Cable

Cable

Cable

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

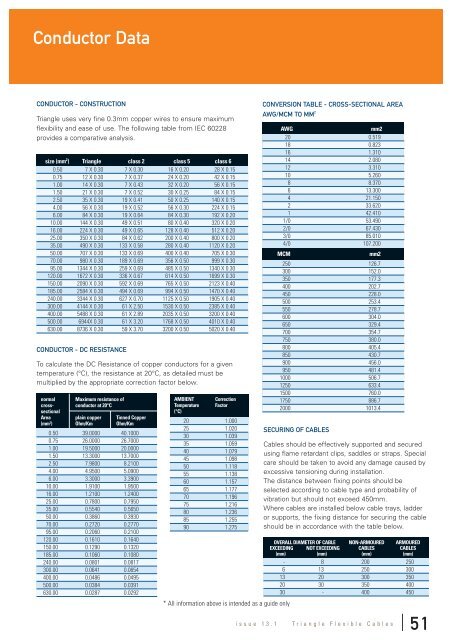

Conductor DataCONDUCTOR - CONSTRUCTIONTriangle uses very fine 0.3mm copper wires to ensure maximumflexibility and ease of use. The following table from IEC 60228provides a comparative analysis.size (mm 2 ) Triangle class 2 class 5 class 60.50 7 X 0.30 7 X 0.30 16 X 0.20 28 X 0.150.75 12 X 0.30 7 X 0.37 24 X 0.20 42 X 0.151.00 14 X 0.30 7 X 0.43 32 X 0.20 56 X 0.151.50 21 X 0.30 7 X 0.52 30 X 0.25 84 X 0.152.50 35 X 0.30 19 X 0.41 50 X 0.25 140 X 0.154.00 56 X 0.30 19 X 0.52 56 X 0.30 224 X 0.156.00 84 X 0.30 19 X 0.64 84 X 0.30 192 X 0.2010.00 144 X 0.30 49 X 0.51 80 X 0.40 320 X 0.2016.00 224 X 0.30 49 X 0.65 128 X 0.40 512 X 0.2025.00 350 X 0.30 84 X 0.62 200 X 0.40 800 X 0.2035.00 490 X 0.30 133 X 0.58 280 X 0.40 1120 X 0.2050.00 707 X 0.30 133 X 0.69 400 X 0.40 705 X 0.3070.00 980 X 0.30 189 X 0.69 356 X 0.50 999 X 0.3095.00 1344 X 0.30 259 X 0.69 485 X 0.50 1340 X 0.30120.00 1672 X 0.30 336 X 0.67 614 X 0.50 1699 X 0.30150.00 2090 X 0.30 592 X 0.69 765 X 0.50 2123 X 0.40185.00 2584 X 0.30 494 X 0.69 994 X 0.50 1470 X 0.40240.00 3344 X 0.30 627 X 0.70 1125 X 0.50 1905 X 0.40300.00 4144 X 0.30 61 X 2.50 1530 X 0.50 2385 X 0.40400.00 5488 X 0.30 61 X 2.89 2035 X 0.50 3200 X 0.40500.00 6944X 0.30 61 X 3.20 1768 X 0.50 4010 X 0.40630.00 8736 X 0.30 59 X 3.70 3200 X 0.50 5020 X 0.40CONDUCTOR - DC RESISTANCETo calculate the DC Resistance of copper conductors for a giventemperature (°C), the resistance at 20°C, as detailed must bemultiplied by the appropriate correction factor below.normal Maximum resistance ofcross- conductor at 20°CsectionalArea plain copper Tinned Copper(mm 2 ) Ohm/Km Ohm/Km0.50 39.0000 40.10000.75 26.0000 26.70001.00 19.5000 20.00001.50 13.3000 13.70002.50 7.9800 8.21004.00 4.9500 5.09006.00 3.3000 3.390010.00 1.9100 1.950016.00 1.2100 1.240025.00 0.7800 0.795035.00 0.5540 0.565050.00 0.3860 0.393070.00 0.2720 0.277095.00 0.2060 0.2100120.00 0.1610 0.1640150.00 0.1290 0.1320185.00 0.1060 0.1080240.00 0.0801 0.0817300.00 0.0641 0.0654400.00 0.0486 0.0495500.00 0.0384 0.0391630.00 0.0287 0.0292AMBIENT CorrectionTemperature Factor(°C)20 1.00025 1.02030 1.03935 1.05940 1.07945 1.09850 1.11855 1.13860 1.15765 1.17770 1.19675 1.21680 1.23685 1.25590 1.275CONVERSION TABLE - CROSS-SECTIONAL AREAAWG/MCM TO MM 2AWGmm220 0.51918 0.82316 1.31014 2.08012 3.31010 5.2608 8.3706 13.3004 21.1502 33.6201 42.4101/0 53.4902/0 67.4303/0 85.0104/0 107.200MCMmm2250 126.7300 152.0350 177.3400 202.7450 228.0500 253.4550 278.7600 304.0650 329.4700 354.7750 380.0800 405.4850 430.7900 456.0950 481.41000 506.71250 633.41500 760.01750 886.72000 1013.4SECURING OF CABLES<strong>Cable</strong>s should be effectively supported and securedusing flame retardant clips, saddles or straps. Specialcare should be taken to avoid any damage caused byexcessive tensioning during installation.The distance between fixing points should beselected according to cable type and probability ofvibration but should not exceed 450mm.Where cables are installed below cable trays, ladderor supports, the fixing distance for securing the cableshould be in accordance with the table below.OVERALL DIAMETER OF CABLE NON-ARMOURED ARMOUREDEXCEEDING NOT EXCEEDING CABLESCABLES(mm)(mm)(mm)(mm)- 8 200 2506 13 250 30013 20 300 35020 30 350 40030 - 400 450* All information above is intended as a guide onlyissue 13.1 Triangle Flexible <strong>Cable</strong>s51