Under Jurisdiction of Nagpur Court only WESTERN COALFIELDS ...

Under Jurisdiction of Nagpur Court only WESTERN COALFIELDS ...

Under Jurisdiction of Nagpur Court only WESTERN COALFIELDS ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

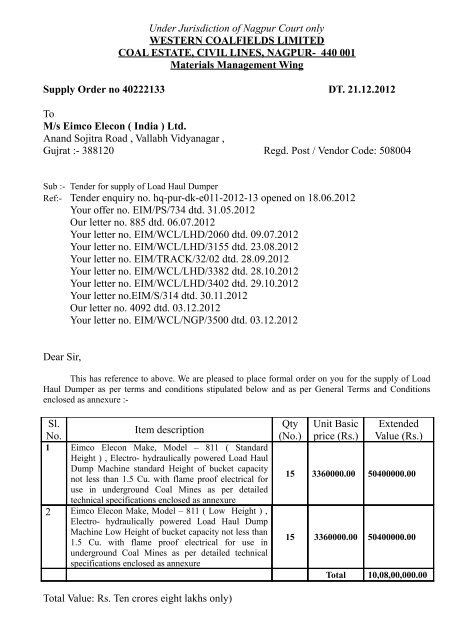

<strong>Under</strong> <strong>Jurisdiction</strong> <strong>of</strong> <strong>Nagpur</strong> <strong>Court</strong> <strong>only</strong><strong>WESTERN</strong> <strong>COALFIELDS</strong> LIMITEDCOAL ESTATE, CIVIL LINES, NAGPUR- 440 001Materials Management WingSupply Order no 40222133 DT. 21.12.2012ToM/s Eimco Elecon ( India ) Ltd.Anand Sojitra Road , Vallabh Vidyanagar ,Gujrat :- 388120 Regd. Post / Vendor Code: 508004Sub :- Tender for supply <strong>of</strong> Load Haul DumperRef:- Tender enquiry no. hq-pur-dk-e011-2012-13 opened on 18.06.2012Your <strong>of</strong>fer no. EIM/PS/734 dtd. 31.05.2012Our letter no. 885 dtd. 06.07.2012Your letter no. EIM/WCL/LHD/2060 dtd. 09.07.2012Your letter no. EIM/WCL/LHD/3155 dtd. 23.08.2012Your letter no. EIM/TRACK/32/02 dtd. 28.09.2012Your letter no. EIM/WCL/LHD/3382 dtd. 28.10.2012Your letter no. EIM/WCL/LHD/3402 dtd. 29.10.2012Your letter no.EIM/S/314 dtd. 30.11.2012Our letter no. 4092 dtd. 03.12.2012Your letter no. EIM/WCL/NGP/3500 dtd. 03.12.2012Dear Sir,This has reference to above. We are pleased to place formal order on you for the supply <strong>of</strong> LoadHaul Dumper as per terms and conditions stipulated below and as per General Terms and Conditionsenclosed as annexure :-Sl.Item descriptionNo.1 Eimco Elecon Make, Model – 811 ( StandardHeight ) , Electro- hydraulically powered Load HaulDump Machine standard Height <strong>of</strong> bucket capacitynot less than 1.5 Cu. with flame pro<strong>of</strong> electrical foruse in underground Coal Mines as per detailedtechnical specifications enclosed as annexure2 Eimco Elecon Make, Model – 811 ( Low Height ) ,Electro- hydraulically powered Load Haul DumpMachine Low Height <strong>of</strong> bucket capacity not less than1.5 Cu. with flame pro<strong>of</strong> electrical for use inunderground Coal Mines as per detailed technicalspecifications enclosed as annexureQty(No.)Unit Basicprice (Rs.)ExtendedValue (Rs.)15 3360000.00 50400000.0015 3360000.00 50400000.00Total 10,08,00,000.00Total Value: Rs. Ten crores eight lakhs <strong>only</strong>)

Western Coalfields Limited ; Supply order no. 40222133 dtd. 21.12.2012 ; M/S Eimco Elecon ( I) Ltd.Price: Prices are FIRM and on FOR Destination basis inclusive <strong>of</strong> packing & forwarding charges.However, Freight & transit Insurance @ Rs.35,000.00 per SDL shall be paid extra for delivery on FORDestination basis .Excise Duty: Excise Duty and cess on ED shall be paid extra as applicable at the time <strong>of</strong> despatch againstdocumentary evidence. Present rate <strong>of</strong> ED & cess on ED is 12.36%. CENVAT Credit shall be obtained asper rule.Sales Tax : Sales Tax shall be paid extra as