The Why, What, How & Who Of Maintenance - AMMJ

The Why, What, How & Who Of Maintenance - AMMJ

The Why, What, How & Who Of Maintenance - AMMJ

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

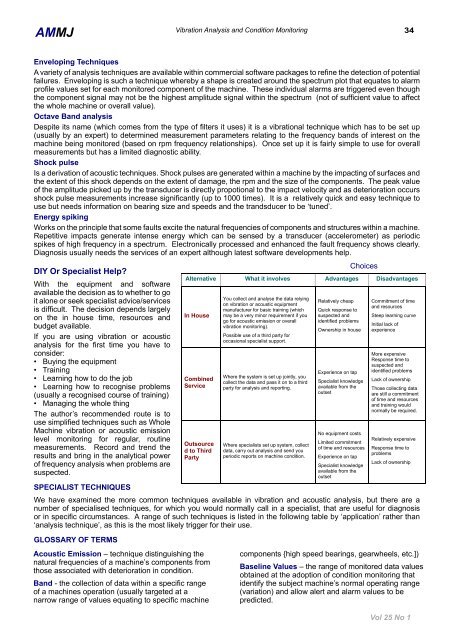

<strong>AMMJ</strong>Vibration Analysis and Condition Monitoring 34Enveloping TechniquesA variety of analysis techniques are available within commercial software packages to refine the detection of potentialfailures. Enveloping is such a technique whereby a shape is created around the spectrum plot that equates to alarmprofile values set for each monitored component of the machine. <strong>The</strong>se individual alarms are triggered even thoughthe component signal may not be the highest amplitude signal within the spectrum (not of sufficient value to affectthe whole machine or overall value).Octave Band analysisDespite its name (which comes from the type of filters it uses) it is a vibrational technique which has to be set up(usually by an expert) to determined measurement parameters relating to the frequency bands of interest on themachine being monitored (based on rpm frequency relationships). Once set up it is fairly simple to use for overallmeasurements but has a limited diagnostic ability.Shock pulseIs a derivation of acoustic techniques. Shock pulses are generated within a machine by the impacting of surfaces andthe extent of this shock depends on the extent of damage, the rpm and the size of the components. <strong>The</strong> peak valueof the amplitude picked up by the transducer is directly propotional to the impact velocity and as deterioration occursshock pulse measurements increase significantly (up to 1000 times). It is a relatively quick and easy technique touse but needs information on bearing size and speeds and the trandsducer to be ‘tuned’.Energy spikingWorks on the principle that some faults excite the natural frequencies of components and structures within a machine.Repetitive impacts generate intense energy which can be sensed by a transducer (accelerometer) as periodicspikes of high frequency in a spectrum. Electronically processed and enhanced the fault frequency shows clearly.Diagnosis usually needs the services of an expert although latest software developments help.ChoicesDIY Or Specialist Help?With the equipment and softwareavailable the decision as to whether to goit alone or seek specialist advice/servicesis difficult. <strong>The</strong> decision depends largelyon the in house time, resources andbudget available.If you are using vibration or acousticanalysis for the first time you have toconsider:• Buying the equipment• Training• Learning how to do the job• Learning how to recognise problems(usually a recognised course of training)• Managing the whole thing<strong>The</strong> author’s recommended route is touse simplified techniques such as <strong>Who</strong>leMachine vibration or acoustic emissionlevel monitoring for regular, routinemeasurements. Record and trend theresults and bring in the analytical powerof frequency analysis when problems aresuspected.SPECIALIST TECHNIQUESWe have examined the more common techniques available in vibration and acoustic analysis, but there are anumber of specialised techniques, for which you would normally call in a specialist, that are useful for diagnosisor in specific circumstances. A range of such techniques is listed in the following table by ‘application’ rather than‘analysis technique’, as this is the most likely trigger for their use.GLOSSARY OF TERMSAlternative <strong>What</strong> it involves Advantages DisadvantagesIn HouseCombinedServiceOutsourced to ThirdPartyYou collect and analyse the data relyingon vibration or acoustic equipmentmanufacturer for basic training (whichmay be a very minor requirement if yougo for acoustic emission or overallvibration monitoring).Possible use of a third party foroccasional specialist support.Where the system is set up jointly, youcollect the data and pass it on to a thirdparty for analysis and reporting.Where specialists set up system, collectdata, carry out analysis and send youperiodic reports on machine condition.Relatively cheapQuick response tosuspected andidentified problemsOwnership in houseExperience on tapSpecialist knowledgeavailable from theoutsetNo equipment costsLimited commitmentof time and resourcesExperience on tapSpecialist knowledgeavailable from theoutsetCommitment of timeand resourcesSteep learning curveInitial lack ofexperienceMore expensiveResponse time tosuspected andidentified problemsLack of ownershipThose collecting dataare still a commitmentof time and resourcesand training wouldnormally be required.Relatively expensiveResponse time toproblemsLack of ownershipAcoustic Emission – technique distinguishing thenatural frequencies of a machine’s components fromthose associated with deterioration in condition.Band - the collection of data within a specific rangeof a machines operation (usually targeted at anarrow range of values equating to specific machinecomponents {high speed bearings, gearwheels, etc.])Baseline Values – the range of monitored data valuesobtained at the adoption of condition monitoring thatidentify the subject machine’s normal operating range(variation) and allow alert and alarm values to bepredicted.Vol 25 No 1