Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

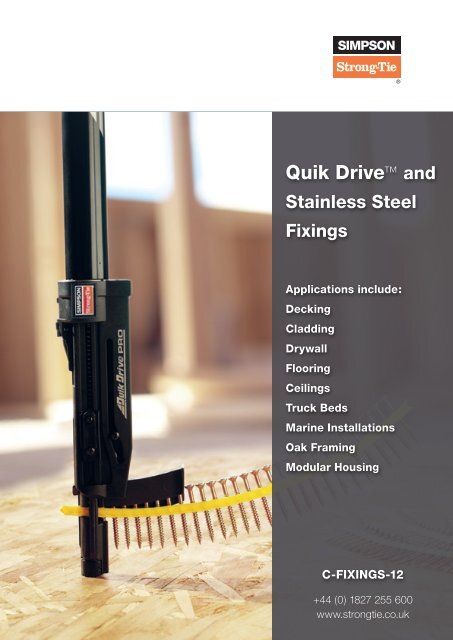

Quik Drive and<br />

Stainless Steel<br />

Fixings<br />

Applications include:<br />

Decking<br />

Cladding<br />

Drywall<br />

Flooring<br />

Ceilings<br />

Truck Beds<br />

Marine Installations<br />

Oak Framing<br />

Modular Housing<br />

C-FIXINGS-12<br />

+44 (0) 1827 255 600<br />

www.strongtie.co.uk

Quik Drive<br />

®<br />

Fast<br />

Simple<br />

Reliable<br />

Quik Drive ® from <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> is the World’s most advanced autofeed screw system. It significantly<br />

reduces the time and effort required when fixing ceilings, floors, decking and mezzanine floors using screws.<br />

The system is compatible with all leading screw guns and offers speedy, easy to load and jam-free<br />

operation using our unique collated screw clips. The unique extension fitting delivers the screws to<br />

floors and ceilings from a normal standing position, and that means a lot less wear and tear to your<br />

knees and back!

Quik Drive and Stainless Steel Fixings<br />

CONTENTS<br />

Collated Tools and Attachments<br />

Collated Screws<br />

Quik Drive General and Safety Information<br />

Pages 7-20<br />

Accessories Full list of Accessories 20<br />

Adaptors Adaptor Compatibility by Gun Manufacturer 16<br />

Bits Correct Bits by Drive Type 19<br />

QD76KE Multi-purpose: Drywall, Flooring, Decking - includes Extension 10-11<br />

QDPRO76SKE Hardwood and Softwood Decking - includes Extension 12<br />

QDHSD60E Mezzanine Floor and Trailer Fastening System 13<br />

QDHSD75E Mezzanine Floor and Trailer Fastening System 13<br />

QDPRO51E Drywall Fastening System 8<br />

QDPRO51KE Drywall Fastening System - includes Extension 8<br />

QDPRO64E Flooring and Deck Fastening System 9<br />

QDPRO64KE Flooring and Deck Fastening System - includes Extension 9<br />

QDPROHX6.4E Metal Roofing and Siding Fastening System 14<br />

QDPROPHE Metal Frame Fastening System 14<br />

Trouble Shooting and Terminology Pages 18-19<br />

Pages 23-33<br />

Applications Full list of Applications and Tool Compatibilty 21<br />

DWC Dry Wall Coarse 26<br />

DWF Dry Wall Fine 27<br />

DWFSD Dry Wall Fine Self Drilling 27<br />

RDWF Reverse Dry Wall Fine 27<br />

WSC Wood Screw Coarse 28<br />

WSNTL Wood Screw Nibs Twin Lead 28<br />

WSNTLG Wood Screw Nibs Twin Lead Galvanised 28<br />

DTHQ Decking Trim Head Quik Guard 29<br />

SSDTH Stainless Steel Deck Trim Head 30<br />

SSWSCB Stainless Wood Screw Coarse Bugle Head 30<br />

SSDHSD Hardwood to Hardwood Decking Screw 30<br />

Self Drilling Screws How They Work 21<br />

TB Wood to Steel Truck Bed 31<br />

TBG Wood to Steel Truck Bed Galvanised 31<br />

FHSD Wood to Steel Flat Head Self Drilling 31<br />

PPSD Wood to Steel Pilot Point Self Drilling 32<br />

PHSD Steel to Steel Pan Head Self Drilling 32<br />

TRSD Steel to Steel Truss Self Drilling 32<br />

CBSD Cement Board Self Drilling 33<br />

BHSD Bugle Head Self Drilling 33<br />

MTH Modified Trim Head 33<br />

Legend: How the Quik Drive Tables Work Pages 25<br />

Quik Drive Coatings and Finishes Page 25<br />

Pages 44-45<br />

Stainless Steel Screws and Nails Pages 34-43<br />

3

4<br />

Quik Drive and Stainless Steel Fixings<br />

CE Marking and Quality<br />

<strong>Simpson</strong>’s Quality Policy<br />

We help people build safer structures economically. We do this by designing, engineering and manufacturing “No Equal” structural<br />

connectors and other related products that meet or exceed our customers’ needs and expectations.<br />

Everyone is responsible for product quality and is committed to ensuring the effectiveness of the Quality Management System.<br />

Terry Kingsfather<br />

President<br />

Testing Laboratory Accreditation<br />

Our European Test Laboratory located in Tamworth, Staffordshire is the first manufacturer’s facility to<br />

achieve third party accreditation to the international standard BS EN ISO/IEC 17025.<br />

