Under Jurisdiction of Nagpur Court only - Western Coalfields Limited

Under Jurisdiction of Nagpur Court only - Western Coalfields Limited

Under Jurisdiction of Nagpur Court only - Western Coalfields Limited

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

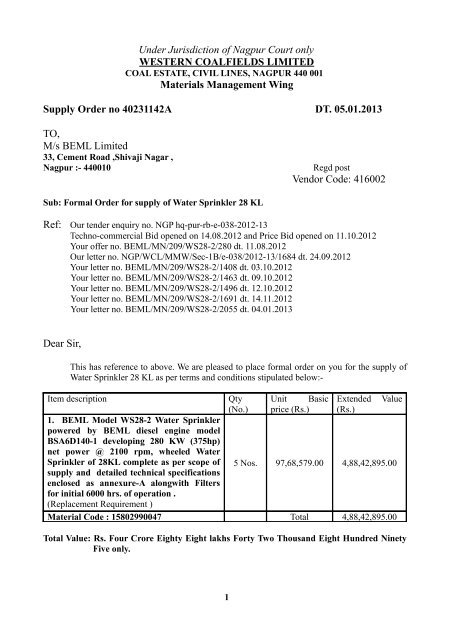

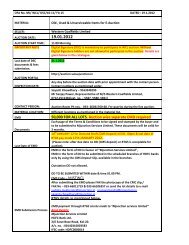

<strong>Under</strong> <strong>Jurisdiction</strong> <strong>of</strong> <strong>Nagpur</strong> <strong>Court</strong> <strong>only</strong>WESTERN COALFIELDS LIMITEDCOAL ESTATE, CIVIL LINES, NAGPUR 440 001Materials Management WingSupply Order no 40231142A DT. 05.01.2013TO,M/s BEML <strong>Limited</strong>33, Cement Road ,Shivaji Nagar ,<strong>Nagpur</strong> :- 440010 Regd postVendor Code: 416002Sub: Formal Order for supply <strong>of</strong> Water Sprinkler 28 KLRef: Our tender enquiry no. NGP hq-pur-rb-e-038-2012-13Techno-commercial Bid opened on 14.08.2012 and Price Bid opened on 11.10.2012Your <strong>of</strong>fer no. BEML/MN/209/WS28-2/280 dt. 11.08.2012Our letter no. NGP/WCL/MMW/Sec-1B/e-038/2012-13/1684 dt. 24.09.2012Your letter no. BEML/MN/209/WS28-2/1408 dt. 03.10.2012Your letter no. BEML/MN/209/WS28-2/1463 dt. 09.10.2012Your letter no. BEML/MN/209/WS28-2/1496 dt. 12.10.2012Your letter no. BEML/MN/209/WS28-2/1691 dt. 14.11.2012Your letter no. BEML/MN/209/WS28-2/2055 dt. 04.01.2013Dear Sir,This has reference to above. We are pleased to place formal order on you for the supply <strong>of</strong>Water Sprinkler 28 KL as per terms and conditions stipulated below:-Item description1. BEML Model WS28-2 Water Sprinklerpowered by BEML diesel engine modelBSA6D140-1 developing 280 KW (375hp)net power @ 2100 rpm, wheeled WaterSprinkler <strong>of</strong> 28KL complete as per scope <strong>of</strong>supply and detailed technical specificationsenclosed as annexure-A alongwith Filtersfor initial 6000 hrs. <strong>of</strong> operation .(Replacement Requirement )Qty(No.)Unit Basicprice (Rs.)Extended Value(Rs.)5 Nos. 97,68,579.00 4,88,42,895.00Material Code : 15802990047 Total 4,88,42,895.00Total Value: Rs. Four Crore Eighty Eight lakhs Forty Two Thousand Eight Hundred NinetyFive <strong>only</strong>.1

<strong>Under</strong> <strong>Jurisdiction</strong> <strong>of</strong> <strong>Nagpur</strong> <strong>Court</strong> <strong>only</strong>WESTERN COALFIELDS LIMITEDCOAL ESTATE, CIVIL LINES, NAGPUR 440 001Materials Management WingSupply Order no 40231142A DT. 05.01.2013Price: Prices are FIRM and on FOR Destination basis inclusive <strong>of</strong> packing & forwarding charges.However, Freight and transit insurance charges shall be reimbursed at actual against documentaryevidence subject to maximum freight <strong>of</strong> Rs.1,47,686.49 per Water Sprinkler + Service tax on 25%freight amount (Rs.4563.51) and transit insurance <strong>of</strong> Rs.2,269.27 per Water Sprinkler Dumper.Excise Duty: Excise Duty and cess on ED shall be paid extra as applicable at the time <strong>of</strong> despatchagainst documentary evidence. Present rate <strong>of</strong> ED & Cess on ED is 12.36%Sales Tax : Sales Tax shall be paid extra as applicable at the time <strong>of</strong> dispatch . Present rate <strong>of</strong> CST is2% against form C. Declaration form shall be given by Consignee.Auto Cess :- Auto Cess shall be paid extra as applicable at the time <strong>of</strong> dispatch. Present rate <strong>of</strong>Auto cess is 0.125 % .As per the latest guidelines <strong>of</strong> the company you will submit a list <strong>of</strong> all invoices with completedetails like CST TIN,item Description,Invoice no ,date & amount including freight charges & othernon taxable elements ,if any ,within 15 days <strong>of</strong> the end <strong>of</strong> each quarter to the sales tax cell at HQ bye mail (wcltax@gmail.com).The correct address at which the C-Form is to be sent is also to begiven.Delivery : To be supplied within 3-4 months from the date <strong>of</strong> placement <strong>of</strong> order. Early supply isacceptable. Delivery period shall be reckoned from the 7 th day <strong>of</strong> placement <strong>of</strong> order.Inspection: Pre-despatch inspection shall be carried out by GM/CM(Excv), CIL, Bangalore.However, final inspection <strong>of</strong> the materials will be carried by consignee at site.Payment terms: 80% value <strong>of</strong> each equipment and the accessories and 100% Excise Duty and fullconcessional ST / CST along with 100% transportation charges will be paid within 21 days <strong>of</strong>receipt <strong>of</strong> the complete equipment at the project site and receipt and acceptance <strong>of</strong> performancebank guarantee by the consignee. The equipment should be accompanied with relevant dispatchdocuments like challan, Maker’s Test-cum-Inspection certificate, Warranty certificate, Pre-dispatchInspection Certificate etc.Balance 20% payment shall be made within 21 days <strong>of</strong> successful completion <strong>of</strong> erection,testing, commissioning and final acceptance <strong>of</strong> the equipment (along with accessories) at site uponpresentation <strong>of</strong> a certificate from the project <strong>of</strong>ficer to the effect that the equipment has been erectedand commissioned to their entire satisfaction.Paying Authority: General Manager (Fin.), WCL, Hqrs., Coal Estate, Civil Lines, <strong>Nagpur</strong> -440001.Mode <strong>of</strong> dispatch: All the stores surely packed are to be dispatched by road transport to theconsignee on Freight paid basis.Security Deposit: Exempted being a CPSU.2

