Mine to Market March-April 2012 - Mount Isa Mines

Mine to Market March-April 2012 - Mount Isa Mines

Mine to Market March-April 2012 - Mount Isa Mines

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

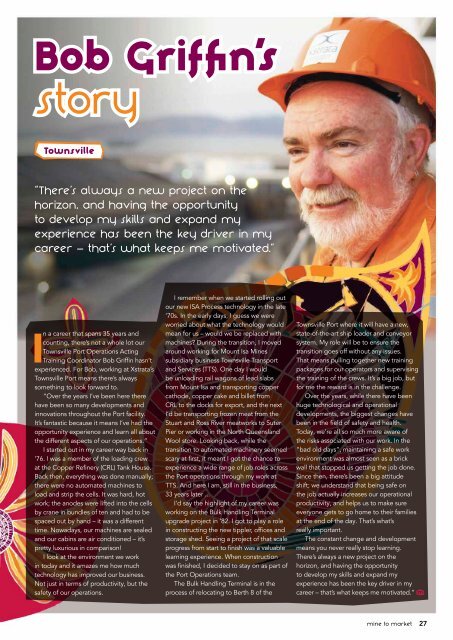

Bob Griffin’ss<strong>to</strong>ryTownsville“There’s always a new project on thehorizon, and having the opportunity<strong>to</strong> develop my skills and expand myexperience has been the key driver in mycareer – that’s what keeps me motivated.”In a career that spans 35 years andcounting, there’s not a whole lot ourTownsville Port Operations ActingTraining Coordina<strong>to</strong>r Bob Griffin hasn’texperienced. For Bob, working at Xstrata’sTownsville Port means there’s alwayssomething <strong>to</strong> look forward <strong>to</strong>.“Over the years I’ve been here therehave been so many developments andinnovations throughout the Port facility.It’s fantastic because it means I’ve had theopportunity experience and learn all aboutthe different aspects of our operations.”I started out in my career way back in‘76. I was a member of the loading crewat the Copper Refinery (CRL) Tank House.Back then, everything was done manually;there were no au<strong>to</strong>mated machines <strong>to</strong>load and strip the cells. It was hard, hotwork; the anodes were lifted in<strong>to</strong> the cellsby crane in bundles of ten and had <strong>to</strong> bespaced out by hand – it was a differenttime. Nowadays, our machines are sealedand our cabins are air conditioned – it’spretty luxurious in comparison!I look at the environment we workin <strong>to</strong>day and it amazes me how muchtechnology has improved our business.Not just in terms of productivity, but thesafety of our operations.I remember when we started rolling ou<strong>to</strong>ur new ISA Process technology in the late‘70s. In the early days, I guess we wereworried about what the technology wouldmean for us – would we be replaced withmachines? During the transition, I movedaround working for <strong>Mount</strong> <strong>Isa</strong> <strong>Mine</strong>ssubsidiary business Townsville Transportand Services (TTS). One day I wouldbe unloading rail wagons of lead slabsfrom <strong>Mount</strong> <strong>Isa</strong> and transporting coppercathode, copper cake and billet fromCRL <strong>to</strong> the docks for export, and the nextI’d be transporting frozen meat from theStuart and Ross River meatworks <strong>to</strong> SuterPier or working in the North QueenslandWool s<strong>to</strong>re. Looking back, while thetransition <strong>to</strong> au<strong>to</strong>mated machinery seemedscary at first, it meant I got the chance <strong>to</strong>experience a wide range of job roles acrossthe Port operations through my work atTTS. And here I am, still in the business,33 years later ...I’d say the highlight of my career wasworking on the Bulk Handling Terminalupgrade project in ’82. I got <strong>to</strong> play a rolein constructing the new tippler, offices ands<strong>to</strong>rage shed. Seeing a project of that scaleprogress from start <strong>to</strong> finish was a valuablelearning experience. When constructionwas finished, I decided <strong>to</strong> stay on as part ofthe Port Operations team.The Bulk Handling Terminal is in theprocess of relocating <strong>to</strong> Berth 8 of theTownsville Port where it will have a new,state-of-the-art ship loader and conveyorsystem. My role will be <strong>to</strong> ensure thetransition goes off without any issues.That means pulling <strong>to</strong>gether new trainingpackages for our opera<strong>to</strong>rs and supervisingthe training of the crews. It’s a big job, butfor me the reward is in the challenge.Over the years, while there have beenhuge technological and operationaldevelopments, the biggest changes havebeen in the field of safety and health.Today, we’re all so much more aware ofthe risks associated with our work. In the“bad old days”, maintaining a safe workenvironment was almost seen as a brickwall that s<strong>to</strong>pped us getting the job done.Since then, there’s been a big attitudeshift; we understand that being safe onthe job actually increases our operationalproductivity, and helps us <strong>to</strong> make sureeveryone gets <strong>to</strong> go home <strong>to</strong> their familiesat the end of the day. That’s what’sreally important.The constant change and developmentmeans you never really s<strong>to</strong>p learning.There’s always a new project on thehorizon, and having the opportunity<strong>to</strong> develop my skills and expand myexperience has been the key driver in mycareer – that’s what keeps me motivated.”mine <strong>to</strong> market27