Mechanical Properties of Metals 6.1 Elastic and Plastic Deformation

Mechanical Properties of Metals 6.1 Elastic and Plastic Deformation

Mechanical Properties of Metals 6.1 Elastic and Plastic Deformation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

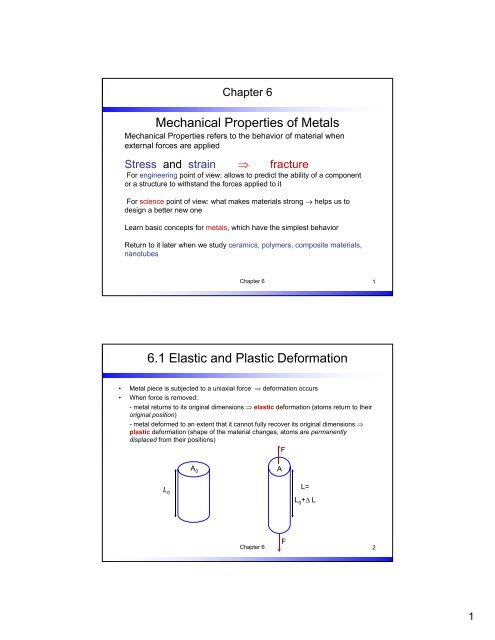

Chapter 6<strong>Mechanical</strong> <strong>Properties</strong> <strong>of</strong> <strong>Metals</strong><strong>Mechanical</strong> <strong>Properties</strong> refers to the behavior <strong>of</strong> material whenexternal forces are appliedStress <strong>and</strong> strain ⇒ fractureFor engineering point <strong>of</strong> view: allows to predict the ability <strong>of</strong> a componentor a structure to withst<strong>and</strong> the forces applied to itFor science point <strong>of</strong> view: what makes materials strong → helps us todesign a better new oneLearn basic concepts for metals, which have the simplest behaviorReturn to it later when we study ceramics, polymers, composite materials,nanotubesChapter 61<strong>6.1</strong> <strong>Elastic</strong> <strong>and</strong> <strong>Plastic</strong> <strong>Deformation</strong>• Metal piece is subjected to a uniaxial force ⇒ deformation occurs• When force is removed:- metal returns to its original dimensions ⇒ elastic deformation (atoms return to theiroriginal position)- metal deformed to an extent that it cannot fully recover its original dimensions ⇒plastic deformation (shape <strong>of</strong> the material changes, atoms are permanentlydisplaced from their positions)FL 0A 0 AL=L 0+∆ LChapter 6F21

6.2 Concept <strong>of</strong> Stress <strong>and</strong> StrainLoad can be applied to the material by applying axial forces:NotdeformedTensionFCompressionL 0A 0AL=AFL=L 0+∆ LL 0+∆ LFF∆L can be measured as a function <strong>of</strong> the applied force; area A 0 changes in responseChapter 63Stress (σ) <strong>and</strong> Strain (ε)Block <strong>of</strong>metalAFFL=L 0+∆ LStress (σ)• defining F is not enough ( F <strong>and</strong> A can vary)• Stress σ stays constantFσ =A•UnitsForce / area = N / m 2 = Pausually in MPa or GPaStrain (ε) – result <strong>of</strong> stress• For tension <strong>and</strong> compression: change in length <strong>of</strong> asample divided by the original length <strong>of</strong> sample∆Lε =LChapter 642

OverviewOJJDP FY 2006 Carryover from FY 2005ProgramsCDFA # 16.541The OJJDP FY 2006 Carryover from FY 2005 Programs was established to provide grants,cooperative agreements, <strong>and</strong> other assistance authorized by the Juvenile Justice <strong>and</strong>Delinquency Prevention Act <strong>of</strong> 2002 to organizations designated by the Office <strong>of</strong> JuvenileJustice <strong>and</strong> Delinquency Prevention <strong>and</strong> identified in Public Law 109–108, the Science, State,Justice, Commerce, <strong>and</strong> Related Agencies Appropriations Act, 2006.Please visit http://www.ojp.usdoj.gov/fundopps.htm for information on other fundingopportunities from the Office <strong>of</strong> Justice Programs.Deadline: RegistrationThe GMS registration deadline is 8:00 p.m. e.t. March 1, 2006.Deadline: ApplicationThe due date for applying for funding under this announcement is 8:00 p.m. e.t., April 17, 2006.EligibilityOJJDP will only accept applications for OJJDP FY 2006 Carryover from FY 2005 Programsfrom agencies <strong>and</strong> organizations that have received an invitation to apply under this program.Applicants should confirm that this program solicitation is the one listed on their invitation letterbefore applying. All other applications will not be processed.Faith-Based <strong>and</strong> Other Community Organizations: Consistent with President George W.Bush’s Executive Order 13279, dated December 12, 2002, <strong>and</strong> 28 C.F.R. Part 38, it is DOJpolicy that faith-based <strong>and</strong> other community organizations that statutorily qualify as eligibleapplicants under DOJ programs are invited <strong>and</strong> encouraged to apply for assistance awards t<strong>of</strong>und eligible grant activities. Faith-based <strong>and</strong> other community organizations will be consideredfor awards on the same basis as other eligible applicants <strong>and</strong>, if they receive assistanceawards, will be treated on an equal basis with all other grantees in the administration <strong>of</strong> suchawards. No eligible applicant or grantee will be discriminated for or against on the basis <strong>of</strong> itsreligious character or affiliation, religious name, or the religious composition <strong>of</strong> its board <strong>of</strong>directors or persons working in the organization.Faith-based organizations receiving DOJ assistance awards retain their independence <strong>and</strong> donot lose or have to modify their religious identity (e.g., removing religious symbols) to receiveassistance awards. DOJ grant funds, however, may not be used to fund any inherently religiousactivity, such as prayer or worship. Inherently religious activity is permissible, although it cannotoccur during an activity funded with DOJ grant funds; rather, such religious activity must beOJJDP FY 2006 Carryover for FY 2005 Programs3