Quality Management: ISO9001:2008<br />

<strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> is an ISO 9001 registered company.<br />

ISO 9001 is an internationally-recognised quality management system standard, which lets our<br />

customers know that they can count on the consistent quality of <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>’s products<br />

and services.<br />

The Environment: ISO14001, Health and Safety: BS 18001<br />

<strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> <strong>UK</strong> designs, manufactures and distributes pressed steel products for the<br />

construction industry. It recognises that its processes and products do impact on the environment<br />

and so is committed to minimise this impact through the following measures:<br />

• Comply with applicable legislation, industry codes of practice and other requirements.<br />

• Avoiding, controlling or reducing pollution resulting from its operations.<br />

• Take account of the concerns of interested parties such as regulators, shareholders, employees<br />

and the public.<br />

• Set objectives to drive continual improvement programmes and regularly review performance to<br />

evaluate effectiveness.<br />

• Ensure that all persons working for or on behalf of the branch are aware of this policy and are<br />

trained in their responsibilities.<br />

• Minimise the risk and protect our associates and the communities in which we operate by utilising<br />

safe technologies and operating procedures.<br />

• Employ management systems and procedures specifically designed to prevent activities and<br />

conditions that pose a threat to health, safety or the environment.<br />

• Ensure our suppliers adhere to basic workplace standards, comply with applicable laws and<br />

regulations and operate in a socially and environmentally responsible manner.<br />

129-150<br />

4024<br />

ISO9001<br />

FM14704<br />

ISO14001<br />

EMS517722<br />

BS18001<br />

OHS57006<br />

0

3 Year Warranty<br />

Our collated screw systems are designed and built<br />

to last, with all moving components factory coated<br />

with Teflon ® , they’ll give the building professional<br />

years of reliable use, in all manner of environments.<br />

To prove our confidence and give you peace of<br />

mind, we offer a free 3 year warranty. To register<br />

your Quik Drive ® tool kit, simply complete and return<br />

the registration card included with it.<br />

5

6<br />

Collated Quik Drive and and Corrosion Stainless Resistant Steel Fixings Fastenings<br />

