Thermalhydraulic Safety Characteristics Of CANDU ... - Canteach

Thermalhydraulic Safety Characteristics Of CANDU ... - Canteach

Thermalhydraulic Safety Characteristics Of CANDU ... - Canteach

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>CANDU</strong> <strong>Safety</strong> #4:<strong>Thermalhydraulic</strong> <strong>Safety</strong> <strong>Characteristics</strong><strong>Of</strong> <strong>CANDU</strong> ReactorsF. J. DoriaAtomic Energy of Canada Limited24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 1

OverviewλλλλλDescription of the primary heat transport system and safetyrequirementsNatural circulation after loss of forced flow in the primary heattransport systemDescription of steam generators, primary heat transportpumps and safety requirementsDescription of reactor headers, feedersLoop isolation, emergency core cooling24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 2

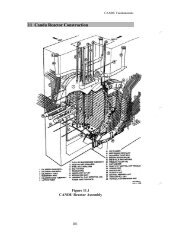

λλλλλλλPrimary Heat Transport System (PHT)2 separate loops4 steam generators4 primary heat transportsystem pumpsPressurized heavy water inloops380 horizontal fuel channels380 inlet feeders; 380 outletfeeders4 inlet headers; 4 outletheaders24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 3

Figure 8 layoutλλλλλλCirculation in Primary Heat Transport SystemFlow from inlet header-1through core to outletheader-1Then through steamgenerator-1 1 to pump-1Then to inlet header-2on the other side ofreactor faceBack through the coreto the outlet header-2Then through the steamgenerator-2 2 to pump-2This constitutes onecomplete pass in one ofthe loops24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 4

Some <strong>Safety</strong> Requirements of the PHTλλλλλIn the event where the PHT system boundary fails, must limitthe fuel damage to satisfy dose limits, in conjunction with themitigating systems such as reactor shutdown: SDS1, SDS2;and emergency core cooling systemPromote decay heat removal by natural circulation(thermosyphoning) after the total loss of PHT pumping powerProvide a rotational inertia to each PHT pump so that coolantflow prevents overheating of the fuel, if power is lost to thepump motorProvide process measurements for tripping and shutting downthe reactor to ensure that system pressure is within allowablelimitsProvide process measurements for detecting LOCA’s and theinitiation of ECC injection into the core24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 5

Thermosyphoning PhenomenaλλλλOccurs in the absence of forced flow in the primary heattransport system (i.e., loss of PHT pumps due to loss of ClassIV power)Decay heat generated by the fuel is transported to the steamgenerators by natural circulation (thermosyphoningphenomena)Thermosyphoning is defined as the natural circulation in thePHT induced by the difference in coolant densities in thevertical sections of the:– reactor inlet pipes and– reactor outlet pipesThe thermosyphoning flow through the core is sufficient tocool the fuel24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 6

PHT Pump & MotorSpecificationsλ Pump– Vertical-type, type, centrifugal– Single suction; doubledischarge– Flow rate: 2228 L/s– Operating Temperature:266 o C– Head: 215 mλ Motor– Power supply is Class IV24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 10

λλSingle PHT Pump TripFor each loop in the PHT system, there are 2 PHT pumpsFollowing a single PHT Pump Trip, the other pump will still provide forcedcirculation through the systemCORE FLOW FOR SINGLE PUMP TRIP; 80% Full-Power24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 12

SpecificationsλλHeadersInlet Headers– 4 inlet headers– 0.37 m inside diameter– Operating pressure: 11.25 MPa(g)– Operating temperature: 266 o COutlet Headers– 4 outlet headers– 0.406 m inside diameter– Operating pressure: 9.89 MPa (g)– Operating temperature: 310 o CSteam GeneratorsPHT PumpReactorHeadersInlet and OutletFeeders24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 13

FeedersSpecificationsλ 380 inlet feeders; 380 outletfeedersλ Connects fuel channel to headersλ The flow in each feeder is setaccording to the fuel channelpower (high channel power ==>high feeder flow)λ Inside diameter ranges from 38.1mm to 85.4 mmλ Maximum channel flow: 26.5 kg/s24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 14

Loop Isolation for LOCA eventsλλλλDuring some accident scenarios, loop isolation is initiated (forexample in LOCA events were a break occurs in the reactorheaders)Isolation of the two separate loops occurs after the loopisolation signal is received (i.e., detection of a LOCA)By separating the two loops from each other, then only half thecore is affected by the breakForced circulation before the pump trips and thermosyphoningafter the pumps trip provide adequate fuel cooling in the intactloop24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 15

λλλλ<strong>Thermalhydraulic</strong>s of Emergency Core Cooling(ECC) SystemHigh pressureinjection by gasMedium pressureinjection by ECCpumps and dousingtank water supplyLow pressureinjection by ECCpumps and reactorbuilding sumpInjection intoreactor headers24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 17

Some <strong>Safety</strong> Requirements of ECCλλλTo prevent any fuel sheath failures during small LOCAsTo limit the number of fuel sheath failures for large LOCA suchthat the acceptable dose limits are satisfiedTo maintain a coolable fuel bundle geometry for large LOCADepressurization of Inlet Headers during a Large 35% RIH LOCA24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 18

Emergency Core Cooling &PHT Refill of Broken Loop24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 19

Pressure and Inventory ControlλλConsists of:– pressurizer– bleed condenser– feed pumps– feed and bleedvalves– storage tankFunctions:– pressure andinventory controlfor each PHTloopBleed ValvesBleed CondenserReactor HeadersPressurizerFeed Pumps24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 20

λλλλλλSome Requirements of Pressure & InventoryControlTo accommodate the PHT coolant swell (cool water to hotwater) and shrink (hot water to cool water) associated withwarm-up, cooldown and power maneuvering (feed and bleedsystem)Provide relief for over-pressure protection of PHT system(liquid relief valves) and contain the relief from PHT (bleedcondenser)Control the PHT system pressure (by pressurizer or feed andbleed system)Minimize rapid pressure reduction in PHT system for accidentscenarios and prevent PHT pump suction pressure fromdropping to a value that would cause PHT pump cavitationIsolate loops following LOCAProvide a low-level level trip signal to the reactor shutdown system24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 21

<strong>CANDU</strong> Fuel Channelλλλλλ380 horizontally-oriented oriented fuel channelsin coreZircaloy-2.5wt%Nb pressure tubes– 103.4 mm inside diameter– 4.2 mm wall thicknessZircaloy-2 2 calandria tubes– 129 mm inside diameter– 1.4 mm wall thicknessFuel Bundles– 37 fuel elements– Natural UO 2 with Zircaloy sheaths– Centre pin, 6 elements in innerring, 12 elements in intermediatering, 18 elements in outer ring380 inlet end fittings and 380 outlet endfittings– links the feeders and channels24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 22

Some T/H <strong>Safety</strong> Features of ChannelsλλPermits the PHT coolant to efficiently remove heat from thefuel with a low pressure drop across the channel and minimizevibration in channelDuring single-channel accidents such as flow blockage andfeeder stagnation break, the accident only affects the single-channel (i.e., degraded cooling conditions in 1 channel out of380 channels, severe fuel temperatures in 1 channel). Theunaffected channels behave similar to a small loss-ofof-coolantaccident (i.e., no fuel failures)24-May-01 <strong>CANDU</strong> safety - #4 - <strong>Thermalhydraulic</strong>s.ppt Rev. 0 23