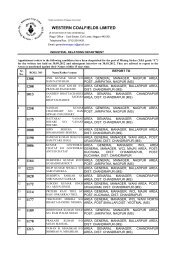

<strong>Under</strong> <strong>Jurisdiction</strong> <strong>of</strong> <strong>Nagpur</strong> <strong>Court</strong> <strong>only</strong>WESTERN COALFIELDS LIMITEDCOAL ESTATE, CIVIL LINES, NAGPUR 440 001Materials Management WingSupply Order no 40231142A DT. 05.01.2013Consignee & Allocation :- (REPLACEMENT BASIS)Project / Area Quantity ( no) ConsigneeSasti OCM 1 The Depot Officer, Ballarpur AreaDurgapur OCM 1 The Depot Officer, Chandrapur AreaPadmapur OCM 1 The Depot Officer, Chandrapur AreaNiljai OCM 1 The Depot Officer, Wani AreaUmrer OCM 1 The Depot Officer, Umrer AreaTotal 5Performance Bank Guarantee :- Performance Bank Guarantee valid for 21 months from the datereceipt and acceptance <strong>of</strong> equipment, equivalent to 10% value <strong>of</strong> the contract including taxes andduties etc. to the FOR Destination price <strong>of</strong> the equipment on order, covering the warranty period.The bank guarantee shall be released after successful completion <strong>of</strong> the guarantee/warranty periodafter confirmation from GM(Excv) I/C, WCL/Hqrs. The PBG must be submitted within 15 daysfrom the date <strong>of</strong> placement <strong>of</strong> order. No payment shall be made without submission <strong>of</strong> PBG. BankGuarantee format is enclosed.Guarantee /Warranty Clause :- Shall be as per the technical specifications enclosed as annexureLiquidated Damages clause :-In the event <strong>of</strong> failure to deliver the stores within the stipulated date / period in accordance with thesamples and / or specifications mentioned in the supply order and in the event <strong>of</strong> breach <strong>of</strong> any<strong>of</strong> the terms and conditions mentioned in the supply order, Coal India <strong>Limited</strong> and / or itssubsidiary Companies should have the right :-a. To recover from successful tenderer, as agreed liquidated damages, a sum not less than 0.5% <strong>of</strong>the price <strong>of</strong> the store which successful tenderer has not been able to supply (for this purposepart <strong>of</strong> a unit supplied will not be considered) as aforesaid for each week or part <strong>of</strong> a weekduring which the delivery <strong>of</strong> such stores may be in arrears limited to 10 %. Where feltnecessary the limit <strong>of</strong> 10% can be increased to 15% at the discretion <strong>of</strong> Head <strong>of</strong> the MaterialsManagement Divisionb. To purchase from elsewhere, after due notice to the successful tenderer, on the account and atthe risk <strong>of</strong> the defaulting supplier the stores not supplied or others <strong>of</strong> a similar descriptionwithout canceling the supply order in respect <strong>of</strong> consignment not yet due for supply orc. To cancel the supply order or a portion there<strong>of</strong>, and if so desired, to purchase the store at therisk and cost <strong>of</strong> the defaulting supplier and alsod. To extend the delivery period with or without imposition <strong>of</strong> Liquidated Damages as may beconsidered fit and proper. The penalty if imposed shall not be more than the agreed liquidateddamages referred to clause (a) above.3

<strong>Under</strong> <strong>Jurisdiction</strong> <strong>of</strong> <strong>Nagpur</strong> <strong>Court</strong> <strong>only</strong>WESTERN COALFIELDS LIMITEDCOAL ESTATE, CIVIL LINES, NAGPUR 440 001Materials Management WingSupply Order no 40231142A DT. 05.01.2013e. To forfeit security deposit in full or part.f. Whenever under the contract a sum <strong>of</strong> money is recoverable from and payable by thesupplier, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong>, shall be entitled to recover such sum by appropriating, inpart or in whole by deducting any sum or which at any time thereafter, may become due to thesuccessful tenderer in this or any other contract, with <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong>. Should thissum be not sufficient to cover the full amount recoverable, the successful tenderer shall pay to<strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong>, on demand the remaining balance. The supplier shall not beentitled to any gain on any such purchase.Submission <strong>of</strong> Bills: For claiming payment, following documents are to be submitted alongwithoriginal bills as per terms <strong>of</strong> the supply order to the consignee.i. Pre-receipted and stamped Invoice (and / or Original Buyer’s copy <strong>of</strong> invoice wherever ED ispayable)ii. Required dealer invoice as mentioned in Taxes & Duties clause no. 16 / or Transporters copy <strong>of</strong>Invoice in case <strong>of</strong> supplies by manufacturers, for obtaining CENVAT credit wherever CENVATcredit is applicable.iii. Packing list in original list in original giving details <strong>of</strong> bill <strong>of</strong> materialsiv. Consignment note / RR/ LR in originalv. Warranty / Guarantee certificatevi. Manfuacturers test certificate as per supply order termsvii. DGMS / BIS / Pre dispatch inspection certificates / any other document, if required as per thecontract.Please indicate your Bank Account number ,Name <strong>of</strong> Banker, Nature <strong>of</strong> Account ,MICR Codeand IFSC code to facilitate payment through EFT while submitting your bill.vii) As the order is being placed on the basis <strong>of</strong> consideration that you are a manufacturer <strong>of</strong> theordered material, you will have to provide a certificate to the following effect on the body <strong>of</strong> eachbill “Certified that items supplied and included in this bill/ invoiced are own make and have actuallybeen manufactured at your works situated at ________________ (address <strong>of</strong> factory”)Force Majeure Clause: If the execution <strong>of</strong> the contract / supply orders delayed beyond the periodstipulated in the contract / supply order as a result <strong>of</strong> outbreak <strong>of</strong> hostilities, declaration <strong>of</strong> anembargo or blockade, or fire, floods, acts <strong>of</strong> nature or other contingency beyond the supplier’scontrol, due to act <strong>of</strong> God then <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> may allow such additional time byextending the delivery period as it consider to be justified by the circumstances <strong>of</strong> the case and itsdecision shall be final. If and when additional time is granted by <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong>, thecontract / supply order shall be read and understood as if it had contained from its inception thedelivery date as extended4

<strong>Under</strong> <strong>Jurisdiction</strong> <strong>of</strong> <strong>Nagpur</strong> <strong>Court</strong> <strong>only</strong>WESTERN COALFIELDS LIMITEDCOAL ESTATE, CIVIL LINES, NAGPUR 440 001Materials Management WingSupply Order no 40231142A DT. 05.01.2013Manufacturing certificate: : As the order is being placed on the basis <strong>of</strong> consideration that you area manufacturer <strong>of</strong> the ordered material, you will have to provide a certificate to the following effecton the body <strong>of</strong> each bill.“Certified that the items supplied and included in this bill/ invoice are our own make and have beenactually manufactured in our works situated at _______________ (address <strong>of</strong> the factory)Unless otherwise specified above, the purchase order shall also be governed by the terms andconditions given in the General terms and conditions enclosed. THE INTEGRITY PACT IS APPLICABLEFOR THIS ORDER.Enclosures: - General terms and conditions, technical specifications, Integrity pact and PerformanceBank Guarantee format.Copy to :1. CGM/ SO(Excv) /SO(MM) /AFM/Depot Officer, WCL, Ballarpur Area2. CGM/ SO(Excv) /SO(MM) /AFM/Depot Officer, WCL, Chandrapur Area3. CGM/ SO(Excv) /SO(MM) /AFM/Depot Officer, WCL, Wani Area4. CGM/ SO(Excv) /SO(MM) /AFM/Depot Officer, WCL, Umrer Area5. GM(Excv)I/C / GM(CP)I/C/ GM(Fin.) I/C -I /Sr.Manager (Excv.) , WCL Hq., <strong>Nagpur</strong>6. Sr.Manager (Fin./CP) / Sr. Manager (Excv), WCL Hq., <strong>Nagpur</strong>7. GM (F), WCL Hq., <strong>Nagpur</strong> vide Budget diary no FA/WCL/Cap/ BC /HEMM/130 dt03.01.2013 for Rs. 5,68,12,346.008. GM(MM), SECL, MCL, CCL, BCCL, ECL, NCL9. RD, CMPDIL, RI IV, <strong>Nagpur</strong>10. Chief Manager (Excv), CIL, BangaloreSd/-CHIEF MANAGER(MM)Yours faithfullySd/-Sd/-(P V BABU) (SANT LAL)CHIEF MANAGER(MM)GENERAL MANAGER (MM)Sd/-GENERAL MANAGER (MM)5