APPLICATIONS<br />

TOOLS<br />

Quik Drive ®<br />

Auto-Feed Systems<br />

increase productivity<br />

while providing<br />

superior fastener<br />

performance<br />

• Fast, jam free operation<br />

• Re-usable screw clips<br />

• Extension allows access to floors<br />

and ceilings without crouching,<br />

bending or over-stretching<br />

• Wide range of applications from<br />

Decking to Drywall<br />

• Moving components factory<br />

coated with Teflon ®<br />

• Three Year Warranty

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

TOOLS<br />

QDPRO51E<br />

QDPRO51KE<br />

Drywall Fastening<br />

QDPRO64E<br />

QDPRO64KE<br />

Flooring and Decking<br />

QD76KE<br />

Page 10<br />

Multi-purpose: Drywall,<br />

Flooring and Decking<br />

QD76KEG<br />

As above with Screw Gun<br />

Page 8<br />

Page 9<br />

QD76PROSKE<br />

Hardwood and<br />

Softwood Decking<br />

QDHSD60E<br />

QDHSD75E<br />

Engineered for Trailer and<br />

Mezzanine Floor Fastening<br />

QDPROHX6.4E<br />

Metal Roofing with<br />

Hex Drive Screws<br />

QDPROPHE<br />

Metal Roofing and<br />

Cladding<br />

Page 12<br />

Page 13<br />

Page 14<br />

Page 14<br />

7

8<br />

Quik Drive and Stainless Steel Fixings<br />

TOOLS<br />

QDPRO51 - Drywall Applications or Light Gauge Steel<br />

1<br />

Applications: Drywall-Wood or Light Gauge Steel<br />

• Teflon ® material, no lubricating required.<br />

• Possible 360 o turn of the attachment on adaptor or extension.<br />

• Easy connection to screw gun or extension.<br />

• Mandrel 165E-RC<br />

2<br />

QDPRO51E QDPRO51KE<br />

3 x BIT2PE<br />

1 x BIT2SE<br />

1 x BIT3SUE<br />

1 Smooth nose will not mark drywall surface.<br />

2 Self-locking depth adjustment for consistent countersink.<br />

Suitable from 25mm up to 51mm<br />

BHSD Page 33<br />

DWC Page 26<br />

DWF Page 26<br />

DWFSD Page 26<br />

MTH Page 33<br />

RDWF Page 27<br />

3 x BIT2PE<br />

1 x BIT2SE<br />

1 x BIT3SUE

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

TOOLS<br />

QDPRO64 - Flooring and Decking Applications<br />

Suitable from 38mm up to 64mm<br />

CBSD Page 33<br />

DTHQ Page 29<br />

PPSD Page 32<br />

SSDCL Page 26<br />

SSDTH Page 30<br />

SSWSCB Page 30<br />

WSC Page 28<br />

WSNTL Page 28<br />

WSNTLG Page 28<br />

1<br />

1 Non-skid nose piece increases stability (not interchangeable).<br />

2 Uniform toe-nailing and countersink on slick surfaces.<br />

Applications: Flooring and Decking<br />

Teflon ® material, no lubricating required.<br />

• Possible 360 o turn of the attachment on adaptor or extension.<br />

• Easy connection to screw gun or extension.<br />

• Mandrel 191E-RC.<br />

• Curved feeding guide for quick strip loading.<br />

2<br />

• Replaceable non-skid teeth for slick surfaces.<br />

• Self-locking depth adjustment for consistent countersink.<br />

QDPRO64E QDPRO64KE<br />

2 x BIT2SE<br />

2 x BIT3SUE<br />

2 x BIT2SE<br />

2 x BIT3SUE<br />

9

10<br />

Quik Drive and Stainless Steel Fixings<br />

TOOLS<br />

QD76KE - Multipurpose Drywall, Flooring and Decking Applications<br />

51mm Nose Piece<br />

Interchangeable nose pieces included:<br />

51mm for 25mm to 51mm screws<br />

64mm for 38mm to 64mm screws<br />

76mm for 76mm screws only<br />

Applications: Drywall, Flooring and Decking<br />

• Teflon ® material, no lubricating required.<br />

• Possible 360 o turn of the attachment on adaptor or extension.<br />

• Easy connection to screw gun or extension.<br />

• Mandrel 191E-RC.<br />

• Self locking depth adjustment for consistent countersink<br />

QD76KE<br />

64mm Nose Piece 76mm Nose Piece<br />

2 x BIT2PE<br />

1 x BIT3SE<br />

1 x BIT2SE<br />

1 x BIT2UE<br />

1 x BIT3SUE<br />

Suitable from 25mm up to 76mm<br />

BHSD Page 33<br />

CBSD Page 33<br />

DTHQ Page 29<br />

DWC Page 26<br />

DWF Page 26<br />

DWFSD Page 26<br />

MTH Page 33<br />

PPSD Page 32<br />

RDWF Page 27<br />

SSDTH Page 30<br />

SSWSCB Page 30<br />

WSC Page 28<br />

WSNTL Page 28<br />

WSNTLG page 28

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

TOOLS<br />

QD76KEG - Multipurpose Drywall, Flooring and Decking Applications<br />

Interchangeable nose pieces included:<br />

51mm for 25mm to 51mm screws<br />

64mm for 38mm to 64mm screws<br />

76mm for 76mm screws only<br />

Suitable from 25mm up to 76mm<br />

BHSD Page 33<br />

CBSD Page 33<br />

DTHQ Page 29<br />

DWC Page 26<br />

DWF Page 26<br />

DWFSD Page 26<br />

MTH Page 33<br />

PPSD Page 32<br />

RDWF Page 27<br />

SSDTH Page 30<br />

SSWSCB Page 30<br />

WSC Page 28<br />

WSNTL Page 28<br />

WSNTLG Page 28<br />

Makita is a registered trademark Makita Corporation.<br />

All of the features and equipment available as part of QD76KE,<br />