applicable at the time <strong>of</strong> dispatch . Present rate <strong>of</strong> CST is 2%against form C. Declaration form shall be given by Consignee.Delivery : Delivery <strong>of</strong> four machines ( LHD) within two months from the date <strong>of</strong> placement <strong>of</strong> order andcompletion <strong>of</strong> the supply at the minimum rate <strong>of</strong> six LHDs per month thereafter. The delivery period shall bereckoned from seventh day <strong>of</strong> supply order date. (However, early delivery is preferred).Inspection: Final inspection <strong>of</strong> the materials will be carried by consignee at site.Payment terms: 80% value <strong>of</strong> each equipment and the accessories and 100% Excise Duty and fullconcessional ST / CST along with 100% transportation charges will be paid within 21 days <strong>of</strong> receipt <strong>of</strong>the complete equipment at the project site and receipt and acceptance <strong>of</strong> performance bank guarantee bythe consignee. The equipment should be accompanied with relevant dispatch documents like challan,Maker’s Test-cum-Inspection certificate, Warranty certificate, WCL’s Inspection Certificate etc.Balance 20% payment shall be made within 21 days <strong>of</strong> successful completion <strong>of</strong> erection, testing,commissioning and final acceptance <strong>of</strong> the equipment (alongwith accessories) at site upon presentation <strong>of</strong>a certificate from the project <strong>of</strong>ficer to the effect that the equipment has been erected and commissionedto their entire satisfaction.Paying Authority: General Manager (Fin.), WCL, Coal Estate, Civil Lines, <strong>Nagpur</strong> 440 001.Details for payment through EFT :-Name <strong>of</strong> Bank and Branch :- State bank <strong>of</strong> India , Comm. Branch , Anand., Jay Laxmi Plaza,GaneshCrossing,Anand, GujratAccount Number :- 00000010201747608Nature <strong>of</strong> Account :- Cash CreditIFSC code <strong>of</strong> the the Branch :- SBIN0004084Mode <strong>of</strong> dispatch: All the stores surely packed are to be dispatched by road transport to the consignee onFreight paid basis. Safe arrival <strong>of</strong> the consignment shall be the responsibility <strong>of</strong> the vendor.Security Deposit: _ Security money for 10% value <strong>of</strong> the equipment on FOR Destination basis shall besubmitted by you within 15 days <strong>of</strong> placement <strong>of</strong> order. In case <strong>of</strong> failure to deposit the security money.The order shall be canceled and the case shall be processed to order elsewhere and the firm's performancewill be kept recorded for future dealings. Security Money as per present Statutory levies works out toRs. 1,16,57,406.00 ( Rupees One crore sixteen lakhs fifty seven thousand four hundred six) <strong>only</strong>.Consignee & Allocation :- As mentioned below for Standard Height and Low Height LHDs.