Technical Specifications Annexure A1. IntroductionThese Technical Specifications identify the technical requirements <strong>of</strong> the Goodsand Services which are the subject <strong>of</strong> this Tender.The Technical Specifications are presented in following parts.A. Scope <strong>of</strong> SupplyB. General Requirements1)Geography and Climatic Conditions2)Goods (Equipment and Machinery)3)Standards4)Supplier’s Responsibility5)Spare Parts Provisions6)Composite Warranty / Guarantee7)Performance Guarantee8)Quality AssuranceC. Equipment Specifications2. Conformity with SpecificationsThe Equipment to be provided shall conform with the requirements definedin these parts. Where stated requirements conflict, the order in which thespecifications shall prevail is as follows:Part A followed by Part B followed by Part CSite VisitsThe Bidder prior to making any Bid calculation and as part <strong>of</strong> thepreparation <strong>of</strong> it's Bid, shall be deemed to have visited and inspected theSite(s), made all enquiries and collected all information documentary orotherwise, including climatic conditions, as considered necessary by theBidder for the proper and accurate preparation <strong>of</strong> it's bid.Technical ResponseBidders shall provide a Clause by Clause commentary demonstratingcompliance with the Purchaser's Technical Specifications, identifying anydeviations thereto, together with full supporting technical literature anddata sheets. The Equipment <strong>of</strong>fered by Bidders will be evaluated technicallybased on the information presented in the bid without reference to extrinsicevidence.Additionally Bidders shall provide the information specifically requested inthe Attachment to the Technical Specifications.Failure to provide any information requested in any part <strong>of</strong> this specificationmay deem the bid non- responsive.6

A. Scope <strong>of</strong> SupplyA.1 Equipment PackageThe Supplier is required to bid as per the equipment package detailed in the TenderDocumentA.2 Supplementary ItemsI. The Equipment shall be provided with a comprehensive tool kit, which shallinclude any special tools required for erection, commissioning and for themaintenance and repair <strong>of</strong> all the Equipment.II. First fill <strong>of</strong> all oils, grease and lubricants needed for test and commissioning <strong>of</strong>each equipment.III. All filters & O rings including standard engine filters required for first 6000working hours.A.3 Information and DrawingsThe Supplier shall provide for each equipment(a) One suitably illustrated copy <strong>of</strong> Operating, Repair and MaintenanceInstructions, written in the English language substantially bound in book form;(b) One suitably illustrated copy <strong>of</strong> detailed Spares Parts Manuals covering allplant, Equipment and accessories substantially bound in book form;The Supplier shall also submit the data identified in the specifications for each item <strong>of</strong>Equipment proposed. In addition to the Equipment drawings requested, whereappropriate the Supplier shall supply detailed drawings illustrating erection/assemblysite(s), foundation and accommodation requirements for such items as drive motors, switchinstallations etc.At least one month before the scheduled installation date, the Supplier shall providetwo sets <strong>of</strong> Operating, Repair & Maintenance Manual as well as Spares Parts Manualsagainst each order <strong>of</strong> equipments irrespective <strong>of</strong> their quantity shall be submitted in the<strong>of</strong>fice <strong>of</strong> GM (Excavation), WCL, Coal Estate Civil Lines , <strong>Nagpur</strong>.A.4 Erection/Assembly, Commissioning and Performance TestingThe Supplier shall provide the Services <strong>of</strong> Specialist Technicians to supervise theinstallation/erection/assembly, commissioning and any performance testing <strong>of</strong> the plant,Equipment and accessories supplied.The Technicians shall remain at site following commissioning until all necessarypersonnel are fully conversant with the maintenance and operation <strong>of</strong> the Equipment.A.5 TrainingThe Supplier shall also be responsible for the provision and deliver content <strong>of</strong> anysuitable training program necessary for operation and maintenance <strong>of</strong> the Equipment.B. General RequirementsB.1 Geography and Climatic ConditionsElevation :- The natural surface varies from 100 to 1000m above mean sea level. Climate.The climate is sub-tropical to tropical, dusty, with a hot and humid atmosphere.7

Monsoon rains occur in the period from June to October.Ambient Conditions Relative Humidity- Maximum 98%Temperature Minimum 0 o CMaximum 50 oRainfall The mean annual rainfall is 1,000 mm, 90 to 95% <strong>of</strong>which may fall in rainy season from June to October.Wind April to September - South to South WesterlyOctober to March - North WesterlySpeed - 8 km per hr average- 100 km per hr maximum<strong>Under</strong> footSlushy and highlyabrasive.B.2 Goods (Equipment and Machinery)Detailed specifications <strong>of</strong> the Equipment to be supplied are given in this section.In general, all items shall be:New, unused and <strong>of</strong> the current design (incorporating latest proven features) and not likelyto be discontinued or become obsolete in near futureDesigned and constructed to handle without overload and for the working hours stated, themaximum volumes/rates specified;Designed to facilitate ready access, cleaning, inspection, maintenance and repair<strong>of</strong> component parts;Designed to facilitate rapid changeover <strong>of</strong> consumable items.The component parts <strong>of</strong> all items shall, wherever possible, be selected from thestandard ranges <strong>of</strong> reputable manufacturers.The Equipment and accessories shall be physically robust and where necessary capable <strong>of</strong>dismantling for transportation and ready re-assembly using simple tools. All Equipmentitems provided shall be designed to be compatible within the proposed overall Scope <strong>of</strong>Supply.Electrical Equipment shall provide all protection devices, controls and interfaces for theEquipment to operate safely and efficiently.All workmanship and materials shall be <strong>of</strong> first class quality in every respect.All parts and surfaces, which are exposed to corrosive environments, shall be suitablyprotected to prevent any effects <strong>of</strong> corrosion or erosion.B.3 StandardsBeside conforming to the Standards specified in the Equipment Specification, theEquipment shall also has to meet approval <strong>of</strong> the Statutory Government Authoritiesincluding Director General <strong>of</strong> Mines Safety (DGMS) having jurisdiction over theEquipment and its use.8

Compliance <strong>of</strong> Safety & functional aspect <strong>of</strong> dumpers and as per ARAI guidelines may beincorporated as under ;-1. All Water Sprinkler shall permanently carry a sign stating “NOT MEANT FORRUNNING ON PUBLIC ROADS (Preferably White colour sheeting on BlackBackground) in retro reflective colour sheeting, which shall be visible from the frontside and rear side <strong>of</strong> the vehicle.2. All Water Sprinkler shall be fitted with WHITE REFLEX REFLECTORS (Circular/Rectangular) AT FRONT having dimension MORE THAN 28.5 SQ. CMS. Anddistance between two Reflectors should be between 2.8 to 3.0 Mtrs.3. All Water Sprinkler shall be fitted with RED REFLECTORS (Circular/Rectangular) at REAR having dimension MORE THAN 28.5 SQ. CMS. Anddistance between two Reflectors should be between 2.8 to 3.0 Mtrs.4. All Water Sprinkler shall be fitted with AMBER COLOUR REFLECTORS(Circular/ Rectangular) at LEAST THREE Nos ON EACH SIDE OF DUMPERhaving dimension MORE THAN 28.5 SQ. CMS. And distance between twoReflectors should be between 2.8 to 3.0 Mtrs.The system <strong>of</strong> units for all measurements shall be the S y st è m e In te rn a tio n a l d ’U n i t é s( S.I .) .B.4 Suppliers ResponsibilityThe Purchaser requires that the Supplier shall accept responsibility for theprovision <strong>of</strong> complete operable and compatible Equipment and systems within the Scope<strong>of</strong> Supply. This document identifies <strong>only</strong> the major items required for the installationand the Supplier shall ensure that the total supply includes all necessary Equipmentfor it to function effectively and safely. Any additional items the Supplierconsiders necessary to ensure compliance with such a requirement shall beidentified and included.If the Supplier observes that this Specification document contains any anomalies,ambiguities, flaws, errors or omissions, the Supplier shall immediately bring these to theattention <strong>of</strong> the Purchaser.The Supplier shall be responsible for the testing and commissioning <strong>of</strong> the Equipmentand ensure that it meets the requirements as specified. The commissioning and settingto work <strong>of</strong> the whole Equipment Supply package shall be carried out under thesupervision <strong>of</strong> the Supplier in conjunction with the Purchaser’s nominated personnelB.5 Spare Parts ProvisionsB.5.1Availability <strong>of</strong> Spare Parts.All items and Equipment proposed shall be <strong>of</strong> current design and manufacture. TheSupplier shall warrant that sufficient spares and servicing facilities will be availableto maintain the Equipment in use throughout its life.B.5.2Provision <strong>of</strong> Spare PartsWithin the Contract Price, the Purchaser shall agree to purchase all filters and Orings including standard engine filters required for first 6000 hours <strong>of</strong> operation <strong>of</strong> each9