<strong>Elastic</strong> <strong>Properties</strong> <strong>of</strong> Materials• Most materials will get narrow when stretched <strong>and</strong> thicken when compressed• This behaviour is qualified by Poisson’s ratio, which is defined as the ratio <strong>of</strong> lateral<strong>and</strong> axial strainεPoisson's _ Ratio : ν = −εxz= −εεyz• the minus sign is there because usually if ε z > 0, <strong>and</strong> ε x + ε y < 0 ⇒ ν > 0• It can be proven that we must have ν ≤ ½; ν = ½ is the case when there is novolume change( l + ∆l)( l + ∆l)( l + ∆l) = l × l × lxxyyzzxyzChapter 67Poisson’s Ratio, ν•For isotropic materials (i.e. material composed <strong>of</strong> many r<strong>and</strong>omly - oriented grains) ν= 0.25• For most metals:0.25 < ν < 0.35•If ν = 0 :means that the width <strong>of</strong> the material doesn’t change when it is stretched orcompressed• Can be:ν < 0(i.e. the material gets thicker when stretched)Chapter 684

6.3 Modulus <strong>of</strong> elasticity, or Young’s Modulus• Stress <strong>and</strong> strain are properties that don’t depend on the dimensions <strong>of</strong> thematerial (for small ε), just type <strong>of</strong> the material• E – Young’s Modulus, Paσ ( stress)E = ε ( strain)• Comes from the linear range in the stress-strain diagram• many exceptions…Behavior is related to atomic bonding between the atomsMaterial<strong>Metals</strong>PolypropeleneRubberHydrogels <strong>and</strong> live cellsYoung’s Modulus [GPa]20-1001.5-20.01

Tensile Test1. Modulus <strong>of</strong> elasticity2. Yield strength at 0.2% <strong>of</strong>fset3. Ultimate tensile strength4. Percent elongation at fracture5. Percent reduction in area at fractureChapter 611Other tensile test characteristics:• Yield strength (at 0.2% <strong>of</strong>fset)• Ultimate Tensile Strength (UTS): themaximum strength reached in the stressstraincurveF ∆Lσ == E ×A(original)L• Percent elongation at fracture (measure <strong>of</strong>ductility <strong>of</strong> the metal)• Percent reduction in area at fractureAinitial− Afinal% _ reduction _ in _ area =× 100%AinitialChapter 6126

True <strong>and</strong> Engineering Stressσengineeringσ=trueFAinitial=FA∆L= E ×LinstantChapter 6136.4 HardnessHardness: a measure <strong>of</strong> the resistance <strong>of</strong> a material to plastic(permanent) deformationMeasured by indentation• indenter material (ball, pyramid, cone) is harder than thematerial being tested (i.e.: tungsten carbide, diamond)• indenter is pressed at 90 o• hardness is based on the depth <strong>of</strong> the impression or its crosssectionalareaSeveral common hardness tests: hardness numbers can becalculatedMaterial strength <strong>and</strong> hardness are relatedHardness test is nondestructive ⇒ <strong>of</strong>ten usedChapter 6147

Hardness tests: hardness numbersChapter 6156.5 <strong>Plastic</strong> deformations <strong>of</strong> single crystal metalsA rod <strong>of</strong> a single crystal Zn (hcp) stressedbeyond its elastic limit:• slipb<strong>and</strong>s: slip <strong>of</strong> metal atoms on specificcrystallographic planes (slip planes)•slip is predominately along the basal planesChapter 6A rod <strong>of</strong> a single crystal Cu (fcc) duringplastic deformation:• slip lines: 50-500 atoms apart• slipb<strong>and</strong>s: separated by ~>10,000atomic planes168

Other mechanical characteristics• Ductility: amount <strong>of</strong> plastic deformation that occurs before fracture- if ductility is high, the material can be deformed by applying stresses.Ex.: gold- if it is low, material breaks first, without significant deformation (material is brittle)- depend on T: at low T many metals become brittle <strong>and</strong> can break as a glass• Resilience: ability to have high yield strength <strong>and</strong> low E.Ex.: good springs• Toughness: ability to absorb energy up to a fractureChapter 617Mechanism <strong>of</strong> Slip deformationthe group <strong>of</strong> atoms do NOT slide over eachother during plastic shear deformation ⇒the process requires too much energyThe process takes less energy!!!Chapter 6189