also including a Screw Gun and Aluminium adaptor<br />

(adaptor reference AMA9E-RC).<br />

Choice of 110v or 240v Screw Gun.<br />

Applications: Drywall Flooring and Decking<br />

• Teflon ® material, no lubricating required.<br />

• Possible 360 o turn of the attachment on adaptor or extension.<br />

• Easy connection to screw gun or extension.<br />

• Mandrel 191E-RC.<br />

• Self locking depth adjustment for consistent countersink.<br />

QD76KEG<br />

2 x BIT2PE<br />

1 x BIT3SE<br />

1 x BIT2SE<br />

1 x BIT2UE<br />

1 x BIT3SUE<br />

11

12<br />

Quik Drive and Stainless Steel Fixings<br />

TOOLS<br />

QDPRO76SKE - Hardwood to Hardwood and Softwood Decking Applications<br />

Applications: Hardwood to Hardwood<br />

and Softwood Decking<br />

• Decking on decks and docks.<br />

• Subfloor to wood or steel.<br />

• Wall plates, stair treads, sheathing.<br />

• Fibre-cement siding to steel.<br />

Suitable from 25mm up to 76mm<br />

CBSD Page 33<br />

DTHQ Page 29<br />

SSDTH Page 30<br />

SSDHSD Page 30<br />

WSNTL Page 28<br />

WSNTLG page 28<br />

QDPRO76SKE

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

TOOLS<br />

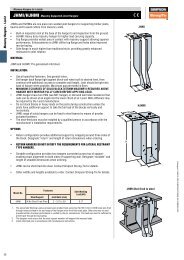

QDHSD - Trailer, Truckbed and Mezzanine Floor Applications<br />

QDHSD60E (suitable for use with 45mm to 60mm screws)<br />

QDHSD75E (suitable for use with 60mm to 75mm screws)<br />

Applications: Trailer, Truckbed and Mezzanine Floors<br />

• Teflon ® material, no lubricating required.<br />

• Possible 360 o turn of the attachment on<br />

adaptor or extension.<br />

• Easy connection to screw gun or extension.<br />

• Mandrel 191E-RC.<br />

• Self locking depth adjustment for consistent countersink.<br />

• Broad nose increases stability.<br />

QDHSD<br />

3 x BIT3SE<br />

+<br />

TB Page 31<br />

TBG Page 31<br />

FHSD Page 31<br />

Extension sold seperately. Not available in kit form at<br />

time of print.<br />

13

14<br />

Quik Drive and Stainless Steel Fixings<br />

TOOLS<br />

QDPROPHE - For Metal Roofing and Cladding Applications<br />

+<br />

Available in 19mm only.<br />

PHSD Page 32<br />

TRSD Page 32<br />

Extension sold seperately.<br />

QDPROPHX6.4E<br />

QDPROHX6.4E - For Metal Roofing with Hex Drive Screws<br />

Available in 38mm only.<br />

HG Call SST<br />

Extension sold seperately.<br />

+<br />

Applications: Metal Roofing and Cladding<br />

Teflon ® material, no lubricating required.<br />

• Possible 360 o turn of the attachment on<br />

adaptor or extension.<br />

• Easy connection to screw gun or extension.<br />

• Mandrel 165E-RC.<br />

• Self locking depth adjustment.<br />

QDPROPHE<br />

Applications: Metal Roofing and Sidings<br />

• Teflon ® material, no lubricating required.<br />

• Possible 360 o turn of the attachment on<br />

adaptor or extension.<br />

• Easy connection to screw gun or extension.<br />

• Self locking depth adjustment.<br />

QDPROHX6.4E<br />

3 x BIT2PE<br />

1 x BIT2SE

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Collated and Corrosion Resistant Fastenings<br />

Fast Technical Support<br />

For the best technical support and practical advice, contact our Technical<br />

Support Team.<br />

Call +44(0)1827 255600 or Fax +44(0)1827 255629 or<br />

Email: uktechnical@strongtie.com<br />

For sales enquiries call:<br />

01827 255600 or visit: www.strongtie.co.uk<br />

15

16<br />

Quik Drive and Stainless Steel Fixings<br />

ADAPTORS<br />

Adaptor Selection By Screw Gun Manufacturer<br />

BOSCH ® RPM<br />

GSR 6-25<br />

GSR 6-45<br />

GSR 6-25<br />

(after 2008)<br />

GSR 6-40<br />

(after 2008)<br />

GSR 12VET<br />

(after 2008)<br />

DEWALT ® RPM<br />

DW979K<br />

ADW1-RC<br />

2,300<br />

DC520N 2,900<br />

DW263K<br />

ABO1E-RC<br />

ABOE-RC<br />

ADWE-RC<br />

2,500<br />

4,500<br />

2,500<br />

4,500<br />

2,000<br />

2,500<br />

DW264K 2,000<br />

DW274K 4,000<br />

DW275K 5,300<br />

DC827KL ADW2E-RC 2,700<br />

AEG ® is a trademark of AEG Electrowerkzenge, Bosch ® is a trademark of Bosch Tool Corporation, Hilti ® is a trademark of Hilti<br />

Corporation, Berner ® is a trademark of Berner International Corp., Fein is a trademark of C. & E. FEIN GmbH, Festool ® is a trademark<br />

of FEIN GmbH, Hitachi ® is a trademark of Hitachi Koki Co., LTD., Holzher ® is a trademark of HOLZ-HER U.S. Inc, Metabo ®<br />

is a trademark of Metabowerke GmbH, Kress is a trademark of KRESS-elektrik GmbH & Co. KG, Milwaukee ® is a trademark of<br />

Milwaukee Electric Tool Corporation, Tools, Inc., DeWalt ® is a trademark of DeWalt Industrial Tool, Co., Makita ® is a trademark of<br />

Makita Corporation, Spit ® is a trademark of Illinois Tool Works Inc., Wurth ® is a trademark of Adolf Würth GmbH & Co. KG.<br />

