Coil-Wound Heat Exchangers - Linde Engineering

Coil-Wound Heat Exchangers - Linde Engineering

Coil-Wound Heat Exchangers - Linde Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

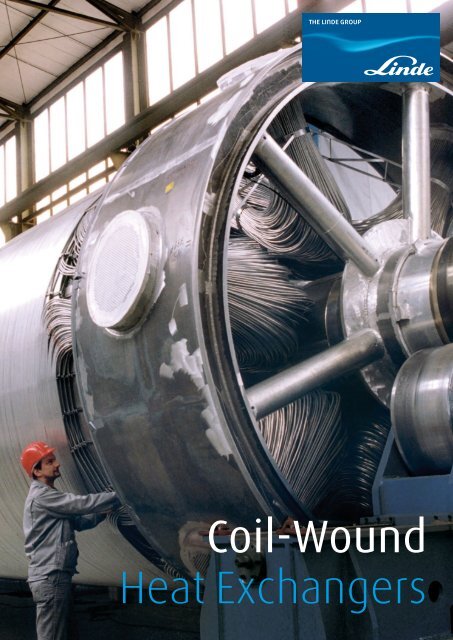

<strong>Coil</strong>-<strong>Wound</strong><strong>Heat</strong> <strong>Exchangers</strong>

3Introduction.<strong>Coil</strong>-wound heat exchangers (CWHE) have been usedin the industry since the early days, when Carl von<strong>Linde</strong> liquefied air on an industrial scale for the firsttime in May 1895. Until today, more than thousandcoil-wound heat exchangers have been manufacturedin <strong>Linde</strong>’s fabrication facilities.<strong>Coil</strong>-wound heat exchangers are compact and reliablewith a broad temperature and pressure rangeand suitable for single phase as well as two phasestreams. Multiple streams can be accommodated inone exchanger.3

4Characteristics.Each coil-wound heat exchanger is designed tomeet the project requirements for the thermaland hydraulic performance as well as for themechanical design and material selection.The special features of the geometry and thepossibility to use various materials allow a widerange of applications. <strong>Coil</strong>-wound heat exchangersare manufactured in stainless steel, aluminiumalloy, carbon steel and special alloys.<strong>Heat</strong>ing surfaces of up to 40,000 square metersand more can be installed in one unit. Bundlediameters of approx. 5,500 mm and unit weightsup to 250 metric tons can be manufactured in<strong>Linde</strong>‘s fabrication facilities. Larger diameters orhigher unit weights are feasible and are assembledin <strong>Linde</strong>‘s assembly yards located at the coast.Thermal and hydraulic designFor the thermal and hydraulic design <strong>Linde</strong>‘sproprietary computer program GENIUS is used.This software determines the temperature andpressure profiles of the individual streams andcalculates the distribution of the tubes to thevarious layers.All methods for simulating heat transfer andpressure drop used by the program have beenextensively tested. <strong>Linde</strong>‘s own research anddevelopment is complemented by the cooperationwith professional R & D instituts like HTRIand HTFS.The coil-wound heat exchanger is known forits robustness in particular during start-up andshut-down or plant trip conditions.<strong>Coil</strong>-wound tube bundle for the productionof Liquefied Natural Gas (LNG)

