Design of Extrusion Dies - Kostic - Northern Illinois University

Design of Extrusion Dies - Kostic - Northern Illinois University

Design of Extrusion Dies - Kostic - Northern Illinois University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

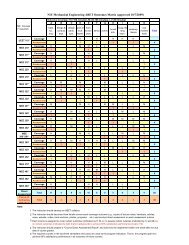

634 <strong>Design</strong> <strong>of</strong> <strong>Extrusion</strong> <strong>Dies</strong><br />

Fig. 1 Coat hanger-type sheet die concept (A): (1) central inlet port; (2) manifold (distributes melt); (3) island (along with manifold,<br />

provides uniform pressure drop from inlet to die lip; (4) die lip (die exit forms a wide slit); and schematic <strong>of</strong> sheet die (B): (1)<br />

upper die plate; (2) lower die plate; (3) manifold; (4) island; (5) choker bar; (6) choker bar adjustment bolt; (7) flex die lip; (8) flex<br />

lip adjustment bolt; (9) lower lip; (10) die bolt; (11) heater cartridge.<br />

The shear thinning causes the volumetric flow to be<br />

very sensitive to slight changes in die geometry. For<br />

example, the flow for a typical polymer melt through<br />

a slit will vary with the cubic thickness <strong>of</strong> the gap.<br />

Thus, a small change in the die gap along the contour<br />

<strong>of</strong> the die exit may cause considerable change <strong>of</strong> the<br />

melt flow. The term ‘‘die swell’’ refers to the enlargement<br />

in the direction orthogonal to the flow direction.