union pr 150 union pr 160 union pr 200 union pr 250

union pr 150 union pr 160 union pr 200 union pr 250

union pr 150 union pr 160 union pr 200 union pr 250

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

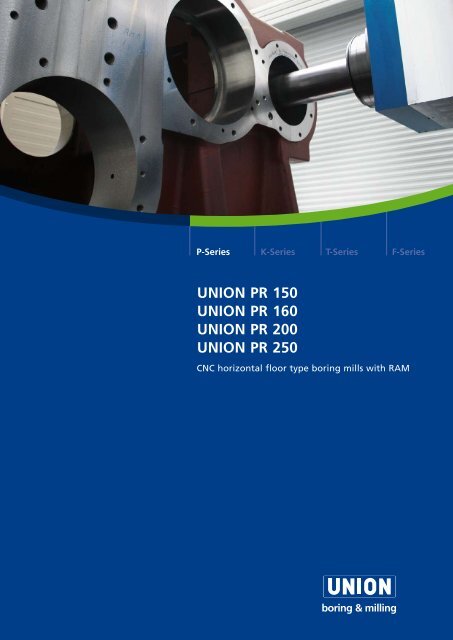

P-Series K-Series T-Series F-Series<br />

UNION PR <strong>150</strong><br />

UNION PR <strong>160</strong><br />

UNION PR <strong>200</strong><br />

UNION PR <strong>250</strong><br />

CNC horizontal floor type boring mills with RAM

2<br />

CNC horizontal floor type boring mills with RAM<br />

PR <strong>150</strong>, PR <strong>160</strong>, PR <strong>200</strong>, PR <strong>250</strong><br />

These machines <strong>pr</strong>ovide heavy duty milling, finishing and 5-side machining of large and heavy workpieces by integration of<br />

floor plates, rotary, traversing and tilting tables and automatic accessory or heavy tool changing via pick up stations. The<br />

machining envelope can be configured up to 40 m (131’ lengthwise) by 10 m (32.8’ vertical) with rotary table loads up to <strong>250</strong> t.<br />

Classification<br />

P = floor type<br />

C = with automatic tool changer<br />

R = with RAM<br />

<strong>150</strong>, <strong>160</strong>, <strong>200</strong>, <strong>250</strong> = diameter of the boring spindle in mm<br />

Example: PCR <strong>200</strong> = floor type boring mill with automatic tool changer and RAM; boring spindle diameter <strong>200</strong> mm<br />