equipment. The Bidder shall stock sufficient fast moving & maintenance and otherspares in their Local Depots to ensure maximum availability <strong>of</strong> their equipmentB.5.3 Emergency Spare PartsThe Bidder shall ensure that Spare Parts required urgently by the Purchaser forrepair <strong>of</strong> breakdown equipment are supplied at over riding priority .B.5.4Lifetime Spare PartsThe Supplier undertakes and guarantees to produce and maintain stocks, to be availablefor purchase by the Purchaser under separate agreement, <strong>of</strong> all Spare Parts andConsumables as may be required for maintenance and repair <strong>of</strong> the Plant throughout itsworking life. In the event that the Supplier wishes to terminate production <strong>of</strong> such SpareParts, the Supplier shall:(a) give not less than six months notice in writing <strong>of</strong> it's intention to terminateproduction in order to permit the Purchaser reasonable time in which toprocure needed requirements; and(b) immediately following termination, provide to the Purchaser at no cost,manufacturing drawings material specifications and all necessary permissionsto facilitate manufacture <strong>of</strong> the Spare Parts elsewhere.In any event, the Supplier shall not seek to terminate manufacture <strong>of</strong> spare partsfor a period <strong>of</strong> not less than ten (10) years from taking-Over.B.5.5Oils, Lubricants and FluidsNot less than one (1) month before the scheduled date for Acceptance, the Suppliershall provide to the Purchaser a detailed schedule <strong>of</strong> all necessary oils, lubricants, fluidsand the like for the operation and maintenance <strong>of</strong> Equipment. The schedule shallindicate estimated annual consumption and specify the appropriate international standardnumber or the name and reference number <strong>of</strong> an equivalent available in India consideredto be acceptable by the Supplier.B.5 6 GeneralNothing in this Clause B.5 shall relieve the Supplier <strong>of</strong> any Guarantee,Availability, Performance or other obligations or liabilities under the Contract.B.6 Composite Warranty / GuaranteeThe Bidder shall warrant that the equipment supplied under this contract is:--a) In accordance with the contract specifications.b) The equipment shall have no defects arising out <strong>of</strong> design; material orworkmanship & the Complete Equipment shall be warranted for 12 monthsor 3000 Hrs (which is earlier) from the accepted date <strong>of</strong> commissioning.The warranty shall cover for total equipment so that ultimate responsibility lies <strong>only</strong>with the Equipment Bidder although components may be supplied by differentsuppliers to the Bidder.10

B 7B.7.1Performance GuaranteeIntroductionB.7.1.1 The Supplier shall guarantee that the Equipment supplied pursuant to thisContract shall be available for use by the Purchaser and shall meet the performancecriteria specifications at the level and in accordance with the terms and conditions <strong>of</strong>the Availability Guarantee herein contained.B.7.1.2 Where Equipment supplied under the Contract fails to meet the criteria <strong>of</strong>the Availability Guarantee, the Supplier shall, at it's own cost, provide suitablyqualified and experienced personnel at Site to demonstrate to the Purchaser'ssatisfaction that the required level <strong>of</strong> availability can be achieved and maintained.B.7.1.3 The Supplier shall provide the Services <strong>of</strong> such personnel at Site withinseven (7) days <strong>of</strong> notification by the Purchaser that the availability criteria has notbeen met in any one (1) month.B.7.2 GuaranteeB.7.2.1 The Supplier shall guarantee that the Equipment supplied pursuant to theContract shall be available to the Purchaser at the level hereinafter defined to perform tocriteria <strong>of</strong> not less than that defined in the Technical Specifications incorporated in theContract.B.7.2.2 The Supplier shall guarantee that the Equipment shall be available toperform its duty to minimum criteria and to the minimum availability percentage levelas defined in the individual Equipment Specifications included as the Attachment tothe Technical Specifications. The method <strong>of</strong> assessment applied shall be as follows:Method <strong>of</strong> Assessment:The following calculation shall determine the availability <strong>of</strong> the Equipment:Scheduled Available Time - Downtime% Availability = ------------------------------------------------------- x 100Scheduled Available TimeSch e d u l e d Av ail abl e Ti me shall equate to 24 hours.D o w n t i me shall mean all hours <strong>of</strong> work lost due to mechanical, electrical orother failure, in clu d in g :a) routine servicing and maintenance in accordance with the manufacturer'spublished recommendations, including: changing oils, oil filters and airfilters; lubrication; changing identified consumable or wear parts.b) planned preventative maintenance program;It shall not however include:I. damage due to abusive use or incorrect operation methods by the Purchaser;II. accidents;11

III. strikes or stoppage <strong>of</strong> work by the Purchaser's personnel;IV. natural disaster;V. lack <strong>of</strong> Spare Parts not attributable to a failure <strong>of</strong> the Supplier, it'sAgents or Representatives.Downtime shall also specifically include all hours lost due to failures determinedto be guarantee failures. The Supplier shall state the number <strong>of</strong> hours per day required tocarry out (a) and (b) above. The time stated shall, with the agreement <strong>of</strong> the Purchaser,form the basis <strong>of</strong> the assessment <strong>of</strong> the availability. The average maintenance hours shallnot be more than 2 hours per day.In case the site personnel <strong>of</strong> are unable to carry out the daily maintenance in two hoursand train the project personnel to enable them carry out the normal routinemaintenance within two hours everyday.The Purchaser will assist the Supplier, without relieving the Supplier <strong>of</strong> anyother obligations under the Contract, to achieve the guaranteed availability by:Providing normal and proper maintenance, including preventative maintenancein accordance with the Supplier’s standard/published recommendations, andmaking all necessary repairs using <strong>only</strong> genuine manufacturer's spares.Providing co-operation to all Supplier’s authorised representatives, complying withall reasonable procedural suggestions to improve efficiency <strong>of</strong> machine operation orreduce downtime.Where appropriate, providing and maintaining such conditions as: Proper electrical Supply Terrain Area Bench preparation Reasonable floor conditionsProviding all Supplier’s authorized representatives access at all reasonable times tothe machine service and repair facilities.Maintaining a logbook for each shift wherein the working hours, breakdowntimes, maintenance hours, idle time, etc. shall be recorded. This record will be availablefor examination and signature by the Supplier’s representative.B.7.3Effect and Duration <strong>of</strong> GuaranteeB.7.3.1 This Guarantee shall become effective on the day on which the Equipment iscommissioned at the Site. Commissioning shall be evidenced by the issue <strong>of</strong>the Purchaser's Acceptance Certificate.B.7.3.2 This Guarantee shall remain effective for twelve (12) months from the date <strong>of</strong>commissioning, irrespective <strong>of</strong> the hours operated by the Equipment during the period <strong>of</strong>the guarantee.B.7.3.3 In the event that the Equipment fails to achieve the Availability herein providedduring this twelve (12) month period, the Supplier shall be liable to pay to thePurchaser, as Penalty, a sum equal to, as indicated hereunder for each equipment: -12

