View Kool Star Brochure pdf file - Master-Bilt

View Kool Star Brochure pdf file - Master-Bilt

View Kool Star Brochure pdf file - Master-Bilt

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

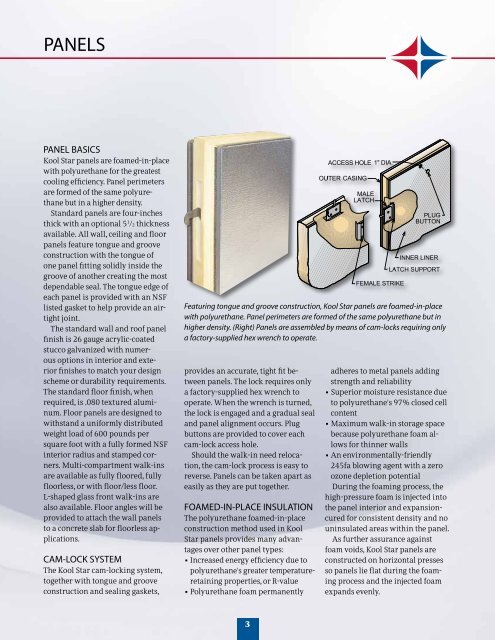

PANELSPANEL BASICS<strong>Kool</strong> <strong>Star</strong> panels are foamed-in-placewith polyurethane for the greatestcooling efficiency. Panel perimetersare formed of the same polyurethanebut in a higher density.Standard panels are four-inchesthick with an optional 5 1 /2 thicknessavailable. All wall, ceiling and floorpanels feature tongue and grooveconstruction with the tongue ofone panel fitting solidly inside thegroove of another creating the mostdependable seal. The tongue edge ofeach panel is provided with an NSFlisted gasket to help provide an airtightjoint.The standard wall and roof panelfinish is 26 gauge acrylic-coatedstucco galvanized with numerousoptions in interior and exteriorfinishes to match your designscheme or durability requirements.The standard floor finish, whenrequired, is .080 textured aluminum.Floor panels are designed towithstand a uniformly distributedweight load of 600 pounds persquare foot with a fully formed NSFinterior radius and stamped corners.Multi-compartment walk-insare available as fully floored, fullyfloorless, or with floor/less floor.L-shaped glass front walk-ins arealso available. Floor angles will beprovided to attach the wall panelsto a concrete slab for floorless applications.CAM-LOCK SYSTEMThe <strong>Kool</strong> <strong>Star</strong> cam-locking system,together with tongue and grooveconstruction and sealing gaskets,Featuring tongue and groove construction, <strong>Kool</strong> <strong>Star</strong> panels are foamed-in-placewith polyurethane. Panel perimeters are formed of the same polyurethane but inhigher density. (Right) Panels are assembled by means of cam-locks requiring onlya factory-supplied hex wrench to operate.provides an accurate, tight fit betweenpanels. The lock requires onlya factory-supplied hex wrench tooperate. When the wrench is turned,the lock is engaged and a gradual sealand panel alignment occurs. Plugbuttons are provided to cover eachcam-lock access hole.Should the walk-in need relocation,the cam-lock process is easy toreverse. Panels can be taken apart aseasily as they are put together.FOAMED-IN-PLACE INSULATIONThe polyurethane foamed-in-placeconstruction method used in <strong>Kool</strong><strong>Star</strong> panels provides many advantagesover other panel types:• Increased energy efficiency due topolyurethane's greater temperatureretainingproperties, or R-value• Polyurethane foam permanentlyadheres to metal panels addingstrength and reliability• Superior moisture resistance dueto polyurethane's 97% closed cellcontent• Maximum walk-in storage spacebecause polyurethane foam allowsfor thinner walls• An environmentally-friendly245fa blowing agent with a zeroozone depletion potentialDuring the foaming process, thehigh-pressure foam is injected intothe panel interior and expansioncuredfor consistent density and nouninsulated areas within the panel.As further assurance againstfoam voids, <strong>Kool</strong> <strong>Star</strong> panels areconstructed on horizontal pressesso panels lie flat during the foamingprocess and the injected foamexpands evenly.3