Sanitary Tanks

Sanitary Tanks

Sanitary Tanks

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

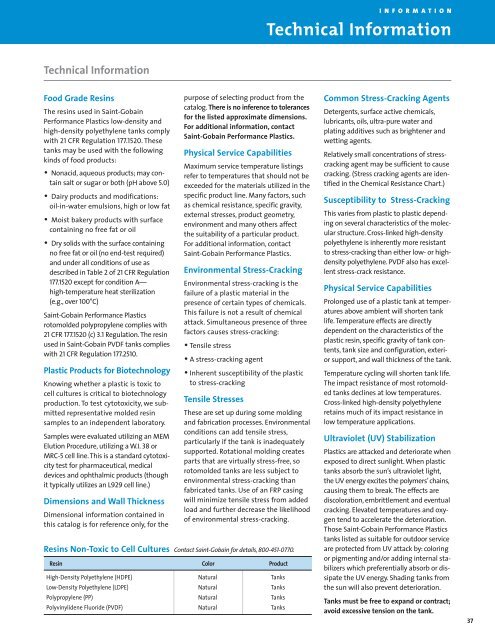

I N F O R M A T I O NTechnical InformationTechnical InformationFood Grade ResinsThe resins used in Saint-GobainPerformance Plastics low-density andhigh-density polyethylene tanks complywith 21 CFR Regulation 177.1520. Thesetanks may be used with the followingkinds of food products:• Nonacid, aqueous products; may containsalt or sugar or both (pH above 5.0)• Dairy products and modifications:oil-in-water emulsions, high or low fat• Moist bakery products with surfacecontaining no free fat or oil• Dry solids with the surface containingno free fat or oil (no end-test required)and under all conditions of use asdescribed in Table 2 of 21 CFR Regulation177.1520 except for condition A—high-temperature heat sterilization(e.g., over 100°C)Saint-Gobain Performance Plasticsrotomolded polypropylene complies with21 CFR 177.1520 (c) 3.1 Regulation. The resinused in Saint-Gobain PVDF tanks complieswith 21 CFR Regulation 177.2510.Plastic Products for BiotechnologyKnowing whether a plastic is toxic tocell cultures is critical to biotechnologyproduction. To test cytotoxicity, we submittedrepresentative molded resinsamples to an independent laboratory.Samples were evaluated utilizing an MEMElution Procedure, utilizing a W.I. 38 orMRC-5 cell line. This is a standard cytotoxicitytest for pharmaceutical, medicaldevices and ophthalmic products (thoughit typically utilizes an L929 cell line.)Dimensions and Wall ThicknessDimensional information contained inthis catalog is for reference only, for thepurpose of selecting product from thecatalog. There is no inference to tolerancesfor the listed approximate dimensions.For additional information, contactSaint-Gobain Performance Plastics.Physical Service CapabilitiesMaximum service temperature listingsrefer to temperatures that should not beexceeded for the materials utilized in thespecific product line. Many factors, suchas chemical resistance, specific gravity,external stresses, product geometry,environment and many others affectthe suitability of a particular product.For additional information, contactSaint-Gobain Performance Plastics.Environmental Stress-CrackingEnvironmental stress-cracking is thefailure of a plastic material in thepresence of certain types of chemicals.This failure is not a result of chemicalattack. Simultaneous presence of threefactors causes stress-cracking:• Tensile stress• A stress-cracking agent• Inherent susceptibility of the plasticto stress-crackingTensile StressesThese are set up during some moldingand fabrication processes. Environmentalconditions can add tensile stress,particularly if the tank is inadequatelysupported. Rotational molding createsparts that are virtually stress-free, sorotomolded tanks are less subject toenvironmental stress-cracking thanfabricated tanks. Use of an FRP casingwill minimize tensile stress from addedload and further decrease the likelihoodof environmental stress-cracking.Resins Non-Toxic to Cell Cultures Contact Saint-Gobain for details, 800-451-0770.Resin Color ProductHigh-Density Polyethylene (HDPE)Low-Density Polyethylene (LDPE)Polypropylene (PP)Polyvinylidene Fluoride (PVDF)NaturalNaturalNaturalNatural<strong>Tanks</strong><strong>Tanks</strong><strong>Tanks</strong><strong>Tanks</strong>Common Stress-Cracking AgentsDetergents, surface active chemicals,lubricants, oils, ultra-pure water andplating additives such as brightener andwetting agents.Relatively small concentrations of stresscrackingagent may be sufficient to causecracking. (Stress cracking agents are identifiedin the Chemical Resistance Chart.)Susceptibility to Stress-CrackingThis varies from plastic to plastic dependingon several characteristics of the molecularstructure. Cross-linked high-densitypolyethylene is inherently more resistantto stress-cracking than either low- or highdensitypolyethylene. PVDF also has excellentstress-crack resistance.Physical Service CapabilitiesProlonged use of a plastic tank at temperaturesabove ambient will shorten tanklife. Temperature effects are directlydependent on the characteristics of theplastic resin, specific gravity of tank contents,tank size and configuration, exteriorsupport, and wall thickness of the tank.Temperature cycling will shorten tank life.The impact resistance of most rotomoldedtanks declines at low temperatures.Cross-linked high-density polyethyleneretains much of its impact resistance inlow temperature applications.Ultraviolet (UV) StabilizationPlastics are attacked and deteriorate whenexposed to direct sunlight. When plastictanks absorb the sun’s ultraviolet light,the UV energy excites the polymers’ chains,causing them to break. The effects arediscoloration, embrittlement and eventualcracking. Elevated temperatures and oxygentend to accelerate the deterioration.Those Saint-Gobain Performance Plasticstanks listed as suitable for outdoor serviceare protected from UV attack by: coloringor pigmenting and/or adding internal stabilizerswhich preferentially absorb or dissipatethe UV energy. Shading tanks fromthe sun will also prevent deterioration.<strong>Tanks</strong> must be free to expand or contract;avoid excessive tension on the tank.37