5Mechanical design.<strong>Linde</strong> coil-wound heat exchanger on its way to jobsite<strong>Linde</strong>‘s coil-wound heat exchangers are suppliedin line with the major codes for the design, fabricationand testing of pressure vessels:– ASME– German AD-Merkblatt– European Pressure Equipment Directive (PED)Other codes are possible upon request.Fabrication and special featuresGenerally a coil-wound heat exchanger comprisesmultiple layers of tubes wound arounda centre pipe (mandrel).After assembly with the prefabricated pressurevessel (shell) the coil-wound tube bundle is suspendedon top only. This proprietary suspensionsystem allows the <strong>Linde</strong> coil-wound heat exchangerto cope easily with large temperature differencesand changes during operation whileeffectively avoiding any kind of bundle sagging.<strong>Linde</strong> coil-wound heat exchangers are 100%self-draining. This special feature can be importante.g. during shutdown for avoiding possiblecorrosion defects.Applications<strong>Coil</strong>-wound heat exchangers are used for a widerange of applications as for example:– Cooler/heater– Liquefier– Vaporiser– Isothermal reactorThey are used in petrochemical plants, air andgas separation plants as well as in gas liquefactionunits.World-class LNG plants are equipped with <strong>Linde</strong>coil-wound heat exchangers, e. g.:– Snøhvit LNG– Brunei LNG– North West Shelf Venture– Sakhalin Energy– Pluto LNG

6Benefits.– Broad temperature and pressure ranges– Multiple fluids can be treated in one exchanger– Compact unit with large specific heat transferarea per volume– Capable for high pressure service– Robust design suitable to cope with transientoff-spec conditions– Integrated two-phase separator and distributor,if required– No bundle sagging due to proprietary supportsystem– 100% self-draining– Available in various materials– Possibility for bundle temperature recordingTypical tube arrangementFully welded tube-to-tubesheet connectionsSelected referencesMaterial of Unit weight empty Year of Number of units Country ofService construction [metric tons] supply supplied installationASU Aluminium 45 1969 5 GermanyEthylene 9 % Ni-steel 96 1975 1 NetherlandsRectisol 3.5 % Ni-steel 31 1978 1 USARectisol Stainless steel 90 1984 4 South AfricaMethanol CS/SS 142 1996 1 GermanyLNG Aluminium 25 1998 1 South AfricaCO shift Carbon steel 87 1998 1 AustraliaAir separation 3.5 % Ni-steel 65 1998 4 ArgentinaEthylene Carbon Steel 145 2000 1 UAERectisol 3.5% Ni - Steel 39 2000 1 P.R. ChinaAir separation 9 % Ni-steel 23 2000 1 P.R. ChinaEthylene Carbon steel 110 2001 1 IranEthylene Carbon steel 60 2001 2 GermanyLNG Aluminium 170 2002 2 AustraliaLNG Stainless steel 60 2002 1 AustraliaLNG Aluminium 90 2003 1 NorwayLNG Aluminium 130 2003 1 NorwayLNG Aluminium 60 2003 1 P.R. ChinaNGL CS/SS 59 2003 1 NorwayMethanol CS/SS 40 2003 1 IndiaLNG Aluminium 110 2004 4 BruneiLNG Aluminium 180 2005 4 RussiaLNG Aluminium 190 2005 4 RussiaLNG Stainless steel 60 2005 2 RussiaLNG Aluminium 170 2006 2 AustraliaLNG Stainless steel 60 2006 1 AustraliaLNG Aluminium 190 2009 2 AustraliaLNG Stainless steel 60 2009 1 AustraliaEthylene Stainless steel 45 2009 4 U.A. Emirates

7Subcooler bundle Δ<strong>Coil</strong>-wound heat exchangerfabrication.Fabrication 1951Fabrication 1973 (all aluminium)

8Isothermal reactors.CharacteristicsThe <strong>Linde</strong> isothermal reactor is a fixed-bed reactorsuitable for endothermic and exothermic catalyticreactions with indirect heat transfer. Based on thesteam raising design, the isothermal mode of operationresults in excellent temperature characteristicsfor all conditions like start-up, partial load and plantupsets.Isothermal reactor withcoil-wound tube bundle insideApplications<strong>Linde</strong>‘s isothermal reactor can be used for gas/gas,gas/liquid and liquid/liquid reactions. Thus being anexcellent solution for various processes in the chemicalindustry e.g.:– Methanol synthesis– Shift conversion– Hydrogenation– Methanization– CLINSULF ® sulfur recoveryBenefits– Easy temperature control by adjusting the steampressure– Integrated steam drum– Smooth behaviour during normal operation andfast start-up and shut-down procedures– Easy and quick catalyst loading and unloadingIsothermal reactor for ammonia/methanol co-production

Design tools.<strong>Linde</strong> coil-wound heat exchangers fora large LNG plant during installation<strong>Linde</strong>‘s sophisticated design tools allow thedetailed 3-dimensional modelling of coil-woundheat exchangers including tie-in simulations.This contributes significantly to the smoothinstallation on site.

