drawings

drawings

drawings

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

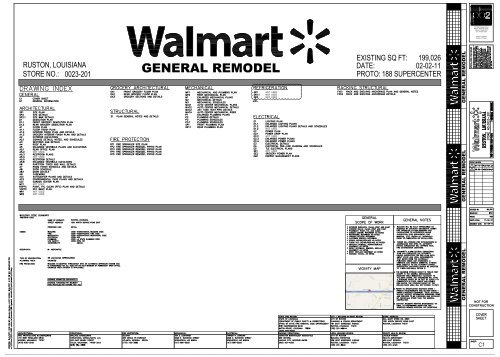

GENERAL REMODELGENERAL REMODELGENERAL REMODEL710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsRUSTON, LOUISIANASTORE NO.:0023-201GENERAL REMODELEXISTING SQ FT: 199,026DATE:02-02-11PROTO: 188 SUPERCENTERSTIPULATION FOR REUSE{DRAWING INDEX}{GROCERY ARCHITECTURAL} {MECHANICAL}{GENERAL}C1 COVER SHEETN1 GENERAL INFORMATION{ARCHITECTURAL}SP1 SITE PLANSP2 SITE DETAILSSP2.1 SITE BMP DETAILSD1 DEMOLITION PLAND1.1 FRONT GROCERY DEMOLITION PLAND1.2 REAR GROCERY DEMOLITION PLANA1 FLOOR PLANA1.1 FLOOR FINISH PLANA1.2 INTERIOR FINISH PLAN AND DETAILSA1.3 GROCERY INTERIOR FINISH PLAN AND DETAILSA2 EXTERIOR ELEVATIONSA2.1 SIGNAGE DETAILS, NOTES, AND SCHEDULESA3 SECTIONS AND DETAILSA4 ROOF PLANA5 ENLARGED VESTIBULE PLANS AND ELEVATIONSA5.1 REAR OFFICE PLANA5.2 {NOT USED}A5.3 RESTROOM PLANSA5.4 {NOT USED}A5.5 RESTROOM DETAILSA5.6 ENLARGED VESTIBULE ELEVATIONSA6 PARTITION TYPES AND WALL DETAILSA7 ROOM FINISH SCHEDULE AND DETAILSA8 DOOR SCHEDULEA8.1 DOOR DETAILSA9 CASEWORKAC1 AUTOCENTER PLANS AND DETAILSAC2 ENVIRONMENTAL CAGE PLANS AND DETAILSGC1 GARDEN CENTER PLANMC1 {NOT USED}RXPFC PAINT, FIX, CLEAN (PFC) PLAN AND DETAILSVCPFC PFC WMVC PLANWR1 {NOT USED}WR2 {NOT USED}GA1 FRONT GROCERY FLOOR PLANGA2 REAR GROCERY FLOOR PLANGA3 GROCERY SECTIONS AND DETAILS{STRUCTURAL}S1 PLAN GENERAL NOTES AND DETAILS{FIRE PROTECTION}FP1 FIRE SPRINKLER SITE PLANFP2 FIRE SPRINKLER REMODEL PIPING PLANFP3 FIRE SPRINKLER REMODEL PIPING PLANFP4 FIRE SPRINKLER REMODEL PIPING PLANFP5 FIRE SPRINKLER REMODEL PIPING PLANMP1 MECHANICAL AND PLUMBING PLANMP2 ROOF MECHANICAL PLANM1 ENLARGED MECHANICAL PLANSM2 MECHANICAL DETAILSM3 MECHANICAL SCHEDULESMAC1 AUTO CENTER MECHANICAL PLANSMAC2 AUTO CENTER MECHANICAL DETAILSMAC3 AST TANK VENT PIPE DETAILSMAC4 AUTO CENTER MECHANICAL RISERP1 ENLARGED PLUMBING PLANSP2 PLUMBING DETAILSP3 PLUMBING SCHEDULESP3.1 PLUMBING SCHEDULESGP1 FRONT PLUMBING PLANGP1.1 REAR PLUMBING PLAN{REFRIGERATION}{ELECTRICAL}{RACKING STRUCTURAL}FXS1 RACK AND SHELVING ANCHORAGE PLAN AND GENERAL NOTESFXS2 RACK AND SHELVING ANCHORAGE DETAILSSTORE NO.GENERAL REMODELJOB NUMBER:ISSUE BLOCKCHECKED BY:DRAWN BY:BUILDING CODE SUMMARY188/C010-CODEPROTO:188NAME OF PROJECT:RUSTON, LOUISIANAPROTO CYCLE:11-19-10STREET ADDRESS:1201 NORTH SERVICE ROAD EASTDOCUMENT DATE:02-09-11CODES:PROPOSED USE:BUILDING:FIRE:MECHANICAL:ELECTRICAL:PLUMBING:LIFE SAFETY:ACCESSIBILITY:RETAIL2006 INTERNATIONAL BUILDING CODE2006 INTERNATIONAL FIRE CODE2006 INTERNATIONAL MECHANICAL CODE2008 NEC2000 LA STATE PLUMBING CODE2009 NFPA 101ADAAG* EXTERIOR SURFACES: CLEAN, PREP AND PAINT* INTERIOR WALLS: CLEAN, PREP AND PAINT* PHARMACY: PAINT, FIX, AND CLEAN* GARDEN CENTER: REFURBISH AS NOTED* RESTROOMS: REFURBISH AS NOTED* VARIOUS OFFICES: REFURBISH* CUSTOMER SERVICE: REFURBISH* DOORS: REPAIR/REPLACE AS NOTED* FLOOR TILE: REPAIR/REPLACE AS NOTED* GROCERY: REMODEL, REPAIR/REPLACE EQUIPMENT AS NOTED* ENTRY VESTIBULE: REMODEL, REPLACE EQUIPMENT AS NOTED* ROOF: REPLACE EQUIPMENT AS NOTED* SIGNAGE: INSTALL AS NOTEDOCCUPANCY:M- MERCANTILETYPE OF CONSTRUCTION:ALLOWABLE AREA:FIRE PROTECTION:5B unprotected (SPRINKLERED)UNLIMITEDBUILDING IS EQUIPPED THROUGHOUT WITH AN AUTOMATIC SPRINKLER SYSTEM AND IS SURROUNDED ON ALL SIDES BY 60 FEET MINIMUM OF PERMANENT OPEN SPACE. UNLIMITED AREA CRITERIA IS APPLICABLE.SIGNAGESIGNAGEFURNISHEDPERMITTEDBY WALMART AND INSTALLEDSEPARATELYBY OTHERS. REF A2.1PRINTED: 8/4/2011 3:26 PM BY: Brenda Garrison LAST SAVED: 8/4/2011 2:10 PM BY: BRIANCARLTONe:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\c010.dwgNOT FORCONSTRUCTIONSHEET:

{KEYNOTES}SHEET NOTES:REMOVED NOTE 211. POWER WASH SIDEWALK AROUND THE ENTIRE PERIMETER OF BUILDING.2. REMOVE SEALANT AND BACKER MATERIAL FROM JOINT BETWEEN BUILDING AND SIDEWALK. FILL AND SEAL JOINTS, REF SPEC 07900.3. REPAINT PERIMETER SIDEWALK AND FIRE LANE CURB.4. NOT USED5. NOT USED6. NOT USED7. NOT USED{8. NOT USED}9. NOT USED10. RAISE ALL SITE SIGNS WITHIN CLOSE PROXIMITY TO STRUCTURE TO 7'-0" ABOVE GRADE.{}11. REPLACE ALL DAMAGED, MISSING, OR FADED SITE SIGNS WITHIN CLOSE PROXIMITY TO STRUCTURE.12. INSTALL ALL SITE SIGNS AT BUILDING SIDE OF DRIVE LANE IN BOLLARDS. REF 12-SP2.{13. NOT USED14. NOT USED}15. NOT USED16. NOT USED17. NOT USED{18. NOT USED}19. NOT USED20. NOT USED{21. NOT USED}{22. NOT USED23. NOT USED24. NOT USED25. REMOVE SEALANT AND BACKER MATERIALS FROM ALL BUILDING CONTROL AND EXPANSION JOINTS. FILL AND SEAL JOINTS. REF SPEC 07900}710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. Phillips35'-2" 38'-2" 34'-0" 33'-0" 48'-0" 48'-0" 48'-0" 48'-0" 48'-0" 48'-0" 48'-0" 48'-0" 48'-0" 34'-0"JOB NUMBER:51'-8"STORE NO.50'-8"STIPULATION FOR REUSEGENERAL REMODEL49'-6"ISSUE BLOCKARCHITECTURAL FINISH FLOOR = 100.00'%NOTE:FINISH FLOOR ELEVATION ATALL EXTERIOR DOORS = 100.00'UNLESS NOTED OTHERWISE40'-4"REFER TO SHEET SP2.1 AND SPEC SECTION 01500 FOR DETAILS AND REQUIREMENTS FOR STORMWATER POLLUTION CONTROLS AND SITE STORAGE OF MATERIALS AND EQUIPMENT. DEVIATION(S) FROM DETAILS SHOWN MUST BE SUBMITTED FOR APPROVAL IN ACCORDANCE WITH SPEC SECTION 01330.41'-4"CHECKED BY:DRAWN BY:PROTO:1886'-0"FV5'-0"8'-8"5'-0"58'-8"PROTO CYCLE:DOCUMENT DATE:11-19-1002-09-11NEW RAMPREF 9-SP2 SIMFV56'-2"6'-0"6'-0"FV41'-4"EXISTING PLANTER BOX AREAAND INNER SIDEWALK TO REMAIN10'-2"FV10'-0"FV10'-2"FV10'-0"FVPRINTED: 8/4/2011 3:27 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 1:09 PM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\sp010.dwg14'-11{}"FV6'-0"(FV)19'-9"2 EQUALSPACES(FV)9'-6"5'-0"(FV)NEW RAMPREF 9-SP25'-0"(FV)105'-9"9 EQUAL SPACES13'-0"9'-4{}"13'-8"8'-6{}"FVFVFVFV49'-7{}"4 EQUAL SPACES(FV)28'-3{}"2 EQUALSPACES(FV)7 EQUAL SPACES(FV)67'-8"3'-11"FV14'-11"FV134'-6{}"14 EQUAL SPACES(FV)REPLACE EXISTING CURB AT PERIMETER OF BUILDING WHERE SIDEWALK MEETS EXISTING CMU WALL REF 11-SP213'-8"FV13'-4"9'-4{}"FVFV7 EQUAL SPACES(FV)67'-8"4'-0"FV13'-8"14'-7{}"32'-2{}"3 EQUAL SPACES(FV)60'-0"6 EQUAL SPACES6'-0"FV56'-4{}"18'-0"2 EQUALSPACES(FV)9 EQUAL SPACES(FV)15'-0"51'-0"NOT FORCONSTRUCTIONSHEET:

SINKREMOVE EYEWASH REF MEPSDSDUPC/INVOICINGSD SD SD VDRELOCATE EXISTING REFRIGERATORREMOVE CABINETRY IN ITS ENTIRETYREMOVE SINK REF MEPTRAININGPHOTO STORAGECBLAP MONITORMANAGERS OFFICEASSOCIATE WOMENFIXTURESCORRIDORMANAGEMENTAP OFFICECUSTOMER MEN{1. GC TO REMOVE ANY INTERIOR TENANT SIGNAGE ORORNAMENTATION INSTALLED ON THE FRONT OR SIDE TENANTBULKHEADS. WALMART OWNED TENANT SIGNS ANDORNAMENTS ARE TO BE RETURNED TO THE STORE MANAGER.NON-WALMART OWNED TENANT SIGNS AND ORNAMENTS ARETO BE RETURNED TO THE TENANT.2. GC TO REMOVE ALL EXTERIOR BUILDING MOUNTEDSIGNAGE, LIT AND UNLIT. COORDINATE REMOVAL OFEXTERIOR TENANT SIGNAGE WITH CM AND TENANT PRIOR TOREMOVAL. GC WILL REMOVE ALL EXTERIOR TENANT SIGNAGEAND DELIVER TO TENANT. PATCH AND REPAIR EXTERIOR WALLSURFACES, DAMAGED OR EXPOSED DUE TO SIGNAGEREMOVAL, TO MATCH ADJACENT AS REQUIRED.3. COORDINATE EXTERIOR LIT SIGNAGE REMOVAL WITHWALMART CM. EXTERIOR LIT SIGNS CANNOT BE REMOVEDWITHOUT WALMART CM APPROVAL. DISPOSE OF EXISTINGFLUORESCENT LAMPS AND BALLASTS IN ACCORDANCE WITHSPEC SECTION 01743 PRIOR TO PLACING SIGN(S) IN WASTEMANAGEMENT CONTAINER.4. UNLIT EXTERIOR SIGNAGE MAY BE REMOVED WITHOUTPRIOR APPROVAL.5. NOT USED.6. NOT USED.7. SALES FLOOR TO BE ACCESSIBLE TO CUSTOMERS DURINGNON-CONSTRUCTION HOURS. PROVIDE TEMPORARY COVERSCAPABLE OF WITHSTANDING SHOPPING CART TRAFFIC ANDOCCUPANTS FOR PITS AND TUNNELS, REMOVECONSTRUCTION FENCING AND DUST WALLS INTERFERINGWITH CUSTOMER CIRCULATION OR ACCESS.8. NOT USED.}STIPULATION FOR REUSE710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsSITE TO STOREBREAKROOMCUSTOMER WOMENDEMOLITION LEGENDEXISTING TO REMAINASSOCIATE MENDEMOLISH/REMOVEAREA TO BE DEMOLISHEDRELOCATEGENERAL REMODELNOTE:THE GENERAL CONTRACTOR SHALLREPAIR/REPLACE ANY DAMAGED FLOORTILE DUE TO INSTALLATION OR REMOVALCONTINUOUS SEALANTSTORE NO.CORRIDOR2x WOOD PLATE1/2" C/D EXT. PLYWOOD SCREWED TO STUDS OVER 6 MIL CLEAR POLY SHEETSEXISTING WALL TO REMAIN3'-0"MIN.PHARMACY STORAGEBALERDEPARTMENT MANAGERS WORKSTATIONELECTRICAL ROOM-1FIRE CORRIDORUPC/INVOICINGFIRE CORRIDORSPRINKLERSECURITY ROOMCLAIMSMANAGEMENTFIXTURESMANAGERS OFFICEAP MONITORPHOTO STORAGETRAININGFIRE CORRIDORFIXTURE STORAGEMARKET MANAGERS OFFICEDELI FREEZERDELI COOLERHALLWAYDELI PREPDEPT. 82ISSUE BLOCKJOB NUMBER:RECEIVING-GMSTOCKROOMCOMPACTORSTOCKROOMCBLDAIRY COOLERSERVICE DELI{SALES}2x4 STUDS @ 24" OC (TYPICAL)CONTINUOUS SEALANT BOTH SIDES OF SILL PLATEEXISTING OPENING{DEMO AREA}TIRE AND BATTERY STORAGECUSTOMER SERVICETOILETSTORAGEREMOVE DOORS SHOWN DASHED. FRAMES TO REMAIN UNO ON DOOR SCHEDULE OR PLANBREAKROOMSITE TO STOREASSOCIATE WOMENASSOCIATE MENJANITORCUSTOMER MENAP OFFICECUSTOMER WOMENGROCERY SALESCOMPACTORRECEIVING-GRFIRE CORRIDORSTOCKROOMGROCERY FREEZERCHECKED BY:2x4 TREATED WOOD SILL PLATE2'-0" MAXLUBE AND TIRE MOUNTING AREAELECTRICAL ROOM-4SECURITYREMOVE CARPETING AND ADHESIVE FROM COLUMNSELECTRICAL ROOM-5DRAWN BY:PROTO:PROTO CYCLE:DOCUMENT DATE:18811-19-1002-09-11REMOVE EYEWASH REF MEPWET DEVELOPING EQUIPMENT TO BE REMOVED BY EQUIPMENT VENDORSILVER RECOVERY UNIT TO BE REMOVED BY OTHERS. GC TO CAP EXISTING DRAIN/CONNECTION AS REQUIREDSALESREMOVE ALL WALL STANDARDS ABOVE 96" AFF ON SALES FLOORMEAT COOLERMEAT PREPROOF DECKREMOVE EXISTING RAMPAND PORTION OFEXISTING CONCRETE. REFWATER FILTRATION SYSTEM TO BE REMOVED BY OTHERS. GC TO DISCONNECT WATER LINE TO WATER FILTRATION SYSTEM AND MAINTAIN CONNECTION OF WATER LINE TO SINKPHOTO LABMEAT HOLDINGGROCERY COOLERCONTINUE PLYWOOD TO DECKDO NOT USE DUSTWALL TO SHORE ROOF JOISTSICE CREAM FREEZERSEAFOOD COOLERWALL TO BE REMOVEDSEASONAL SHOPGROCERY SALESSEAFOOD FREEZERSEAFOODPRINTED: 8/4/2011 3:27 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 1:09 PM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\d010.dwg1/2" CD PLYWOOD 4'-0"X8'-0" HORIZONTAL PROVIDE 2x4 NAILER AT ALL JOINTSINSTALL CONTINUOUS LAYER 6 MIL POLY SHEETS TAPE ALL JOINTS2x4 AT 24" OCSALESSEALANT UNDER BOTTOM PLATE6'-0" LOAD BEARING4'-0" ELSEWHEREDEMO AREANOTES:1. INSTALL TEMPORARY WALL IN SECTIONS APPROX 40'-0" PER DAY (COORDINATE WITH STORE MANAGER AND WALMART CONSTRUCTION MANAGER)2. LOCATE VERTICAL 2x4'S AS NOT TO INTERFERE WITH CEILING GRID OR LIGHT FIXTURES3. LOCATE HORIZONTAL 2x4 AT 2" ABOVE CEILING EXCEPT LIGHT FIXTURE LOCATIONS4. SCREW PLYWOOD (MAX SPACING 12" OC)CONTINUOUS SEALANTAGAINST PLATEANCHOR AT 24" OC COORDINATE W/SPECIFICATION SECTION 01500.REMOVE EXISTING SODA MACHINESGARDEN CENTERREMOVE AQUARIUM WALLREPLACE COUNTERS IN THEIR ENTIRETYREPLACE COUNTERTOP EXISTING CABINETRY TO REMAINCART STORAGE - GMELECTRICALROOM-3OTHER INCOME - GMVESTIBULE - GMREMOVE EXISTING CARPET TILE. REPLACE WITH WALMART SUPPLIED CARPET TILEREMOVE EXISTING ICE MACHINEEXISTING ICE MACHINE TO REMAINVISION CENTERWOODFOREST NATIONAL BANKVESTIBULE - GRREMOVE EQUIPMENT STORE MANAGER TO COORDINATE REMOVAL WITH VENDOR IF NOT WALMART OWNEDREMOVE EQUIPMENT STORE MANAGER TO COORDINATE REMOVAL WITH VENDOR IF NOT WALMART OWNEDREMOVE EXISTING CURB AS SHOWN DASHED REF SP1 FOR EXTENT OF WORKREMOVE EXISTING RAMP REF SP1 FOR EXTENT OF WORK REMOVE EXISTING CONCRETE, AND DETECTABLE WARNING AS SHOWN. REF SP1 FOR EXTENT OF WORKEXISTING BOLLARDS TO REMAIN, TYPREMOVE EXISTING CONCRETE AND DETECTABLE WARNING AS SHOWN. REF SP1 FOR EXTENT OF WORKDEMOLITION INCLUDES BUT IS NOT LIMITED TO ITEMS SHOWN DASHED REF DEMOLITION REQUIREMENTS NOTES ON N1 SHEETEXISTING BOLLARDS TO REMAIN, TYP.FIRE CORRIDORCOUNTCASHMONEY CENTERREGAL NAILSREMOVE EXISTING CAPRET TILE. REPLACE WITH WALMART SUPPLIED CARPET TILECUSTOMER WOMENJANITORCUSTOMER MENPICTURE MESMART STYLEFLORALCAKE DECORATINGRLCART STORAGE - GRELECTRICALROOM-2OTHER INCOME - GRBAKERYPLUMBING/ MECHANICALPRODUCE PREPPRODUCE COOLERBAKERY COOLERBAKERY FREEZERNOT FORCONSTRUCTIONSHEET:

DEMOLITION LEGENDEXISTING TO REMAINDEMOLISH/REMOVEAREA TO BE DEMOLISHEDRELOCATEDEMOLITION INCLUDES BUT IS NOT LIMITED TO ITEMS SHOWN DASHED REF DEMOLITION REQUIREMENTS NOTES ON N1 SHEET710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsSTIPULATION FOR REUSEEXISTING M/D FRESH MEAT CASESMEAT HOLDINGGENERAL REMODELEXISTING COFFINCASE TO REMAINSTORE NO.EXISTING REFRIGERATED CASESGROCERY COOLERJOB NUMBER:EXISTING REFRIGERATED CASESEXISTING REFRIGERATED CASESEXISTING M/D FRESH MEAT CASESICE CREAM FREEZERSTOCKROOMISSUE BLOCKEXISTING REFRIGERATED CASESSEAFOOD COOLERSEAFOOD FREEZEREXISTING PRODUCE CASESREMOVE DOORSSHOWN DASHED.FRAMES TO REMAINUNO ON DOORSCHEDULE OR PLANEXISTING REACH-IN FREEZERS TO REMAINSEAFOODCHECKED BY:DRAWN BY:GROCERYSALESEXISTING M/D SEAFOOD CASE TO REMAINPROTO:PROTO CYCLE:DOCUMENT DATE:18811-19-1002-09-11PRODUCE PREPEXISTING CULLIGAN WATER DISPENSERPASTRY CASES TO REMAINEXISTING REACH-IN FREEZER TO REMAINEXISTING CAKE CASES TO REMAINPRODUCE COOLERCAKE DECORATINGBAKERYBAKERY COOLERPRINTED: 8/4/2011 3:27 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 1:09 PM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\d011.dwgDINNING AREASERVICE AREARLCOOLERFREEZERUTILITYEXISTING THERMOGLAZER TO REMAINBAKERY OVENS TO REMAINPROOFER TO REMAINEXISTING ICING TABLE TO REMAINRACK WASHER TO REMAINPLUMBING/ MECHANICALBAKERY FREEZERNOT FORCONSTRUCTIONSHEET:

DEMOLITION LEGENDEXISTING TO REMAINREMOVE EXISTING WASTE COOKINGOIL TANKS. AFTER REMOVINGWASTE OIL PIPING, REPAIR ANDSEAL MORTAR JOINTS AND SEALFROM WATER PENETRATIONDEMOLISH/REMOVEAREA TO BE DEMOLISHEDRELOCATEDEMOLITION INCLUDES BUT IS NOT LIMITED TO ITEMS SHOWN DASHED REF DEMOLITION REQUIREMENTS NOTES ON N1 SHEET710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsBALERMARKET MANAGERS OFFICEDELI FREEZERDELI PREPDEPT. 82STIPULATION FOR REUSE51'-0"GROCERY FREEZERISSUE BLOCKCHECKED BY:DRAWN BY:PROTO:PROTO CYCLE:DOCUMENT DATE:STORE NO.GENERAL REMODELJOB NUMBER:18811-19-1002-09-11PRINTED: 8/4/2011 3:27 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 1:09 PM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\d012.dwgDAIRY COOLERHALLWAYEXISTING VENT HOOD TO REMAINDELI COOLEREXISTING COFFIN CASES TO REMAINSERVICE DELIEXISTING M/D DAIRY/DELI CASES TO REMAINEXISTING M/D FRESH MEAT CASES TO REMAINMEAT COOLERMEAT PREPRECEIVING-GREXISTINGCOFFIN CASES TOREMAINEXISTING M/D BEER CASESGROCERYSALESEXISTING M/D DAIRY CASESCOORDINATE REMOVAL AND DISPOSALOF EXISTING REFRIGERATED CASES AND FIXTURESWITH WALMART CONSTRUCTIONAND STORE MANAGERS.REMOVE DOORS SHOWN DASHED. FRAMES TO REMAIN UNO ON DOOR SCHEDULE OR PLANEXISTING DAIRY CASES TO REMAINDELIFRYER AND ROTISSERIE TOREMAINREPLACE CEILING GRIDAND TILE 4'-0" FROMEXHAUST HOODEXISTING COFFIN CASE TO REMAINEXISTING CASETO REMAINEXISTING COFFIN CASE TO REMAINEXISTING CASES TO REMAINEXISTING CASES TO REMAINEXISTING M/D DAIRY/DELI CASES TO REMAINEXISTING DELI HOT CASE TO REMAINREMOVEEYEWASHFIRE CORRIDORSTOCKROOMELECTRICAL ROOM-5NOT FORCONSTRUCTIONSHEET:

REDBOX(TYP AT HALF-GONDOLAS)OMIT PAINT AS INDICATEDPAINT AS INDICATED1'-0"DRY MERCHANDISE SHELVING SHOWN DASHED FOR CLARITY.1'-0"AT ALL PERIMETER HALF-GONDOLAS EXTEND PAINT BEYOND VERTICAL EDGE OF END GONDOLAS.WAINSCOT AS INDICATED. ON EXPOSED WALLS WHERE WAINSCOT IS NOT TO BE INSTALLED, CONTINUE PAINT TO FINISH FLOOR.PAINT DOORP102PAINT FRAME P102RESTROOM SIDEPAINT FRAME P16 OPPOSITE SIDE{RESTROOM}PAINT DOORP16{ALCOVE, SALES OR CUSTOMER SERVICE}TO DECKMATCH WALL COLOR{ANY SALES FLOOR COLUMN WHICH FALLS WITHIN 2'-0" OF A PERIMETER WALL}7'-0"TO DECK{NON PERIMETERGM SALES FLOOR COLUMNS}TO DECK7'-0"{NON-PERIMETERGROCERY COLUMNS}STIPULATION FOR REUSE710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsSPRINKLERPHOTO STORAGERECEIVING-GMPHARMACY STORAGESTOCKROOMFIRE CORRIDORELECTRICAL ROOM #1STOCKROOMCLAIMSJANITORSECURITY ROOMSITE TO STOREFIRE CORRIDORUPC/INVOICINGTRAININGBREAKROOMASSOCIATEMENBREAKROOMASSOCIATEWOMENFIXTURESAP OFFICECUSTOMERWOMENCORRIDORCUSTOMERMENMANAGER'S OFFICEMANAGEMENTSTORE NO.GENERAL REMODELTIRE AND BATTERY STORAGECUSTOMER SERVICEISSUE BLOCKJOB NUMBER:LUBE & TIRE MOUNTING AREASTORAGECOLUMN PAINTTO MATCH SALES WALLPAINT STRUCTURE AS INDICATED ON DETAILS 2-A1.2 AND 3-A1.2ALL HM DOORS AND FRAMES LOCATED IN PAINTED WALLS TO BE PAINTED SAME AS WALL COLOR. DOORS IN WALLS WITH WAINSCOT SHALL BE PAINTEDCOLORS SHOWN IN GROCERY FOR BULKHEAD ONLY. REFER TO A1.3 FOR WALL FINISHESCHECKED BY:DRAWN BY:PROTO:188PROTO CYCLE:11-19-10DOCUMENT DATE:02-09-11SALESGROCERY SALESPAINT GIRDER OR JOIST DIRECTLY ADJACENT TO WALL TO MATCH. COLOR AS INDICATEDPAINT COLUMN TO MATCH ADJACENT WALL AS INDICATEDSEASONAL SHOPMONEYCENTERPHARMACYPAINT HVAC GRILLS TO MATCH ADJACENT WALLPRINTED: 8/4/2011 3:27 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 1:09 PM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\a012.dwgPAINT CMU FROM FINISH FLOOR TO DECK AS SCHEDULEDFLOOR FINISH AS SCHEDULEDGARDEN CENTERGM CART STORAGE GMELECTRICAL ROOM-3WAL-WMGREETOTHER INCOME-GMVESTIBULE-GMREFLECTED SOFFIT PLANVISION CENTERCOURTESYDESKCASHCOUNTCUSTOMERWOMENFIRE CORRIDORPICTUREMEALL HM DOORS AND FRAMES LOCATED IN VISION CENTER TO BE PAINTED P40CUSTOMERMENREGAL NAILSSMART STYLEREFLECTED SOFFIT PLANWOODFORESTNATIONALBANKFLORALVESTIBULE-GRWAL- WMGREETRB PANELGR CART STORAGE-GRELECTRICAL ROOM-2OTHER INCOME-GRNOT FORCONSTRUCTIONSHEET:

1'-0"2'-0"4'-10{}"4'-6{}"4'-10{}"{NEW SIGNREF 5-A2.1}{NEW SIGNSREF 7-A2.1}{NEW SIGNSREF 6-A2.1}REF SPECIFICATIONSSHEET NOTES:REMOVE SHEET NOTE 3ADDED NOTE 171. DOOR HOODS, STEEL DOORS AND FRAMES, EXPOSEDMETAL FLASHING, HANDRAILS, GAS LINES, AND EXPOSEDMISCELLANEOUS STEEL SHALL MATCH ADJACENT BUILDINGCOLOR UNO. IF THERE ARE TWO COLORS AT WALL ADJACENTTO DOOR AND FRAME. USE BOTTOM COLOR FOR ENTIREDOOR AND FRAME.2. REPAIR GUTTERS AND DOWNSPOUTS. REPLACE MISSINGSECTION(S) WITH LIKE MATERIAL. PAINT TO MATCH ADJACENTWALL COLOR.3. NOT USED.4. POWER WASH 100% OF EXTERIOR WALLS PRIOR TOPAINTING.5. PAINT ENTIRE EXTERIOR OF BUILDING.6. NOT USED.7. PAINT JIB CRANE - P36 ON JIB BOOM, P5 ON HANDRAILS.8. NOT USED.9. PAINT GARDEN CENTER STEEL DOORS AND FRAMES TOMATCH ADJACENT BUILDING WALL. IF THERE ARE TWOCOLORS AT ADJACENT WALL, USE BOTTOM COLOR FORENTIRE DOOR AND FRAME.10. PAINT SPRINKLER VALVES P4. DO NOT PAINT OVER SIGHTGLASS.11. DO NOT PAINT OVER FIRE ALARM BELL.12. PAINT ALL EXTERIOR BOLLARDS TO MATCH EXISTINGCOLOR UNLESS NOTED TO RECEIVE PLASTIC BOLLARDSLEEVE.13. PAINT SECURITY WALL PACK HOUSINGS TO MATCHADJACENT WALL.14. CLEAN SECURITY WALL PACKS. REMOVE PAINTOVERSPRAY FROM LENSES.15. REMOVE ALL BRANDED SIGNAGE AND TLE OIL SIGNAGEPRIOR TO PAINTING.16. CLEAN ALL SIGNS THAT ARE EXISTING TO REMAIN.17. CLEAN EXISTING FACTORY SECTIONAL OVERHEADDOORS AT CART STORAGE.STIPULATION FOR REUSE710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. Phillips4'-6{}"4'-10{}"ELEVATIONS APPROVED BY WALMART BRANDING ON 08/30/10CAP (TYP)CAP (TYP)STORE NO.GENERAL REMODELGARDEN CENTER FENCE SHOWN DASHED FOR CLARITYJOB NUMBER:ISSUE BLOCKPAINT STAIRSAND RAILINGCHECKED BY:DRAWN BY:PROTO:188PROTO CYCLE:11-19-10DOCUMENT DATE:02-09-11PRINTED: 8/4/2011 3:28 PM BY: Brenda Garrison LAST SAVED: 8/3/2011 4:00 PM BY: BRIANCARLTONe:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\a020.dwg19'-7"GARDEN CENTER FENCE SHOWN DASHED FOR CLARITYNEW SIGNREF 4-A2.14'-7{}"TENANTSIGNAGEHATCH AREA INDICATES RESURFACED EXISTING EIFS. REF SPEC SECTION 7240 HATCH AREA INDICATES RESURFACED EXISTING EIFS. REF SPEC SECTION 724064'-5{}"10'-0"4'-6{}"4'-8{}"23'-10"MONEW SIGNREF 2-A2.126'-0"4'-5"NEW SIGNREF 1-A2.14'-6{}"25'-0"NEW SIGNREF 3-A2.123'-10"MO10'-0"TENANTSIGNAGENOT FORCONSTRUCTIONSHEET:

{KEYNOTES}KEYNOTES:REVISED KEYNOTE 6.24710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsJOB NUMBER:STORE NO.GENERAL REMODELSTIPULATION FOR REUSEISSUE BLOCKCHECKED BY:DRAWN BY:PROTO:188PROTO CYCLE:11-19-10DOCUMENT DATE:02-09-11OPEN TO CART STORAGEOPENTOOTHERPRINTED: 8/4/2011 3:28 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 1:11 PM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\a056.dwgOPENTOOTHEROPEN TO CART STORAGENOT FORCONSTRUCTIONSHEET:

REFERENCE SIDEOPPOSITE SIDE1.NOT USED.METAL STUDS5/8" GYPSUM BOARDUSE 5/8" WATER RESISTANT GYPSUM BOARD AT WET AREAS UNO2.3.4.5.6.7.USE 1/2" GYPSUM BOARD ON NON-RATED PARTITIONS UNO.USE 5/8" TYPE X GYPSUM BOARD ON FIRE RATED PARTITIONS.REF ROOM FINISH SCHEDULE FOR ROOMS THAT RECEIVE FRP.CONTINUE FINISH MATERIAL TO A MINIMUM OF 4" ABOVE SUSPENDED CEILING SYSTEMS UNO.REF PARTITION KEY SYMBOL FOR STUD THICKNESSES.WHERE NO CEILING IS INDICATED CONTINUE FINISH TO DECK UNO. MAINTAIN CLEARANCE BELOW STRUCTURE PER CAPTURE TRACK DETAILS710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. Phillips8.C\a060-ptY9.10.11.STUD PARTITIONS REQUIRING A FIRE RATING OF ONE HOUR SHALL COMPLY WITH UL#U465 OR UL #U442. MASONRY PARTITIONS REQUIRING ONE HOUR FIRE RATING SHALL COMPLY WITH UL#U905.STUD WALLS RECEIVING PLYWOOD SHALL BE 22 GAUGE OR HEAVIER.MAXIMUM HEIGHT OF NON LOAD BEARING WALL ABOVE HEADER TO BE 20'-0".{REF SPECIFICATIONS FOR LATERAL BRACING OF STUD PARTITIONS.}STIPULATION FOR REUSE12.NOT USED.13.USE GYPSUM BOARD BEHIND ALL FRP BOARD UNO.14.WHERE NO CEILING IS SCHEDULED, STOP 1/2" PLYWOOD SUBSTRATE AT 10'-0" AFF.15.PROVIDE FIRE BLOCKING AT FLOOR AND ROOF LEVELS, CONCEALED SPACES BETWEEN STAIRWAY STRINGERS, PENETRATIONS IN FLOOR/CEILING ASSEMBLIES AND OTHER LOCATIONS AS REQUIRED BY CODE.16.ROOMS THAT HAVE 5/8" IMPACT RESISTANT GYP BD TO 48" AFF NEED 5/8" GYP BD ABOVE 48" AFF. REF A7 FOR LOCATIONS.17. NOT USED.DETAIL:GENERAL REMODELPLAN:LETTER INDICATES PARTITIONTYPEREF PLANS AND SHEET A6REFERENCE SIDEOPPOSITE SIDE1 - 1 5/8" METAL2 - 2 1/2" METAL3 - 3 5/8" METALNUMBER INDICATES STUDHEIGHTNO NUMBER INDICATESSTUD HEIGHT TO BOTTOMOF ROOF DECK TYPNUMBER INDICATES STUD SIZE AS FOLLOWS:6 - 6" METAL8 - 8" CMU12 - 12" CMU1 HOUR RATED GYPSUM BOARD (NEW) UL#U442OR U465,1 HOUR RATED CMU (NEW) UL#U905STORE NO.JOB NUMBER:NON-RATED GYPSUM BOARD WALL (NEW)ACOUSTICAL INSULATION FULL WALL THICKNESS (NEW)CHAIN LINK FENCE (NEW)COOLER/FREEZER WALL (NEW)INDICATES (NEW) 48" HIGH PLASTIC LAMINATE WAINSCOT OR PROTECTIVE SURFACE WAINSCOT UNO.INDICATES (NEW) 48" HIGH PLYWOOD WAINSCOT WITH 2x8 WOOD BASE AND DB5 BASE UNOISSUE BLOCKEXISTING 1 HOUR RATED GYPSUM BOARD TO REMAINEXISTING PARTITION OR WALL TO REMAINCMU WALL (NEW)EXISTING WALL TO BE DEMOLISHEDCHAIR RAIL FURNISHED BY WALMART, INSTALLED BY G.C.NON-RATED GYPSUM BOARD WALL (NEW) (GROCERY PREP AREAS) WITH SILL SEALERCHECKED BY:DRAWN BY:PROTO:188PROTO CYCLE:11-19-10DOCUMENT DATE:02-09-11{INTERIOR NON-LOAD BEARING PARTITION HEADER SCHEDULE}HEADER LENGTH2' TO 6'6' TO 8'8' TO 10'10' TO 12'12' TO 14'14' TO 16'16' TO 18'18' TO 26'HEADER MEMBERS(2) 6" x 18 GAUGE(2) 6" x 16 GAUGE(2) 6" x 14 GAUGE(2) 8" x 18 GAUGE(2) 8" x 16 GAUGE(2) 8" x 14 GAUGE(2) 10" x 14 GAUGE(2) 12" x 16 GAUGEMINIMUM EFFECTIVE PROPERTIES PER STUDIx = 2.042 Sx = 0.670Ix = 2.518 Sx = 0.839Ix = 3.094 Sx = 1.031Ix = 4.134 Sx = 1.033Ix = 5.110 Sx = 1.277Ix = 6.303 Sx = 1.576Ix = 12.325 Sx = 2.456Ix = 15.730 Sx = 2.334DOUBLE MTL STUD AT JAMBSMETAL STUDPRINTED: 8/4/2011 3:27 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 1:11 PM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\a060.dwgBOX BEAMPC 18 GA TRACK{SECTION B}BOTTOM TRACKTOP TRACK2 STUD HEADERSFINISH AS INDICATEDBOTTOM TRACKVARIES{SECTION A}METAL STUD HEADERPC 18 GA TRACK WITH (3) #10 TEKSCREWS EACH SIDE TO HEADER AND (6) #10 TEK SCREWS TOJAMBMETAL STUD JAMBNOT FORCONSTRUCTIONSHEET:

SCHEDULE NOTES:1. CLEAN JOISTS, JOIST GIRDERS, DECKING, LIGHTS, CONDUIT, HVAC GRILLES, SPRINKLER PIPES AND SECURITY GLOBES (IFEXISTING).2. CLEAN CEILING TILES, GRID, AIR GRILLES/DIFFUSERS, SECURITY GLOBES, SPRINKLER HEADS AND LIGHT LENSES. REPLACEANY DAMAGED ITEMS.3. CLEAN CEILING GRID, AIR GRILLE/DIFFUSERS, SECURITY GLOBES, SPRINKLER HEADS, AND LIGHT LENSES. REPLACE ANYDAMAGED ITEMS.4. CLEAN WINDOWS. REMOVE EXISTING PAINT AND DIRT FROM GLASS.5. CLEAN EXISTING RESTROOMS.6. CLEAN CERAMIC TILE.7. CLEAN KALWALL.8. CLEAN AIR DOOR AND GRATE.9. REMOVE CARPETING. INSTALL LAMINATE, DB10, BLACK PLASTIC CORNERS TO 58" AFF TO GYP BD WRAPPED COLUMNS. REF4-A1.210. PAINT ALL EXPOSED COLUMNS. USE EPOXY PAINT TO 7'-0" AFF AND LATEX PAINT ABOVE. REF 3-A1.2 FOR LOCATIONS.11. SEAL BASE OF ALL COLUMNS ON VCT TILE W/WHITE SEALANT AND ON PVC PLANK FLOORING W/BROWN SEALANT..12. REINSTALL ALL FIRE EXTINGUISHERS IMMEDIATELY AFTER REMOVING THE CARPETING AND REPAINTING COLUMNS AND ATALL OTHER LOCATIONS.13. INSTALL MISSING COLUMN TRIM AT CEILING.14. REMOVE ALL SECTIONS OF WALL STANDARDS. PAINT WALLS AFTER REMOVAL.15. REPLACE CEILING TILE AT SALES FLOOR TO 50' AS INDICATED ON 1-A1.16. PAINT GYPSUM BOARD WALLS TO 6" BEHIND TOP AND SIDES OF FIXTURE CASES17. REPLACE DAMAGED PIECES OF EXISTING CERAMIC TILE FROM FLOOR TO CEILING. GROUT TO MATCH ADJACENT.18. REMOVE ALL WALL COVERINGS, PREP AND TEXTURE WALLS WITH TEXTURED FINISH AS SPECIFIED.19. WALLS TO RECEIVE MEDIUM KNOCK-DOWN TEXTURE. FINISH TEXTURE WITH FINAL COAT OF PAINT.20. PAINT PRODUCE PREP HALLWAY UP TO DECK P40. INSTALL 2X8 WOOD BASE W/CHAMFERED TOP AND DB5.21. REPLACE DAMAGED FRP PANELS.22. INSTALL PLASTIC LAMINATE WAINSCOT WITH EDGE TRIM AT ALL EXPOSED EDGES AS INDICATED ON PLANS. DO NOT INSTALLON BLOCK WALLS.23. INSTALL 1/2" PLYWOOD WAINSCOT WITH TOP EDGE ROUNDED OFF 48" BEHIND 2X8 WOOD BASE AT GYPSUM WALLS ONLYWHERE INDICATED ON PLANS. REF 2-A3.24. INSTALL 1/2" PLYWOOD WAINSCOT WITH TOP EDGE ROUNDED OFF 48" ON WALLS ONLY WHERE INDICATED ON PLANS. PAINTPLYWOOD TO MATCH WALL ABOVE. DO NOT PAINT CURB.25. REPAIR GYP BD CEILING. CLEAN LIGHTS, HVAC GRILLES, SPRINKLER HEADS AND REPAIR ANY DAMAGED ITEMS.26. REPAINT CEILING GRID IN SALES AREA.27. REPLACE DAMAGED/DISCOLORED CEILING TILES TO MATCH EXISTING.28. CEILING TILES TO HAVE HOLD DOWN CLIPS REF SPECS29. IN AREA OF REMOVED SMOKERS BREAKROOM, RE-LAYOUT CEILING GRID TO LINE UP WITH CEILING GRID OF BREAKROOM.30. PAINT EXPOSED HVAC DUCT WORK AND PLENUMS P33.31. WHERE UNPAINTED ROOF STRUCTURE, DECK, CONDUIT, AND FIRE SPRINKLER PIPING (FIRE SPRINKLER HEADS TO REMAINUNPAINTED) HAVE BEEN EXPOSED IN SALES AND/OR GROCERY SALES AREA BY OTHER PORTIONS OF THE OVERALL SCOPE OFWORK, PAINT TO MATCH EXISTING ITEMS OF SAME TYPE32. INSTALL ACCESS DOOR AND FRAME IN HARD CEILING33. PAINT ALL AIR DIFFUSERS34. REPAIR FLOORING TO MATCH ADJACENT35. CAULK BASE AT WALL AND FLOOR36. REPAIR EXISTING COVE BASE37. REFER TO SHEET GA2 FOR COVE BASE INSTALLATION DETAILS38. REMOVE ADJUSTABLE COUNTER SUPPORTS AND INSTALL PIPE SUPPORTS. REF 2-A939. AT MAIN JANITOR CLOSET EXTEND PLYWOOD TO 8'-0" AND PROVIDE 8'-0" FRP1 PANEL ON ALL WALL(S).40. INSTALL NEW CART RAIL(S). LOCATION TO BE DETERMINED BY FINAL MERCHANDISE PLAN.41. REPLACE DAMAGED SLIDING GLASS AND HARDWARE ON WALL OPENING PASS-THRU.42. RE-LAMINATE SILL(S) AT WINDOW LOCATIONS WITH PL20.43. PROVIDE 8'-0" FRP1 PANEL ON ALL GYP WALL(S).44. CAULK ALL MIRRORS, SINKS, AND TOILETS.45. PROPERLY SEAL ALL NEW PENETRATIONS IN EXISTING FIREWALLS TO MAINTAIN FIRE RATING.46. CLEAN METAL SOFFIT PANELS.47. CONTRACTOR TO REMOVE EXISTING DOOR, FRAME, HARDWARE, CMU AND STRUCTURE AS REQUIRED TO CREATE NEW 10'-0"X 10'-0" OPENING. REF STRUCTURAL.48. REPLACE DAMAGED, MISSING, OR BENT TRUSSES, CROSS BRACES, COLUMNS AND CAPS. MATCH EXISTING TO REMAIN.49. POWER WASH UNDERSIDE OF CANOPY. REMOVE ALL BIRD NESTS AND REPLACE MISSING OR DAMAGED PREMOLDEDCLOSURE STRIPS.50. INSTALL PREMOLDED CLOSURE STRIPS AT BOTH SIDES OF CANOPY, END TO END, AND ABOVE CANOPY LIGHTING.51. PAINT ALL STEEL COLUMNS AND STEEL CANOPY STRUCTURE TO MATCH ADJACENT WALL. PAINT UNDERSIDE OF CANOPY P33.IF STEEL CANOPY HAS NOT PREVIOUSLY BEEN PAINTED - DO NOT PAINT.52. PIECE REPLACE VCT FLOORING AS DIRECTED BY WALMART CONSTRUCTION MANAGER53. REMOVE FRP AROUND COMPACTOR DOOR OPENING. PAINT P16 TO 8'-0" AFF, 8'-0" WIDE.54. PAINT BATTERY/TIRE STORAGE AREA INCLUDING CANOPY, COLUMNS AND BEAM TO MATCH EXTERIOR COLOR SCHEME. DONOT PAINT FENCE OR PLASTIC SLATS IF APPLICABLE. IF STEEL CANOPY DECKING HAS NOT PREVIOUSLY BEEN PAINTED - DO NOTPAINT.55. ALIGN NEW CEILING GRID WITH ADJACENT.56. PAINT HAND RAILS ENTIRELY AND STAIRS DOWN TO THE BULK HEAD P5.57. INSTALL 2X10 WOOD BASE W/CHAMFERED TOP TO ALL NON-CMU WALLS. DO NOT PAINT.58. STOP PLYWOOD SUBSTRATE AT 10'-0" AFF59. CARPET OR ENTRY TILE TRANSITION STRIP FURNISHED BY WALMART, INSTALLED BY GC60. INSTALL FLOOR MAT SYSTEM.61. INSTALL PROTECTIVE SURFACE WAINSCOT AS INDICATED ON PLANS. DO NOT INSTALL ON BLOCK WALLS.62. CARPETING INSTALLED IN PHARMACY WORK AREA AND PHARMACY CHECKOUT PER MANUFACTURERS RECOMMENDATIONS.63. CLEAN FRP WALLS.64. REPLACE OAK CAP ON HALF WALL WITH SOLID SURFACE MATERIAL.65. INSTALL BASE DB10 UNDER COOLER DOORS ENTIRE LENGTH OF RUN. INSTALL PL4 TO 48" ON WALLS AT SIDE OF COOLERDOORS.66. PRIME WALLS, DO NOT PAINT67. INSTALL 5" DIA. 48" LONG PVC TUBE W/SCREW CAP FOR REMODEL PLAN STORAGE. MOUNT INSIDE EDC #1 - IN ADDITION TOEXISTING TUBE.68. REMOVE EXISTING FLOOR TILE AND INSTALL NEW AS SCHEDULED69. REPLACE DAMAGED PIECES OF EXISTING SANITARY FLOOR MOLDING AS REQUIRED70. INSTALL 5/8" IMPACT RESISTANT GYPSUM BOARD TO 48" AFF.71. PROPERLY SEAL ALL EXISTING PENETRATIONS IN EXISTING FIREWALLS TO ACHIEVE X HOUR RATING.72. PAINT FLOOR P5. PAINT PATTERN TO MATCH EXISTING.73. PAINT PLYWOOD WAINSCOT AND WOOD BASE P76 BLUE.74. PAINT PLYWOOD WAINSCOT AND WOOD BASE P106 YELLOW.75. CLEAN ALL MECHANICAL AND ELECTRICAL CAGES AND ROOMS.76. NOT USED.77. AT MOPSINK PROVIDE 8'-0"x8'-0" FRP1 PANEL ON WALL(S) BEHIND MOPSINK. IF MOPSINK IN CORNER, PROVIDE 8'-0"x8'-0" FRP1ON BOTH WALL SURFACES. DOES NOT APPLY AT SIDE(S) OF MOPSINK ADJACENT TO COOLER PANEL(S).78. PAINT CUSTOMER WALKWAY P16 TO 8'-0" AFF, DO NOT PAINT ABOVE.GENERAL NOTESC/A070-SGN1. PAINT ALL METAL DOOR FRAMES VISIBLE TO CUSTOMER (EXCEPT DOORS IN CMU WALLS) WITH EPOXY PAINT. PAINT ALL METALDOORS AND METAL FRAMES TO MATCH ADJACENT WALLS UNO. WHERE ADJACENT WALLS ARE UNFINISHED PAINT METAL DOORSAND METAL FRAMES P33 UNO.2. WHEN PIECE REPLACING CEILING TILE GC TO MATCH NEW TILE TO ADJACENT SURROUNDING CEILING TILE.3. INSTALL MISSING CEILING TILES IN ALL ROOMS WHERE LAY-IN CEILING TILE IS ETR.MATERIAL KEYMARKABCDEETRFGHJMNPQTDESCRIPTIONCONCRETEGLASS AND ALUMINUM FRAMESMOOTH FACE CMUSPLIT FACE CMUCHAIN LINKEXISTING TO REMAINEXPOSED STRUCTUREGYPSUM BOARDMETAL SOFFITSHADECLOTHPLYWOODORNAMENTAL FENCECOOLER/FREEZER PANELTRANSLUCENT WALL PANELFIBERGLASS ROOF PANELSGLASS-MAT BACKER MATERIALFINISH KEYREF SPECIFICATIONS FOR EXACT COLORS REQUIREDMARK FINISH COLOR DESCRIPTIONACT1 ACOUSTICAL CEILING TILE WHITE 24"x48"ACT2 ACOUSTICAL CEILING TILE WHITE 24"x48" VINYL FACED NON-PERFORATEDACT3 ACOUSTICAL CEILING TILE WHITE 24"x48"ACT4 ACOUSTICAL CEILING TILE WHITE 24"x48"ACTG ACOUSTICAL CEILING GRID WHITEB4 RESILIENT BASE BLACK 4"B6 PLASTIC BASE BLACK6"x 1/4"B9 PLASTIC BASEBLACK4"x 1/4"B10 PLASTIC BASE OUTSIDE CORNER BLACKC1C3CCP5TCWBCUSHION BACK TILE CARPETCONCRETE CURBCT2 ENTRY TILERED12"x 24"x 3/8"CT6 GLAZED WALL TILE MEDIUM TAN6"x6"x5/16"CT9 ACCENT TILE LIGHT BROWN6"x6x3/8"6"x6"x5/16"6"x6"x5/16"CT10 GLAZED WALL TILE DARK BLUECT12 GLAZED WALL TILE LIGHT TANCT13 PORCELAIN TILE BROWNCT15 GLAZED WALL TILE BLACKCT16CT17CT19ECFRP2G5ICCMOSAIC FLOOR TILEGLAZED WALL TILEEXPOSED CONCRETEFIBERGLASS REINFORCED PLASTICGROUTINTEGRAL COLORED CONCRETEPAINTPL15 PLASTIC LAMINATE BROWNPL20 PLASTIC LAMINATE TANTEXTURED CONCRETE2x8 WOOD BASETANALMONDDB5 DURA-TUFF BASE BLACK 5"DB10 DURA-TUFF BASE BLACK 10"BEIGEG1 GROUT DARK GRAYG2 GROUT DARK GRAYG3G13G14P4PF4GROUTGROUTPAINTPREFINISHED METALIVORYBEIGEMUSHROOMBROWNDARK ZINCPL18 PLASTIC LAMINATE MEDIUM TANPVC1 PVC PLANK FLOORING WOODGRAINSST1SCB1SCB2SCB4SCB5PORCELAIN TILEGROUTSOLID SURFACESANITARY COVE BASESANITARY COVE BASESANITARY COVE BASESANITARY COVE BASEIVORYLT TANREDGRAYREDGRAYGRAY6"x6"x5/16"3"x3"x5/16"6"x6"x5/16"CT21 CERAMIC FLOOR TILE GRAY2"x 2"CT22 CERAMIC FLOOR TILE GRAY4"X4"ETRFRP1FRP5EXISTING TO REMAING4 GROUT DARK GRAYG6 GROUT SILVERFRP WALL PANELFRP7 FIBERGLASS REINFORCED PLASTIC GRAY FRP WALL PANELG7 GROUT BROWNP8 PAINT "PURE WHITE" # 7005P12 PAINT "BISCUIT" # 6112P16 PAINT"SOFTWARE" #7074P17 PAINT"ROW HOUSE TAN" #7689P18 PAINT"GRIZZLE GRAY" #7068P23 PAINT"PURE WHITE" #7005P33 PAINT"DOVER WHITE" #6385P36 PAINT"DOMINO" #6989P37 PAINT"WHITE HYACINTH" #0046P40 PAINT"GARDENIA" #6665P41 PAINT"PRACTICAL BEIGE" #6100P76 PAINT"MEDIUM WALMART BLUE" #076P81 PAINT"TRICOM BLACK" #6258P83 PAINT"COBBLE BROWN" #6082P88 PAINT"ROOKWOOD CLAY" #2823P93 PAINT"TAMARIND" #7538P94P98 PAINT"OAK CREEK" #7718P100 PAINT"NOTABLE HUE" #6521P102 PAINT"BEACH HOUSE" #7518P103 PAINT"TOASTY" #6095P105 PAINT"ICELANDIC" #6526P106 PAINT"AFTERNOON" #6675P107 PAINT"STRAW HARVEST" #7698PL4 PLASTIC LAMINATE MAPLEPL8 PLASTIC LAMINATE SANDPL9QT3 QUARRY TILE GRAY 6"X6" ABRASIVEQT31 QUARRY TILE RED 6"X6" ABRASIVERF1 RESINOUS FLOOR GRAYRF2 RESINOUS FLOOR REDVCT9 VINYL COMPOSITION TILE WHITE12"x12"x1/8"VCT11 VINYL COMPOSITION TILE BEIGE12"x12"x1/8"VCT12 VINYL COMPOSITION TILE TAN12"x12"x1/8"WB10FIBERGLASS REINFORCED PLASTICFIBERGLASS REINFORCED PLASTICG10 GROUT REDPAINTPLASTIC LAMINATE2x10 WOOD BASEWHITEALMOND"THEATER RED" #1602DARK GRAYPL12 PLASTIC LAMINATE BLACKPL19 PLASTIC LAMINATE CHAMPAGNEPL23 PLASTIC LAMINATE DARK GRAYPS1 PROTECTIVE SURFACE WALMART BLUESSCUSHION BACK TILE CARPETSTAINLESS STEELWG PLASTIC WALL GUARD BLACK OR GRAY"SAFETY YELLOW" OSHA STANDARD"EXTERIOR DROMEDARY CAMEL" #7694 (EXT)SVP1 SOLID VINYL PLANK FLOORING STRIP BAMBOO CARAMELREF SPECSREF SPECSFRP WALL PANELFRP WALL PANELNRP2 {NON-FIBERGLASS REINFORCED PLASTIC} ALMOND NRP WALL PANELPL6 PLASTIC LAMINATE LIGHT TANPL28 PLASTIC LAMINATE ALOEFINISH KEY:ADD C38" H ANTIMICROBIAL PLASTIC FOR QT8" H ANTIMICROBIAL PLASTIC FOR QT8" H ANTIMICROBIAL PLASTIC8" H ANTIMICROBIAL PLASTICBROOM FINISH SCHEDULERM # ROOM NAMEPLAN FLOOR WALL CEILINGS NOTESREFERENCECD ORIENTATIONA B C DAFINISH BASE MAT FINISH BASE MAT FINISH BASE MAT FINISH BASE MAT FINISH MAT FINISH HEIGHT093 FIXTURE STORAGE ETR --- ETR P94 --- ETR --- --- ETR --- --- ETR --- --- --- --- ---094 ROOF STAIRCASE CAGE ETR --- ETR P88 --- ETR --- --- ETR --- --- ETR --- --- --- --- ---100 SALES ETR REF A1.2 ETR REF A1.2 REF A1.2 ETR,G REF A1.2 --- --- --- REF A1.2 ETR REF A1.2 ETR --- ETR 10, 11, 12, 16,22, 30, 31, 52,61, 79101 VESTIBULE-GM C3 --- B --- --- B --- DB5 ETR P105 DB5 ETR P105 ACT4 --- ETR ---102 JANITOR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---103 OTHER INCOME-GM C3 DB5 ETR P105 DB5 ETR P105 DB5 ETR P105 DB5 ETR P105 ACT4 --- ETR 3, 28104 CART STORAGE-GM ETR ETR ETR P105 ETR ETR P105 --- ETR P105 ETR ETR P105 ACT4 --- ETR 3, 28105 COURTESY DESK ETR DB5 ETR P105, PS1 DB5 ETR P105, PS1 DB5 ETR P105, PS1 DB5 ETR P105, PS1 ACT1 --- ETR 3, 52, 61107 CASH ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ---108 COUNT ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ---110 FIRE CORRIDOR ETR ETR ETR ETR ETR ETR ETR ETR ETR, G ETR ETR ETR ETR ETR --- ETR 45, 71111 CUSTOMER MEN ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR P33 ETR 5, 17, 25, 44112 CUSTOMER WOMEN ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR P33 ETR 5, 17, 25, 44113 ALCOVE ETR DB5 ETR P105, PS1 --- --- --- DB5 ETR P105, PS1 DB5 ETR P105, PS1 ACT1 --- ETR 3, 52, 61115 VESTIBULE-GR C3 --- B --- --- B --- DB5 ETR P105 --- ETR P105 ACT4 --- ETR 3, 28116 ELECTRICAL ROOM-2 ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---117 OTHER INCOME-GR C3 DB5 ETR P105 DB5 ETR P105 DB5 ETR P105 DB5 ETR P105 ACT4 --- ETR 3, 28118 CART STORAGE-GR ETR ETR ETR P105 ETR ETR P105 --- ETR P105 --- ETR P105 ACT4 --- ETR 3, 28119 AP OFFICE ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---121 AP RETENTION ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---122 ELECTRICAL ROOM-3 ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---126 SEASONAL SHOP ETR --- ETR P105 --- ETR P105 --- ETR P105 --- ETR P105 ETR --- ETR 10, 30, 31, 79133 ALCOVE ETR --- --- --- DB5 ETR P105, PS1 DB5 ETR P105, PS1 DB5 ETR P105, PS1 ETR P33 ETR 25, 52, 61145 ASSOCIATE MEN ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---146 ASSOCIATE WOMEN ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---150 FIRE CORRIDOR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR 45, 71151 BREAKROOM ETR ETR ETR ETR, P105 ETR ETR ETR, P105 ETR ETR ETR, P105 ETR ETR ETR, P105 ETR --- ETR 2, 27, 52152 BREAKROOM ETR ETR ETR ETR, P105 ETR ETR ETR, P105 ETR ETR ETR, P105 ETR ETR ETR, P105 ETR --- ETR 2, 27, 52154 ELECTRICAL ROOM-1 ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR 67155 PHARMACY STORAGE ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---157 CORRIDOR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---158 JANITOR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---159 SPRINKLER ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---160 CLAIMS ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---162 FIRE CORRIDOR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR 45, 71, 72163 SITE TO STORE ETR DB5 ETR P105, PS1 DB5 ETR P105, PS1 DB5 ETR P105, PS1 DB5 ETR P105, PS1 ACT1 --- ETR 3, 52, 61164 ALCOVE ETR DB5 ETR P105, PS1 DB5 ETR P105, PS1 --- --- --- DB5 ETR P105, PS1 ETR P33 ETR 25, 52, 61165 CUSTOMER MEN ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR P33 ETR 5, 17, 25, 44166 CUSTOMER WOMEN ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR P33 ETR 5, 17, 25, 44168 PHOTO STORAGE ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---171 UPC/INVOICING ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---172 TRAINING ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR 38174 MARKET MANAGERS OFFICE ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR 38175 MANAGEMENT ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR 38176 FIRE CORRIDOR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR 45,71177 MANAGERS OFFICE ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR 38178 RECEIVING-GM ETR --- ETR --- --- ETR --- --- --- --- --- ETR --- ETR --- ETR 53179 STOCKROOM ETR --- ETR --- --- ETR --- --- ETR --- --- --- --- ETR --- ETR ---180 STOCKROOM ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---186 SECURITY ROOM ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---187 FIXTURES ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---PHARMACY300 PHARMACY C1 B9 ETR P40 B9 ETR P40 B9 ETR P40 B9 ETR P40 ACT1 --- ETR 3304 PHARMACY STORAGE ETR B9 ETR P40 B9 ETR P40 B9 ETR P40 B9 ETR P40 ETR --- ETR 2, 27, 52FOOD SERVICE TENANT401 UTILITY ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---402 DINING AREA ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---404 SERVICE AREA ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---GARDEN CENTER501 GARDEN CENTER ETR --- ETR --- --- ETR P88, P94 --- ETR P88 --- ETR P88 P94 --- --- --- 49AUTO CENTER600 LUBE & TIRE MOUNTING AREA ETR --- ETR ETR --- ETR ETR --- ETR ETR --- ETR ETR ETR --- ETR ---601 TOILET ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---602 ELECTRICAL ROOM-4 ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---603 SECURITY ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---604 CUSTOMER SERVICE ETR DB5 ETR P105, PS1 DB5 ETR P105 DB5 ETR P105 DB5 ETR P105 ACT1 --- ETR 3, 4, 52, 61605 STORAGE ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---609 LUBE PIT ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR 56610 TIRE/BATTERY STORAGE ETR, A --- ETR --- --- ETR, C --- --- ETR --- --- ETR, E --- ETR --- ETR 54611 CUSTOMER WALKWAY ETR --- ETR P16 --- ETR P16 --- ETR P16 ETR ETR --- ETR --- ETR 78614 ENVIRONMENTAL CAGE ETR --- ETR --- --- ETR --- --- E --- --- ETR --- ETR --- ETR 54VISION CENTER700 OPTICAL SALES ETR B9 ETR P40 B9 ETR P40 B9 ETR P40 B9 ETR P40 ETR --- ETR 2, 27, 34701 ADJUSTMENTS ETR B9 ETR P40 B9 ETR P40 B9 ETR P40 B9 ETR P40 ETR --- ETR 2, 27, 34702 CONTACTS ETR B9 ETR P40 B9 ETR P40 B9 ETR P40 B9 ETR P40 ETR --- ETR 2, 27, 34703 PRETEST ETR B9 ETR P40 B9 ETR P40 B9 ETR P40 B9 ETR P40 ETR --- ETR 2, 27, 34704 RECORD RETENTION ETR B9 ETR P40 B9 ETR P40 B9 ETR P40 B9 ETR P40 ETR --- ETR 2, 27, 34705 EXAM #1 ETR B9 ETR P40 B9 ETR P40 B9 ETR P40 B9 ETR P40 ETR --- ETR 2, 27, 34706 EXAM #2 ETR B9 ETR P40 B9 ETR P40 B9 ETR P40 B9 ETR P40 ETR --- ETR 2, 27, 34707 WAITING ETR B9 ETR P40 B9 ETR P40 B9 ETR P40 --- --- --- ETR --- ETR 2, 27, 34709 STORAGE ETR B9 ETR P40 B9 ETR P40 B9 ETR P40 B9 ETR P40 ETR --- ETR 2, 27, 34713 HALLWAY ETR B9 ETR P40 B9 ETR P40 B9 ETR P40 B9 ETR P40 ETR --- ETR 2, 27, 34TENANTS800 BANK ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---802 PICTURE ME ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---803 REGAL NAILS ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---804 FLORAL ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---HAIR CARE809 CLOSET ETR --- ETR ETR --- ETR ETR --- ETR ETR --- ETR ETR ETR --- ETR ---810 SALON ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---811 UTILITY ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---812 STORAGE ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---GROCERY900 GROCERY SALES ETR REF A1.3 ETR REF A1.3 REF A1.3 ETR REF A1.3 REF A1.3 ETR REF A1.3 REF A1.3 ETR REF A1.3 ETR --- ETR 10, 11, 12, 16,22, 30, 31, 52,65, 79901 SERVICE DELI ETR SCB5 ETR FRP2, P106 SCB5 ETR FRP2 SCB5 ETR FRP2 SCB5 ETR FRP2, P106 ACT2 --- ETR 3, 34, 35, 37902 DELI PREP ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR 2, 21, 27, 34,35, 63, 69906 BAKERY ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR 2, 21, 27, 34,35, 63, 69907 DEPARTMENT 82 ROOM ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---908 MEAT HOLDING ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR 34, 35, 69909 PRODUCE PREP ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ACT2 --- ETR 3, 21, 35, 63,69912 MEAT PREP ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR 34, 35, 69914 SEAFOOD ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---916 STOCKROOM ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---917 PLUMBING/MECHANICAL ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---918 FIRE CORRIDOR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR 45, 71, 72920 RECEIVING-GR ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR 53922 ELECTRICAL ROOM-5 ETR --- ETR --- --- ETR --- --- ETR --- --- ETR --- ETR --- ETR ---926 HALLWAY ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR ETR --- ETR ---935 CAKE DECORATING ETR SCB5 ETR FRP2 --- ETR P106 SCB5 ETR FRP2 SCB5 ETR FRP2 ACT2 --- ETR 3, 34, 35, 37STIPULATION FOR REUSEISSUE BLOCKCHECKED BY:DRAWN BY:PROTO:710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209PROTO CYCLE:Architect of RecordBradley J. PhillipsDOCUMENT DATE:STORE NO.GENERAL REMODELJOB NUMBER:18811-19-1002-09-11PRINTED: 8/4/2011 3:26 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 11:38 AM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\a070.dwgROOM FINISH SCHEDULE:REVISED ROOMS 093, 101, 126, 604, 909, 935ADDED ROOM 177NOT FORCONSTRUCTIONSHEET:

DOOR SCHEDULEDETAIL REFERENCES ARE TO SHEET A8.1 UNOPRINTED: 8/4/2011 3:27 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 11:43 AM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\a080.dwg3'-6"2"2"5"N12"HOLLOW METALC\a080-01NARROW LITEC\a080-DRNSLIDE6"3'-7"1'-8"AFFMAX4" 2" 2"SLIDEAAAUTOMATIC SLIDING SO-SX-SX-SOC\a080-DRAA2HOLLOW METALC\a080-022"S12"MOTION DETECTOR TYPMUNTIN BARSECTIONAL OVERHEADC\a080-DRS13HOLLOW METALC\a080-032" CRASH BARS AT 6" AND 24" TYP10" BOTTOM STILES TYP3'-6"2"4"2"SLIDES34"4HOLLOW METALC\a080-04SLIDEBBAUTOMATIC SLIDING SO-SX-SX-SOC\a080-DRBBSECTIONAL OVERHEADC\a080-DRS32"4"U2"MOTION DETECTOR TYP1/4" TEMPERED GLASS TYPMUNTIN BAR2" CRASH BARS AT 6" AND 24" TYP10" BOTTOM STILES TYPCOILINGC\a080-DRU3'-7"8HOLLOW METALC\a080-0082"EFLEXIBLE TRAFFICC\a080-DREU1COILINGC\a080-DRU1CLEAR VIEW VISION PANEL5"x18" STEEL JAMB GUARDS2'-0" HIGH IMPACT BUMPER ON EACH SIDE OF DOORFFLUSHC\a080-DRFCHAIN LINKC\a080-DRV3'-0"3'-6"AFFMAX6" 6"GHALF GLASSC\a080-DRGORNAMENTAL FENCEC/A080-DRVV112808GENERAL NOTES:REMOVE 1-4COILING SHUTTERPFLUSH PASS-THRUC\a080-DRP8"W3(MAX.)ORNAMENTAL1. SCHEDULED WIDTH AND HEIGHT INDICATEFINISHED OPENING SIZE.2. AUTOMATIC SLIDING DOOR. SCHEDULEDWIDTH AND HEIGHT INDICATE ROUGH OPENINGSIZE.3. SIGNAGE: PROVIDE 1" HIGH LETTERS INCONTRASTING COLORS TO BACKGROUND, TEXTTO READ "THIS DOOR TO REMAIN UNLOCKEDDURING BUSINESS HOURS". SIGNAGEFURNISHED BY WALMART AND INSTALLED BYGENERAL CONTRACTOR.4. INSTALL SECTIONAL DOOR TRACK RETURN ATMAXIMUM HEIGHT AND AND AS CLOSE TO ROOFSTRUCTURE AS ALLOWABLE BY MANUFACTURER.5. INSTALL/REPLACE FLEXIBLE STRIP DOOR.6. DOOR COLOR TO BE BLACK7. SIGNAGE: PROVIDE 1" HIGH LETTERS INCONTRASTING COLORS TO BACKGROUND, TEXTTO READ "IN EMERGENCY PUSH TO OPEN".8. FULLY GASKETED FOR NEUTRALIZATION.9. DOOR, FRAME AND HARDWARE BYCONTRACTOR. SUB-FRAME BY CANOPYMANUFACTURER.10. PROVIDE VENDOR WITH FIELD DIMENSION OFCLEAR WIDTH AFTER REFRIGERATED CASES HAVEBEEN INSTALLED.11. NOT USED12. PROVIDE 1" CLEARANCE BETWEEN EDGE OFSTRIKE SIDE OF DOOR AND ADJACENTCASEWORK.13. NOT USED14. REPAIR AND ADJUST EXISTING DOOR TRACKSAND ALL ACCESSORIES.15. NOT USED{16. NOT USED}17. REPLACE BROKEN, MISSING, OR DAMAGEDGLASS.18. REMOVE EXISTING DOOR AND HARDWARE.EXISTING FRAME TO REMAIN. INSTALL HINGEFILLER PLATE AND STRIKE FILLER PLATE INHOLLOW METAL FRAME.19. WELDED FRAME20. REPLACE DAMAGED SECTIONAL DOORPANELS.21. REPAIR EXISTING DOOR.22. FLEXIBLE TRAFFIC DOOR COLOR TO BE KHAKI.PAINT DOOR FRAME P17.23. NOT USED.24. FLEXIBLE TRAFFIC DOOR COLOR TO BEBLACK. PAINT DOOR FRAME TO MATCH ADJACENTWALL.25. PROVIDE TACTILE "EXIT" SIGN, REF N126. NOT USED27. NOT USED28. NOT USED29. NOT USED30. REPAIR DAMAGED GATE.31. REMOVE DOOR CLOSER. PATCH AS NEEDED.32. ENLARGE DOCK DOOR OPENING. INSTALLNEW SEALS.33. INSTALL/REPLACE STOP. REF SPEC34. INSTALL 5"X20" WINDOW IN DOOR.35. INSTALL/REPLACE ALL DOOR HARDWARE. REFSPEC36. INSTALL/REPLACE EXIT DEVICE OR EXITALARM. REF SPEC37. INSTALL/REPLACE ONE-WAY VIEWER. REFSPEC38. ENSURE GATE IS OPERATIONAL ANDLATCHES.39. REPAIR DAMAGED EXTERIOR WALL CORNERSAT ROLL DOOR OPENINGS.40. INSTALL/REPLACE ELECTROMAGNETIC DOORHOLDER(S). REF SPEC41. INSTALL/REPLACE BUTTS. REF SPEC42. INSTALL/REPLACE CYLINDER(S), THUMBTURN,LOCK, LATCH AND/OR DEADLOCK. REF SPEC43. INSTALL/REPLACE PUSH AND/OR PULL. REFSPEC44. INSTALL/REPLACE THRESHOLD. REF SPEC45. INSTALL/REPLACE SAFETY HASP AND STAPLE.REF SPEC46. INSTALL/REPLACE SURFACE BOLT(S). REFSPEC47. INSTALL/REPLACE FLUSH BOLT(S). REF SPEC48. INSTALL/REPLACE DRIP CAP. REF SPEC49. INSTALL/REPLACE DOOR COORDINATOR. REFSPEC50. INSTALL/REPLACE DOOR ALARM ANDCYLINDER. REF SPEC51. INSTALL/REPLACE ELECTROMAGNETIC LOCK.REF SPEC52. INSTALL/REPLACE CLOSER. REF SPEC53. INSTALL/REPLACE LOCK GUARD. REF SPEC54. INSTALL/REPLACE ARMOR PLATE AND/ORKICKPLATE55. REPAIR DOOR, TRACK AND ACCESSORIES TOLIKE-NEW CONDITION56. INSTALL/REPLACE DEADBOLT LOCK. REFSPEC57. INSTALL/REPLACE DOOR HOLDER. REF SPEC58. INSTALL/REPLACE CONTINUOUS GEARED1. NOT USED.2. NOT USED.3. NOT USED.4. NOT USED.5. INSTALL/REPLACE ALL WEATHERSTRIPPING AND GASKETSAT ALL EXTERIOR HOLLOW METAL DOORS. REF SPEC6. ALL DOORS SCHEDULED AS NEW ARE TO RECEIVECOMPLETE NEW HARDWARE SETS AS LISTED INSPECIFICATIONS.7. INSTALL/REPLACE REINFORCING PIVOT AT ALL INTERIORHOLLOW METAL DOOR LOCATIONS WHERE MISSING ORBROKEN.8. ALL UL RATED DOORS MUST HAVE UL LABELS IN PLAINSIGHT AND BE LEGIBLE. IF EXISTING LABELS HAVE BEENPAINTED OVER, TEST PAINT REMOVAL IN ONE LOCATION. IFPAINT REMOVAL DAMAGES UL LABEL, CONTACT CM FORFURTHER DIRECTION. IF TEST UL LABEL IS NOT DAMAGEDFROM PAINT REMOVAL, REMOVE PAINT FROM ALL UL LABELS.9. AT EXTERIOR HOLLOW METAL DOORS, ENSURE EXITDEVICE/ALARM IS WORKING PROPERLY10. AT ALL DOORS IMMEDIATELY ADJACENT TO CUSTOMERAREAS, ADJUST EXISTING DOOR HARDWARE TO PROPERWORKING CONDITION.MATERIAL KEYMARKACRYLALALUMCLHM-STLOMPLASTSTLSTL-PSTL-BPTEMP{ROLLERS BY GATE MFR. }DESCRIPTIONACRYLICALUMINUM LINKALUMINUMCHAIN LINKHOLLOW METAL-STEELORNAMENTAL METALPLASTICSTEEL{ORNAMENTAL METAL GATE}STEEL PIPESTEEL BENT PLATETEMPEREDSLIDEXSIDE FOLDING GRILLEC/A080-DRX112604C/A080-FKEYSIDE FOLDING GRILLE (SEEDOOR SCHEDULE FOR SINGLE ORBI-PARTING)MARK ROOM NAME DOOR FRAME FIRERATINGNEW/ TYPE MATERIAL COLOR QTY NOMINAL SIZE GLASS NEW/ TYPE MATERIAL COLOR DETAILS(MIN)ETRETRW H T HEAD JAMB THRESHOLD093A FIXTURE STORAGE ETR V CL --- PR 3'-6' 8'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 093A094A ROOF STAIRCASE CAGE ETR V CL --- 1 4'-0' 8'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 094A100A SALES ETR F HM-STL P105 2 3'-0" 7'-0" 1 3/4" --- ETR 4 HM-STL P105 --- --- --- --- 25 100A100B SALES ETR F HM-STL P105 2 3'-0" 7'-0" 1 3/4" --- ETR 4 HM-STL P105 --- --- --- --- 25 100B100C SALES ETR F HM-STL P105 2 3'-0" 7'-0" 1 3/4" --- ETR 4 HM-STL P105 --- --- --- --- 25 100C100D SALES ETR F HM-STL P105 2 3'-0" 7'-0" 1 3/4"" --- ETR 4 HM-STL P105 --- --- --- --- 25 100D101A VESTIBULE-GM NEW BB ALUM --- 1 12'-0" 10'-0" 1 1/2" TEMP NEW --- ALUM --- 6 5 3 --- 2, 3, 7 101A101B VESTIBULE-GM NEW BB ALUM --- 1 12'-0" 10'-0" 1 1/2" TEMP NEW --- ALUM --- 6 5 3 --- 2, 3, 7 101B101C VESTIBULE-GM NEW BB ALUM --- 1 12'-0" 10'-0" 1 1/2" TEMP NEW --- ALUM --- 6 5 4 --- 2, 3, 7 101C101D VESTIBULE-GM NEW BB ALUM --- 1 12'-0" 10'-0" 1 1/2" TEMP NEW --- ALUM --- 6 5 4 --- 2, 3, 7 101D102A JANITOR ETR F HM-STL P16 1 4'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL P16 --- --- --- --- 59 102A104A CART STORAGE-GM ETR S1 STL --- 1 16'-0" 4'-8" --- --- ETR --- STL --- --- --- --- --- 1, 5 104A107A CASH ETR F HM-STL --- 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL --- --- --- --- --- --- 107A108A COUNT ETR F HM-STL P16 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL P16 --- --- --- --- 59 108A110B FIRE CORRIDOR ETR F HM-STL --- 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL --- --- --- --- --- 25 110B110F FIRE CORRIDOR ETR N HM-STL P16 1 3'-0" 7'-0" 1 3/4" RATED ETR 1 HM-STL P16 --- --- --- 1 HR 25, 59 110F111A CUSTOMER MEN ETR F HM-STL REF 4-A1.2 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL REF 4-A1.2 --- --- --- --- 52, 58, 59 111A112A CUSTOMER WOMEN ETR F HM-STL REF 4-A1.2 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL REF 4-A1.2 --- --- --- --- 52, 58, 59 112A115A VESTIBULE-GR NEW BB ALUM --- 1 12'-0" 10'-0" 1 1/2" TEMP NEW --- ALUM --- 6 5 3 --- 2, 3, 7 115A115B VESTIBULE-GR NEW BB ALUM --- 1 12'-0" 10'-0" 1 1/2" TEMP NEW --- ALUM --- 6 5 3 --- 2, 3, 7 115B115C VESTIBULE-GR NEW BB ALUM --- 1 12'-0" 10'-0" 1 1/2" TEMP NEW --- ALUM --- 6 5 4 --- 2, 3, 7 115C115D VESTIBULE-GR NEW BB ALUM --- 1 12'-0" 10'-0" 1 1/2" TEMP NEW --- ALUM --- 6 5 4 --- 2, 3, 7 115D116B ELECTRICAL ROOM-2 ETR F HM-STL P105 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL P105 --- --- --- --- 59 116B118A CART STORAGE-GR ETR S1 STL --- 1 16'-0" 4'-8" --- --- ETR --- STL --- --- --- --- --- 1, 5 118A119A AP OFFICE ETR N HM-STL --- 1 3'-0" 7'-0" 1 3/4" TEMP ETR 1 HM-STL --- --- --- --- --- --- 119A121A AP RETENTION ETR F HM-STL --- 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL --- --- --- --- --- --- 121A122C ELECTRICAL ROOM-3 ETR F HM-STL P105 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL P105 --- --- --- --- 59 122C126A SEASONAL SHOP NEW AA ALUM --- 1 12'-0" 7'-4" 1 1/2" TEMP NEW --- ALUM --- 7 5 8 --- 2, 3, 7, 25 126A126B SEASONAL SHOP ETR F HM-STL P105 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL P105 --- --- --- --- 25 126B126C SEASONAL SHOP ETR F HM-STL P105 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL P105 --- --- --- --- 25 126C126D SEASONAL SHOP ETR S1 STL --- 1 6'-0" 8'-8" --- --- ETR --- --- --- --- --- --- --- 1 126D145A ASSOCIATE MEN ETR F HM-STL P105 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL P105 --- --- --- --- --- 145A146A ASSOCIATE WOMEN ETR F HM-STL P105 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL P105 --- --- --- --- --- 146A150A FIRE CORRIDOR ETR F HM-STL --- 2 3'-0" 7'-0" 1 3/4" --- ETR 4 HM-STL --- --- --- --- --- 25 150A150M FIRE CORRIDOR ETR U STL --- 1 8'-0" 9'-0" --- --- ETR --- --- --- --- --- --- 1 HR 1 150M150N FIRE CORRIDOR ETR N HM-STL --- 1 3'-0" 7'-0" 1 3/4" RATED ETR 1 HM-STL --- --- --- --- 1 HR 25 150N150P FIRE CORRIDOR NEW F HM-STL P16 PR 3'-0" 7'-0" 1 3/4" --- NEW 3 HM-STL P16 14 13 --- 1 HR 25 150P150Q FIRE CORRIDOR ETR F HM-STL --- PR 3'-0" 7'-0" 1 3/4" --- ETR 3 HM-STL --- --- --- --- 1 HR 25, 36 150Q151F BREAKROOM ETR G HM-STL P16 1 3'-0" 7'-0" 1 3/4" TEMP ETR 1 HM-STL --- --- --- --- --- 59 151F151G BREAKROOM ETR G HM-STL P16 1 3'-0" 7'-0" 1 3/4" TEMP ETR 1 HM-STL P16 --- --- --- --- 52, 59 151G154A ELECTRICAL ROOM-1 ETR V CL --- PR 3'-0" 8'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 154A154C ELECTRICAL ROOM-1 ETR V CL --- 1 3'-0" 8'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 154C155B PHARMACY STORAGE ETR V CL --- 1 3'-0" 8'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 155B157A FIRE CORRIDOR ETR F HM-STL --- 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL --- --- --- --- --- 25 157A158C JANITOR ETR F HM-STL --- PR 2'-0" 7'-0" 1 3/4" --- ETR 3 HM-STL --- --- --- --- --- --- 158C159A SPRINKLER ETR V CL --- 1 3'-0" 8'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 159A160D CLAIMS ETR V CL --- 1 3'-0" 7'-6" --- --- ETR --- STL-P --- --- --- --- --- --- 160D162A FIRE CORRIDOR ETR F HM-STL --- 2 3'-0" 7'-0" 1 3/4" --- ETR 4 HM-STL --- --- --- --- --- 25 162A162D FIRE CORRIDOR NEW F HM-STL P16 PR 3'-0" 7'-0" 1 3/4" --- ETR 3 HM-STL P16 --- --- 1 HR 25 162D162M FIRE CORRIDOR ETR N HM-STL --- 1 3'-0" 7'-0" 1 3/4" RATED ETR 1 HM-STL --- --- --- --- 1 HR 25 162M162N FIRE CORRIDOR ETR U STL --- 1 8'-0" 9'-0" --- --- ETR --- --- --- --- --- --- 1 HR 1 162N163A SITE TO STORE ETR F HM-STL P16 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL P16 --- --- --- --- 52, 59 163A165A CUSTOMER MEN ETR F HM-STL REF 4-A1.2 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL REF 4-A1.2 --- --- --- --- 52, 58, 59 165A166A CUSTOMER WOMEN ETR F HM-STL REF 4-A1.2 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL REF 4-A1.2 --- --- --- --- 52, 58, 59 166A168A PHOTO STORAGE ETR F WOOD --- 1 3'-0" 7'-0" 1 3/4" --- ETR 1 WOOD --- --- --- --- --- --- 168A171A UPC/INVOICING ETR G HM-STL --- 1 3'-0" 7'-0" 1 3/4" TEMP ETR 1 HM-STL --- --- --- --- --- --- 171A171B UPC/INVOICING ETR N HM-STL --- 1 3'-0" 7'-0" 1 3/4" RATED ETR 1 HM-STL --- --- --- --- 1 HR --- 171B171C UPC/INVOICING ETR U STL --- 1 2'-0" 2'-0" --- --- ETR --- --- --- --- --- --- 1 HR 1 171C171D UPC/INVOICING ETR U STL --- 1 2'-0" 2'-0" --- --- ETR --- --- --- --- --- --- 1 HR 1 171D174B MARKET MANAGERS OFFICE ETR F HM-STL --- 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL --- --- --- --- --- --- 174B175A MANAGEMENT ETR N HM-STL --- 1 3'-0" 7'-0" 1 3/4" TEMP ETR 1 HM-STL --- --- --- --- --- --- 175A176A FIRE CORRIDOR ETR F HM-STL --- 2 3'-0" 7'-0" 1 3/4" --- ETR 4 HM-STL --- --- --- --- --- 25 176A176D FIRE CORRIDOR ETR F HM-STL P16 PR 3'-0" 9'-0" 1 3/4" --- ETR 3 HM-STL P16 --- --- --- 1 HR 25 176D176H FIRE CORRIDOR ETR N HM-STL ETR 1 3'-0" 7'-0" 1 3/4" RATED ETR 1 HM-STL ETR --- --- --- 1 HR 17, 25 176H176J FIRE CORRIDOR ETR N HM-STL ETR 1 3'-0" 7'-0" 1 3/4" RATED ETR 1 HM-STL ETR --- --- --- 1 HR 17, 25 176J176K FIRE CORRIDOR ETR U STL --- 1 8'-0" 9'-0" --- --- ETR --- --- --- --- --- --- 1 HR 1 176K176L FIRE CORRIDOR ETR U STL --- 1 8'-0" 9'-0" --- --- ETR --- --- --- --- --- --- 1 HR 1 176L177A MANAGERS OFFICE ETR N HM-STL --- 1 3'-0" 7'-0" 1 3/4" TEMP ETR 1 HM-STL --- --- --- --- --- --- 177A178A RECEIVING-GM ETR F HM-STL --- 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL --- --- --- --- --- 25,37 178A178B RECEIVING-GM ETR S1 STL --- 1 7'-4" 8'-8" --- --- ETR --- STL --- --- --- --- --- 1 178B178C RECEIVING-GM ETR S1 STL --- 1 7'-4" 8'-8" --- --- ETR --- STL --- --- --- --- --- 1 178C178D RECEIVING-GM ETR S1 STL --- 1 7'-4" 8'-8" --- --- ETR --- STL --- --- --- --- --- 1 178D178E RECEIVING-GM ETR S1 STL --- 1 7'-4" 8'-8" --- --- ETR --- STL --- --- --- --- --- 1 178E186A SECURITY ROOM ETR N HM-STL --- 1 3'-0" 7'-0" 1 3/4" TEMP ETR 1 HM-STL --- --- --- --- --- --- 186A187B FIXTURES ETR V CL --- PR 3'-0" 8'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 187BPHARMACY300A PHARMACY ETR P HM-STL P16 1 3'-6" 7'-0" 1 3/4" --- ETR 1 HM-STL P16 --- --- --- --- 59 300A300B PHARMACY ETR U STL --- 1 9'-7" 4'-4" --- --- ETR --- --- --- --- --- --- --- --- 300B300C PHARMACY ETR U STL --- 1 6'-10" 3'-4" --- --- ETR --- --- --- --- --- --- --- --- 300C300E PHARMACY ETR U STL --- 1 2'-6" 2'-6" --- --- ETR --- --- --- --- --- --- 1 HR 1 300E304A PHARMACY STORAGE ETR F HM-STL P40 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL P40 --- --- --- --- --- 304AFOOD SERVICE TENANT401B UTILITY ETR F HM-STL ETR 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL ETR --- --- --- --- --- 401B402E DINING AREA ETR X --- --- 1 10'-8" 9'-0" --- --- ETR --- --- --- --- --- --- --- --- 402EGARDEN CENTER501E GARDEN CENTER ETR F HM-STL REF A2 PR 3'-0" 7'-0" 1 3/4" --- ETR 8 HM-STL REF A2 --- --- --- --- 25, 48 501E501F GARDEN CENTER ETR VV OM --- 1 4'-0" 8'-0" --- --- ETR --- OM --- --- --- --- --- 25 501F501K GARDEN CENTER ETR W3 OM --- 1 8'-0" 8'-0" --- --- ETR --- OM --- --- --- --- --- --- 501KAUTO CENTER600C LUBE & TIRE MOUNTING AREA ETR S3 STL --- 1 12'-0" 10'-0" --- ACRYL ETR --- STL --- --- --- --- --- 1 600C600D LUBE & TIRE MOUNTING AREA ETR S3 STL --- 1 12'-0" 10'-0" --- ACRYL ETR --- STL --- --- --- --- --- 1 600D600E LUBE & TIRE MOUNTING AREA ETR S3 STL --- 1 12'-0" 10'-0" --- ACRYL ETR --- STL --- --- --- --- --- 1 600E600F LUBE & TIRE MOUNTING AREA ETR S3 STL --- 1 12'-0" 10'-0" --- ACRYL ETR --- STL --- --- --- --- --- 1 600F600G LUBE & TIRE MOUNTING AREA ETR S3 STL --- 1 12'-0" 10'-0" --- ACRYL ETR --- STL --- --- --- --- --- 1 600G600H LUBE & TIRE MOUNTING AREA ETR S3 STL --- 1 12'-0" 10'-0" --- ACRYL ETR --- STL --- --- --- --- --- 1 600H600J LUBE & TIRE MOUNTING AREA ETR S3 STL --- 1 12'-0" 10'-0" --- ACRYL ETR --- STL --- --- --- --- --- 1 600J600K LUBE & TIRE MOUNTING AREA ETR S3 STL --- 1 12'-0" 10'-0" --- ACRYL ETR --- STL --- --- --- --- --- 1 600K600L LUBE & TIRE MOUNTING AREA ETR F HM-STL --- 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL --- --- --- --- --- 25 600L601A TOILET ETR F HM-STL P16 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL P16 --- --- --- 45 MIN --- 601A602F ELECTRICAL ROOM-4 ETR V CL --- 1 3'-0" 8'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 602F603A SECURITY ETR F HM-STL --- 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL --- --- --- --- --- --- 603A604D CUSTOMER SERVICE ETR N HM-STL P105 1 3'-0" 7'-0" 1 3/4" RATED ETR 2 HM-STL P105 --- --- --- 45 MIN --- 604D604E CUSTOMER SERVICE ETR F HM-STL P105 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL P105 --- --- --- --- 25 604E605G STORAGE ETR F HM-STL P16 1 4'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL P16 --- --- --- 45 MIN --- 605G605H STORAGE ETR S1 STL --- 1 6'-0" 8'-8" --- --- ETR --- --- --- --- --- --- --- 1 605H605J STORAGE ETR F HM-STL P16 PR 3'-0" 7'-0" 1 3/4" --- ETR 3 HM-STL P16 --- --- --- --- 52 605J610C TIRE & BATTERY STORAGE NEW F HM-STL P88 PR 3'-0" 7'-0" 1 3/4" --- NEW 8 HM-STL P88 8-AC2 7-AC2 --- --- --- 610C611A CUSTOMER WALKWAY ETR G HM-STL P16 1 3'-0" 7'-0" 1 3/4" TEMP ETR 2 HM-STL P16 --- --- --- --- 25 611A611B CUSTOMER WALKWAY ETR G HM-STL P16 1 3'-0" 7'-0" 1 3/4" TEMP ETR 2 HM-STL P16 --- --- --- --- 25 611B611C CUSTOMER WALKWAY ETR U STL --- 1 8'-0" 3'-4" --- --- ETR --- --- --- --- --- --- 45 MIN 1 611C611D CUSTOMER WALKWAY ETR V CL --- 1 4'-0" 4'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 611D611E CUSTOMER WALKWAY ETR V CL --- 1 4'-0" 4'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 611E614C ENVIRONMENTAL CAGE NEW F HM-STL P88 PR 3'-0" 7'-0" 1 3/4" --- ETR 8 HM-STL P88 --- --- --- --- --- 614CVISION CENTER701A ADJUSTMENTS ETR G HM-STL P40 1 3'-0" 7'-0" 1 3/4" TEMP ETR 1 HM-STL P40 --- --- --- --- 59 701A702A CONTACTS ETR F HM-STL P40 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL P40 --- --- --- --- 59 702A704A RECORD RETENTION ETR F HM-STL P40 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL P40 --- --- --- --- 59 704A705A EXAM #1 ETR F HM-STL P40 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL P40 --- --- --- --- 59 705A706A EXAM #2 ETR F HM-STL P40 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL P40 --- --- --- --- 59 706A709A STORAGE ETR F HM-STL P40 1 3'-0" 7'-0" 1 3/4" ---- ETR 1 HM-STL P40 --- --- --- ---- 59 709ATENANTS800A BANK ETR F HM-STL --- 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL --- --- --- --- --- 25 800A803B REGAL NAILS ETR X ALUM --- 1 14'-0" 9'-0" --- --- ETR --- ALUM --- --- --- --- --- --- 803B804A FLORAL ETR F HM-STL ETR 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL ETR --- --- --- --- 25 804A804B FLORAL ETR U1 STL --- 1 10'-0" 9'-11" --- --- ETR --- --- --- --- --- --- --- --- 804BHAIR CARE809A CLOSET ETR F HM-STL --- 1 2'-6" 7'-0" 1 3/4" --- ETR 1 HM-STL --- --- --- --- --- --- 809A810E SALON ETR F HM-STL --- 1 3'-0" 7'-0" 1 3/4" --- ETR 2 HM-STL --- --- --- --- --- 25 810E810G SALON ETR U1 STL --- 1 13'-10" 9'-10" --- --- ETR --- --- --- --- --- --- --- --- 810G811B UTILITY ETR F HM-STL --- 1 3'-0" 7'-0" 1 3/4" --- ETR 1 HM-STL --- --- --- --- --- --- 811BGROCERY901A SERVICE DELI NEW E PLAST KHAKI 1 3'-0" 7'-0" --- ACRYL ETR --- STL-BP P102 --- --- --- --- --- 901A901C SERVICE DELI NEW E PLAST KHAKI 1 3'-0" 7'-0" --- ACRYL ETR --- STL-BP P102 --- --- --- --- --- 901C902A DELI PREP ETR E PLAST --- PR 3'-0" 7'-0" --- ACRYL ETR --- STL-BP --- --- --- --- --- --- 902A906C BAKERY NEW E PLAST BLACK 1 3'-0" 7'-0" --- ACRYL ETR --- STL-BP P36 --- --- --- --- --- 906C906D BAKERY ETR E PLAST --- PR 4'-0" 7'-0" --- ACRYL ETR --- STL-BP --- --- --- --- --- --- 906D907A DEPT 82 ROOM ETR N HM-STL --- 1 3'-0" 7'-0" 1 3/4" TEMP ETR 1 HM-STL --- --- --- --- --- --- 907A908A MEAT HOLDING NEW E PLAST BLACK 1 3'-6" 6'-8" --- ACRYL ETR --- STL-BP P36 --- --- --- --- --- 908A909B PRODUCE PREP NEW E PLAST BLACK PR 4'-0" 9'-0" --- ACRYL ETR --- STL-BP P36 --- --- --- --- 25 909B914A SEAFOOD PREP ETR E PLAST --- PR 3'-0" 7'-0" --- ACRYL ETR --- STL-BP --- --- --- --- --- --- 914A916B STOCKROOM ETR F HM-STL --- 2 3'-0" 7'-0" 1 3/4" --- ETR 4 HM-STL --- --- --- --- --- 25 916B917C PLUMBING/MECHANICAL ETR N HM-STL --- 1 3'-0" 7'-0" 1 3/4" TEMP ETR 1 HM-STL --- --- --- --- --- --- 917C918B FIRE CORRIDOR ETR F HM-STL --- 2 3'-0" 7'-0" 1 3/4" --- ETR 4 HM-STL --- --- --- --- --- 25 918B918D FIRE CORRIDOR NEW N HM-STL P106 PR 4'-0" 9'-0" 1 3/4" RATED NEW 3 HM-STL P106 14 13 --- 1 HR 25 918D918J FIRE CORRIDOR ETR U STL --- 1 8'-0" 9'-0" --- --- ETR --- --- --- --- --- --- 1 HR 1 918J918K FIRE CORRIDOR ETR U STL --- 1 8'-0" 9'-0" --- --- ETR --- --- --- --- --- --- 1 HR 1 918K918L FIRE CORRIDOR ETR N HM-STL --- 1 3'-0" 7'-0" 1 3/4" RATED ETR 1 HM-STL --- --- --- --- 1 HR 25 918L918M FIRE CORRIDOR ETR N HM-STL --- 1 3'-0" 7'-0" 1 3/4" RATED ETR 1 HM-STL --- --- --- --- 1 HR 25 918M920A RECEIVING-GR ETR S1 STL --- 1 6'-0" 8'-8" --- --- ETR --- STL --- --- --- --- --- 1 920A920B RECEIVING-GR ETR S1 STL --- 1 8'-0" 8'-8" --- --- ETR --- STL --- --- --- --- --- 1 920B920C RECEIVING-GR ETR S1 STL --- 1 8'-0" 8'-8" --- --- ETR --- STL --- --- --- --- --- 1 920C920D RECEIVING-GR ETR S1 STL --- 1 8'-0" 8'-8" --- --- ETR --- STL --- --- --- --- --- 1 920D920E RECEIVING-GR ETR S1 STL --- 1 8'-0" 8'-8" --- --- ETR --- STL --- --- --- --- --- 1 920E922C ELECTRICAL ROOM-5 ETR V CL --- 1 3'-6" 8'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 922C922D ELECTRICAL ROOM-5 ETR V CL --- 1 3'-6" 8'-0" --- --- ETR --- STL-P --- --- --- --- --- --- 922D935A CAKE DECORATING NEW E PLAST KHAKI 1 3'-0" 7'-0" --- ACRYL ETR --- STL-BP P102 --- --- --- --- --- 935ADOOR SCHEDULE:REVISED 101A, 101B, 101C, 101D, 110F, 115A, 115B, 115C, 115D, 119A,150N, 151F, 162M, 171A, 171B, 172A, 186A, 300B, 300C, 602F, 604D,611A, 611B, 701A, 902A, 906D, 907A, 914D, 917C, 918D, 918L, 918MAND 935AADDED 121A, 171C, 171D, 177A AND 300ENOTESMARKSTIPULATION FOR REUSEISSUE BLOCKCHECKED BY:DRAWN BY:PROTO:PROTO CYCLE:DOCUMENT DATE:SHEET:710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsSTORE NO.GENERAL REMODELJOB NUMBER:18811-19-1002-09-11NOT FORCONSTRUCTION