The calculation <strong>of</strong> % availability:8760 – (Maintenance hours + Breakdown hours)Percentage Availability = ---------------------------------------------------------- x 1008760Please also refer Technical specification for Performance Guarantee .Western Coalfields Limited ; Supply order no. 40222133 dtd. 21.12.2012 ; M/S Eimco Elecon ( I) Ltd.Performance Bank Guarantee: You will have to furnish the performance Bank guarantee on Scheduled/ Nationalised Bank in India for individual machines to the paying authority <strong>of</strong> WCL. The PBG has to bevalid for 12 (twelve) months from the date <strong>of</strong> commissioning or 18(eighteen) months from the date <strong>of</strong>receipt and acceptance by the Company. PBG should be for 10% <strong>of</strong> the value <strong>of</strong> the equipment includingtaxes and duties etc to the landed value <strong>of</strong> the materials on order as a coverage towards the suppliersperformance against the contract, in the standard format. No Payment will be made without submission <strong>of</strong>PBG. OBG submitted by the firm and if valid can be considered towards PBG to the extent <strong>of</strong> PBG value.Liquidated Damages cum Risk Purchase clause :-In the event <strong>of</strong> failure to deliver the stores within the stipulated period mentioned in the order and in theevent <strong>of</strong> breach <strong>of</strong> any <strong>of</strong> the terms and conditions in the order WCL has the right :-To recover from successful tenderer, as agreed liquidated damages, a sum not less than 0.5% <strong>of</strong> the price<strong>of</strong> the store which successful tenderer has not been able to supply (for this purpose part <strong>of</strong> a unit suppliedwill not be considered) as aforesaid for each week or part <strong>of</strong> a week during which the delivery <strong>of</strong> suchstores may be in arrears limited to 10 %. Where felt necessary the limit <strong>of</strong> 10% can be increased to 15%at the discretion <strong>of</strong> buyerTo purchase from elsewhere, after due notice to the successful tenderer, on the account and at the risk <strong>of</strong>the defaulting supplier the stores not supplied or others <strong>of</strong> a similar description without canceling thesupply order in respect <strong>of</strong> consignment not yet due for supply orTo cancel the supply order or a portion there<strong>of</strong>, and if so desired, to purchase the store at the risk and cost<strong>of</strong> the supplier and alsoTo extend the delivery period with or without imposition <strong>of</strong> Liquidated Damages as may be considered fitand proper. The penalty if imposed shall not be more than the agreed liquidated damages referred toclause (a) above.To encash any available Bank Guarantee / security deposit for recovery <strong>of</strong> the penalty.Whenever under the contract a sum <strong>of</strong> money is recoverable from and payable by the supplier, WesternCoalfields Limited, shall be entitled to recover such sum by appropriating, in part or whole by deductingany sum or which at any time thereafter, may be due to the successful tenderer in this or any othercontract, with Western Coalfields Limited or any <strong>of</strong> its Subsidiary Company. Should this sum be notsufficient to cover the full amount recoverable, the successful tenderer shall pay to Western CoalfieldsLimited, on demand the remaining amount.Submission <strong>of</strong> Bills: For claiming payment, following documents are to be submitted alongwith originalbills as per terms <strong>of</strong> the supply order to the consignee.i. Pre-receipted and stamped Invoice (Original Buyer’s copy <strong>of</strong> invoice & Transporter copy <strong>of</strong> Invoice) inquadriplicateii. Packing list in original list in original giving details <strong>of</strong> bill <strong>of</strong> materialsiii. Consignment note / RR/ PWB in original

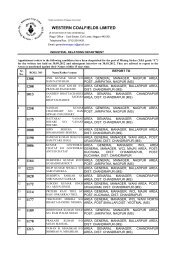

