Mine to Market March-April 2012 - Mount Isa Mines

Mine to Market March-April 2012 - Mount Isa Mines

Mine to Market March-April 2012 - Mount Isa Mines

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

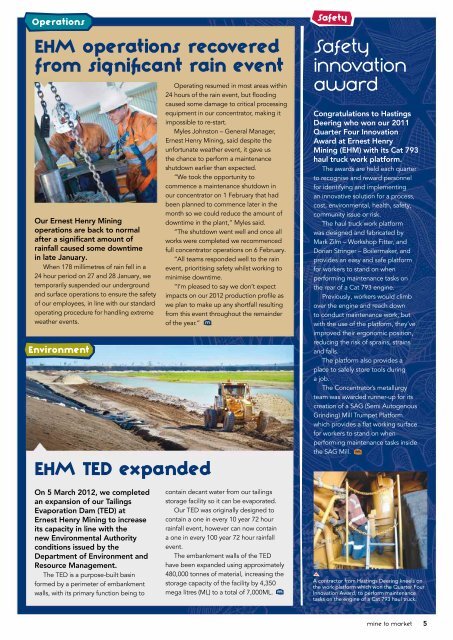

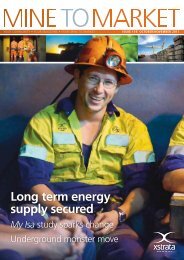

EHM operations recoveredfrom significant rain eventOur Ernest Henry Miningoperations are back <strong>to</strong> normalafter a significant amount ofrainfall caused some downtimein late January.When 178 millimetres of rain fell in a24 hour period on 27 and 28 January, wetemporarily suspended our undergroundand surface operations <strong>to</strong> ensure the safetyof our employees, in line with our standardoperating procedure for handling extremeweather events.EHM TED expandedOn 5 <strong>March</strong> <strong>2012</strong>, we completedan expansion of our TailingsEvaporation Dam (TED) atErnest Henry Mining <strong>to</strong> increaseits capacity in line with thenew Environmental Authorityconditions issued by theDepartment of Environment andResource Management.The TED is a purpose-built basinformed by a perimeter of embankmentwalls, with its primary function being <strong>to</strong>Operating resumed in most areas within24 hours of the rain event, but floodingcaused some damage <strong>to</strong> critical processingequipment in our concentra<strong>to</strong>r, making itimpossible <strong>to</strong> re-start.Myles Johns<strong>to</strong>n – General Manager,Ernest Henry Mining, said despite theunfortunate weather event, it gave usthe chance <strong>to</strong> perform a maintenanceshutdown earlier than expected.“We <strong>to</strong>ok the opportunity <strong>to</strong>commence a maintenance shutdown inour concentra<strong>to</strong>r on 1 February that hadbeen planned <strong>to</strong> commence later in themonth so we could reduce the amount ofdowntime in the plant,” Myles said.“The shutdown went well and once allworks were completed we recommencedfull concentra<strong>to</strong>r operations on 6 February.“All teams responded well <strong>to</strong> the rainevent, prioritising safety whilst working <strong>to</strong>minimise downtime.“I’m pleased <strong>to</strong> say we don’t expectimpacts on our <strong>2012</strong> production profile aswe plan <strong>to</strong> make up any shortfall resultingfrom this event throughout the remainderof the year.”contain decant water from our tailingss<strong>to</strong>rage facility so it can be evaporated.Our TED was originally designed <strong>to</strong>contain a one in every 10 year 72 hourrainfall event, however can now containa one in every 100 year 72 hour rainfallevent.The embankment walls of the TEDhave been expanded using approximately480,000 <strong>to</strong>nnes of material, increasing thes<strong>to</strong>rage capacity of the facility by 4,350mega litres (ML) <strong>to</strong> a <strong>to</strong>tal of 7,000ML.SafetySafetyinnovationawardCongratulations <strong>to</strong> HastingsDeering who won our 2011Quarter Four InnovationAward at Ernest HenryMining (EHM) with its Cat 793haul truck work platform.The awards are held each quarter<strong>to</strong> recognise and reward personnelfor identifying and implementingan innovative solution for a process,cost, environmental, health, safety,community issue or risk.The haul truck work platformwas designed and fabricated byMark Zilm – Workshop Fitter, andDorian Stringer – Boilermaker, andprovides an easy and safe platformfor workers <strong>to</strong> stand on whenperforming maintenance tasks onthe rear of a Cat 793 engine.Previously, workers would climbover the engine and reach down<strong>to</strong> conduct maintenance work, butwith the use of the platform, they’veimproved their ergonomic position,reducing the risk of sprains, strainsand falls.The platform also provides aplace <strong>to</strong> safely s<strong>to</strong>re <strong>to</strong>ols duringa job.The Concentra<strong>to</strong>r’s metallurgyteam was awarded runner-up for itscreation of a SAG (Semi Au<strong>to</strong>genousGrinding) Mill Trumpet Platformwhich provides a flat working surfacefor workers <strong>to</strong> stand on whenperforming maintenance tasks insidethe SAG Mill.A contrac<strong>to</strong>r from Hastings Deering kneels onthe work platform which won the Quarter FourInnovation Award, <strong>to</strong> perform maintenancetasks on the engine of a Cat 793 haul truck.mine <strong>to</strong> market5