HITACHI ® RPM<br />

WH18DL<br />

WH18DMR<br />

W8VB<br />

W8VB2<br />

W6VB2<br />

W6VB3<br />

W6VA3<br />

ST1800<br />

AHI1E-RC 2,600<br />

AHIE-RC<br />

AHTE-RC<br />

1,700<br />

2,600<br />

W6VA4 3,000<br />

W6V3<br />

W6V4<br />

W6VM<br />

AHIE-RC 4,000<br />

HOLZHER ® RPM<br />

3352 AHEE-RC 2,850<br />

HILTI ® RPM<br />

SF4000 AHT2E-RC 4.000<br />

SF4000A<br />

4,000<br />

SD2500 AHT2E-RC 2,500<br />

SD5000 5,000<br />

1,800<br />

ST2500 2,500

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

ADAPTORS<br />

Adaptor Selection By Screw Gun Manufacturer<br />

MAKITA ® RPM<br />

6823<br />

6824<br />

6825RK<br />

6826<br />

6842/43 AMA4E-RC<br />

AMAE-RC 2,500<br />

4,700 /<br />

6,000<br />

6807 AMA2E-RC 2.200<br />

6827 AMA5E-RC 2,500<br />

6821 AMA6E-RC 4,000<br />

BTD140RFE<br />

BTD130RFE<br />

BFS440RFE<br />

14,4 V & BFS450RFE 18 V<br />

AMA7E-RC 2,300<br />

AMA8E-RC 4,000<br />

MAKITA ® RPM<br />

FS2300K<br />

2,500<br />

FS4300K AMA9E-RC 4,000<br />

FS6300RK 6,000<br />

AEG ®<br />

SE2500<br />

AMIE-RC<br />

RPM<br />

HASTIGHED<br />

(o/m)<br />

2,500<br />

SE4000 4,000<br />

MAKITA ® RPM<br />

BFS450RFE 18 V AMA8E-RC 4,000<br />

FS2300K<br />

METABO ®<br />

SE2800<br />

SE4000<br />

SE5025<br />

MILWA<strong>UK</strong>EE ® RPM<br />

TKSE2500 Q<br />

AMIE-RC<br />

RPM<br />

HASTIGHED<br />

(o/m)<br />

AME1E-RC 2,850<br />

AMEE-RC<br />

2,500<br />

FS4000K AMA9E-RC 4,000<br />

FS6300RK 6,000<br />

2,500<br />

SE5040 4,000<br />

2,500<br />

DWSE4000 Q 4,000<br />

FESTOOL ® RPM<br />

C12 DUO AFTE-RC 1,500<br />

KRESS ® RPM<br />

TBS650 AKR1E-RC 4,500<br />

17

18<br />

Quik Drive and Stainless Steel Fixings<br />

SYSTEM TERMINOLOGY<br />

COMPONENTS<br />

Attachment<br />

TOOL<br />

Extension<br />

Extension Shaft<br />

* 110v or 240v screw guns are available on request<br />

Depth Adjustment Wheel<br />

Locking Lever<br />

Bit Release Key Feed Pawl Lever<br />

(Must be engaged in<br />

feed pawl assembly slot)<br />

Bit Release Slot<br />

Screw Gun (not included) *<br />

Handle<br />

Nose Piece<br />

Guide Tube<br />

Feed Pawl<br />

Assembly<br />

Mandrel Hex Mandrel (inside attachment)<br />

Bit<br />

Nose

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

TROUBLESHOOTING GUIDE<br />

Fault Diagnosis<br />

Quik Drive ® tools are easy to use. As with any power tool, there are a few basic things to remember.<br />

Symptom Solution<br />

Screws won’t drive. They spin for a second, then<br />

lay over on their side. Providing little or no<br />

penetration.<br />

Screws won’t drive completely. They go down<br />

about halfway then the bit spins out.<br />

Screws are almost completely driven but won’t<br />

countersink fully.<br />

Screws don’t advance properly, causing the tool<br />

to jam.<br />

Correct Bit Use<br />

Using the correct driving bit is necessary.<br />

This is the most commonly reported issue. Make sure the screw gun<br />

is not set to reverse, if it is, set to forward<br />

(indicated by arrow located near screw gun trigger).<br />

Check that you are using the correct bit for the type of screws being<br />

driven. Check the bit for wear as it may need replacing with a new<br />

one (a free bit is provided with every box of screws).<br />

If you hear a “clacking” sound whilst driving screws, apply more<br />

pressure.<br />

Check the depth adjustment on the attachment, reset if necessary.<br />

You may have missed the substrate (typically occurs in flooring applications<br />

if you miss the joist).<br />

Ensure that the screw is strip is inserted correctly (pointed end first).<br />

Engage screw gun trigger before nose piece makes contact with the<br />

surface.<br />

Lift the tool completely off the surface after driving each screw -<br />

don’t drag screw strips along the work surface as you move along to<br />

the next position.<br />

Ensure the feed pawl lever is intact and the feed lever is engaged.<br />

The free bit(s) included in each box of Quik Drive ® screws should drive the entire box.<br />

Variations in materials and driving technique can cause excessive wear so additional bit packs are available for<br />

purchase. Reference the description on the bit sticker in your box of screws or the screw box label to ensure correct<br />

selection. BIT2SUE and BIT3SUE undersized are suitable for use with galvanised screws..<br />

Bits and Recess Drives<br />

#2 Square Drive BIT2SE<br />

#2U Undersized BIT2SUE<br />

#3 Square Drive BIT3SE<br />

#3U Undersized BIT3SUE<br />

#2 Phillips BIT2PE<br />

19

20<br />

Quik Drive and Stainless Steel Fixings<br />

ACCESSORIES<br />

Description Reference<br />

Bit pack - 3 ea. #2 Phillips drive and wrench BIT2PE-RC3<br />

Bit pack - 3 ea. #2 square bit and wrench BIT2SE-RC3<br />

Bit pack - 3 ea. #2 undersized square bit and wrench BIT2SUE-RC3<br />

Bit pack - 3 ea. #3 square drive bit and wrench BIT3SE-RC3<br />

Bit pack - 3 ea. #3 undersized square bit and wrench BIT3SUE-RC3<br />

Bit pack - 10 ea. #2 Phillips drive bit BIT2PE-RC10<br />

Bit pack - 10 ea. #2 square drive bit BIT2SE-RC10<br />

Bit pack - 10 ea. #2 undersized square bit BITSUE-RC10<br />

Bit pack - 10 ea. #3 square drive bit BIT3SE-RC10<br />

Bit pack - 10 ea. #3 undersized square bit BIT3SUE-RC10<br />

Mandrel 165mm for QDPRO51 / QDPROPH MANDREL165E-RC<br />

Mandrel 191mm for QDPRO64 / QD76KE / QDHSD MANDREL191E-RC<br />

Nose Piece Alignment Aid for QD76KE NPADECKAE-RC<br />

Decking Nose Piece DNPE<br />

Extension - 51cm QDEXTE<br />

Extension Long - 57cm QDEXTLE<br />

Feed Pawl for QDPRO51 / QD76 PFEEDPAWLTLE<br />

Feed Pawl for QDPRO64 PFEEDPAWLE<br />

Feed Pawl for QDPROPH PFEEDPAWL2E<br />

Feed Pawl for QDHSD PFEEDPAWL3E<br />

Heavy Duty Case for kits TOOLCASE-LGE<br />

Spring for QD76KE QDSPRING4E<br />

Nose Clip for QDPRO64E PNOSECLIPE<br />

Replacement attachment for QD76KE (excludes nose pieces) QDSPA76E<br />

QDEXTLE<br />

BIT PACK (availble in packs of 3 or 10)<br />

FEED PAWL<br />

TOOLCASE (LARGE)<br />

MANDREL<br />

ALIGNMENT AID<br />

DECKING NOSE PIECE<br />

(Note protrusion to ease<br />

location into Decking<br />

Groove)

