WX 95 Series2 - Case Construction

WX 95 Series2 - Case Construction

WX 95 Series2 - Case Construction

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

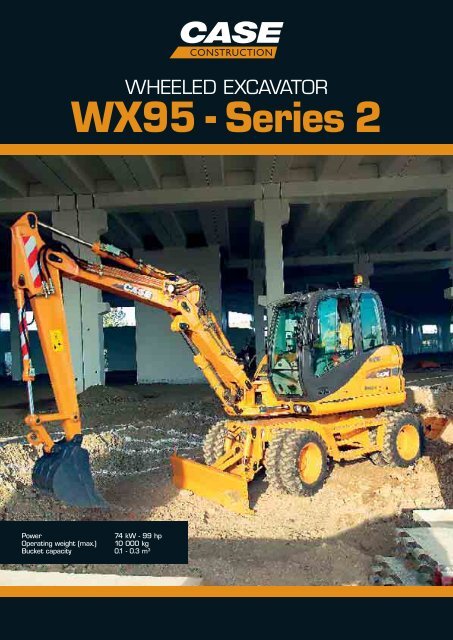

WHEELED EXCAVATOR<strong>WX</strong><strong>95</strong> - Series 2Power74 kW - 99 hpOperating weight (max.) 10 000 kgBucket capacity 0.1 - 0.3 m 3

CLEAN PERFORMANCEA powerful four cylinder Tier III engine offers 5% higher productivity and around 1% fuel saving overthe previous Tier II model. Low noise output and reduced gaseous emissions make this an ideal machinefor confined urban site operation.Environmentally friendly. Highly productive.TOTAL CONTROLHigh specification hydraulic system offers simultaneous use of multiplefunctions for smooth digging and lifting performance. Electronic enginespeed sensing control provides full use of the hydraulic pump output.The machines comes with an automatic priority device with swingpressure control for outstanding controllability.Smooth operation. Reduced fatigue.2CHASSIS VERSATILITYTwo or four wheel steering with crab steer facility to move the machine diagonally away from obstructions.Minimal turning circle of just 7.7 m. Customers can choose between rear blade, rear stabilisers, frontblade and rear stabilisers or four stabiliser legs. Stabilisers and blade work independently controlled bythe boom joystick. Maximum travel speed of 33 km/h or 20 km/h according to local regulations.Agile performer. Operator control.

ERGONOMICENVIRONMENTHigh space cab offers the same internal volume as larger excavators.Excellent all round visibility with tinted glass to all windows, including modulartotal or partial opening windscreen. Fully adjustable suspension seat andsteering column ensure complete comfort for operators of all sizes. Majorityof operating controls are located on joysticks, with forward and reversemovement controlled by the accelerator pedal.Enhanced visibility. Ease of operation.DESIGNED FORPRODUCTIVITYThe compact <strong>Case</strong> <strong>WX</strong> upperstructure has a longitudinalmounted engine for a reduced tailswing radius. Theslew function uses the main load sensing hydraulicsystem with an integrated automatic priority systemand automatic static brake. Patented anti-drop valvesstandard on boom and dipper cylinders. A wide choiceof booms and dipper arms is available and the boomfoot has hydraulic articulation, allowing digging up to awall or obstruction.Robust design. Practical operation.SERVICE ACCESSThree lift up canopy doors around the rear and sides of the machine allow easy access to regular service andmaintenance components. Tier III engine has 500 hour oil change intervals and all service points can be easilyreached from ground level for technician safety. Ecological engine drain tap and hoses standard and biodegradableoil can be specified as an option.Reduced downtime. Maximum productivity.3

UPPERCARRIAGEDesigned as a compact midi class machine, the <strong>WX</strong><strong>95</strong> Series 2has a very small rear overhang, with a tailswing radius of just1485 mm. The longitudinal engine mounting ensures that servicepoints are easily reached, despite this compact design, withground level access to all regular maintenance areas. Themachine has hydraulic boom offset to allow working against wallsand other obstructions. With a choice of main boom and dipperarm lengths and specifications, the machine features patentedanti-drop valves on main boom and dipper arm cylinders.UNDERCARRIAGEA two gear range transmission offers a maximum travel speedbetween job sites of 33 km/h. Maximum drawbar pull in lowrange is 62 kN. The <strong>WX</strong><strong>95</strong> Series 2 can be specified with twowheel steering or four wheel steering, and a choice of single ordouble wheels. In four wheel steering the machine offers a crabsteering mode to allow diagonal movement away from a wall orobstruction, protecting the upperstructure and reducing the riskof impact on site.ARTICULATED EQUIPMENTThe Tier III compliant <strong>WX</strong><strong>95</strong> Series 2 is designed to operate inconfined spaces. Its full articulated boom, combined with a shortradius upper structure, makes it possible for the machine towork in narrow urban applications. The standard offset boomallows the <strong>WX</strong><strong>95</strong> Series 2 to work alongside a wall or otherobstruction. The boom itself is also articulated, enabling theoperator to carry loads close in to the machine. The boom isequipped with a standard auxiliary hydraulic circuit to poweradditional hydraulic services, such as quick couplers, 4-in-1buckets and hydraulic attachments.4

