union pr 150 union pr 160 union pr 200 union pr 250

union pr 150 union pr 160 union pr 200 union pr 250

union pr 150 union pr 160 union pr 200 union pr 250

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2<br />

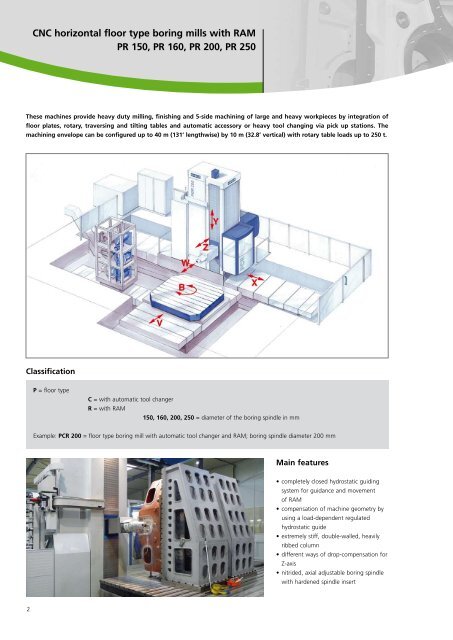

CNC horizontal floor type boring mills with RAM<br />

PR <strong>150</strong>, PR <strong>160</strong>, PR <strong>200</strong>, PR <strong>250</strong><br />

These machines <strong>pr</strong>ovide heavy duty milling, finishing and 5-side machining of large and heavy workpieces by integration of<br />

floor plates, rotary, traversing and tilting tables and automatic accessory or heavy tool changing via pick up stations. The<br />

machining envelope can be configured up to 40 m (131’ lengthwise) by 10 m (32.8’ vertical) with rotary table loads up to <strong>250</strong> t.<br />

Classification<br />

P = floor type<br />

C = with automatic tool changer<br />

R = with RAM<br />

<strong>150</strong>, <strong>160</strong>, <strong>200</strong>, <strong>250</strong> = diameter of the boring spindle in mm<br />

Example: PCR <strong>200</strong> = floor type boring mill with automatic tool changer and RAM; boring spindle diameter <strong>200</strong> mm<br />

Main features<br />

• completely closed hydrostatic guiding<br />

system for guidance and movement<br />

of RAM<br />

• compensation of machine geometry by<br />

using a load-dependent regulated<br />

hydrostatic guide<br />

• extremely stiff, double-walled, heavily<br />

ribbed column<br />

• different ways of drop-compensation for<br />

Z-axis<br />

• nitrided, axial adjustable boring spindle<br />

with hardened spindle insert