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

APPLICATIONS<br />

Drywall<br />

Flooring<br />

Deck/Dock<br />

Wood-to-Steel<br />

Steel-to-Steel<br />

Speciality<br />

QDPRO51E/KE<br />

QDPRO64E/KE<br />

QD76KE<br />

QDPRO76SKE<br />

QDHSD60E<br />

QDHSD75E<br />

QDPROPHE<br />

QDPROHX6.4<br />

DWC3525PE • • 26 ●<br />

DWC3535PE • • 26 ●<br />

DWC3540PE • • • 26 ●<br />

DWC3550PE • • • 26 ●<br />

DWC3930PE • • 26<br />

DWC3955PE • • 26<br />

DWC3965PE • • 26 ●<br />

DWF3525PE • • 26 ●<br />

DWF32PE • • 26 ●<br />

DWF41PE • • • 26 ●<br />

DWFSD32PE • • 26 ●<br />

DWFSD41PE • • • 26 ●<br />

RDWF30BE • • 27 ●<br />

RDWF40BE • • • 27 ●<br />

WSC32E • • 28 ●<br />

WSC38E • • • 28 ●<br />

WSNTL44E • • • 28 ●<br />

WSNTL51E • • • 28 ●<br />

WSNTL64E • • 28 ●<br />

WSNTL76E • 28 ●<br />

WSNTLG51E • • • 28 ●<br />

WSNTLG64E • • 28 ●<br />

DTHQ51E • • • 29<br />

DTHQ64E • • 29<br />

DTHQ76E • 29<br />

SSDTH51E • • • 30<br />

SSDTH64E • • 30<br />

SSDHSD50E • 30<br />

SSDHSD60E • 30<br />

SSWSCB51E • • • 30<br />

SSWSCB64E • • 30<br />

FHSD64E • 31<br />

PPSD49E • • • 32<br />

TB645E • 31<br />

TB660E • • 31<br />

TB675E • 31<br />

TBG645E • 31<br />

TBG660E • • 31<br />

PHSD19E • 32<br />

TRSD19E1012 • 32<br />

CBSDQ41E • • • 33<br />

CBSDQ55E • • 33<br />

BHSDZ41PE • • • 33<br />

MTH32E • • 33<br />

MTHZ25E • • 33<br />

PAGE<br />

CE Approved<br />

21

22<br />

Quik Drive and Stainless Steel Fixings<br />

SELF DRILLING SCREWS<br />

See pages 31 and 32 for products<br />

which are self drilling.<br />

HOW SELF-DRILLING SCREWS WORK<br />

When selecting a self-drilling screw it is important to select a<br />

suitable point for the material thickness. Three key things to be<br />

aware of:<br />

1. Drill Flute: The height of the flutes determines the material<br />

thickness which the screw can penetrate. Since the<br />

flutes remove debris during drilling, if they become completely<br />

embedded in the material, debris will become trapped in the<br />

flutes and cutting action will cease. This will cause the point<br />

to heat up and break.<br />

2. Point Length: The unthreaded portion of the point, known<br />

as the pilot section, must be long enough to completely penetrate<br />

the material before the threads engage. Since the<br />

threads advance faster than the drilling process, if they engage<br />

before drilling is done the fastener can bind and break.<br />

3. Fastening Thicker Material to Metal: When fastening thicker<br />

materials such as wood to metal, it is necessary to use a fastener<br />

with “wings” on the shaft. The wings will enlarge the<br />

hole in the fastened material so that the threads can pass<br />

through without binding or damage. Once the wings contact<br />

the metal they break away and the threads engage.<br />

Wing Reamer<br />

Head<br />

Threads<br />

Wings<br />

Pilot Section<br />

Flute<br />

Point<br />

Wings ream hole larger than threads so threads do not engage wood.<br />

Wings then break off when they hit steel, then threads engage.<br />

Screw Point Type Screw Diameter Material Thickness *<br />

#2<br />

#3<br />

#4<br />

3.5<br />

4.2<br />

4.8<br />

4.2<br />

4.8<br />

5.5<br />

6.1<br />

5.5<br />

6.1<br />

* All dimensions in mm. Total thickness of steels including spacing between layers.<br />

0.9 - 2.5<br />

0.9 - 2.5<br />

0.9 - 2.8<br />

2.5 - 3.6<br />

2.8 - 4.4<br />

2.8 - 5.3<br />

2.8 - 5.3<br />

4.4 - 5.6<br />

4.4 - 5.6

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

COLLATED SCREWS<br />

DRYWALL SCREWS<br />

WOOD-TO-WOOD SCREWS<br />

WOOD-TO-STEEL SCREWS<br />

STEEL-TO-STEEL SCREWS<br />

SPECIALITY SCREWS<br />

Page 26<br />

Page 28<br />

HARDWOOD DECKING SCREWS Page 30<br />

Page 31<br />

Page 32<br />

Page 33<br />

23

Quik Drive<br />

The fastest and most<br />

reliable auto-feed system<br />

•drywall<br />

•ceilings<br />

•flooring<br />

•decking<br />

•wood to steel<br />

•steel-steel<br />

•speciality screws

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Collated Quik Drive and and Corrosion Stainless Resistant Steel Fixings Fastenings<br />