10Quality standards.Quality management and inspection is an indispensablepart of our corporate strategy andtherefore a managerial responsibility carriedout at all levels of the company. We considerthe improvement of our product quality and thecontinued development of our quality managementsystem as a permanent challenge.The Schalchen plant of the <strong>Engineering</strong> Divisionis certified according to:– EN ISO 9001 / 2000– German AD-Merkblatt– ASME (U, U2, R-stamp)– Manufacture license China– etc.

11Water-bath vaporisersfor liquefied gases.Characteristics<strong>Linde</strong>´s water-bath vaporiser are the robust andreliable solution for the gasification of cryogenicfluids. The unit consists of a water vessel in whicha coiled tube bundle is installed.The characteristics of the <strong>Linde</strong> steam-heatedwater-bath vaporisers are:– The water is heated up by direct steam injectionthrough one or more steam lances– The steam flow is controlled by the watertemperature– During stand-by conditions, the water temperatureis kept through a small steam lanceat 60°CBenefits– Excellent solution for stand-by or discontinuousoperation– Availability of full capacity within seconds– Reliable operation from 0 to 100 percent ofnominal capacity– Two or three streams of different liquefiedgases can be treated in one unit– Load range from approximately 500 Nm 3 /hup to 150,000 Nm 3 /h– Multiple heating sources installed in oneapparatus (e.g. steam and warm water)Please contact the <strong>Linde</strong> sales team for aseparate brochure.Vaporizer tube-bundle during fabrication

Designing processes – constructing plants.<strong>Linde</strong>´s <strong>Engineering</strong> Division continuously develops extensive process engineering know-how in the planning,project management and construction of turnkey industrial plants.The range of products comprises:− Petrochemical plants− LNG and natural gas processing plants− Synthesis gas plants− Hydrogen plants− Gas processing plants− Adsorption plants− Air separation plants− Cryogenic plants− Biotechnology plants− Furnaces for petrochemical plants and refineriesMore than 4,000 plants worldwide document the leading position of the <strong>Engineering</strong> Division in internationalplant construction.Production facilities.At <strong>Linde</strong> <strong>Engineering</strong> Schalchen Plant over 700skilled engineers and workers design and manufacturecomponents and complete modules fornumerous applications in process plants such asethylene plants, hydrogen and synthesis gasplants, LNG plants and air separation plants. Productioncapacity totals approx. 1.3 million hoursper year.In addition, the plant offers services for field installationand advice on operation. A specialisedservice crew is available for immediate and professionalrepair services.Product range.– Aluminium plate-fin heat exchangers assingle units or as manifolded assemblies– Cold boxes with aluminium plate-fin heatexchangers, columns and vessels– <strong>Coil</strong>-wound heat exchangers and isothermalreactors for chemical and petrochemicalplants– Columns and pressure vessels in aluminiumfor cryogenic plants– Spiral-welded pipes in aluminium– Storage tanks for liquefied gases– Steam-heated waterbath vaporisers as wellas air-heated vaporisers for liquefied gasesFor further information please contact:<strong>Linde</strong> AG<strong>Engineering</strong> Division, Schalchen PlantCarl-von-<strong>Linde</strong>-Strasse 15, 83342 Tacherting, GermanyPhone +49.8621.85-6434, Fax +49.8621.85-6622E-Mail: plantcomponents@linde-le.com, www.linde-plantcomponents.comP/3.1.e/12