> au<strong>to</strong>mated machinery seemedscary at first, it meant I got the chance <strong>to</strong>experience a wide range of job roles acrossthe Port operations through my work atTTS. And here I am, still in the business,33 years later ...I’d say the highlight of my career wasworking on the Bulk Handling Terminalupgrade project in ’82. I got <strong>to</strong> play a rolein constructing the new tippler, offices ands<strong>to</strong>rage shed. Seeing a project of that scaleprogress from start <strong>to</strong> finish was a valuablelearning experience. When constructionwas finished, I decided <strong>to</strong> stay on as part ofthe Port Operations team.The Bulk Handling Terminal is in theprocess of relocating <strong>to</strong> Berth 8 of theTownsville Port where it will have a new,state-of-the-art ship loader and conveyorsystem. My role will be <strong>to</strong> ensure thetransition goes off without any issues.That means pulling <strong>to</strong>gether new trainingpackages for our opera<strong>to</strong>rs and supervisingthe training of the crews. It’s a big job, butfor me the reward is in the challenge.Over the years, while there have beenhuge technological and operationaldevelopments, the biggest changes havebeen in the field of safety and health.Today, we’re all so much more aware ofthe risks associated with our work. In the“bad old days”, maintaining a safe workenvironment was almost seen as a brickwall that s<strong>to</strong>pped us getting the job done.Since then, there’s been a big attitudeshift; we understand that being safe onthe job actually increases our operationalproductivity, and helps us <strong>to</strong> make sureeveryone gets <strong>to</strong> go home <strong>to</strong> their familiesat the end of the day. That’s what’sreally important.The constant change and developmentmeans you never really s<strong>to</strong>p learning.There’s always a new project on thehorizon, and having the opportunity<strong>to</strong> develop my skills and expand myexperience has been the key driver in mycareer – that’s what keeps me motivated.”mine <strong>to</strong> market27