LEGEND - How The Quik-Drive Tables Work<br />

Head<br />

Diameter<br />

Head Style Thread Style Point Style<br />

Thread<br />

Diameter<br />

Flat Head<br />

Hi-Lo Threads<br />

Drill Point w/wings<br />

Length<br />

of Screw<br />

Bugle Head<br />

Twin Lead<br />

Type 17 Point<br />

Curved or<br />

Straight<br />

Strip Screw<br />

Cap Head<br />

Coarse Thread<br />

COATINGS - FINISHES - STAINLESS STEEL<br />

1/4” Hex Washer Head<br />

Drill Point<br />

Quantity of<br />

Screws per<br />

Box<br />

Box Thread<br />

Pilot Point<br />

Recommended<br />

Screw drive<br />

Motor RPM<br />

304/305 (A2) Stainless Steel: 304/305 (A2) stainless steel is a nickel chromium austenitic grade of stainless steel<br />

and is inherently non-magnetic. This material provides very good corrosion resistance. No visible sign of surface red<br />

rust at 1000 hours of salt spray test.<br />

N2000 ® Mechanically Galvanised: Mechanical galvanisation provides a protective zinc nickel alloy coating over base<br />

metal. The coating is applied by mechanically tumbling base metal with non-metallic impact beads and zinc powder.<br />

Less than 10% surface red rust at 1,000 hours of salt spray test.<br />

Quik Guard ®: is a proprietary double barrier coating that provides a level of corrosion protection suitable for many<br />

preservative-treated wood applications. Less than 10% surface red rust at 950 hours of salt spray test.<br />

Yellow Zinc Dichromate: Coating offers minimum amount of corrosion protection and is intended for dry, noncorrosive<br />

applications only.<br />

Clear Zinc: Coating offers minimum amount of corrosion protection and is intended for dry, non-corrosive<br />

applications only.<br />

Tool<br />

Part<br />

Number<br />

Grey Phosphate: Coating offers minimum amount of corrosion protection and is intended for dry, non-corrosive<br />

applications only.<br />

General Note About Salt Spray Testing: Salt spray testing is in accordance with ASTM B117, is not intended to<br />

represent real world corrosive performance of screw coatings. It should only be used for comparative evaluation<br />

between like products. Many variables can affect the outcome of the salt spray test, such as screw features, coating<br />

types, post coating processes etc.<br />

Pan Head<br />

Fine Thread<br />

Sharp Point<br />

Truss Head<br />

Trim Head with Nibs<br />

Ribbed Wafer Head<br />

25

26<br />

Collated Quik Drive and and Corrosion Stainless Resistant Steel Fixings Fastenings<br />

DRYWALL<br />

BIT2PE<br />

Grey Phosphate finish.<br />

BIT2PE<br />

BIT2PE<br />

DWC (Dry Wall Coarse)<br />

• Drywall to wood applications<br />

Item Reference<br />

DWC3525PE 8.2 3.5 25 30 2,500<br />

DWC3535PE 8.2 3.5 35 30 2,500<br />

DWC3540PE 8.2 3.5 40 30 2,500<br />

DWC3550PE 8.2 3.5 50 30 2,000<br />

DWC3930PE 8.2 3.9 30 30 2,500<br />

DWC3955PE 8.2 3.9 55 30 2,000<br />

DWC3965PE 8.2 3.9 65 30 1,500<br />

DWF (Dry Wall Fine)<br />

• Drywall to steel applications<br />

• For 0.6mm to 0.9mm Steel<br />

Item Reference<br />

DWF3525PE 8.2 3.5 25 30 2,500<br />

DWF32PE 8.2 3.8 35 30 2,500<br />

DWF41PE 8.2 3.8 40 30 2,500<br />

Grey Phosphate finish.<br />

DWFSD (Dry Wall Fine Self Drilling)<br />

• Drywall to steel applications<br />

• For 1.2mm to 2.2mm Steel<br />

• #2 Drill point<br />

Item Reference<br />

2,500<br />

6,000<br />

2,500<br />

6,000<br />

2,500<br />

6,000<br />

2,500<br />

4,500<br />

2,500<br />

6,000<br />

2,500<br />

6,000<br />

2,500<br />

4,500<br />

2,500<br />

6,000<br />

2,500<br />

6,000<br />

2,500<br />

6,000<br />

QDPRO51/QD76KE<br />

QDPRO51/QD76KE<br />

QDPRO51/QD76KE<br />

QDPRO51/QD76KE<br />

QDPRO51/QD76KE<br />

QDPRO51/QD76KE<br />

QD76KE<br />

QDPRO51/QD76KE<br />

QDPRO51/QD76KE<br />

QDPRO51/QD76KE<br />

DWFSD32PE 8.2 3.4 32 30 2,500 2,500 QDPRO51/QD76KE<br />

DWFSD41PE 8.2 3.4 31 30 2,500 2,500 QDPRO51/QD76KE<br />

Yellow zinc dichromate.<br />

Please note: All dimensions in millimetres.<br />

EN 14566<br />

EN 14566<br />

EN 14566

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Collated Quik Drive and and Corrosion Stainless Resistant Steel Fixings Fastenings<br />

