Author: Professor, Dr. Dietrich Stein - TrenchlessOnline

Author: Professor, Dr. Dietrich Stein - TrenchlessOnline

Author: Professor, Dr. Dietrich Stein - TrenchlessOnline

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

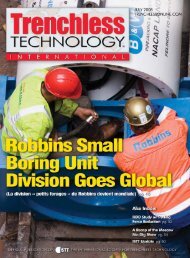

INTERNATIONAL<br />

hydraulic shoes allow for continuous control of line and<br />

grade, while a laser target system provides instantaneous<br />

measurement of boring accuracy.<br />

SBU Technology & Microtunneling<br />

Many of the crossings on the pipeline are using microtunneling<br />

machines (MTBMs) — 11 crossings utilized MTBMs for<br />

excavation during Phase II of the project, mostly in soft soil<br />

to mixed ground conditions with expected water ingress.<br />

MTBMs are superior in jobs below the water table or in soft<br />

ground; however, they can be highly inefficient in hard rock<br />

conditions.The machines use tungsten carbide drag bits on<br />

the cutting head,which tend to break off in rock above 75 to<br />

100 MPa UCS. The broken bits require expensive replacements,<br />

therefore slowing progress and increasing man-hours.<br />

In dry or near dry conditions, when an auger is used in<br />

conjunction with the MTBM for spoils removal, the microtunneling<br />

method is still more expensive than an SBU<br />

machine with ABM.An MTBM using an auger in this fashion<br />

requires that all rock chipped from the face be further<br />

crushed for removal, resulting in slower excavation rates.<br />

SBU systems, in contrast, use interchangeable single disc<br />

cutters to size the rock chips directly at the face.<br />

While MTBMs are superior in some conditions, they are<br />

much more expensive for hard rock excavation than either<br />

an SBU-A/ABM combination or an SBU-M/ABM setup.<br />

Purchasing a typical MTBM will often cost five to 10 times<br />

more than using an SBU-A, and two to three times as much<br />

as purchasing an SBU-M of the same size.<br />

Advantages of SBU Technology<br />

Williams based his decision to use Robbins SBUs on past<br />

jobsite experience. B&W originally purchased two Robbins<br />

SBU-As in 2002 for a similar natural gas pipeline through siltstone.This<br />

previous project involved six hard rock crossings<br />

along a 70-km pipeline extending from St. Fergus to<br />

Aberdeen in Scotland, United Kingdom.<br />

B&W Tunnelling sees its use of SBUs as a competitive<br />

advantage in the United Kingdom, where the product is not<br />

well known compared to the United States. “These<br />

machines can definitely compete with microtunneling<br />

machines given that they can use concrete pipe and sacrificial<br />

casings. SBUs also do not require slurry — microtunneling<br />

machines are dependent on slurry, which can often be<br />

messy and inefficient,” explained Williams.<br />

Excavating the Crossings<br />

As of summer 2007, SBU excavation has gone extremely<br />

well.Average rates of SBU-M excavation are 1.5 to 2.0 m per<br />

hour and none of the machines have required rebuilding<br />

between crossings.<br />

B&W began excavating the crossings using five Robbins<br />

machines — three 1.2-m diameter SBU-As and two 1.2-m diameter<br />

SBU-Ms.The machines utilize 6.5-,9.5- or 11.5-in.diameter<br />

disc cutters (depending on the rock hardness) to bore<br />

through geology between 70 and 200 MPa UCS. Many of the<br />

crossings are in ground consisting of hard rock interbedded<br />

with clay and gravel, necessitating careful cutterhead design.<br />

Circle 22 on reader service card. Circle 52 on reader service card.<br />

54 TRENCHLESS TECHNOLOGY September 2007 www.trenchlessonline.com