a )1% <strong>of</strong> the delivered price <strong>of</strong> the equipment for every percentage reductionfrom the Guaranteed Availability for the first 5%b )10% <strong>of</strong> the delivered price <strong>of</strong> the equipment for reduction beyond 5%from the Guaranteed Availability.The Supplier has however the option to modify the equipment, if felt necessary, to bringits availability to the guaranteed level within three ( 3 ) months after expiry <strong>of</strong> initialguarantee period <strong>of</strong> twelve (12 ) months from the date <strong>of</strong> commissioning.B7.3.4 When the supplier is unable to supply the replacement <strong>of</strong> a failed partunder warranty within 21 days <strong>of</strong> giving intimation by the consignee and if themachine is commissioned by using the spare from the stock <strong>of</strong> the project the period(after 21 days) till the supplier replaces the part under warranty shall be treated as“Deemed Breakdown” (the credit for keeping machine available shall not be given tothe supplier).B7.3.5 SP E C I A L CO N D I T I O N :- The machines under supply against this tendershould have the same major assys. / sub assys. which were fitted on the machines suppliedagainst CIL/WCL’s last supply order. In case any change is contemplated prior clearance<strong>of</strong> WCL will be necessary.B.8 Quality AssuranceB.8.1 The Supplier should furnish in detail its quality assurance plan for variousstages <strong>of</strong> manufacture.. The Quality Assurance plan shall comply with aninternationally recognised quality assurance standard such as ISO 9000.B.8.2 The Supplier shall provide facilities to Purchaser or their authorizedrepresentatives for progress inspection during manufacture at his works and furnish alltest data available in this regard for quality control, both for bought out items and hisown manufactured items.B.8.3 The Purchaser or his agent, when so required by him, shall also be provided withsamples <strong>of</strong> “bought-out” materials for the purposes <strong>of</strong> undertaking independent tests whichindependent tests shall be at the expense <strong>of</strong> the Purchaser.CEquipment Specifications:-The equipment shall comply with the following specifications, included as an attachmentto thisSection.13

EQUIPMENT SPECIFICATION OF WATER SPRINKLER 28 KL1. Scope Of SpecificationBEML Model WS 28 – 2 Water Sprinkler powered by BEML BSA6D140- 1 diesel enginedeveloping 280 kW (375 hp) @ 2100 rpm, wheeled water sprinkler <strong>of</strong> 28 KL capacity for use inopen cast mine in WCL.2. ReferencesThe following International Standards are referred to in, and form part <strong>of</strong>, theSpecification:ISO 2867 Earth-moving machinery - Access systemsISO 3450 Earth-moving machinery - Wheeled machines - Performance requirements and testprocedures for braking systemsISO 3457 Earth-moving machinery - Guards and shields - Definitions andspecificationsISO 3471 Earth-moving machinery - Roll-over protective structures - Laboratory tests andperformance requirementsISO 5010 Earth-moving machinery - Rubber-tyred machines - Steering requirementsISO 6014 Earth-moving machinery - Determination <strong>of</strong> ground speedISO 6405-1 Earth-moving machinery - Symbols for operator controls and other displays - Part 1 :Common symbolsISO 6405-2 Earth-moving machinery - Symbols for operator controls and other displays - Part 2 :Specific symbols for machines, equipment and accessoriesISO 6483 Earth-moving machinery - Dumper bodies - Volumetric ratingISO 6682 Earth-moving machinery - Zones <strong>of</strong> comfort and reach for controlsISO 6750 Earth-moving machinery - Operation and maintenance - Format and content <strong>of</strong>manualsISO 7132 Earth-moving machinery - Dumpers - Terminology and commercialspecificationsISO 7457 Earth-moving machinery - Measurement <strong>of</strong> turning dimensions <strong>of</strong> wheeledmachinesISO 9249 Earth-moving machinery - Engine test code - Net powerISO 10268 Earth-moving machinery - Retarders for dumpers and tractor-scrapers - PerformancetestsISO 10968 Earth-moving machinery - Operator’s controls3. Design CriteriaThe Water Sprinkler WS 28-2 is capable <strong>of</strong> continuous operation for protractedperiods on a system <strong>of</strong> 3 shifts each <strong>of</strong> 8 hours duration per day throughout the year.The Water Sprinkler WS 28–2 consists <strong>of</strong> 28,000 Ltrs capacity water tank andpressurized spraying through nozzles for higher spreading width for effective dustsettling.

4. Technical Requirements4.1 EngineThe Water Sprinkler WS28-2 is powered by a direct injection 4-stroke diesel engine <strong>of</strong> 280 KW NetPower measured at 2100 r/min according to ISO 9249. The engine shall be provided with 24Velectric starting, dry type 2-stage air-cleaner with manual dust evacuator and dust level indicatorfor easy maintenance. Two stage fuel filters with water separator is provided.The engine shall have a water jacket cooling system, thermostatically controlled, using anengine driven water pump, with the cooling water re-circulated through a heavy-duty radiator.The system shall be capable <strong>of</strong> providing sufficient cooling to allow the dumper to continuouslyoperate at the full rated output at the maximum ambient temperature.The moving parts <strong>of</strong> the engine shall be lubricated by an engine driven oil pump, with fullflow oil filtration and cooling.The engine shall be equipped with an over-speed governor. The engine shall be provided with a heavyduty pan guard.4.2 TransmissionThe water sprinkler, WS 28 – 2 shall be provided with an <strong>of</strong>f-highway automaticpower shift hydraulic transmission ( AVTEC Model CLT 754 ) with lock-up clutch and downshiftand reverse inhibitors. Suitable protection <strong>of</strong> the transmission pan from external damageshould be provided. The pan guard should be designed to minimise accumulation <strong>of</strong> dirt anddebris.4.3 Drive SystemA dynamically balanced propel shaft with universal joints at both ends should be utilised fortransmission <strong>of</strong> power. Adequate means should be provided to prevent damage to other components inthe event <strong>of</strong> failure <strong>of</strong> the universal joints.The final drive shall comprise a heavy-duty differential with high quality spiral bevel gear andpinions, and a suitable heavy duty final drive system / heavy duty planetary gear system and drive axle.4.4 SuspensionFront and rear suspension shall be <strong>of</strong> hydra-air type to absorb road shocks and prolong tyre life4.5 SteeringFull hydraulic orbitrol power steering and emergency steering, which complies with ISO 5010,shall be provided.4.6 HosesAll hoses shall be grouped as far as possible and suitably clipped to reduce damage from scuffing.4.7 BrakesSuitable reliable service, secondary and parking brakes, which comply with ISO 3450 shall