STANDARD HEIGHT LHDSl.noDescription1.0 ITEM DESCRIPTIONStandard Height Electro-hydraulically powered Load Haul Dump machine (Hydro-statically power Transmission1.1 arrangement is not acceptable). It should be <strong>of</strong> articulated construction to enable negotiation <strong>of</strong> sharp right angle turnsin galleries without repeated maneuvering, and to operate in a mucky floor condition with a maximum gradient <strong>of</strong> 1 in 6and cross gradient <strong>of</strong> 1 in 10.The machine should have <strong>only</strong> flame pro<strong>of</strong> electricals and shall be fitted with automaticcoiling type cable reeling attachment.EIMCO ELECON MAKE MODEL 811 LHD ( STANDARD HEIGHT )2.0 SCOPE OF SUPPLYSR.No. DescriptionQuantity RequiredNumber <strong>of</strong> LOAD HAUL DUMP machine complete with2.1 15 nos.FLP electricalDescriptionParameterGate End Box ( As per enclosed specification ) - 12.2 Not Requiredno. ( for each LHD)2.3 Tool Kit 1 set with each LHD.2.4 Operation & Maintenance manual 4 sets (with each LHD)2.5 Spare parts catalogue 4 sets (with each LHD)2.6 Spare parts catalogue for gate end box Not Applicable2.7First fill <strong>of</strong> hydraulic oil, FRHF, grade HF-B 68, DGMS Full quantity (with each LHD)approved and Lubricants.a) Pressure Line filter ( 10 microns) – 1 set with each LHD2.8 Set <strong>of</strong> filter elements for 1st schedule oil replacement/ b) Return line filter ( 25 microns,650LPM) – 1 no .with eachmaintenance period(Ref.Clause No.6.3)LHD3.0 Technical parametrsSR.No. DescriptionParameter3.1 Height <strong>of</strong> machine Standard Height3.2 Overall height with canopy not to exceed 2000 mm – 2200 mm3.3 Bucket arrangement Push Plate , front discharge bucket3.4 Bucket capacity Not less than 1.5 Cu. Mtr3.5 Overall length in carrying position shall not be more than 6550 mm3.6Overall length in bucket down ( digging position) shall not be6900 mmmore than3.7 Width 1800 mm approx.3.8 Ground clearance shall not be less than 170 mm3.9 Inner turning radius not to exceed 2400 mm3.10 Outer turning radius not to exceed 4500 mm3.11No. <strong>of</strong> wheels ( wheel includes Rim, lock ring, tyre,tube & flap5 nos. ( 4 nos. fitted with equipment & 1 no. spare wheel)complete in all respect)3.12 Type and size <strong>of</strong> tyresTube type,hard rock lug pattern, heat and cut resistant rubber compound,9.00 x 20 – 16 PR3.13 Travel speed at level Not less than 8 KmPHThe machine shall be powered by an FLP induction motor <strong>of</strong>rating (continuous) not less than 37 KW, suitable for 525 V ±3.14 Motor6%, 3 Ph, 50 Hz systems and provided with suitablearrangement/ mechanism to receive trailing cable, and shallbe approved by DGMS for use in machine.3.15 Ambient temperature 45 deg. cent.3.16 Humidity 98.00%3.17 Operating time/Duty ContinuousThe plug and socket on the machine shall be suitable to receive trailing3.18Size <strong>of</strong> plug and socketcable <strong>of</strong> size 16 Sq.mm type FT-7 conforming to IS:14494-1998 asamended up to dateHydraulically driven. Length <strong>of</strong> cable to be accommodated in reeling drum3.19Type <strong>of</strong> cable reelerto be furnished. However, the cable reeler shall accommodate not lessthan 100 meter trailing cable.3.20Axles & Transmission MakeDana Spicer make3.21 Optional power take-<strong>of</strong>f arrangement. The same is provided on service control valve

4.0 OTHER TECHNICAL CONDITIONSSR.No. DescriptionParameter4.1 Distance (Horizontal length) between front wheel center to Tip <strong>of</strong> the bucket at rest position (on ground) - Not less than 2550 mm.