Coil-Wound Heat Exchangers - Linde Engineering

Coil-Wound Heat Exchangers - Linde Engineering

Coil-Wound Heat Exchangers - Linde Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

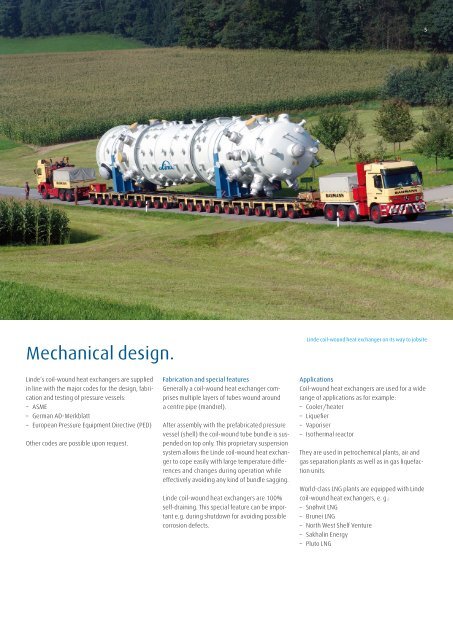

5Mechanical design.<strong>Linde</strong> coil-wound heat exchanger on its way to jobsite<strong>Linde</strong>‘s coil-wound heat exchangers are suppliedin line with the major codes for the design, fabricationand testing of pressure vessels:– ASME– German AD-Merkblatt– European Pressure Equipment Directive (PED)Other codes are possible upon request.Fabrication and special featuresGenerally a coil-wound heat exchanger comprisesmultiple layers of tubes wound arounda centre pipe (mandrel).After assembly with the prefabricated pressurevessel (shell) the coil-wound tube bundle is suspendedon top only. This proprietary suspensionsystem allows the <strong>Linde</strong> coil-wound heat exchangerto cope easily with large temperature differencesand changes during operation whileeffectively avoiding any kind of bundle sagging.<strong>Linde</strong> coil-wound heat exchangers are 100%self-draining. This special feature can be importante.g. during shutdown for avoiding possiblecorrosion defects.Applications<strong>Coil</strong>-wound heat exchangers are used for a widerange of applications as for example:– Cooler/heater– Liquefier– Vaporiser– Isothermal reactorThey are used in petrochemical plants, air andgas separation plants as well as in gas liquefactionunits.World-class LNG plants are equipped with <strong>Linde</strong>coil-wound heat exchangers, e. g.:– Snøhvit LNG– Brunei LNG– North West Shelf Venture– Sakhalin Energy– Pluto LNG