e provided.4.7.1 Service brakesThe front service brakes shall be dry calliper disc type and actuated by air-over hydraulic system.The rear service brakes shall be oil cooled multiple disc type and actuated by air – over hydraulicsystem. Operates automatically in the event <strong>of</strong> low air pressure.They should be fully enclosed to prevent entry <strong>of</strong> dust and water, and designed for lowmaintenance.4.7.2 Parking brakesSpring applied air released dry calliper type parking brake provided will be operatedautomatically at zero air pressure.4.7.3 RetarderSuitable retarding system to control speed while descending grades shall be provided.4.8 TyresTubeless, rock duty, cut-resistant E-4 type tyres size 18.00 - 25 (32PR) shall be provided.4.9 FrameThe frame should be a rugged, durable construction <strong>of</strong> high strength steel and free from any stressconcentration. The design must take care <strong>of</strong> all forces encountered during the operation <strong>of</strong> the watersprinkler.4.10 Water TankThe water tank should be <strong>of</strong> minimum 28KL capacity. Water tank should be welded and reinforced withsuitable steel plate, cross baffles should be provided to avoid heavy surging. Interior <strong>of</strong> the tank shouldbe coated with special anti-corrosive paint. The design <strong>of</strong> water tank should be such that the stability <strong>of</strong>the machine is maintained in all operating conditions especially during turning.4.11 Fuel TankThe fuel tank shall be <strong>of</strong> sufficient capacity and be provided with a level indicator and a lockable, hingedfiller cap. Construction <strong>of</strong> the tank should be such that it provides for easy accumulation and drainage <strong>of</strong>water with minimum loss <strong>of</strong> fuel.4.12 Operator's CabA fully insulated, sound suppressed operator's cab with safety glass, rear-view mirror,

windshield wipers and washers and a ROPS, which complies, with ISO 3471 shall be provided.All operating controls, gauges (with colour indication for safe and unsafe working), monitoringand working signals shall be conveniently located within easy reach <strong>of</strong> the operator. It shouldcomply with ISO 6405 -1 and ISO 6405-2, ISO 6682 & ISO 10968.A fully adjustable operator ’ s seat, passenger seat, floor mat and a cooling fan shall be provided.Steps and handrails shall be provided for access to the operator ’ s cab. It shall comply to ISO 2867.4.13 Gauges and IndicatorsThe following shall be provided as a minimum:a) Water temperatureb) Engine oil pressurec) Transmission oil temperature gauged) Fuel capacitye) Engine tachometerf) Engine hour-meterg) Speedometerh) Air pressure (if applicable)i) Air Cleaner restriction Gauge.4.14 Warning Alarms/LightsAudio/visual warning alarm systems shall be provided for the following:a) Reversing Alarmb) Parking brake actuationc) High torque converter oil temperatured) Low engine oil pressuree) High coolant temperaturef) Low air pressure (if applicable)g) Emergency steering4.15 Electrical EquipmentThe Water Sprinkler shall be provided with the following:a) 24V DC electrical system with 24 V, 45 A alternator <strong>of</strong> reputable makeb) 24V , 7.5 kw Electric starting Motorc) Two numbers 12V, 200 Ah high capacity batteries <strong>of</strong> reputed make are providedd) Battery isolation switche) Electrical wires shall pass through Flexible Conduit.All electrical circuits shall be protected by adequately rated MCBs / fuses which shall be easilyaccessible for maintenance. At least two spare fuses <strong>of</strong> each size shall be provided in each fuse box.4.16 LightingAdequate lighting shall be provided for safe night shift operation. The lighting system shouldinclude the following:a) 4 (no) Headlightsb) Stop and tail LED lights

c) Turn signal lights (left and right) on both front and reard) Fog LampsHeadlights and rear lights shall be fitted in steel protective enclosures.4.17 Guards and ShieldsAdequate guards and shields which comply with ISO 3457 shall be provided.4.18 Fire Extinguisher1 no. fire extinguisher shall be provided suitably mounted in a heavy duty bracket for ease <strong>of</strong>removal. The extinguisher shall be dry powder (cartridge type) with a capacity <strong>of</strong> 5 kg and shallcomply with Indian Standard IS: 2171.4.19 Water Sprinkling SystemThe water sprinkling system should be provided with centrifugal water pump driven by ahydraulic motor through flexible coupling. The suction & discharge pipe should be <strong>of</strong> adequatediameter with suitable valves. The sprinkling should be pressurised and constant sprinklingvelocity is to be maintained by centrifugal pump. In addition to pressurised sprinkling, provision<strong>of</strong> gravity sprinkling should also be provided through perforated manifold connected to tankbottom. Self-filling provision from outside reservoir or pond by connecting the pump suctionthrough armoured hose with foot valve should be provided. The system should be equipped withquick connecting adopter(s) & suitable nozzles for fire fighting unit adoption.4.20 Automatic Fire Detection and Suppression System:Automatic Fire Detection and Suppression System shall be provided and suitably mounted in theEquipment. The materials and chemicals to be used in Fire Detection and Fire Suppression Systemto be supplied with the equipment. The type and make <strong>of</strong> the system must be approved by DGMS.5. Ancillary Equipment And Other RequirementsThe following shall be provided on the dumper:a) Front and rear tow hooks and two lifting loops.b) Pressurised radiator capc) Head light high-beam indicator.d) Water separators in air lines.e) Rock ejector bars between each set <strong>of</strong> dual rear wheelsf) Front pressurised sprinkling6. Safety DevicesThe following Safety devices shall be provided on the dumper:a) Mechanical Steering Locking Device.b) Seat Belt for Operatorc) Blind Spot Mirrord) Audio Visual Reverse Alarm (DGMS Approved)e) Fire/ Heat Resistant Hydraulic Hoses in place <strong>of</strong> ordinary Hoses.

f) Propeller Shaft Guard.7. Special GuaranteesThe following guarantee will apply for the different componentsi) Body chassis & differential including final drive - 10,000 hours or 1000 calendar days(whichever is earlier)ii) Complete engine system - 24 months or 6500 hours (whichever is earlier).In case <strong>of</strong> failure <strong>of</strong> engine system within 6500 hrs. , the failed components <strong>of</strong> the enginesystem will have to be replaced / repaired depending on the merit <strong>of</strong> the case, free <strong>of</strong> cost by thesupplier.In case <strong>of</strong> failure <strong>of</strong> engine system beyond 6500 hrs. the system will have to be replaced onpro- rata payment basis taking the life <strong>of</strong> the engine system as 7550 W/hrs.iii) Transmission Assy. - 24 months or 6500 hrs. (Whichever is earlier)iv) Electrical Items - 6 months or 1000 hrs. (Whichever is earlier)v) Engine Hour Meter - 12 months or 3000 hrs. (Whichever is earlier)vi) Calipar and Disc Brake - 24 months or 6000 hours (whichever is earlier)In case <strong>of</strong> any guarantee failure intimated reasonably in time to the bidder, thereplacement or repair job (as per guarantee settlement) must be completed within 21 days at siteby the bidder at no cost to the purchaser.8. Performance GuaranteeIn accordance with the provisions <strong>of</strong> clauses B.7.2.2 and B.7.3.2 <strong>of</strong> the Technical Specifications,the Supplier shall guarantee that the availability <strong>of</strong> the equipment shall be not less than 72%(seventy two per cent) for a period <strong>of</strong> 12 months from the accepted date <strong>of</strong> commissioning.9. General9.1 Details <strong>of</strong> special tools to be provided with the equipment as per annexure enclosed9.2 Technical Detailsa) Maximum speed determined according to ISO 6014: 40.11 Kmphb) Result <strong>of</strong> service and secondary brake stopping tests carried out according to ISO3450 :-Brake System Tested Slope ( % ) M/S Speed ( Km/h) Stopping distance (M)Service 9 40 34Secondary 9 25 18.5d) Turning diameter as per ISO 7457 is 16.0 Meters.e) Auto fire suppression system <strong>of</strong> Southern Eeltronics make will be provided and all will be DGMSapproved.f) Detail list <strong>of</strong> all filters and O-rings along with equipment for 6000 Hrs <strong>of</strong> operation shall beas per Annexure.g) Operation and maintenance manuals in accordance with ISO 6750 shall be provided.

