Gas Processing Plants - Linde Engineering

Gas Processing Plants - Linde Engineering

Gas Processing Plants - Linde Engineering

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

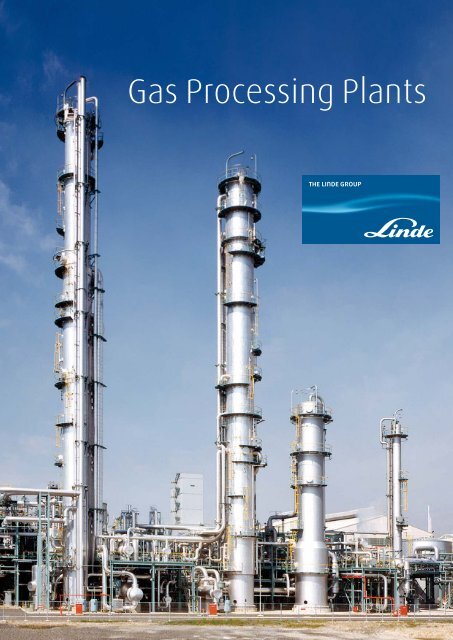

<strong>Gas</strong> <strong>Processing</strong> <strong>Plants</strong>

2<strong>Gas</strong> processing plants.<strong>Gas</strong> processing plants are a group of single processunits offered by <strong>Linde</strong> <strong>Engineering</strong>. Theseunits include a great deal of proprietary processand component manufacturing know-how in thearea of cryogenic separation and purification ofgases. They serve for the purification and cryogenicseparation of gas mixtures. Cryogenicseparation technology and physical or chemicalscrubbing processes come into application forthese units that frequently are enquired by engineeringcompanies implementing them as singleunits within a larger contract plant. Independentlyendusers may install them as supplement toexisting gas generation facilities. <strong>Gas</strong> processingplants are therefore to a large extend based on<strong>Linde</strong>´s proprietary process and production knowhow.The units are tailored to the individual applicationand requirement of the client. Plant designand scope of supply will typically include severalproprietary equipment items produced in <strong>Linde</strong>workshops like plate-fin heat exchangers, coilwoundheat exchangers or the isothermal reactor.Frequently such equipment will be assembledin the workshop and supplied to site as cold box.Partial condensation processesand liquid methane washCryogenic processes for the recovery of purecarbon monoxide and pure hydrogen fromgases resulting from partial oxidation or catalyticreforming processes. Carbon monoxide is mainlyused for the production of acetic acid, formidacid, polyurethane, poly-carbonates andmethyl-acrylates. The desired purity of carbonmonoxide depends on the prevailing requirementsand can be adjusted into the ppmrange with respect to the residual contentsof hydrogen and methane.Liquid nitrogen washThe production of ammonia requires the adjustmentof the stochiometric nitrogen/hydrogenratio to a value of 1:3. Simultaneously other traceimpurities like methane, argon and carbon monoxide(below 5ppm) should be removed to preferentiallyoperate the ammonia synthesis in theabsence of inert components. The liquid nitrogenwash is typically arranged downstream ofthe RECTISOL ® scrubbing process, if partial oxidationof coal or residue oil were selected asfeedstock basis for ammonia production. Theunit is generally supplied as assembled coldboxand includes an upstream adsorber station.Partial condensation cold box in Clearlake, USA

3<strong>Gas</strong>ification complex in TaiwanSeparation of hydrogen, olefinsand LPG from refinery fuel gasRefineries may recover hydrogen olefins and/orLPG from off-gases and thus make more profiton these pro ducts instead of simply using themas fuel gas. By cryogenic proces ses such highquality products can be economically recovered.Similarly the dehydrogenation of butanes by theOleflex or Catofin process within MTBE plantsresult in a mixture of hydrogen and condensableC 4 /C 8 hydrocarbons. Separation of hydrogenfrom a bulk quantity of heavy componentsresults in particular adjustments that should beregarded for the heat exchanger design. It hasturned out to be of advantage for the designrequirements of this cryogenic concept that<strong>Linde</strong> can offer design and equipment manufacturingin one hand.Rare gas processingArgon may be recovered from the purge gas ofammonia plants. It can be separated and recoveredas liquid argon in a cryogenic process. Ifsuitable feedstock is available, also other raregases like He, Ne, Kr and Xe can be recovered.<strong>Gas</strong> liquefaction<strong>Linde</strong> offers processes for the production ofcarbon dioxide with food quality. The mainfeedstocks are off-gases from ammonia plantsor natural gas sources.Also the liquefaction of SO 2 downstream of fluegas scrubbing plants is a process of this category.Physical and chemical washesAny cryogenic gas separation process requiresthe upstream removal of H 2 S, CO 2 and COS astypical sour gas impurities to meet the specificationfor clean products and prevent theirplugging of the process equipment.RECTISOL ® is the best known proprietary <strong>Linde</strong>scrubbing process and can simultaneouslyremove all above mentioned sour gas componentsin one process step. RECTISOL ® is selectedfor almost all oil and coal gasification projectswith chemicals as final product.<strong>Linde</strong> can quote other chemical and physicalwash processes including various kinds of MDEAtype of amine washes, MEA, DEA, Benfield,Sulfinol, Caustic, NMP, Alkacid wash and others.However, due to their number and various applicationsthey are not discussed in this context.

