Scroll Compressor Application Guidelines - Desco Energy

Scroll Compressor Application Guidelines - Desco Energy

Scroll Compressor Application Guidelines - Desco Energy

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

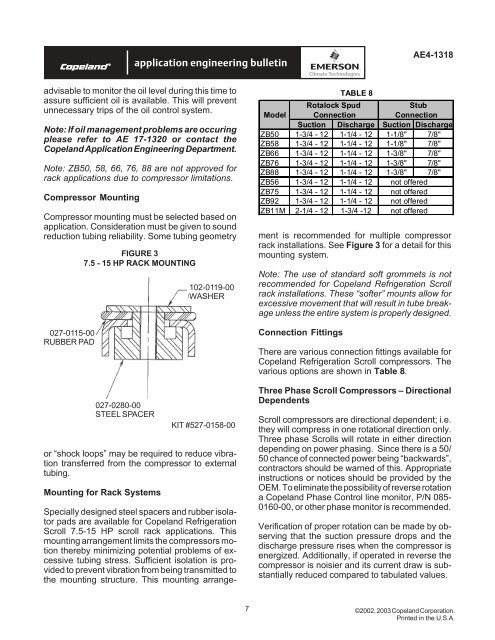

AE4-1318advisable to monitor the oil level during this time toassure sufficient oil is available. This will preventunnecessary trips of the oil control system.Note: If oil management problems are occuringplease refer to AE 17-1320 or contact theCopeland <strong>Application</strong> Engineering Department.Note: ZB50, 58, 66, 76, 88 are not approved forrack applications due to compressor limitations.<strong>Compressor</strong> Mounting<strong>Compressor</strong> mounting must be selected based onapplication. Consideration must be given to soundreduction tubing reliability. Some tubing geometry027-0115-00RUBBER PADFIGURE 37.5 - 15 HP RACK MOUNTING027-0280-00STEEL SPACER102-0119-00WASHERKIT #527-0158-00or “shock loops” may be required to reduce vibrationtransferred from the compressor to externaltubing.Mounting for Rack SystemsSpecially designed steel spacers and rubber isolatorpads are available for Copeland Refrigeration<strong>Scroll</strong> 7.5-15 HP scroll rack applications. Thismounting arrangement limits the compressors motionthereby minimizing potential problems of excessivetubing stress. Sufficient isolation is providedto prevent vibration from being transmitted tothe mounting structure. This mounting arrange-TABLE 8ModelRotalock SpudConnectionStubConnectionSuction Discharge Suction DischargeZB50 1-3/4 - 12 1-1/4 - 12 1-1/8" 7/8"ZB58 1-3/4 - 12 1-1/4 - 12 1-1/8" 7/8"ZB66 1-3/4 - 12 1-1/4 - 12 1-3/8" 7/8"ZB76 1-3/4 - 12 1-1/4 - 12 1-3/8" 7/8"ZB88 1-3/4 - 12 1-1/4 - 12 1-3/8" 7/8"ZB56 1-3/4 - 12 1-1/4 - 12 not offeredZB75 1-3/4 - 12 1-1/4 - 12 not offeredZB92 1-3/4 - 12 1-1/4 - 12 not offeredZB11M 2-1/4 - 12 1-3/4 -12 not offeredment is recommended for multiple compressorrack installations. See Figure 3 for a detail for thismounting system.Note: The use of standard soft grommets is notrecommended for Copeland Refrigeration <strong>Scroll</strong>rack installations. These “softer” mounts allow forexcessive movement that will result in tube breakageunless the entire system is properly designed.Connection FittingsThere are various connection fittings available forCopeland Refrigeration <strong>Scroll</strong> compressors. Thevarious options are shown in Table 8.Three Phase <strong>Scroll</strong> <strong>Compressor</strong>s – DirectionalDependents<strong>Scroll</strong> compressors are directional dependent; i.e.they will compress in one rotational direction only.Three phase <strong>Scroll</strong>s will rotate in either directiondepending on power phasing. Since there is a 50/50 chance of connected power being “backwards”,contractors should be warned of this. Appropriateinstructions or notices should be provided by theOEM. To eliminate the possibility of reverse rotationa Copeland Phase Control line monitor, P/N 085-0160-00, or other phase monitor is recommended.Verification of proper rotation can be made by observingthat the suction pressure drops and thedischarge pressure rises when the compressor isenergized. Additionally, if operated in reverse thecompressor is noisier and its current draw is substantiallyreduced compared to tabulated values.7©2002, 2003 Copeland Corporation.Printed in the U.S.A.