9.3 Dimensions, Weights and Performance Details9.3.1 Dimensionsa) Maximum overall length 7565 mmb) Maximum overall width 3800 mmc) Maximum height, without tank 3675 mmd) Maximum height, with tank 4028 mme) Wheelbase 3600 mm9.3.2 Weight Distributiona) Empty vehicleFront axleRear axleTotal12079 Kg13621 Kg25700 Kg.b) Loaded vehicleWater Weight28000 KgFront axle 17721 KgRear axle35979 KgTotal53700 Kg.9.3.3 Enginea) Manufacturer and model BEML; BSA6D140-1b) Number <strong>of</strong> cylinders 6c) Bore 140 mmd) Stroke 165 mme) Displacement 15.5 Ltrs.f) ISO net power at.........r/min 280 Kw @ 2100 rpmg) Maximum torque 1627 N- m @ 1400 rpm9.3.4 Transmissiona) Make and Model AVTEC model CLT 754b) Type Power shift with automatic lock up clutchc) Number <strong>of</strong> gear speeds, forward and reverse 6 speeds (5 forward and 1 reverse)d) Travel speeds, forward and reverseForward 17.74 KMPHForward 212.57 KMPHForward 319.85 KMPHForward 429.06 KMPHForward 540.11 KMPHReverse3.94 KMPH9.3.5 Differentiala) Type & Make Traction sensing, automatic, BEML Makeb) Ratio 3.23 : 19.3.6 Final Drivea) Type & Make Planetary final drive, BEML make

) Ratio 4.58 : 19.3.7 Suspension9.3.7.1 Fronta) Type & Make Frame mounted hydro- pneumatic with integralrebound control, BEML makeb) Stroke 365 mmc) Load - deflection rate, loaded and empty Empty 408 kg/cmLoaded 5504 Kg/cm9.3.7.2 Reara) Type & Make Axle mounted inverted hydro- pneumatic withintegral rebound control ,BEML makeb) Stroke 170 mmc) Load - deflection rate, loaded and empty Empty 408 Kg/cmLoaded 5504 Kg/cm9.3.8 Steeringa) Type & Make Orbitrol full time power shifting steering stg. Cyl.BEML makeb) Emergency steer method Emergency steering is through electrical motor& Pump and can be operated manually in theevent <strong>of</strong> failure <strong>of</strong> normal steering.9.3.9 Brakes9.3.9.1 Service brakes: Make & Model BEML Make9.3.9.1.1 Fronta) Type Dry disc caliperb) Actuating system Air over hydraulic actuated9.3.9.1.2 Reara) Type Oil cooled wet multiple disc brakeb) Actuating system Air over hydraulic actuated9.3.9.2 Secondary brakesa) Type Either front or rear brakes independently meets thesecondary braking requirementb) Actuating system Air over hydraulic actuated9.3.9.3Parking brakea) Type Disc type parking brakeb) Actuating system Spring applied, Air released & willautomatically apply, whenever air pressuredrops.9.3.9.4 Retarder a) TypeRear Brake acts as a retarder brake. Oil cooled wetmultiple disc brakeb) Actuating system Air over hydraulic actuated. Separate handcontrol valve is provided to actuate rear brake

as retarder brake9.3.10 Tyresa) Make Goodyear/MRF/CEAT/JK/BKT/Dunlop/APOLLO/Reputedb) Size and type 18.00 x 25, 32PR (E4) tubeless typec) Tread Deep tread Rock gripd) Ply rating 32 PRe) Rim size 13.00 x 259.3.11 Hydraulic Systema) Make & model, number, flow rates, operating pressures <strong>of</strong> pumps: - 1 No.DOWTY make Tandem gear pimp for Hydraulic Motor, steering & brake cooling.Flow rate 213 Ltr/min + 70 Ltr./min @ 2100rpmRelief pressure : Hyd.Motor – 12. 7 Mpa ( 130 kg/cm2)Steering system : 12.4 Mpa ( 126 kg/cm2)Brake cooling system : 0.54 Mpa ( 5.5 kg/cm2)b) Make & model, number, piston diameters, stroke lengths <strong>of</strong> cylinders :-2 nos. steering cylinder , double acting , BEML/UT/WIPRO makePiston dia : 110 mm, stroke : 435 mmc) Relief valve operating pressures 12.7 Mpa ( 130 kg/cm2)d) Make & model, number, flow rates <strong>of</strong> motors Vickers,Model no. 25M 42A-1C-20flow rate: 128 lpm@ 2900r/min. / EATONmake9.3.12 Electrical Systema) Starter make and model LUCAS-TVS/Delco Remy (India)-42MT/ REIL Makeb) Starter control make and model through reputed make Key switchc) Alternator make and model LUCAS/TVS,2SA23-45a-24V/REIL maked) Batteries, numbers and rating 200 Amp Hr – 2 nos. ,12Ve) Lighting details Tail and stop light LED type, Turn signal lamp LH &RH LED type head light, cabin lamp, backup light,Fog light9.3.13 Water System9.3.13.1 Water Pumpa) Type <strong>of</strong> pump Kirloskar make centrifugal pumpb) Capacity <strong>of</strong> pump in CuM/Hour @----------- r/min & Head----- meter:110m≤/hr@2900r/min & 55m headc) Drive to pump Hydraulic motor through flexible coupling

9.3.13.2 Pipinga) Suction Dia 80mmb) Discharge Dia 50mmc) Type <strong>of</strong> valve Butterfly type valve9.3.13.3 Sprinklinga) Details <strong>of</strong> pressurized sprinkling system Constant sprinkling velocitymaintained by centrifugal pump 110cu.mtr/hr. @ 2900 r/minb) Spreading Width 14 mts.c) Details <strong>of</strong> Gravity Sprinkling Arrangement : Additional provision forgravity sprinkling is providedthrough perforated manifold byconnected to tank bottomd) Type <strong>of</strong> Nozzles Fish Tail type nozzele) Details <strong>of</strong> Self filling system By connecting the pump suction tothe outside reservoir or pond througharmoured hose foot valve unit.f) Details <strong>of</strong> firefighting unit adoption Quick connecting adopter providedwith canvas hose and triple purposenozzle.

ANNEXURE-BSL.NO.List <strong>of</strong> Initial Filters & O-Rings for 6000 Hrs <strong>of</strong> Operation <strong>of</strong> One No. WS28-2 WaterSprinkler as per Clause No. A.2.III / 9.2 (n)-FREE OF COSTPART NO. DESCRIPTION QTY /EQPTPeriodicityQTYfor6000HrsENGINE MAINTENANCE SPARES1 41Z9900472 SERVICE KIT (250 HRS.) 01 250 242 53Z1200016 ELEMENT ASSY. 01 500 12CHASSIS CONSUMABLES1 560308020000 ELEMENT(T/M) 1 1000 62 560308040000 RING FILTER SEAL (T/M FILT) 1 1000 63 985AS91628 DESICCANT Cartridge 1 2000 34 0706301210 ELEMENT(HYD) 1 1000 65 CHS0115175 O-RING(HYD.FILTER) 1 1000 66 4196015250 ELEMENT (BREATHER) 1 1000 67 575400160600 FILTER ELEMENT(STG.) 1 1000 68 575400160800 BACK UP RING(STG.FILT) 1 1000 69 575400160900 O-RING 1 1000 610 575400160700 O-RING(STG.) 1 1000 6