Motion <strong>of</strong> DislocationsIn the metal slip mechanism,dislocations move through the metalcrystals like wave fronts, allowingmetallic atoms to slide over each otherunder low shear stress ⇒deformation without fractureChapter 619Slip SystemsTypically slip planes are the most densely packed planes (less energy is required tomove from one position to another), which are the farthest separatedCombination <strong>of</strong> a slip plane <strong>and</strong> a slip direction: slip systemChapter 62010

Slip systems observed in crystal structuresFor hcp crystals: 3 slip systems, restricts their ductilityChapter 621Schmid’s LawF cosλcosφτr==AoFAoSlip process begins within the crystal when theshear stress on the slip plane in slip directionreaches critical resolved shear stress τ chcp (Zn, Mg): 0.18, 0.77 MPafcc (Cu): 0.48 MPaFrτr=AF r= F cosλslip _ planecos λ cosφ= σ cosλcosφSchmid’s lawAoAslip _ plane=cosφChapter 62211

Q.: A stress <strong>of</strong> 75 MPa is applied in the [0 01] direction on an fcc single crystal.Calculate(a) the resolved shear stress acting on the (111) [-101] slip system <strong>and</strong>,(b) (b) the resolved shear stress acting on the (111) [-110] slip system.Chapter 623<strong>Mechanical</strong> TwinningAnother important plastic deformation mechanism (low T)Schematic diagram <strong>of</strong> surfaces <strong>of</strong> a deformedmetal after (a) slip <strong>and</strong> (b) twinningfrom G. GottsteinChapter 62412

6.6 <strong>Plastic</strong> <strong>Deformation</strong>s in Polycrystalline <strong>Metals</strong>• Majority <strong>of</strong> engineering alloys <strong>and</strong> metals arepolycrystalline• Grain boundaries – act as diffusion barriers fordislocation movements• In practice: fine grain materials are stronger <strong>and</strong>harder (but less resistant to creep <strong>and</strong> corrosion)• Strength <strong>and</strong> grain size are related by Hall-Pelchequation:kσy= σo+dσ o <strong>and</strong> k – constantsas grain diameter decreases, theyield strength <strong>of</strong> the materialincreasesChapter 625Pile-up <strong>of</strong> dislocationsSchematicObserved in stainlesssteel (TEM)Grain shape changes with plastic deformationDislocation arrangement changesChapter 62613

6.7 Cold <strong>Plastic</strong> <strong>Deformation</strong> for Strengthening <strong>of</strong> <strong>Metals</strong>• The dislocation density increases with increased cold deformation• New dislocations are created by the deformation <strong>and</strong> must interact with those alreadyexisting• As the dislocation density increases with deformation, it becomes more <strong>and</strong> moredifficult for the dislocations to move through the existing dislocations⇒ Thus the metal work or strain hardens with cold deformationPercent cold work versus tensile strength <strong>and</strong>elongation for unalloyed oxygen-free copperCold work is expressed as a percent reduction incross-sectional area <strong>of</strong> the metal being reduced.Chapter 6276.8 Superplasticity in <strong>Metals</strong>Superplasticity: the ability <strong>of</strong> some metals to deform plastically by 1000-2000% at hightemperature <strong>and</strong> low loading ratesEx.: Ti alloy (6Al – 4V) 12% @ RT, typical tensile test load rates~1000% @ 840 o C, lower loading ratesRequirements:1. The material must possess very fine grain size (5-10mm) <strong>and</strong> be highly strain-ratedensity2. A high loading T (>0.5 T m ) is required3. A low <strong>and</strong> controlled strain rate in the range <strong>of</strong> 0.01-0.00001 s - 1 is requiredChapter 62814

Nanocrystalline <strong>Metals</strong>• Nanocrystalline metals: d < 10-50nmσy= σo+• Consider Cu: σ o = 25 MPa, k = 0.11 MPa m 0.5 (from Table 6.5)σσIs this possible?10µmkd0.11MPa25MPa+−8=100.11MPa25MPa+−51010 nm=?Different dislocation mechanism: grain boundary sliding, diffusion, etcChapter 629Summary•Introduced stress, strain <strong>and</strong> modulus <strong>of</strong> elasticityFσ =A• <strong>Plastic</strong> deformations <strong>of</strong> single crystal metals- In the single crystal metal - slip mechanism: dislocations move through the metalcrystals like wave fronts, allowing metallic atoms to slide over each other under low shearstress- Slip process begins within the crystal when the shear stress on the slip plane in slipdirection reaches critical resolved shear stress τ c-Schmid’slaw:F cosλcosφFτr== cos λ cosφ= σ cosλcosφA A• <strong>Plastic</strong> deformations in polycrystalline metals- Strength <strong>and</strong> grain size are related by Hall-Pelch equation:• Nanocrystalline materialso∆Lε =LoChapter 6σ ( stress)E = ε ( strain)σy= σo+kd3015