OPERATOR’S CABThe <strong>WX</strong><strong>95</strong> Series 2 uses the <strong>Case</strong> High Space cab, that offerssimilar internal volume to much larger excavators. The spaciousenvironment is further improved by the extensive use of tintedglass to offer excellent all round visibility and a large transparentcab roof to allow additional light into the cabin. A fully adjustablesuspension seat and tilting steering column ensure thatoperators of all sizes will be able to find a comfortable positionin this exceptionally quiet cab. Simple to operate joystick controlsand pedals ensure low effort and reduced fatigue for theoperator over a full working day.

ENGINEElectronically-controlled turbo charged diesel engine meetsTier III emissions regulations. In tests the 99 hp (74 kW)engine offers increased productivity and lower fuelconsumption. Engine and hydraulic pump monitoring andcontrol system offers multifunction use with high output,increasing productivity and tonne/litre output for the customer.HYDRAULICS<strong>Case</strong> has been a manufacturer of class-leading excavators formany years and the <strong>WX</strong><strong>95</strong> Series 2 builds on that success. Thehydraulic system has on-board computer and engine speedsensor control to maximise hydraulic flow and pressure to meetthe operator’s needs. A swing pressure control offers the driveroutstanding controllability, while the flow pump saving circuitminimises oil return to ensure smooth flowing movement of theboom and dipper arm.SERVICE AND MAINTENANCEThree large gullwing doors at the rear and side of theupperstructure afford excellent access to the engine and hydrauliccomponents. All regular service work can be carried out fromground level and the Tier III engine has 500 hour oil changeintervals to minimise downtime. The electronic managementsystem incorporates self-diagnostic software that can beaccessed via the large monitor in the cab. Standard ecologicaldrain plugs and hoses are included and customers can opt forfully biodegradable oil if working in sensitive areas.6

SPECIFICATIONSENGINELatest generation engine, meeting European requirementsfor "Low exhaust emissions" Tier III in accordance with directive97/68/CEMake _________________________________CASE FAMILY IIIType _____________________F4GE9484P*J/ 445TA/MNB4 cyl. 2 Val TAA rotary injection pumpNumber of cylinders_________________________________4Bore - Stroke ___________________________104 x 132 mmDisplacement ___________________________________4.5 lHorsepower EEC80/1269____________74 kW @ 2100 rpmMaximum Torque __________________415 Nm @ 1250 rpmHYDRAULIC SYSTEMTotal max. flow _____________________________151 l/minAttachment max pressure______________________350 barTravel max pressure___________________________350 barSwing max pressure ___________________________190 barSWINGMax upperstructure swing speed ________________8.0 rpmSwing torque _______________________________23.0 kNmTail swing radius_____________________________1485 mmTRAVELMax travel speed (field range) __________________11 km/hMax travel speed (road range)__________________33 km/hMax drawbar pull (field range)_____________________62 kNELECTRICAL SYSTEMVoltage ________________________________________24 VBatteries ___________________________2 x 12 V - 100 A/hStarter motor __________________________________4 kWAlternator______________________________________70 AUNDERCARRIAGE2 wheel steering turning circle diameter ___________12.6 m4 wheel steering turning circle diameter ____________7.7 mCIRCUIT AND COMPONENT CAPACITIESFuel tank_______________________________________128 lHydraulic tank ___________________________________94 lEngine oil________________________________________13 lCooling circuit ___________________________________22 lSwing gear _______________________________________3 lBRAKESService brakes ________________________oil bath disc typeWork brake __________________acts on service brakes andlocks front axle oscillationParking brake _____________ spring type mechanical actingon rear axleEmergency brake _____double braking circuit and automaticparking brake actuation with the engine shut downTYRES4 wheels ________________________________500/45 - 208 wheels with twinning rings ___________________8.25 - 20BUCKETS *GENERAL PURPOSESAE capacityWidthWeightlmmkg* For other bucket sizes, please contact your CASE dealer96 135 193 237 280350 450 600 700 800<strong>95</strong> 110 130 140 145SHIPPING DIMENSIONSAND WEIGHTDipper 1.85 mDipper 2.20 mPL P2A P2AL P4ARear Blade Rear Stabilisers Front Blade + Rear Stab. 4 Stabilisersmax max max max max max max maxlength height length height length height length heightmm mm kg mm mm kg mm mm kg mm mm kg6970 3025 <strong>95</strong>50 6940 3025 9400 6940 3025 9<strong>95</strong>0 6940 3025 98007340 3025 9600 7310 3025 9450 7310 3025 10000 7310 3025 985010

