OSIRIS REACTOR - Centre de Cadarache - CEA

OSIRIS REACTOR - Centre de Cadarache - CEA

OSIRIS REACTOR - Centre de Cadarache - CEA

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

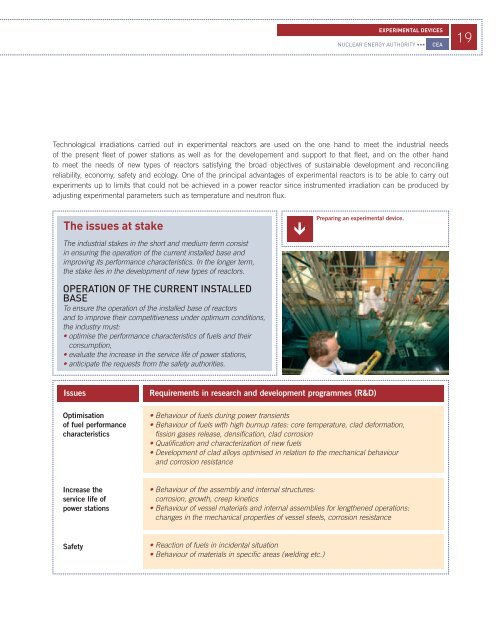

EXPERIMENTAL DEVICESNUCLEAR ENERGY AUTHORITY ••• <strong>CEA</strong>19Technological irradiations carried out in experimental reactors are used on the one hand to meet the industrial needsof the present fleet of power stations as well as for the <strong>de</strong>velopement and support to that fleet, and on the other handto meet the needs of new types of reactors satisfying the broad objectives of sustainable <strong>de</strong>velopment and reconcilingreliability, economy, safety and ecology. One of the principal advantages of experimental reactors is to be able to carry outexperiments up to limits that could not be achieved in a power reactor since instrumented irradiation can be produced byadjusting experimental parameters such as temperature and neutron flux.The issues at stakePreparing an experimental <strong>de</strong>vice.The industrial stakes in the short and medium term consistin ensuring the operation of the current installed base andimproving its performance characteristics. In the longer term,the stake lies in the <strong>de</strong>velopment of new types of reactors.OPERATION OF THE CURRENT INSTALLEDBASETo ensure the operation of the installed base of reactorsand to improve their competitiveness un<strong>de</strong>r optimum conditions,the industry must:• optimise the performance characteristics of fuels and theirconsumption,• evaluate the increase in the service life of power stations,• anticipate the requests from the safety authorities.IssuesOptimisationof fuel performancecharacteristicsRequirements in research and <strong>de</strong>velopment programmes (R&D)• Behaviour of fuels during power transients• Behaviour of fuels with high burnup rates: core temperature, clad <strong>de</strong>formation,fission gases release, <strong>de</strong>nsification, clad corrosion• Qualification and characterization of new fuels• Development of clad alloys optimised in relation to the mechanical behaviourand corrosion resistanceIncrease theservice life ofpower stations• Behaviour of the assembly and internal structures:corrosion, growth, creep kinetics• Behaviour of vessel materials and internal assemblies for lengthened operations:changes in the mechanical properties of vessel steels, corrosion resistanceSafety• Reaction of fuels in inci<strong>de</strong>ntal situation• Behaviour of materials in specific areas (welding etc.)