(The mechanism/arrangement <strong>of</strong> front wheel, connecting arm and the bucket shall be designed and fabricated in view <strong>of</strong> maintainingsufficient gap between front wheel & bucket, so that safe and centralized loading on 1000 mm conveyor belt is also possible withoutdamaging the conveyor structure).4.2 The front and rear frames shall be made <strong>of</strong> heavy duty, having suitable metallurgical composition and it is to be designed and fabricated forlife time under specified conditions.5.0 SALIENT FEATURESSR.No. DescriptionParameter5.1 This specification covers design, manufacture, supply, erection and commissioning requirements <strong>of</strong> loaders for use in coal faces for thepurposes <strong>of</strong> loading coal. The machines will be required to work in underground coal faces to scoop and load run <strong>of</strong> mine coal.5.2 You will supply Eimco Elecon Make Model 811 standard height LHD that has the approval <strong>of</strong> Directorate General <strong>of</strong> Mines Safety, Dhanbad,India.6.0 SAFETY FEATURESSR.No. DescriptionParameterThe machine shall be fitted with effective service brake and parking brake (one <strong>of</strong> them fail safe), which will allow the machine to stand in a6.1gradient <strong>of</strong> 1 in 6 and cross gradient <strong>of</strong> 1 in 10 (without rolling down).(a) The machine can be started by operator from machine itself keeping gate end box at far end.6.2(b) Hose fail check valves on lift ram and roll back rams.(a) Pilot operation (Hydraulically operated pilot circuit operation to be used in rear end operated machines.).(b) All the hydraulic loop/loops shall be provided with high pressure line filters <strong>of</strong> suitable capacity and 10 microns (constant) equipped withcolour indicators to indicate the cleanliness <strong>of</strong> the filter element as given below :-(i) Filter element in good condition(ii) Filter element dirty and needs replacements.6.3(iii) Filter element too dirty and the filter by passed.(c) Suction strainers <strong>of</strong> 40 mesh shall be provided. The capacity should not be less than two times <strong>of</strong> pump discharge. The strainers shallbe easily accessible with minimum handling <strong>of</strong> hydraulic fluid to facilitate regular cleaning <strong>of</strong> the strainers.(d) In addition to the above, a tank mounted replaceable filter <strong>of</strong> 25 micron, 650 LPm shall be provided on the return line with by passarrangement.Low fluid level cut <strong>of</strong>f and high fluid temperature cut <strong>of</strong>f switch, having adjustable limit between 65 to 75 deg. Cent, should be provided andfitted. The design <strong>of</strong> equipment and cooling system shall be such that fluid temperature does not exceed permissible limits under6.4continuous operation at full load on above mentioned environment.The cut <strong>of</strong>f switch shall operate at 65 degree centigradeThe machine should be fitted with suitable light at the front and back to ensure good visibility. The lighting arrangement should be suitable6.5to work at 12 volt/24 volt and all fittings used should be FLP duly approved by DGMS.The machine shall be fitted with suitable audio-visual alarm operative when the machine is put to travel in forward/reverse direction. AVA6.6shall be duly approved by DGMS.The hydraulic hoses and hose assemblies used on the machine shall be in accordance with DGMS circular No.1 <strong>of</strong> 1996 dated 31.1.19966.7and shall be approved by DGMS for use in underground coal mines.6.8 The hydraulic fluid used for the machine shall be non toxic, Fire Resistant, invert emulsions type, HF-B 68 grade,conforming to IS:10532 (Part-2)-1983 duly approved by DGMS for use in underground coal mines.However, the machine shall also be suitable for use with Organic Esters type, HFDU grade D68 fluid.6.9 Machine must have canopy for operator.6.1 Self sealing hydraulic oil filling arrangement to prevent ingress <strong>of</strong> dirt should be provided.6.11 Limit switch for cable reeler.6.12 Indicators for(a) Pressure gauge with selector,(b) Temperature indicator,(c) Fluid level indicators.7.0 LIFE TIME SPARES PARTSSR.No. DescriptionParameterThe supplier undertakes and guarantees to produce and maintain stock to be available for purchase by the purchaser under separate7.1 agreement <strong>of</strong> all spare parts and consumables as may be required for maintenance and repair <strong>of</strong> the plant/equipment through-out its lifeminimum 06 years or stipulated 21500 