710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsSTIPULATION FOR REUSENEW 1/4" CHAMFER AT SEALED HARDWOOD EDGE BOTH SIDESPLASTIC LAMINATE ON EXISTING SUBSTRATE TOPDO NOT LAMINATE REAR OR INSIDE OF CABINETSTORE NO.GENERAL REMODELPLASTIC LAMINATE ON EXISTING SUBSTRATE FRONT AND SIDES2'-2"4"ISSUE BLOCKJOB NUMBER:TRUEBRO BASIN GUARDPHONE: 1-800-340-5969INTERNET: HTTP://WWW.IPSCORP.COM/TRUEBROEMAIL: INFO@TRUEBRO.COMFIXTURE AND CABINET DIMENSIONS ARE CRITICAL TO ADAAG AND LOCAL ACCESSIBILITY CODE REQUIREMENTS. ENSURE INSTALLATION COMPLIES.2'-1"SINK AS SCHEDULED(REF PLUMBING)CHECKED BY:4"ONE PIECE PREFORMED ROLLED FRONT COUNTERTOP BY PLUNKETT DISTRIBUTING 1-800-833-4393 CONTACT HOLLIE PIERCEDRAWN BY:PROTO:1881x4 WOOD BLOCKINGPROTO CYCLE:11-19-102'-10" MAX2'-5"2'-3" MINTO BOTTOM OF SCALD GUARD9" MIN8" MINPROVIDE UNDERSINK PROTECTIVE ENCLOSUREPLASTIC LAMINATEON{}" PLYWOOD PANELSDOCUMENT DATE:02-09-1111" MINPRINTED: 8/4/2011 3:27 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 1:11 PM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\a090.dwgEXISTINGFV{}"PLASTIC LAMINATE ON EXISTING 3/4" SUSBSTRATE TOPPLASTIC LAMINATE ON FRONT STILES1/4" CHAMFER ATPLASTIC LAMINATEAND HARDWOODEDGESEALEDHARDWOODEDGE TRIM TYP2'-10"MAX AFF4"{}"5{}"{}"WIRE PULL1{}"HARDWOOD EDGE TRIM TYP4"1{}"2'-1"ONE PIECE PREFORMED ROLLED FRONT COUNTERTOP BY PLUNKETT DISTRIBUTING 1-800-833-4393 CONTACT HOLLIE PIERCE1x4 WOOD BLOCKINGDRAWER, OMITTED UNDER SINK3/4" SUBSTRATE ADJUSTABLE SHELF OMITTED UNDER SINK3/4" SUBSTRATE FRONT AND ENDS3/4" SUBSTRATE BOTTOM2x WOOD BLOCKING4"2'-10"TO TOP OF SINK{NOTE:}INSULATE ALL EXPOSED PIPINGAT SINK3'-11"2'-5"BASE BEYOND12'-0"3'-0"SINK3'-6"5'-1"UNDERSINK PROTECTIVE COVERONE PIECE PREFORMED ROLLED FRONT COUNTERTOP BY PLUNKETT DISTRIBUTING 1-800-833-4393 CONTACT HOLLIE PIERCEPREFABRICATED OAK FACE AND TRIM COUNTER BASE1/4" CHAMFER AT PLASTICLAMINATE ANDHARDWOODEDGESEALEDHARDWOODEDGE TRIM TYP{}"EXISTING{}"1{}"PLASTIC LAMINATE ON EXISTING 3/4" SUBSTRATE1 1/4" OD STEEL PIPE AT 48" OC MAX. UNO PAINTENSURE ALL FLANGES ARE SECURELY ATTACHED TO COUNTER AND FLOORFLANGE ATTACHMENTIF ADJUSTABLE SQUARE SUPPORT POSTS ARE EXISTING, REPLACE WITH PIPE SUPPORTS AS SHOWN. OTHERWISE, EXISTING PIPE SUPPORTS ARE TO REMAIN.3'-0"2'-8" AT ADA COUNTER2'-2"PLASTIC LAMINATE ON EXISTING 3/4" SUSBSTRATE TOPCUSTOMER SIDE OF COUNTERCONTINUOUS WOOD BLOCKING INFILLPLASTIC LAMINATE 3/4"SUBSTRATEAT FRONT AND SIDES1{}"EXISTINGFVTOE KICK TO BE INFILLED AS SHOWN AT CUSTOMER SIDE OF COUNTER AT THE TLE, CUSTOMER SERVICE, AND SITE TO STORE AREAS.{}"1/4" CHAMFER ATPLASTICLAMINATE ANDHARDWOODEDGESEALEDHARDWOODEDGE TRIM TYPNOT FORCONSTRUCTIONSHEET:

CI = CERTIFIED INSTALLERGC=GENERAL CONTRACTORES=EQUIPMENT SUPPLIERWM=WAL-MARTQTY53124422111582633112642211122214112NODESCRIPTIONEQUIPMENT SCHEDULEMANUFACTURERMODEL NOINSTALLED BYFINAL CONNSUPPLIED BYAC000-ESCHNOTESGENERAL NOTES1NOTESALL TANKS AND PIPING TO BE INSTALLED AND PROPERLY TESTED IN ACCORDANCE WITH ALL APPLICABLE CODES AND MANUFACTURER REQUIREMENTS. REF SPECIFICATIONS.2 ALL PIPING AND FITTINGS TO BE SUPPLIED BY GENERAL CONTRACTOR AND INSTALLED BY CERTIFIED INSTALLER1 FURNISHED BY WAL-MART AND INSTALLED BY GENERAL CONTRACTOR PER MANUFACTURER'S SPECIFICATIONS2 GENERAL CONTRACTOR IS RESPONSIBLE TO COORDINATE DELIVERY SCHEDULE REF SPECIFICATIONS3 STEEL MOUNTING PLATE FOR WASTE OIL PUMP BY LIFT MANUFACTURER4 NOT USED5 HOSES ROUTED THROUGH EMBEDDED PIPE SLEEVE. REF MECHANICAL6 TB900 SHALL BE PROVIDED WITH LIFTGENERAL CONTRACTOR IS RESPONSIBLE TO COORDINATE INSTALLATION SCHEDULE REF SPECIFICATIONS8 REF MECHANICAL FOR LOCATION9 REFER TO SPECIFICATIONSNOTE:VERIFY EQUIPMENT REQUIRED WITHEQUIPMENT SCHEDULE, ARCHITECTURAL ANDMEP DRAWINGS.EXISTING SUMP PUMPEXISTING LADDERCORE DRILL (2) 6"DIAMETER HOLES 6" APARTTHRU EXISTING SLAB THENCUT BETWEEN TO CREATEONE HOLE. RUN VENT PIPESTHRU SLAB THEN THRU ROOF12'-0"1. WALMART ENVIRONMENTAL MANAGEMENT ANDSUPPORT SHALL BE RESPONSIBLE FOR EMPTYING,HANDLING, REMOVAL AND DISPOSAL OF ALL AST TANKS2. GENERAL CONTRACTOR SHALL PROVIDEDISCONNECTION OF ALL EQUIPMENT, LINES, PIPES ANDRETAINING HARDWARE.3. GENERAL CONTRACTOR SHALL NOT PERFORM ANYWORK BEFORE TANK HAS BEEN EMPTIED.4. GENERAL CONTRACTOR SHALL COORDINATE ALL WORKWITH WALMART CONSTRUCTION MANAGER.5. WALMART CONSTRUCTION MANAGER SHALL CONTACTGREG ROWLAND OR PAT GUTHRIE WITH WALMARTENVIRONMENTAL MANAGEMENT AND SUPPORT FOR TANKREMOVAL COORDINATION (479-204-2108 OR 479-204-2501)1. ONLY REMOVE BULK WASTE, WINDSHIELD FLUID, SPECIALTY OIL AND DIY TANK IF SHOWN TO BE REMOVED. REF GENERAL NOTES1. REF A7 FOR SCHEDULE FINISH KEYSTIPULATION FOR REUSE710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. Phillips8"RELOCATE EXISTING 400 GALLON BULK OIL TANKREMOVE EYEWASHREF MEPRELOCATE EXISTING PLASTIC WINDSHIELD WASHER FLUID TANKEXISTING GEAR OIL,CHASSIS GREASEAND CONTAINMENTCORE DRILL (2) 6" DIAMETER HOLES6" APART THRU EXISTING SLAB THENSAWCUT BETWEEN TO CREATE ONEHOLE. RUN VENT PIPES THRU SLABTHEN THRU ROOFREF MEP AND 3,4,10-AC2RELOCATEEXISTING 400GALLON BULKOIL TANKCORE DRILL (2) 6" DIAMETER HOLES6" APART THRU EXISTING SLAB THENSAWCUT BETWEEN TO CREATE ONEHOLE. RUN VENT PIPES THRU SLABTHEN THRU ROOFREF MEP AND 3,4,10-AC28"UP11{}"1'-10{}"8"SERVICE PLATFORMLUBE PITEXISTING SHELVES TO REMAINSERVICE PLATFORMSTORE NO.GENERAL REMODELJOB NUMBER:RELOCATEEXISTING 800GALLON WASTEOIL TANKISSUE BLOCKENVIRONMENTAL CAGETIRE & BATTERY STORAGECHECKED BY:DRAWN BY:PROTO:188EXISTING SUMP PUMPREF 2,3-AC1 FOR PIT DEMOLITION AND PIT PLAN (BELOW)PROTO CYCLE:DOCUMENT DATE:11-19-1002-09-11EXISTING LADDERVENT PIPING THROUGH FLOOR ABOVEREF MEP AND 3,4,10-AC2RELOCATED 400GALLON BULKOIL TANK14'-2"NEW EYEWASHREF MEP ANDN1 FOR STRIPPINGREQUIREMENTS3"MINEXISTING VENDINGRELOCATED EXISTING PLASTIC WINDSHIELD WASHER FLUID TANKTLE SERVICEEXISTING GEAROIL, CHASSISGREASEAND CONTAINMENTVENT PIPING THROUGH FLOORABOVEREF MEP AND 3,4,10-AC211'-10"SERVICE PLATFORMEXISTING SHELVESSERVICE PLATFORMDNRELOCATED 400GALLON BULKOIL TANK2'-2"RELOCATED 800GALLON WASTEOIL TANK3"MINPRINTED: 8/4/2011 3:27 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 11:46 AM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\ac010.dwg3"MINNEW FILTER CRUSHER AND WASTE OIL RESERVOIR3"MINEQUALEQUALWASTE OIL PUMPRELOCATED EWC REF MEP2'-0"NEW EYEWASHREF MEPNOT FORCONSTRUCTIONSHEET:

5.52 48" GALVANIZED STEEL BOLLARD. REF 8-A5.1710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsJOB NUMBER:STORE NO.GENERAL REMODELSTIPULATION FOR REUSEISSUE BLOCKCHECKED BY:DRAWN BY:PROTO:188PROTO CYCLE:11-19-10DOCUMENT DATE:02-09-11METAL CANOPYPRINTED: 8/4/2011 3:28 PM BY: Brenda Garrison LAST SAVED: 8/3/2011 4:11 PM BY: BRIANCARLTONe:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\gc010.dwg4"4"NOT FORCONSTRUCTIONSHEET:

710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsSTIPULATION FOR REUSEFIELD VERIFYGENERAL REMODELMATCH EXISTINGSTORE NO.3/4" PLYWOOD SUBSTRATEFIELD VERIFYGRAY VINYL WALL GUARDREF SPECIFICATIONSJOB NUMBER:1x TRIMISSUE BLOCK2'-10"FIELD VERIFYCONTINUOUS SEALANT AT TOP OF BASEGRAY VINYL WALL GUARDREF SPECIFICATIONS1 1/4" OD PIPE SUPPORTS AT 48" OC MAX PAINT3'-4{}"ADJUST COUNTERTOP HEIGHT AS NEEDEDCHECKED BY:DRAWN BY:PROTO:188PROTO CYCLE:11-19-10DOCUMENT DATE:02-09-11RELAMINATE ALL COUNTERTOPSREPLACE ADJUSTABLE COUNTERTOPS SUPPORTS WITH 1 {}" OD PIPE SUPPORTS AT 48" OC MAX PAINTWHEN REPLACING COUNTERTOP LAMINATE REMOVE HARDWOOD TRIM FROM EDGE, BAND EDGES WITH PLASTIC LAMINATE TO MATCH COUNTERTOP, TYPWALL CAPS WITH GLASS TO REMAIN TYPREMOVE CORNICE PATCH AND REPAIR WALL FINISH AND REPAINTPAINT INTERIOR OF PHARMACYREPAIR DAMAGED WALLS BOTH INTERIOR AND EXTERIORRELAMINATE COUNTERTOPSCLEAN ALL LIGHT LENSES TYPINSTALL BASEEXISTING BULKHEAD TO REMAININSTALL NEW CARPET TILEPRINTED: 8/4/2011 3:27 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 11:51 AM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\rxpfc010.dwg4'-0"2'-2"ALUMINUM CORNER GUARDS AT ALL OUTSIDE CORNERSPAINT EXTERIOR WALLSPLASTIC LAMINATEGRAY WALL GUARDREPLACE ALL CEILING TILE CLEAN EXISTING CEILING GRIDCLEAN ALL HVAC DIFFUSERS AND SPRINKLER HEADSEXISTING FIXTURES TO REMAIN. RELOCATE AND PROTECT AS REQUIRED DURING INSTALLATION OF NEW WORK WITH MINIMA INTRUSION TO PHARMACY OPERATION. RETURN FIXTURES TO ORIGINAL LOCATIONRELAMINATE VERTICAL SURFACED IN THE PHARMACYPAINT INTERIOR OF PHARMACY STORAGENOT FORCONSTRUCTIONSHEET:

{MISC. GROCERY EQUIPMENT LEGEND}NO. QTY. DESCRIPTIONMFR. OR SUPPLIER NOTESMODEL NO. SUPPLIED BY INSTALLED BY FINAL CONNECTREMOVED REFRIGERATED CASE LEGENDEQUIPMENT NOTES1. REFERENCE SHEET A1 FOR EQUIPMENT LOCATION3. WALMART TO SUPPLY SS FIXTURES BY UNIVERSAL STAINLESS IN THE FOLLOWING STATES: CO, ID, KS, MT, ND, NE, SD, OR, WA,WYWAL-MART TO SUPPLY SS FIXTURES BY WIN-HOLT IN THE FOLLOWING STATES: AK, AL, AR, AZ, CA, CT, DE, FL, GA, HI, IA, IL, IN, KY,4. QUANTITY AND TYPE BY WALMART. RACKS SHOWN ARE FOR POSSIBLE STORAGE AND PREP LOCATIONS5. EQUIPMENT SUPPLIED TO HAVE CLEAR COATED GALVANIZED EXTERIOR, WITH BLACK INTERIOR AND COLOR BANDS6. REFERENCE SPEC SECTION 11400 FOR SPECIAL INSTRUCTIONS FOR STORES WHICH HAVE AN EXISTING WASTE COOKING OIL TANK (EXPANSIONS AND RELOCATIONS ONLY){13. CONNECTED AND INSTALLED BY SUPPLIER. GC TO COORDINATE CONNECTION LOCATIONS FOR MAINTENANCE WITH SUPPLIER, REF MEP}710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsABBREVIATION KEYESGCEQUIPMENT SUPPLIERGENERAL CONTRACTORRC REFRIGERATION CONTRACTOR, REF SPEC 15600WMWALMARTSTIPULATION FOR REUSEEXISTING M/D FRESH MEAT CASESGENERAL REMODELEXISTING COFFINCASES TO REMAINSTORE NO.EXISTING REFRIGERATED CASESGROCERY COOLERJOB NUMBER:ISSUE BLOCKEXISTING REFRIGERATED CASESEXISTING REFRIGERATED CASESEXISTING M/D FRESH MEAT CASESICE CREAM FREEZEREXISTING REFRIGERATED CASESSEAFOOD COOLERSEAFOOD FREEZEREXISTING PRODUCE CASESCHECKED BY:DRAWN BY:SEPARATE CONTRACTOR IS RESPONSIBLE FOR RE-SKIN OF EXISTING REFRIGERATED CASES TO REMAINCASES FURNISHED BY WALMARTINSTALLED BY REFRIGERATIONCONTRACTOR VERIFY VERIFYEXACTLOCATION OF CASES WITHWALMART CONSTRUCTIONEXISTING REACH-IN FREEZERS TO REMAINPROTO:PROTO CYCLE:DOCUMENT DATE:18811-19-1002-09-11EXISTING M/D SEAFOOD TO REMAINEXISTING REACH-IN FREEZER TO REMAINEXISTING CAKE CASES TO REMAINNEW MOPSINK REF MEPBULKHEAD ABOVEPRODUCE COOLERSUBWAYBAKERY COOLERPRINTED: 8/4/2011 3:27 PM BY: Brenda Garrison LAST SAVED: 8/2/2011 11:56 AM BY: LukeSpurgeone:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\ga010.dwgRLCOOLERFREEZERBAKERY FREEZERNOT FORCONSTRUCTIONSHEET:

{KEYNOTES}710 West Roselawn DriveRogers, Arkansas 72756Phone: 479.636.3545Fax: 479.636.1209Architect of RecordBradley J. PhillipsNOTE:THIS DETAIL ONLY OCCURS IN THE GROCERY SERVICE AREAS: PRODUCE, DELI PREP, DELIUTILITY, BAKERY, BAKERY UTILITY, UTILITY, FOOD SERVICE, AND SEAFOOD PREP (IFNEW WASTECOOKINGOIL TANK8'-0"12'-0{}"FVSTIPULATION FOR REUSEBALEREXISTING GYPSUM BOARDEXISTING GYPSUM BOARD1/2" x 10" H GLASS MAT BACKER BOARD5"1"1/2" x 10" H GLASS MAT BACKER BOARDDELI FREEZER5"1"{}"{INSIDE CORNER}{SECTION}EXISTING STEEL TRACK4" BUILDING TAPE FULL HEIGHT OF WALL AND ALL VERTICAL WALL BOARD JOINTS6" BUILDING TAPE AT WALL/FLOOR INTERSECTIONEXISTING GYPSUM BOARDREMOVE BOTTOM 10" OF EXISTING GYP BD AND INSTALL 10"x1/2" GLASS MAT BACKER BOARDPOLYURETHANE SEALANT (REF SPECS)SANITARY COVE BASEPOLYURETHANE SEALANT (REF SPECS){OUTSIDE CORNER}WALL FINISH TO MATCH ADJACENT EXISTINGEXISTING STUDS{}"BUILDING TAPE AT WALL/FLOOR INTERSECTION (REF SPEC 09655){FOOD PREP AREA}4" BUILDING TAPE FULL HEIGHT OF WALL AND ALL VERTICAL WALL BOARD JOINTS6" BUILDING TAPE AT WALL/FLOOR INTERSECTIONDAIRY COOLEREXISTING DAIRY CASES TO REMAINEXISTING CASES TO REMAINDELI COOLEREXISTING CASES TO REMAINSTORE NO.GENERAL REMODELEXISTING COFFIN CASE TO REMAINEXISTING CASETO REMAINNEW EYEWASHREF MEP2'-6"JOB NUMBER:ISSUE BLOCKEXISTING M/D DAIRY CASESEXISTING M/D BEER CASESEXISTING COFFIN CASE TO REMAINCHECKED BY:DRAWN BY:PROTO:188PROTO CYCLE:11-19-10EXISTING M/D DAIRY/DELI CASES TO REMAINDOCUMENT DATE:02-09-11RE-SKIN OF EXISTING REFRIGERATED CASES TO REMAIN SEPARATE CONTRACT.VERIFY EXACT LOCATION OF CASES WITH WALMART CONSTRUCTION MANAGER PRIOR TO STARTING CONSTRUCTION (TYP)GROCERY FREEZEREXISTING COFFIN CASES TO REMAINEXISTING M/D DAIRY/DELI CASES TO REMAINPRINTED: 8/4/2011 3:26 PM BY: Brenda Garrison LAST SAVED: 8/3/2011 4:21 PM BY: BRIANCARLTONe:\2010xxx\2010-0452 ruston_la\4condoc\188 (general remodel-2)\arch\sheets\ga020.dwgEXISTING M/D FRESH MEAT CASES TO REMAINMEAT COOLERNOT FORCONSTRUCTIONSHEET: