The Why, What, How & Who Of Maintenance - AMMJ

The Why, What, How & Who Of Maintenance - AMMJ

The Why, What, How & Who Of Maintenance - AMMJ

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

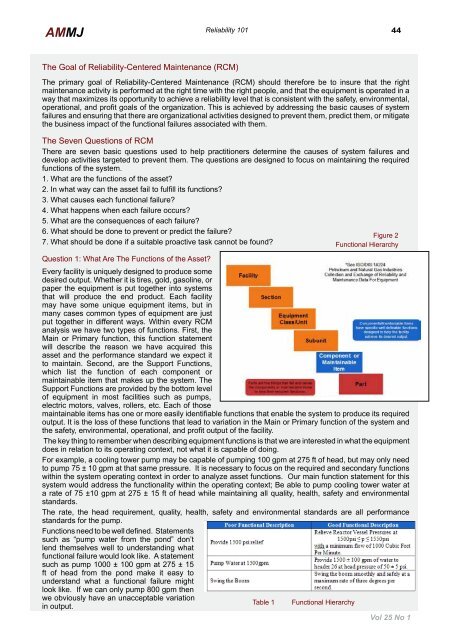

Reliability 10144<strong>AMMJ</strong><strong>The</strong> Goal of Reliability-Centered <strong>Maintenance</strong> (RCM)<strong>The</strong> primary goal of Reliability-Centered <strong>Maintenance</strong> (RCM) should therefore be to insure that the rightmaintenance activity is performed at the right time with the right people, and that the equipment is operated in away that maximizes its opportunity to achieve a reliability level that is consistent with the safety, environmental,operational, and profit goals of the organization. This is achieved by addressing the basic causes of systemfailures and ensuring that there are organizational activities designed to prevent them, predict them, or mitigatethe business impact of the functional failures associated with them.<strong>The</strong> Seven Questions of RCM<strong>The</strong>re are seven basic questions used to help practitioners determine the causes of system failures anddevelop activities targeted to prevent them. <strong>The</strong> questions are designed to focus on maintaining the requiredfunctions of the system.1. <strong>What</strong> are the functions of the asset?2. In what way can the asset fail to fulfill its functions?3. <strong>What</strong> causes each functional failure?4. <strong>What</strong> happens when each failure occurs?5. <strong>What</strong> are the consequences of each failure?6. <strong>What</strong> should be done to prevent or predict the failure?7. <strong>What</strong> should be done if a suitable proactive task cannot be found?Figure 2Functional HierarchyQuestion 1: <strong>What</strong> Are <strong>The</strong> Functions of the Asset?Every facility is uniquely designed to produce somedesired output. Whether it is tires, gold, gasoline, orpaper the equipment is put together into systemsthat will produce the end product. Each facilitymay have some unique equipment items, but inmany cases common types of equipment are justput together in different ways. Within every RCManalysis we have two types of functions. First, theMain or Primary function, this function statementwill describe the reason we have acquired thisasset and the performance standard we expect itto maintain. Second, are the Support Functions,which list the function of each component ormaintainable item that makes up the system. <strong>The</strong>Support Functions are provided by the bottom levelof equipment in most facilities such as pumps,electric motors, valves, rollers, etc. Each of thosemaintainable items has one or more easily identifiable functions that enable the system to produce its requiredoutput. It is the loss of these functions that lead to variation in the Main or Primary function of the system andthe safety, environmental, operational, and profit output of the facility.<strong>The</strong> key thing to remember when describing equipment functions is that we are interested in what the equipmentdoes in relation to its operating context, not what it is capable of doing.For example, a cooling tower pump may be capable of pumping 100 gpm at 275 ft of head, but may only needto pump 75 ± 10 gpm at that same pressure. It is necessary to focus on the required and secondary functionswithin the system operating context in order to analyze asset functions. Our main function statement for thissystem would address the functionality within the operating context; Be able to pump cooling tower water ata rate of 75 ±10 gpm at 275 ± 15 ft of head while maintaining all quality, health, safety and environmentalstandards.<strong>The</strong> rate, the head requirement, quality, health, safety and environmental standards are all performancestandards for the pump.Functions need to be well defined. Statementssuch as “pump water from the pond” don’tlend themselves well to understanding whatfunctional failure would look like. A statementsuch as pump 1000 ± 100 gpm at 275 ± 15ft of head from the pond make it easy tounderstand what a functional failure mightlook like. If we can only pump 800 gpm thenwe obviously have an unacceptable variationTable 1 Functional Hierarchyin output.Vol 25 No 1