Designing processes – constructing plants.<strong>Linde</strong>´s <strong>Engineering</strong> Division continuously develops extensive process engineering know-how in the planning,project management and construction of turnkey industrial plants.The range of products comprises:− Petrochemical plants− LNG and natural gas processing plants− Synthesis gas plants− Hydrogen plants− <strong>Gas</strong> processing plants− Adsorption plants− Air separation plants− Cryogenic plants− Biotechnological plants− Furnaces for petrochemical plants and refineries<strong>Linde</strong> and its subsidiaries manufacture:− Packaged units, cold boxes− Coil-wound heat exchangers− Plate-fin heat exchangers− Cryogenic standard tanks− Air heated vaporizers− Spiral-welded aluminium pipesMore than 3,800 plants worldwide document the leading position of the <strong>Engineering</strong> Division in internationalplant construction.<strong>Engineering</strong> DivisionSchalchen PlantTacherting, GermanyPhone +49.8621.85-0Fax +49.8621.85-6620plantcomponents@linde-le.com<strong>Linde</strong>-KCA-Dresden GmbHDresden, GermanyPhone +49.351.250-30Fax +49.351.250-4800lkca.dresden@linde-kca.comSelas-<strong>Linde</strong> GmbHPullach, GermanyPhone +49.89.7447-470Fax +49.89.7447-4717selas-linde@linde-le.comCryostar SASHésingue, FrancePhone +33.389.70-2727Fax +33.389.70-2777info@cryostar.com<strong>Linde</strong> Cryo<strong>Plants</strong> Ltd.Aldershot, Great BritainPhone +44.1.252.3313-51Fax +44.1.252.3430-62info@linde-lcl.com<strong>Linde</strong> Impianti Italia S.p.A.Rome, ItalyPhone +39.066.5613-1Fax +39.066.5613-200r.tikovsky@lindeimpianti.it<strong>Linde</strong> Kryotechnik AGPfungen, SwitzerlandPhone +41.52.3040-555Fax +41.52.3040-550info@linde-kryotechnik.chCRYO ABGothenburg, SwedenPhone +46.3164-6800Fax +46.3164-2220gunnar.lenneras@cryo.aga.com<strong>Linde</strong> Process <strong>Plants</strong>, Inc.Tulsa, OK, U.S.A.Phone +1.918.4771-200Fax +1.918.4771-100sales@lppusa.comSelas Fluid <strong>Processing</strong> Corp.Blue Bell, PA, U.S.A.Phone +1.610.834-0300Fax +1.610.834-0473john.mcdermott@selasfluid.com<strong>Linde</strong> Engenharia do Brasil Ltda.Rio de Janeiro, BrazilPhone +55.21.3545-2255Fax +55.21.3545-2257jaime.basurto@linde.com<strong>Linde</strong> Process <strong>Plants</strong> (Pty.) Ltd.Johannesburg, South AfricaPhone +27.11.490-0513Fax +27.11.490-0412lindepp@global.co.za<strong>Linde</strong>-KCA Russia BranchMoscow, RussiaPhone +7.495.987-1223Fax +7.795.987-1224lkca.moskau@linde-kca.com<strong>Linde</strong> Arabian Contracting Co. Ltd.Riyadh, Kingdom of Saudi ArabiaPhone +966.1.419-1193Fax +966.1.419-1384linde-ksa@linde-le.com<strong>Linde</strong> <strong>Engineering</strong> Middle East LLCAbu Dhabi, United Arab EmiratesPhone +971.2.447-9313Fax +971.2.447-9318leme@linde.com<strong>Linde</strong> <strong>Engineering</strong> India Pvt. Ltd.Vadodara, Gujarat, IndiaPhone +91.265.3056-789Fax +91.265.2335-213sales@linde-le.com<strong>Linde</strong> Engineerig Far East, Ltd.Seoul, South KoreaPhone +82.2789-6697Fax +82.2789-6698hanyong.lee@linde.com<strong>Linde</strong> <strong>Engineering</strong> DivisionBangkok, ThailandPhone +66.2636-1998Fax +66.2636-1999anuwat.krongkrachang@linde.com<strong>Linde</strong> <strong>Engineering</strong> Co. Ltd.Dalian, P.R. of ChinaPhone +86.411.3953-8819Fax +86.411.3953-8899dalian.led@lindeled.com<strong>Linde</strong> <strong>Engineering</strong> Co. Ltd.Hangzhou, P.R. of ChinaPhone +86.571.87858-222Fax +86.571.87858-200hangzhou.leh@lindeleh.com<strong>Linde</strong> <strong>Engineering</strong> DivisionBeijing Representative OfficeBeijing, P.R. of ChinaPhone +86.10.6437-7014Fax +86.10.6437-6718lindechina@vip.163.com<strong>Linde</strong> AG Taiwan Branch<strong>Engineering</strong> DivisionTaipei, TaiwanPhone +886.2.2786-3131Fax +886.2.2652-5871bernhard.puerzer@linde-le.com<strong>Linde</strong> AG<strong>Engineering</strong> Division, Head office, Dr.-Carl-von-<strong>Linde</strong>-Str. 6-14, 82049 Pullach, GermanyPhone +49.89.7445-0, Fax +49.89.7445-4908, E-Mail: info@linde-le.com, www.linde.comHG/1.1.e/10