working hours whichever is later8 AVAILABILITYSR.No. DescriptionParameterThe supplier shall ensure that availability <strong>of</strong> the machine over a period <strong>of</strong> 12 months does not fall below 75%. For every 1% fall in the %availability below 75%, 1% <strong>of</strong> the value <strong>of</strong> the machine will be deducted. In case the fall in availability below 75% exceeds 10% the8.1equipment will be rejected out right and the supplier will have to refund the full amount.Calculation <strong>of</strong> % availability. :- 8760 – (Maint. Hrs + breakdown hrs )% Availability = ---------------------------------------------------------------- x 1008760

LOW HEIGHT LHDSl.noDescription1.0 ITEM DESCRIPTIONLow Height Electro-hydraulically powered Load Haul Dump machine (Hydro-statically power Transmission arrangement isnot acceptable). It should be <strong>of</strong> articulated construction to enable negotiation <strong>of</strong> sharp right angle turns in galleries1.1 without repeated maneuvering, and to operate in a mucky floor condition with a maximum gradient <strong>of</strong> 1 in 6 and crossgradient <strong>of</strong> 1 in 10.The machine should have <strong>only</strong> flame pro<strong>of</strong> electricals and shall be fitted with automatic coiling typecable reeling attachment.EIMCO ELECON MAKE MODEL 811 LHD ( LOW HEIGHT )2.0 SCOPE OF SUPPLYDescriptionQuantity Required2.1Number <strong>of</strong> LOAD HAUL DUMP machine complete with15 nos.FLP electricalDescriptionParameter2.2Gate End Box ( As per enclosed specification ) - 1Not Requiredno. ( for each LHD)2.3 Tool Kit 1 set with each LHD.2.4 Operation & Maintenance manual 4 sets (with each LHD)2.5 Spare parts catalogue 4 sets (with each LHD)2.6 Spare parts catalogue for gate end box Not Applicable2.7First fill <strong>of</strong> hydraulic oil, FRHF, grade HF-B 68, DGMS Full quantity (with each LHD)approved and Lubricants.a) Pressure Line filter ( 10 microns) – 1 set with each LHD2.8 Set <strong>of</strong> filter elements for 1st schedule oil replacement/ b) Return line filter ( 25 microns,650LPM) – 1 no .with eachmaintenance period(Ref.Clause No.6.3)LHD3.0 Technical parametrsSR.No. DescriptionParameter3.1 Height <strong>of</strong> machine Low Height3.2 Overall height with canopy not to exceed 1500 mm ( Max.)3.3 Bucket arrangement Push Plate , front discharge bucket3.4 Bucket capacity Not less than 1.5 Cu. Mtr3.5 Overall length in carrying position shall not be more than 6550 mm3.6Overall length in bucket down ( digging position) shall not be6900 mmmore than3.7 Width 1800 mm approx.3.8 Ground clearance shall not be less than 170 mm3.9 Inner turning radius not to exceed 2400 mm3.10 Outer turning radius not to exceed 4500 mm3.11No. <strong>of</strong> wheels ( wheel includes Rim, lock ring, tyre,tube & flap5 nos. ( 4 nos. fitted with equipment & 1 no. spare wheel)complete in all respect)3.12 Type and size <strong>of</strong> tyresTube type,hard rock lug pattern, heat and cut resistant rubber compound,9.00 x 20 – 16 PR3.13 Travel speed at level Not less than 8 KmPHThe machine shall be powered by an FLP induction motor <strong>of</strong>rating (continuous) not less than 37 KW, suitable for 525 V ±3.14 Motor6%, 3 Ph, 50 Hz systems and provided with suitablearrangement/ mechanism to receive trailing cable, and shallbe approved by DGMS for use in machine.3.15 Ambient temperature 45 deg. cent.3.16 Humidity 98.00%3.17 Operating time/Duty ContinuousThe plug and socket on the machine shall be suitable to receive trailing3.18 Size <strong>of</strong> plug and socketcable <strong>of</strong> size 16 Sq.mm type FT-7 conforming to IS:14494-1998 asamended up to dateHydraulically driven. Length <strong>of</strong> cable to be accommodated in reeling drum3.19 Type <strong>of</strong> cable reelerto be furnished. However, the cable reeler shall accommodate not lessthan 100 meter trailing cable.3.20 Axles& Transmission MakeDana Spicer make3.21 Optional power take-<strong>of</strong>f arrangement. The same is provided on service control valve.