ANNEXURE-C1S T A N D A R D T O O L L I S T WS28-2- (FREE OF COST)SLNO PART NO. DESCRIPTION Q/ETOOL KIT1 451-TI-02016 BIHEX SOCKET 1/2" SQ DRIVE 1 SETa) 451-TI-11129 BI-HEX SOCKET 1/2" SQ.DR. - 10mm 1b) 451-TI-11137 BI-HEX SOCKET 1/2" SQ.DR. - 13mm 1c) 451-TI-11145 BI-HEX SOCKET 1/2" SQ.DR. - 14mm 1d) 451-TI-11153 BI-HEX SOCKET 1/2" SQ.DR. - 17mm 1e) 451-TI-11161 BI-HEX SOCKET 1/2" SQ.DR. - 19mm 1f) 451-TI-11178 BI-HEX SOCKET 1/2" SQ.DR. - 22mm 1g) 451-TI-11186 BI-HEX SOCKET 1/2" SQ.DR. - 24mm 1h) 451-TI-11194 BI-HEX SOCKET 1/2" SQ.DR. - 27mm 1i) 451-TI-11202 BI-HEX SOCKET 1/2" SQ.DR. - 30mm 1j) 451-TI-11218 BI-HEX SOCKET 1/2" SQ.DR. - 32mm 12 451-TI-11023 ENGG. PATTERN SCREW DRIVER - 8 1X 150 MM3 451-TI-11226 SLIP JOINT PLIER 200 MM L 14 451-TI-11234 NON REVRSIBLE RATCHAT HA 15 451-TI-11242 BALL PEEN HAMMER WITH HAN 16 451-TI-11259 UNIVERSAL JOINT 17 451-TI-11275 EXTN. BAR - 1/2" SQ.DR. - 250 MM 18 451-TI-11283 SWIVEL HANDLE 1/2 IN SQ D 19 778TI01031 PIN STR 210 778TI01048 DISC GAUGE 111 935TI02061 WRENCH STR 112 935TI02126 SOCKET STRUCTURE 113 935TI11425 T HANDLE 114 985TI01002 TOOL BOX 115 985TI11103 THICKNESS GAUGE 116 985TI11111 GREASE GUN WITH SUITABLE1NOZZLE17 985TI11128 BAR 118 985TI11306 WRENCH ADJ. 250 MM LONG 119 985TI11314 PHILIPS SCREW DRIVER - 6 X 100MM20 985TI11322 PHILIPS SCREW DRIVER - 8 X 150MM11

SLNO PART NO. DESCRIPTION Q/E21 985TI11396 L HANDLE 1/2 SQ. DR. - 210 MM 122 985TI02048 OPEN JAW SPANNER DOUBLE E 1SETa 451-TI-11048 D.E.O.J. SPANNER - 8 X 10 MM 1b 451-TI-11056 D.E.O.J. SPANNER - 12 X 14 MM 1c 451-TI-11064 D.E.O.J. SPANNER - 13 X 17 MM 1d 451-TI-11072 D.E.O.J. SPANNER - 19 X 22 MM 1e 451-TI-11081 D.E.O.J. SPANNER - 24 X 27 MM 1f 451-TI-11097 D.E.O.J. SPAN - 30 X 32 MM 123 985-TI-02056 DOUBLE ENDED OPEN JAW SPAN- 1 SETNERa) 985-TI-11193 OJDE SPNR 3/8" X 7/16" 1b) 985-TI-11209 OJDE SPNR 1/2" X 9/16" 1c) 985-TI-11217 OJDE SPNR 11/16" X 19/32" 1d) 985-TI-11225 D.E.O.J SPANNER 7/8" X 13/16" 1e) 985-TI-11233 OJDE SPNR 15/16" X 1" 1f) 985-TI-11241 OJDE SPNR 1 1/16" X 1 1/4" 1g) 985-TI-11258 D.E.O.J SPANNER 1 1/8" X 1" 1h) 985-TI-11266 OJDE SPNR 5/8" X 3/4" 124 985TI02064 ALEN WRENCH 1 SETa) 985-TI-11274 ALLEN WRENCH - 8 MM 1b) 985-TI-11282 ALLEN WRENCH - 6 MM 1c) 985-TI-11299 ALLEN WRENCH - 5 MM 125 985TI02072 BIHEX, SOCKET 1/2 IN SQ. 1a) 935TI11741 SOCKET 1/2" SQ. DRIVE 1/2" 1b) 985TI11339 SOCKET 1/2" SQ. DRIVE 3/8" 1c) 985TI11347 SOCKET 1/2" SQ. DRIVE 7/16" 1d) 985TI11363 SOCKET 1/2" SQ. DRIVE 9/16" 1e) 985TI11371 SOCKET 1/2" SQ. DRIVE 5/8" 1f) 985TI11388 SOCKET 1/2" SQ. DRIVE 13/16" 126 935TI02191 TYRE INFLATION KIT 1a) 935TI03009 TYRE INFLATOR 1b) 935TI11782 ADAPTOR 1

ANNEXURE-C2DETAILS & DESCRIPTION OF MAJOR BOUGHTOUT/MANUFACTURED ASSEMBLIES & SUB-ASSEMBLIES.FOR WS28-2 WATER SPRINKLERSL. NO. DESCRIPTION SOURCE1 CLT 754 TRANSMISSION AVTEC LTD.,2 ROPS CABINBEML Design Cabin manufactured by TRIDENT FABRICATION / SKYLARKANCILLARIES / VIJAYALAXMI / CRYSTAL CABS / KRISHNA FAB /RAMAVILAS SERVICES3 TYRES GOODYEAR / MRF/ CEAT / DUNLOP / JK / BKT / APPOLO / REPUTED4 AUTO FIRE SUPPRESSION SYSTEM SOUTHERN ELECTRONICS5 HYDRAULIC PUMP DOWTY MAKE6 HYDRAULIC MOTOR VIKERS / EATON MAKE

Consignee Details: Annexure- DSl.no.Name <strong>of</strong> the AreaPostal Address <strong>of</strong> the ConsigneeAREAS IN MAHARASHTRA1 <strong>Nagpur</strong> The Depot Officer , Regional stores, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> , P.O.-Silewara Colliery, Distt:- <strong>Nagpur</strong>, M.S.-4411092 Umrer The Depot Officer , Regional stores, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> , P.O.-UmrerProject, Distt:- <strong>Nagpur</strong>, M.S.-4412043 Chandrapur The Depot Officer , Regional stores, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> , Durgapuropen cast ,P.O.-Durgapur, Distt:- Chandrapur , M.S.-4424034 Ballarpur The Depot Officer , Regional stores, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> , BallarpurArea ,P.O.-Sasti, Distt:- Chandrapur , M.S.-4427015 Wani The Depot Officer , Regional stores, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> , P.O.-Ghugus colliery , Distt:- Chandrapur , M.S.-4425056 Wani North The Depot Officer , Regional stores, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> , Wani NorthArea ,P.O.-Ukni, Distt:-Yavatmal , M.S.-4453047 Majri The Depot Officer , Regional stores, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> , New Majri,P.O.-Shivaji Nagar , Distt:- Chandrapur , M.S.-4426038 Central Stores The Depot Officer , Central Stores, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> , UrjagramP.O.-Tadali , Distt:- Chandrapur , M.S.-442406AREAS IN MADHYA PRADESH9 Pench The Depot Officer , Regional stores, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> , Pench1011Area ,P.O.-Chandameta, Distt:- Chindwara , M.P.-480447Kanhan The Depot Officer , Regional stores, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> , KanhanArea ,P.O.-Dongaria, Distt:- Chindwara , M.P.-480553Pathakhera The Depot Officer , Regional stores, <strong>Western</strong> <strong>Coalfields</strong> <strong>Limited</strong> , PathakheraArea, P.O.-PathakheraDistt:- Betul , M.P.-460449

![To [Name & Address of the Assured] Dear Mr./Ms.[______] Subject ...](https://img.yumpu.com/48378713/1/190x245/to-name-address-of-the-assured-dear-mr-ms-subject-.jpg?quality=85)