Electrohydraulic Valves - Moog Inc

Electrohydraulic Valves - Moog Inc

Electrohydraulic Valves - Moog Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

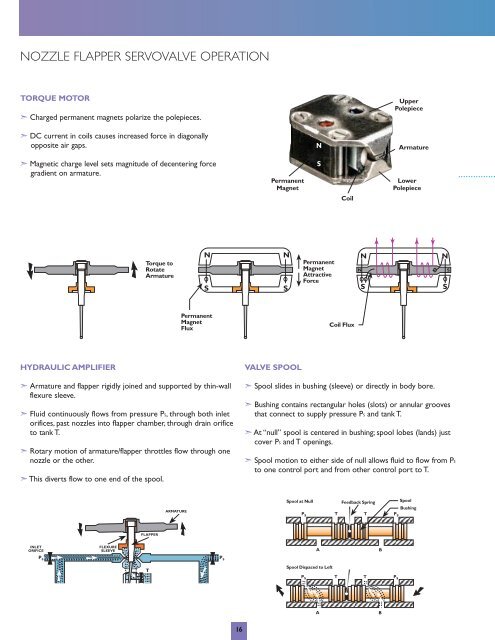

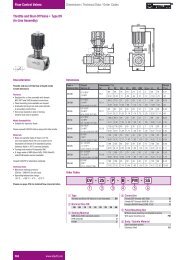

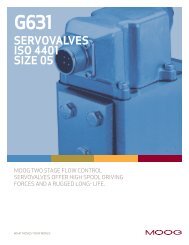

➤➤➤➤NOZZLE FLAPPER SERVOVALVE OPERATIONTORQUE MOTOR➣ Charged permanent magnets polarize the polepieces.UpperPolepiece➣ DC current in coils causes increased force in diagonallyopposite air gaps.NArmature➣ Magnetic charge level sets magnitude of decentering forcegradient on armature.PermanentMagnetSLowerPolepieceCoilTorque toRotateArmatureNSNSPermanentMagnetAttractiveForceNNSNSSPermanentMagnetFluxCoil FluxHYDRAULIC AMPLIFIER➣ Armature and flapper rigidly joined and supported by thin-wallflexure sleeve.➣ Fluid continuously flows from pressure PS, through both inletorifices, past nozzles into flapper chamber, through drain orificeto tank T.➣ Rotary motion of armature/flapper throttles flow through onenozzle or the other.➣ This diverts flow to one end of the spool.VALVE SPOOL➣ Spool slides in bushing (sleeve) or directly in body bore.➣ Bushing contains rectangular holes (slots) or annular groovesthat connect to supply pressure PS and tank T.➣ At “null” spool is centered in bushing; spool lobes (lands) justcover PS and T openings.➣ Spool motion to either side of null allows fluid to flow from PSto one control port and from other control port to T.ARMATURESpool at Null Feedback Spring SpoolBushingP s T T P sFLAPPERINLETORIFICEFLEXURESLEEVEABP SP STSpool Dispaced to LeftP s T T P sÆAB16