GENERAL DIMENSIONSMachine equipped with twin tyres 8.25-20 14PR10702200 <strong>95</strong>01100 2200 <strong>95</strong>0920 2200 <strong>95</strong>04220425040701485*30252902640535 1115169037902200 980220069701485**30252902315410 111516904160 2200<strong>95</strong>022007310Dimensions are indicated in mm* Machine equipped with dipper 1850 mm long** Machine equipped with dipper 2200 mm long7570745960°60°30°**10671010220026<strong>95</strong>11

PERFORMANCE DATAE900080007000600050004000300020001000090008000700060005000C4000D3000200010000F10002000B'B30004000500024406000A'ADIPPERSTICK 1850 mm 2200 mmA Maximum digging reachmm7941 8282A’ Maximum digging reach at ground levelmm7743 80<strong>95</strong>B Maximum digging depthmm3<strong>95</strong>1 4298B’ Digging depth - 2440 mm level bottommm3793 4151C Max digging heightmm8066 8397D Max loading heightmm6147 6490E Minimum front swing radiusmm2<strong>95</strong>9 3189F Max digging depth of vertical wallmm2138 2403Bucket breakout force (350 bar)daN4600 4600Stick breakout force (350 bar)daN4530 401012

LIFTING CAPACITYBASE BOOM: 1.75 m - TOP BOOM: 2.00 m - BUCKET (CECE): 0.193 m3 (130 Kg)Front360°Values are expressed in tonnesREACH3.5 m 4.5 m 6.0 m At max reachm6.0 m4.5 m3.0 m1.5 m0 m-1.5 m-3.0 -2.5 mPL up - DIPPERSTICK 1.85 m2.9* 2.3 2.0 1.5 0 0 1.7 1.3 5.02.9* 2.3 2.0 1.5 1.2 0.9 1.1 0.8 6.32.8 2.1 1.9 1.4 1.2 0.9 1.0 0.7 6.90 0 1.8 1.3 1.2 0.9 0.9 0.7 7.12.4 1.7 1.7 1.2 1.1 0.8 0.9 0.7 6.92.4 1.8 1.7 1.2 1.1 0.8 1.0* 0.8 6.20 0 1.2 1.2 0 0 1.2 1.2 4.76.0 m4.5 m3.0 m1.5 m0 m-1.5 m-3.0 -2.5 mPL down - DIPPERSTICK 1.85 m2.9* 2.7 2.5* 1.8 0 0 1.8* 1.5 5.02.9* 2.7 2.4* 1.8 2.0* 1.1 1.5* 1.0 6.34.0* 2.5 2.8* 1.7 2.1* 1.1 1.5* 0.8 6.90 0 3.2* 1.5 2.1* 1.0 1.6* 0.8 7.14.0* 2.1 3.0* 1.5 1.9* 1.0 1.4* 0.8 6.92.6* 2.1 2.1* 1.5 1.2* 1.0 1.0* 1.0 6.20 0 1.2 1.2 0 0 1.2 1.2 4.76.0 m4.5 m3.0 m1.5 m0 m-1.5 m-2.5 mP2A down - DIPPERSTICK 1.85 m2.9* 2.3 2.5* 1.5 0 0 1.8* 1.2 5.02.9* 2.3 2.4* 1.5 2.0* 0.9 1.5* 0.8 6.34.0* 2.1 2.8* 1.4 2.1* 0.9 1.5* 0.7 6.90 0 3.2* 1.3 2.1* 0.8 1.6* 0.7 7.14.0* 1.7 3.0* 1.2 1.9* 0.8 1.4* 0.7 6.92.6* 1.8 2.1* 1.2 1.2* 0.8 1.0* 0.8 6.20 0 1.2 1.2 0 0 1.2 1.2 4.76.0 m4.5 m3.0 m1.5 m0 m-1.5 m-2.5 mP2AL down - DIPPERSTICK 1.85 m2.9* 2.9 2.5* 1.9 0 0 1.8* 1.6 5.02.9* 2.9 2.4* 1.9 2.0* 1.2 1.5* 1.1 6.34.0* 2.6 2.8* 1.8 2.1* 1.2 1.5* 0.9 6.90 0 3.2* 1.7 2.1* 1.1 1.6* 0.9 7.14.0* 2.3 3.0* 1.6 1.9* 1.1 1.4* 0.9 6.92.6* 2.3 2.1* 1.6 1.2* 1.1 1.0* 1.0 6.20 0 1.2 1.2 0 0 1.2 1.2 4.76.0 m4.5 m3.0 m1.5 m0 m-1.5 m-2.5 mP4A down - DIPPERSTICK 1.85 m2.9* 2.4 2.5* 1.6 0 0 1.8* 1.3 5.02.9* 2.4 2.4* 1.6 2.0* 1.0 1.5* 0.9 6.34.0* 2.2 2.8* 1.5 2.1* 1.0 1.5* 0.8 6.90 0 3.2* 1.4 2.1* 0.9 1.6* 0.7 7.14.0* 1.9 3.0* 1.3 1.9* 0.9 1.4* 0.7 6.92.6* 1.9 2.1* 1.3 1.2* 0.9 1.0* 0.9 6.20 0 1.2 1.2 0 0 1.2 1.2 4.7- Lift capacities are taken in accordance with SAE J 1097/ISO 10567/DIN 15019-2.- Lift capacities shown in tons do not exceed 75% of the tipping load or 87% of the hydraulic lift capacity.- Capacities that are marked with an asterisk are hydraulic limited.- If the machine is equipped with a quick coupler, subtract the weight of the quick coupler from the load shown in the tables to calculate the real lifting capacity.- The machine must be parked on firm, level ground, with stabilisers and/or blade on the ground.14

LIFTING CAPACITYBASE BOOM: 1.75 m - TOP BOOM: 2.00 m - BUCKET (CECE): 0.193 m3 (130 Kg)Front360°Values are expressed in tonnesREACH3.5 m 4.0 m 6.0 m At max reachm6.0 m4.5 m3.0 m1.5 m0 m-1.5 m-2.5 mPL up - DIPPERSTICK 2.20m0 0 2.0 1.5 0 0 1.4 1.1 5.50 0 2.0 1.5 1.3 0.9 1.0 0.8 6.72.8 2.1 1.9 1.4 1.2 0.9 0.9 0.6 7.30 0 1.8 1.3 1.2 0.9 0.8 0.6 7.52.4 1.7 1.7 1.2 1.1 0.8 0.9 0.6 7.22.4 1.7 1.7 1.2 1.1 0.8 1.0 0.7 6.60 0 1.2 1.2 0 0 1.2 1.2 4.96.0 m4.5 m3.0 m1.5 m0 m-1.5 m-2.5 mPL down - DIPPERSTICK 2.20m0 0 2.2* 1.8 0 0 1.5* 1.3 5.50 0 2.2* 1.8 1.9 1.1 1.3* 0.9 6.73.6* 2.5 2.7* 1.7 2.0* 1.1 1.2* 0.8 7.30 0 3.2* 1.6 2.1* 1.0 1.3* 0.7 7.54.4* 2.1 3.1* 1.5 2.0* 1.0 1.3* 0.8 7.23.1* 2.1 2.4* 1.5 1.5* 1.0 1.0* 0.9 6.60 0 1.2 1.2 0 0 1.2 1.2 4.96.0 m4.5 m3.0 m1.5 m0 m-1.5 m-2.5 mP2A down - DIPPERSTICK 2.20m0 0 2.2* 1.5 0 0 1.5* 1.1 5.50 0 2.2* 1.5 1.9 0.9 1.3* 0.8 6.73.6* 2.1 2.7* 1.4 2.0* 0.9 1.2* 0.6 7.30 0 3.2* 1.3 2.1* 0.8 1.3* 0.6 7.54.4* 1.7 3.1* 1.2 2.0* 0.8 1.3* 0.6 7.23.1* 1.7 2.4* 1.2 1.5* 0.8 1.0* 0.7 6.60 0 1.2 1.2 0 0 1.2 1.2 4.96.0 m4.5 m3.0 m1.5 m0 m-1.5 m-2.5 mP2AL down - DIPPERSTICK 2.20m0 0 2.2* 1.9 0 0 1.5* 1.4 5.50 0 2.2* 1.9 1.9 1.2 1.3* 1.0 6.73.6* 2.7 2.7* 1.8 2.0* 1.2 1.2* 0.8 7.30 0 3.2* 1.7 2.1* 1.1 1.3* 0.8 7.54.4* 2.3 3.1* 1.6 2.0* 1.1 1.3* 0.8 7.23.1* 2.3 2.4* 1.6 1.5* 1.1 1.0* 1.0 6.60 0 1.2 1.2 0 0 1.2 1.2 4.96.0 m4.5 m3.0 m1.5 m0 m-1.5 m-2.5 mP4A down - DIPPERSTICK 2.20m0 0 2.2* 1.6 0 0 1.5* 1.1 5.50 0 2.2* 1.6 1.9 1.0 1.3* 0.8 6.73.6 2.3 2.7* 1.5 2.0* 1.0 1.2* 0.7 7.30 0 3.2* 1.4 2.1* 0.9 1.3* 0.7 7.54.4* 1.8 3.1* 1.3 2.0* 0.9 1.3* 0.7 7.23.1* 1.9 2.4* 1.3 1.5* 0.9 1.0* 0.8 6.60 0 1.2 1.2 0 0 1.2 1.2 4.9- Lift capacities are taken in accordance with SAE J 1097/ISO 10567/DIN 15019-2.- Lift capacities shown in tons do not exceed 75% of the tipping load or 87% of the hydraulic lift capacity.- Capacities that are marked with an asterisk are hydraulic limited.- If the machine is equipped with a quick coupler, subtract the weight of the quick coupler from the load shown in the tables to calculate the real lifting capacity.- The machine must be parked on firm, level ground, with stabilisers and/or blade on the ground.15

<strong>WX</strong><strong>95</strong>Series 2STANDARD EQUIPMENT & OPTIONSSTANDARD EQUIPMENT2 wheel steeringRobust, shielded arc-welded, modular chassis in box section designLarge toolbox under the right stepLatest generation CASE Family III Tier 3 diesel engines,comply with currentEuropean emissions standardsDirect injection with turbo chargerWater-cooled, low-consumption and low-exhaust compliant to EU directiveAutomatic battery main switch (coupled to ignition key)Pump Management SystemHydraulic servo controlSingle pump hydraulic load sensing system with two service pumpsEngine and pump monitoring by power limit control6 selectable gears; maximum travel speed 33 Km/hEncased ball bearing slew ring with long-life lubricationSwing drive with low-wearing disc brakeNoise-insulated and flexibly mounted cabin in soft designTinted safety glazing all around, full up and over windscreenSun blinds, transparent roof and rain protectionLCD with integrated error diagnosis functionSteering column incline infinitely variableErgonomic design of arm rests and foot pedalsDriver suspension seat individually adjustable for height and inclineConsoles adjustable for height and lengthForward/Reverse shifting on acceleratorIndependent control of blade and each stabiliserAutomatic axle locking systemTravel and swing hydrostatic brakingCentralised control of blade and stabilisers on right joystickSafety load hook on bucket linkagePatented safety valves for hoist modeHydraulic system provision for hammer and shearsOPTIONS4 wheel steering20 km/h forward speedSingle or twin tyresDozer blade with hydraulic parallel guidanceStabilisers with large, lockable padsTransport holder for transport holder for clamshell grabRadio with 12 V electrical auxiliary supply in cabFront guardFOPS protection for cabAir conditioningElectric diesel filling systemCold starting kitBiodegradable oilRotating beaconPiping for hammer and shearsForm No. 26061059GB - Printed in Italy - LEADER Firenze - 04/08Standard and optional equipment shown can vary by country.Worldwide <strong>Case</strong> <strong>Construction</strong>Equipment Contact InformationEUROPE/AFRICA/MIDDLE EAST:Centre D’affaires EGB5, Avenue Georges Bataille - BP 4040160671 Le Plessis-Belleville - FRANCENORTH AMERICA/MEXICO:700 State StreetRacine, WI 53404 U.S.A.LATIN AMERICA:Av. General David Sarnoff 223732210 - 900 Contagem - MGBelo Horizonte BRAZILASIA PACIFIC:Unit 1 - 1 Foundation Place - ProspectNew South Wales - 2148 AUSTRALIACHINA:No. 29, Industrial Premises, No. 376.De Bao Road, Waigaoqiao Ftz, Pudong,SHANGHAI, 200131, P.R.C.The call is free from a land line. Check in advancewith your Mobile Operator if you will be charged.NOTE: Standard and optional fittings can varyaccording to the demands and specificregulations of each country. The illustrationsmay include optional rather than standard fittings- consult your <strong>Case</strong> dealer. Furthermore, CNHreserves the right to modify machinespecifications without incurring any obligationrelating to such changes.Conforms to directive 98/37/CECASE <strong>Construction</strong> EquipmentCNH UK LtdUnit 4,Hayfield Lane Business Park,Field Lane, Auckley,Doncaster,DN9 3FLTel. 00800-2273-7373Fax +44 1302 802829www.casece.com