Design of Extrusion Dies - Kostic - Northern Illinois University

Design of Extrusion Dies - Kostic - Northern Illinois University

Design of Extrusion Dies - Kostic - Northern Illinois University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

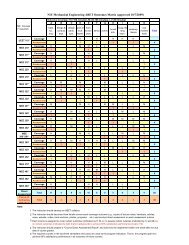

640 <strong>Design</strong> <strong>of</strong> <strong>Extrusion</strong> <strong>Dies</strong><br />

Preland plate: imparts significant flow adjustment<br />

by reducing thickness in high-flow areas and increasing<br />

thickness in low-flow areas anticipated downstream in<br />

the die land to make flow more uniform.<br />

Die land plate: provides a uniform cross-section<br />

passage that is typically 10 times longer than the<br />

thickness <strong>of</strong> the extrudate to relax the viscoelastic<br />

stresses in the melt before leaving the die (reduces<br />

die swell) and forms the shape <strong>of</strong> the extrudate leaving<br />

the die. The die land pr<strong>of</strong>ile has the required<br />

shape to compensate for extrudate deformation<br />

after the die (die swell and drawdown) and yield<br />

the desired shape downstream.<br />

The die exit pr<strong>of</strong>ile shown in Fig. 7 creates an<br />

extrudate that is a U-shaped pr<strong>of</strong>ile with three sides<br />

<strong>of</strong> uniform thickness and perpendicular walls to the<br />

bottom surface. The irregular shape <strong>of</strong> the die exit<br />

was generated with the aid <strong>of</strong> CFD as outlined in the<br />

section Modern <strong>Design</strong> Simulation and Computational<br />

Tools later in this entry.<br />

COEXTRUSION DIES<br />

Fig. 5 Irregular die shapes<br />

required for regular extrudates.<br />

Another important product made with extrusion dies is<br />

the creation <strong>of</strong> multilayered materials. Multilayered<br />

sheet and film materials have two applications:<br />

Making more economical material by sandwiching<br />

a less costly core material between two more expensive<br />

materials.<br />

Fig. 6 Examples <strong>of</strong> poor (on left) and improved<br />

extrusion product designs (on right) to achieve<br />

uniform product thickness: (1) pr<strong>of</strong>ile (A) made<br />

into a hollow pr<strong>of</strong>ile and (2) pr<strong>of</strong>ile (B) made into<br />

an open pr<strong>of</strong>ile.