4.0 OTHER TECHNICAL CONDITIONSSR.No. DescriptionParameter4.1 Distance (Horizontal length) between front wheel center to Tip <strong>of</strong> the bucket at rest position (on ground) - Not less than 2550 mm.(The mechanism/arrangement <strong>of</strong> front wheel, connecting arm and the bucket shall be designed and fabricated in view <strong>of</strong> maintainingsufficient gap between front wheel & bucket, so that safe and centralized loading on 1000 mm conveyor belt is also possible withoutdamaging the conveyor structure).4.2 The front and rear frames shall be made <strong>of</strong> heavy duty, having suitable metallurgical composition and it is to be designed and fabricated forlife time under specified conditions.5.0 SALIENT FEATURESSR.No. DescriptionParameter5.1 This specification covers design, manufacture, supply, erection and commissioning requirements <strong>of</strong> loaders for use in coal faces for thepurposes <strong>of</strong> loading coal. The machines will be required to work in underground coal faces to scoop and load run <strong>of</strong> mine coal.5.2 You will supply Eimco Elecon Make Model 811 Low height LHD that has the approval <strong>of</strong> Directorate General <strong>of</strong> Mines Safety, Dhanbad,6.0 SAFETY India. FEATURESSR.No. DescriptionParameterThe machine shall be fitted with effective service brake and parking brake (one <strong>of</strong> them fail safe), which will allow the machine to stand in a6.1gradient <strong>of</strong> 1 in 6 and cross gradient <strong>of</strong> 1 in 10 (without rolling down).(a) The machine can be started by operator from machine itself keeping gate end box at far end.6.2(b) Hose fail check valves on lift ram and roll back rams.(a) Pilot operation (Hydraulically operated pilot circuit operation to be used in rear end operated machines.).(b) All the hydraulic loop/loops shall be provided with high pressure line filters <strong>of</strong> suitable capacity and 10 microns (constant) equipped withcolour indicators to indicate the cleanliness <strong>of</strong> the filter element as given below :-(i) Filter element in good condition(ii) Filter element dirty and needs replacements.6.3(iii) Filter element too dirty and the filter by passed.(c) Suction strainers <strong>of</strong> 40 mesh shall be provided. The capacity should not be less than two times <strong>of</strong> pump discharge. The strainers shallbe easily accessible with minimum handling <strong>of</strong> hydraulic fluid to facilitate regular cleaning <strong>of</strong> the strainers.(d) In addition to the above, a tank mounted replaceable filter <strong>of</strong> 25 micron, 650 LPm shall be provided on the return line with by passarrangement.Low fluid level cut <strong>of</strong>f and high fluid temperature cut <strong>of</strong>f switch, having adjustable limit between 65 to 75 deg. Cent, should be provided andfitted. The design <strong>of</strong> equipment and cooling system shall be such that fluid temperature does not exceed permissible limits under6.4continuous operation at full load on above mentioned environment.The cut <strong>of</strong>f switch shall operate at 65 degree centigrade.The machine should be fitted with suitable light at the front and back to ensure good visibility. The lighting arrangement should be suitable6.5to work at 12 volt/24 volt and all fittings used should be FLP duly approved by DGMS.The machine shall be fitted with suitable audio-visual alarm operative when the machine is put to travel in forward/reverse direction. AVA6.6shall be duly approved by DGMS.The hydraulic hoses and hose assemblies used on the machine shall be in accordance with DGMS circular No.1 <strong>of</strong> 1996 dated 31.1.19966.7and shall be approved by DGMS for use in underground coal mines.6.8 The hydraulic fluid used for the machine shall be non toxic, Fire Resistant, invert emulsions type, HF-B 68 grade,conforming to IS:10532 (Part-2)-1983 duly approved by DGMS for use in underground coal mines.However, the machine shall also be suitable for use with Organic Esters type, HFDU grade D68 fluid.6.9 Machine must have canopy for operator.6.10 Self sealing hydraulic oil filling arrangement to prevent ingress <strong>of</strong> dirt should be provided.6.11 Limit switch for cable reeler.6.12 Indicators for(a) Pressure gauge with selector,(b) Temperature indicator,(c) Fluid level indicators.7.0 LIFE TIME SPARES PARTSSR.No. DescriptionParameterThe supplier undertakes and guarantees to produce and maintain stock to be available for purchase by the purchaser under separate7.1 agreement <strong>of</strong> all spare parts and consumables as may be required for maintenance and repair <strong>of</strong> the plant/equipment through-out its lifeminimum 06 years or stipulated 21500 working hours whichever is later8.0 AVAILABILITYSR.No. DescriptionParameterThe supplier shall ensure that availability <strong>of</strong> the machine over a period <strong>of</strong> 12 months does not fall below 75%. For every 1% fall in the %availability below 75%, 1% <strong>of</strong> the value <strong>of</strong> the machine will be deducted. In case the fall in availability below 75% exceeds 10% the8.1equipment will be rejected out right and the supplier will have to refund the full amount. Calculation <strong>of</strong> %availability. :- 8760 – (Maint. Hrs + breakdown hrs )% Availability = ----------------------------------------------------------------- x 1008760

![To [Name & Address of the Assured] Dear Mr./Ms.[______] Subject ...](https://img.yumpu.com/48378713/1/190x245/to-name-address-of-the-assured-dear-mr-ms-subject-.jpg?quality=85)