- Page 1 and 2:

BRAND - Your Partner in the Lab.Wor

- Page 3 and 4:

About the ProductOrdering optionsOu

- Page 5:

About usIdeasPartnering for success

- Page 8 and 9:

About usFactory and ProductionAs th

- Page 10 and 11:

1949 195019571961196319641967197319

- Page 12 and 13:

© Mark Weathers Images/Flicks/Gett

- Page 14 and 15:

© Peter de Rooij/Flickr/Getty Imag

- Page 16 and 17:

Product NewsNew in this Catalog!New

- Page 18 and 19:

Liquid HandlingOne of the most impo

- Page 20 and 21:

Dispensette ® IIIDispensette ® Or

- Page 22 and 23:

Dispensette ® IIIDispensette ® Or

- Page 24 and 25:

Dispensette ® III / OrganicDispens

- Page 26 and 27:

Dispensette ® III / OrganicOrderin

- Page 28 and 29:

Dispensette ® III / OrganicAccesso

- Page 30 and 31:

Dispensette ® TANEW!Liquid Handlin

- Page 32 and 33:

Dispensette ® TAUse and HandlingGe

- Page 34 and 35:

seripettor ®seripettor ® proserip

- Page 36 and 37:

seripettor ® · seripettor ® proA

- Page 38 and 39:

seripettor ® · seripettor ® proO

- Page 40 and 41:

Titrette ® - the first bottle-top

- Page 42 and 43:

Titrette ®Use and HandlingLight-we

- Page 44 and 45:

Titrette ®Comparisonof error limit

- Page 46 and 47:

BRAND offers the ideal pipette for

- Page 48 and 49:

Transferpette ® STransferpette ®

- Page 50 and 51:

Transferpette ® SA Closer Look...A

- Page 52 and 53:

Transferpette ® S -8/-12A Closer L

- Page 54 and 55:

Transferpette ®Transferpette ® -8

- Page 56 and 57:

Transferpette ®Tip ejector capErgo

- Page 58 and 59:

Transferpette ®AccessoriesAccessor

- Page 60 and 61:

Transferpette ® -8/-12Ordering Dat

- Page 62 and 63:

Transferpette ® electronicTransfer

- Page 64 and 65:

Transferpette ® electronicA Closer

- Page 66 and 67:

Transferpette ® -8/-12 electronicA

- Page 68 and 69:

Transferpette ® -12 electronicOrde

- Page 70 and 71:

Pipette Tips and Filter TipsConsist

- Page 72 and 73:

Pipette Tips and Filter Tips5 - 300

- Page 74 and 75:

Pipette Tips and Filter TipsTipRack

- Page 76 and 77:

Pipette Tipssterile and non-sterile

- Page 78 and 79:

Filter Tipssterile and non-sterileF

- Page 80 and 81:

ULR Pipette Tipssterile and non-ste

- Page 82 and 83:

ULR Filter Tipssterile and non-ster

- Page 84 and 85:

The Transferpettor pipette is ideal

- Page 86 and 87:

Transferpettor · Ordering DataAppl

- Page 88 and 89:

Serial pipetting can be quick and e

- Page 90 and 91:

HandyStep ® SUse and Handlingn Inc

- Page 92 and 93:

The HandyStep ® electronic repetit

- Page 94 and 95:

HandyStep ® electronicUse and Hand

- Page 96 and 97:

PD-TipsPD-TipsPrecision Dispenser T

- Page 98 and 99:

Pipetting aids from BRAND excel by

- Page 100 and 101:

accu-jet ® pro Single-handed opera

- Page 102 and 103:

micro · micro-classicmicro Pipette

- Page 104 and 105:

The QuikSip bottle-top aspirator f

- Page 106 and 107:

The most frequent cause of inaccura

- Page 108 and 109:

PLT unitUse and HandlingTesting wit

- Page 110 and 111:

BRAND calibration software is compa

- Page 112 and 113:

EASYCAL 4.0 · Ordering DataQuit c

- Page 114 and 115:

Liquid HandlingBRAND onlineLiquid H

- Page 116 and 117:

Life ScienceResearch - and even rou

- Page 118 and 119:

Life ScienceCleanroom productionBRA

- Page 120 and 121:

Microcentrifuge TubesMicrocentrifug

- Page 122 and 123:

Microcentrifuge Tubes1.5 ml, with l

- Page 124 and 125:

Micro TubesMicro tubesattached scre

- Page 126 and 127:

AccessoriesMicrocentrifuge TubesAcc

- Page 128 and 129:

PCR TubesSingle PCR tubes0.2 ml and

- Page 130 and 131:

PCR Strips · PCR PlatesStrips of 8

- Page 132 and 133:

PCR Plates1Life ScienceLow profileL

- Page 134 and 135:

PCR Sealing Mats andSealing FilmsPC

- Page 136 and 137:

Thermal Cycler Compatibilitycontinu

- Page 138 and 139:

Deep-well PlatesDeep-well PlatesThe

- Page 140 and 141:

Racks · Tubes96 tube rackswith 0.6

- Page 142 and 143:

Cryogenic TubesCryogenic TubesDesig

- Page 144 and 145:

BRANDplates ® MicroplatesBRANDplat

- Page 146 and 147:

BRANDplates ®non-treatedApplicatio

- Page 148 and 149:

BRANDplates ®non-treated384-well M

- Page 150 and 151:

BRANDplates ® MicroplatesBRANDplat

- Page 152 and 153:

BRANDplates ®ImmunoassaysApplicati

- Page 154 and 155:

BRANDplates ®Immunoassays384-well

- Page 156 and 157:

BRANDplates ® MicroplatesBRANDplat

- Page 158 and 159:

BRANDplates ®Cell CulturecellGrade

- Page 160 and 161:

BRANDplates ®Insert SystemNEW!BRAN

- Page 162 and 163:

BRANDplates ®Insert SystemA Closer

- Page 164 and 165:

BRANDplates ®OverviewAt a Glance96

- Page 166 and 167:

CuvettesCuvettesLife ScienceFor mor

- Page 168 and 169:

CuvettesLife ScienceStandard Cuvett

- Page 170 and 171:

Life ScienceBRAND onlineLife Scienc

- Page 172 and 173:

VolumetricInstrumentsPrecision anal

- Page 174 and 175:

CertificatesBLAUBRAND ® Volumetric

- Page 176 and 177:

Bulb PipettesBulb pipettes, 1 markB

- Page 178 and 179:

Graduated PipettesGraduated Pipette

- Page 180 and 181:

Graduated PipettesGraduated pipette

- Page 182 and 183:

Graduated PipettesGraduated pipette

- Page 184 and 185:

Volumetric FlasksVolumetric FlasksB

- Page 186 and 187:

Volumetric FlasksVolumetric flasks,

- Page 188 and 189:

Volumetric FlasksVolumetric flasks,

- Page 190 and 191:

Volumetric Flasksmade of PlasticVol

- Page 192 and 193:

Graduated CylindersGraduated cylind

- Page 194 and 195:

Graduated CylindersDispensers, tilt

- Page 196 and 197:

Plastic Graduated CylindersGraduate

- Page 198 and 199:

BurettesBurettes, lateral stopcockB

- Page 200 and 201:

BurettesBurettes, lateral stopcockS

- Page 202 and 203:

BurettesThe Modular Burette Concept

- Page 204 and 205:

BurettesCompact burettes, 'Economy'

- Page 206 and 207:

Automatic BurettesAutomatic burette

- Page 208 and 209:

Automatic BurettesAutomatic burette

- Page 210 and 211:

Automatic BurettesCompact automatic

- Page 212 and 213:

Spare Burette StopcocksSpare burett

- Page 214 and 215:

Burette AccessoriesBurette clampAll

- Page 216 and 217:

Volumetric InstrumentsBRAND onlineV

- Page 218 and 219:

Temperatureand DensityMeasurementFo

- Page 220 and 221:

Oxygen flasksDensity bottles,uncali

- Page 222 and 223:

Sedimentation ConesASTM centrifuge

- Page 224 and 225:

Racks forSedimentation ConesRack fo

- Page 226 and 227:

HydrometersRange finder hydrometers

- Page 228 and 229:

HydrometersGeneral purpose alcoholo

- Page 230 and 231:

ThermometersThermometerBRAND thermo

- Page 232 and 233:

ThermometersSolid-stem thermometers

- Page 234 and 235:

Thermometers1Precision Anschutz the

- Page 236 and 237:

ThermometersASTM thermometersASTMNo

- Page 238 and 239:

Temperature and DensityBRAND online

- Page 240 and 241:

ClinicalLaboratoryClinical laborato

- Page 242 and 243:

JarsJar with snap-on lidJar PS, sna

- Page 244 and 245:

Disposal Bags · ContainersDisposal

- Page 246 and 247:

Culture TubesCentrifuge TubesCultur

- Page 248 and 249:

TubesSample tubesPS, transparent.Cl

- Page 250 and 251:

Pasteur PipettesDropping PipettesPa

- Page 252 and 253:

Disposable MicropipettesDisposable

- Page 254 and 255:

Counting ChambersCounting ChambersC

- Page 256 and 257:

Counting ChambersThomadouble ruling

- Page 258 and 259:

Haematology · MicroscopyHaemacytom

- Page 260 and 261:

MicroscopyStaining trough, CoplinSo

- Page 262 and 263:

Clinical LaboratoryBRAND onlineClin

- Page 264 and 265:

GeneralLaboratorySuppliesSample pre

- Page 266 and 267:

Erlenmeyer Flasks · BeakersErlenme

- Page 268 and 269:

BeakersGraduated beakers with handl

- Page 270 and 271:

Watch GlassesEvaporating DishesWatc

- Page 272 and 273:

Centrifuge tubes · Test tubesCentr

- Page 274 and 275:

FunnelsFunnelsfluted interiorPP. Fo

- Page 276 and 277:

Separating funnelsSeparating funnel

- Page 278 and 279:

Filter FlasksRubber sleevesRubber (

- Page 280 and 281:

DesiccatorsDesiccatorsPC lid. PP ba

- Page 282 and 283:

Gas Wash BottlesWash bottle head wi

- Page 284 and 285: TubingTubingPVC. Particularly high-

- Page 286 and 287: Tubing ConnectorsTubing Connectors

- Page 288 and 289: StopcocksStraight-bore stopcockswit

- Page 290 and 291: Sockets · StoppersSocketswith grip

- Page 292 and 293: StirrersStirrersGood operating char

- Page 294 and 295: Magnetic Stirring BarsCylindrical,

- Page 296 and 297: Magnetic Stirring BarsMagnetic Stir

- Page 298 and 299: Forceps · ScoopsForcepsPMP. Pointe

- Page 300 and 301: BottlesLaboratory bottlesBoro 3.3.

- Page 302 and 303: BottlesWide-mouth bottlesPE-LD, fle

- Page 304 and 305: BottlesWash bottleswithout venting

- Page 306 and 307: ContainersAtomizersPE-HD. By turnin

- Page 308 and 309: ContainersTrays (photographic trays

- Page 310 and 311: Draining RackPipette Trays and Stan

- Page 312 and 313: CleaningCleaningManual Detergents f

- Page 314 and 315: DetergentsMucocit ® -TInstrument d

- Page 316 and 317: General LaboratoryBRAND onlineGener

- Page 318 and 319: TechnicalInformationQuality Managem

- Page 320 and 321: PrecisionPrecisionWhat do "Error Li

- Page 322 and 323: Monitoring ofMeasuring InstrumentsM

- Page 324 and 325: Calculations3. Calculation of the s

- Page 326 and 327: Easy Calibration TechniqueEasy Cali

- Page 328 and 329: Calibration CertificatesDetailed Ca

- Page 330 and 331: Monitoring ofMeasuring InstrumentsD

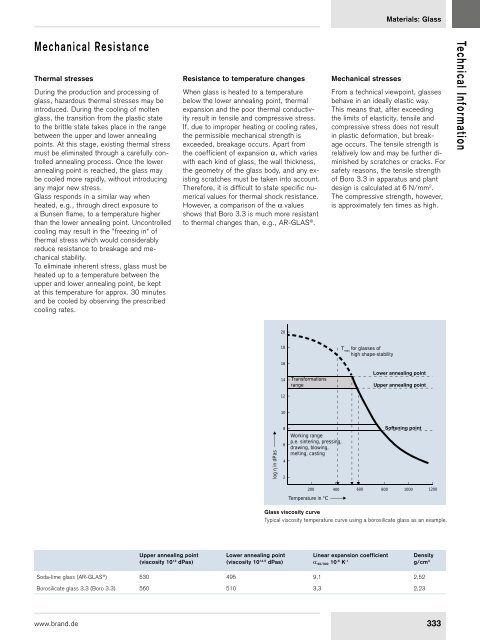

- Page 332 and 333: Materials: GlassLaboratory GlassGen

- Page 336 and 337: Materials: PlasticPVC Vinyl chlorid

- Page 338 and 339: Materials: PlasticBiological Proper

- Page 340 and 341: Materials: PlasticThe data for the

- Page 342 and 343: Materials: PlasticThe data for the

- Page 344 and 345: Cleaning (Basics)Gentle CleaningFor

- Page 346 and 347: IndexGeneral Terms and ConditionsAl

- Page 348 and 349: Alphabetical IndexDisposablesfilter

- Page 350 and 351: Alphabetical IndexSedimentationcone

- Page 352 and 353: Number IndexCat. No.Page4020 38 - 4

- Page 354: © Patrick Escudero/hemis.fr/Getty