Main features<br />

• completely closed hydrostatic guiding<br />

system for guidance and movement<br />

of RAM<br />

• compensation of machine geometry by<br />

using a load-dependent regulated<br />

hydrostatic guide<br />

• extremely stiff, double-walled, heavily<br />

ribbed column<br />

• different ways of drop-compensation for<br />

Z-axis<br />

• nitrided, axial adjustable boring spindle<br />

with hardened spindle insert

RAM<br />

Machine bed<br />

• wide, welded bed with great static<br />

stiffness<br />

• backlash-free rack and double-pinion<br />

drive<br />

Technical features<br />

PR <strong>150</strong>, PR <strong>160</strong><br />

Machine column<br />

• welded steel construction<br />

• Strong ribbed construction inside the<br />

column <strong>pr</strong>ovides great rigidity and<br />

eliminates the need for a mechanical<br />

counter-balance system<br />

• two widely spaced ball screws<br />

Guidance systems<br />

optional design features<br />

• with fully hydrostatic guidance system in<br />

axes X, Y and Z or<br />

• with hydrostatic guidance system in Z<br />

axis and <strong>pr</strong>eloaded linear compact roller<br />

guides in axes X and Y<br />

Hydrostatic guided RAM<br />

• completely closed hydrostatic guiding<br />

system for guidance and movement<br />

of RAM<br />

• (3) different ways of drop-compensation<br />

for RAM<br />

• double bearing of the <strong>pr</strong>ecision spindle<br />

with life cycle lubrication<br />

• thermal monitoring of the spindle<br />

bearings<br />

3

Guidance system<br />

design as machine with fully hydrostatic<br />

guidance system in axes X, Y and Z<br />

Machine bed<br />

• wide, heavily ribbed bed in solid casting<br />

4<br />

with two large guide ways<br />

• drive of X axis by two water cooled<br />

AC-motors (Master-slave) and backlash-<br />

free rack<br />

Technical features<br />

PR <strong>200</strong>, PR <strong>250</strong><br />

Hydrostatic guided RAM<br />

• completely closed hydrostatic guiding<br />

system for guidance and movement<br />

of RAM<br />

• (3) different ways of drop-compensation<br />

for RAM<br />

• spindle bearing by <strong>pr</strong>eloaded high<br />

<strong>pr</strong>ecision spindle bearings<br />

• thermal monitoring of the spindle<br />

bearings<br />

Machine column<br />

• solid cast iron with reinforced outer<br />

walls<br />

• two large guide ways<br />

• Y axis drive by two widely spaced ball<br />

screws driven by two water cooled<br />

AC-motors

Process monitoring<br />

• tool breakage monitoring; automatic<br />

tool identification systems<br />

• tool and work piece measurement<br />

(touch <strong>pr</strong>obe with radio wave transmis-<br />

sion and tool measuring and crack<br />

detection by laser beam)<br />

• torque monitoring; collision monitoring<br />

• capture of <strong>pr</strong>oduction data<br />

• remote diagnosis<br />

Process lubrication<br />

• coolant units for inner and outer<br />

coolant supply<br />

• high <strong>pr</strong>essure coolant units<br />

• mist coolant device<br />

Automatic change of special<br />

accessories by using<br />

pick up stations for<br />

• a wide range of automatic and manual<br />

milling heads<br />

• NC-facing heads<br />

• spindle support, spindle extensions<br />

• special tools<br />

Machine options<br />

Technological solutions<br />

• rotary and traversing tables with a load<br />

up to <strong>250</strong> t<br />

• tilting tables with controlled tilting axis<br />

0…90°, swivelling tables<br />

• carousel tables for turning operations<br />

Automatic tool changer<br />

• on-board tool magazine with up to<br />

165 tools<br />

• tool change into vertical or horizontal<br />

heads possible<br />

• tr<strong>union</strong> devices, floor plates,<br />

clamping devices<br />

• tool packages<br />

• for SK 50, HSK 100 tools, others<br />

available on request<br />

5

Orthogonal milling head<br />

with automatic positioning (2x360x1°)<br />

automatic tool clamping, max power 30 kW<br />

3 D touch <strong>pr</strong>obe<br />

including measurement cycles for auto-<br />

matic measurement of workpieces<br />

Accuracies<br />

machining accuracies<br />

6<br />

Optional accessories, milling heads,<br />

machine accuracies<br />

2 axis NC milling head<br />

automatic tool clamping,<br />

max power 37 kW<br />

deviation from a straight line (reference traverse 630 mm) ≤ 20 µm<br />

diameter accuracy (internal boring) IT 6<br />

deviation from true circle (internal boring); diameter <strong>160</strong> mm ≤ 8 µm<br />

deviation from true circle (external milling, circular); diameter 300 mm ≤ 20 µm<br />

coaxiality of above mentioned circles ≤ 20 µm<br />

positioning accuracy according to VDI/DGQ 3441<br />

axes x, y, z<br />

Adaptable milling heads (examples)<br />

Accessories<br />

Pick up stations<br />

for automatic tool change into the milling<br />

head<br />

positioning uncertainty up to 5,000 mm P 25 µm<br />

positioning uncertainty up to 10,000 mm P 32 µm<br />

positioning uncertainty over 10,000 mm P 40 µm<br />

positional scatter up to 5,000 mm Psmax 10 µm<br />

reversal error up to 5,000 mm Umax 5 µm<br />

positional deviation up to 5,000 mm Pa 8 µm<br />

NC-facing head<br />

for NC-contouring, facing and turning up<br />

to 1<strong>250</strong> mm diameters<br />

Wireless handwheel<br />

for utmost flexibility when setting work-<br />

pieces

Technical data<br />

Technical data<br />

Layout<br />

PR <strong>150</strong>/<strong>160</strong> PR <strong>200</strong>/<strong>250</strong><br />

boring spindle<br />

diameter mm <strong>150</strong>/162 <strong>200</strong>/<strong>250</strong><br />

drive power, max. (S6) kW 68 110/130<br />

torque, max. Nm 5,000 15,000/17,000<br />

speed range, max. min-1 5...3,500 5...2,<strong>200</strong>/1,500<br />

traverses axes<br />

column cross traverse X mm 4,000 4,000<br />

optional extension in steps of X mm 1,000 1,000<br />

headstock vertical traverse Y mm 3,000 3,000<br />

optional extension in steps of<br />

500 mm up to max.<br />

Y mm 6,000 10,000<br />

RAM extension Z mm 1,000/1,500 1,600<br />

boring spindle axial traverse<br />

feeds / rapid traverses<br />

W mm 700 1,000<br />

feed range of all axes mm/min 1...6,000 1...6,000<br />

rapid travers of linear axes max.<br />

automatic tool changer<br />

mm/min 25,000 22,000<br />

number of tool pockets in the magazine 40 - 165 40 - 165<br />

max. tool diameter if adjacent pockets are empty mm <strong>250</strong> <strong>250</strong><br />

max. tool length mm 500 500<br />

max. tool weight kg 30 30<br />

max. tool weight kg 38,500 81,500<br />

subject to correction<br />

UNION only gives general recommenda-<br />

tions concerning the positioning of the<br />

machine to the plate field. However, this<br />

and the positioning of the clamping plates<br />

to the height are variable and have to be<br />

determined before order.<br />

Layout of a PCR <strong>150</strong><br />

model with x = 5,000 mm, y = 3,000 mm;<br />

plate field 6,000 x 2,000 mm<br />

7

UNION<br />

Werkzeugmaschinen GmbH Chemnitz<br />

Clemens-Winkler-Straße 5<br />

D-09116 Chemnitz<br />

Tel.: +49-371-8741-0<br />

Fax: +49-371-8741-407<br />

E-Mail: info@<strong>union</strong>-machines.com<br />

www.<strong>union</strong>-machines.com<br />

2011<br />

e PR<br />

postal address<br />

UNION<br />

change<br />

Werkzeugmaschinen GmbH Chemnitz<br />

to<br />

P.O.Box 1142<br />

D-09070 Chemnitz Subject