DRYWALL<br />

BIT2PE<br />

DWHL RDWF (Dry (Reverse Wall High Dry Low) Wall Fine)<br />

• Dense Drywall to wood<br />

Item Reference<br />

DWHL48PE RDWF30BE 8.2 6.3 4.2 3.8 48 30 30 2,500 2,000<br />

Grey phosphate RDWF40BE finish. 6.3 4.2 40 30 2,500<br />

Grey Phosphate finish.<br />

CURVED COLLATION<br />

Please note: All dimensions in millimetres.<br />

EN 14566<br />

• Easier toenailing<br />

• Easier to move between driving locations without drag<br />

• Strip is pointed at leading end for easy loading<br />

2,500<br />

4,500<br />

2,500<br />

4,500<br />

QDPRO51/QD76KE<br />

QDPRO51/QDPRO64/<br />

QD76KE<br />

Quik Drive ®<br />

Patented Collation<br />

27

28<br />

Quik Drive and Stainless Steel Fixings<br />

SUBFLOORING<br />

BIT2SE<br />

BIT3SE<br />

BIT3SUE<br />

WSC (Wood Screw Coarse)<br />

• Wood to wood applications<br />

Item Reference<br />

WSC32E 8.4 4.2 32 30 2,500<br />

WSC38E 8.4 4.2 38 30 2,000<br />

Yellow Zinc Dichromate.<br />

WSNTL (Wood Screw Nibs Twin Lead)<br />

• Wood to wood applications<br />

Item Reference<br />

WSNTL44E 8.4 4.6 44 30 2,000<br />

WSNTL51E 8.4 4.6 51 30 2,000<br />

2,500<br />

4,500<br />

2,500<br />

4,500<br />

2,500<br />

4,500<br />

2,500<br />

4,500<br />

QDPRO51/QD76KE<br />

QDPRO51/QDPRO64/<br />

QD76KE<br />

QDPRO51/QDPRO64/<br />

QD76KE<br />

QDPRO51/QDPRO64/<br />

QD76KE<br />

WSNTL64E 8.4 4.6 64 30 1,500 2,500 QDPRO64/QD76KE<br />

WSNTL76E 8.4 4.6 76 30 1,000 2,500 QD76KE<br />

Yellow Zinc Dichromate.<br />

WSNTLG (Wood Screw Nibs Twin Lead Galvanised)<br />

• Wood to wood applications<br />

• Suitable for outdoor use<br />

Item Reference<br />

WSNTLG51E 8.4 4.6 51 30 2,000<br />

2,500<br />

4,500<br />

QDPRO51/QDPRO64/<br />

QD76KE<br />

WSNTLG64E 8.4 4.6 64 30 1,500 2,500 QDPRO64/QD76KE<br />

N2000 ® Mechanically galvanised finish.<br />

Please note: All dimensions in millimetres.<br />

EC5<br />

EN 14592<br />

EN 14592<br />

EN 14592

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

DECKING<br />

BIT2SUE<br />

DTHQ (Deck Trim Head Quik Guard ® )<br />

• Decking to wood applications<br />

• Suitable for outdoor use<br />

Item Reference<br />

DTHQ51E 6.2 4.2 51 30 2,000 2,500<br />

QDPRO51/QDPRO64/<br />

QD76KE<br />

DTHQ64E 6.2 4.2 64 30 1,500 2,500 QDPRO64/QD76KE<br />

DTHQ76E 6.2 4.2 76 30 1,000 2,500 QD76KE<br />

Quik Guard ® coating.<br />

29

30<br />

Quik Drive and Stainless Steel Fixings<br />

DECKING<br />

BIT2SE<br />

BIT2SE<br />

BIT2SE<br />

SSDHSD (Stainless Steel Hardwood Decking Screw)<br />

• Hardwood to hardwood decking screw<br />

• Suitable for outdoor use<br />

Item Reference<br />

SSDHSD50E 7.2 5.3 50 30 1,000 2,500 QDPRO76SKE<br />

SSDHSD60E 7.2 5.3 60 30 1,000 2,500 QDPRO76SKE<br />

SSDTH (Stainless Steel Deck Trim Head)<br />

• Decking to wood applications<br />

• Suitable for outdoor use<br />

Item Reference<br />

SSDTH51E 6.3 4.2 51 30 1,000 2,500<br />

QDPRO51/QDPRO64/<br />

QD76KE<br />

SSDTH64E 6.3 4.2 64 30 1,000 2,500 QDPRO64/QD76KE<br />

305 Stainless steel.<br />

SSWSCB (Stainless Wood Screw Coarse Bugle Head)<br />

• Tile roofing to wood applications<br />

• Suitable for outdoor use<br />

Item Reference<br />

SSWSCB51E 8.5 4.6 51 30 2,000 2,500<br />

QDPRO51/QDPRO64/<br />

QD76KE<br />

SSWSCB64E 8.5 4.6 64 30 1,500 2,500 QDPRO64/QD76KE<br />

305 Stainless steel.<br />

Please note: All dimensions in millimetres.

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

WOOD TO STEEL<br />

BIT3SE<br />

BIT3SUE<br />

BIT3SE<br />

TB (Truck Bed)<br />

• Wood to steel applications<br />

• #4 Drill point with wings<br />

Item Reference<br />

TB645E 11.7 6.1 45 23 1,000<br />

TB660E 11.7 6.1 60 23 750<br />

TB675E 11.7 6.1 75 23 750<br />

Yellow Zinc Dichromate finish.<br />

TBG (Truck Bed Galvanised)<br />

• Wood to steel applications<br />

• #4 Drill point with wings<br />

Item Reference<br />

TBG645E 11.7 6.1 45 23 1,000<br />

TBG660E 11.7 6.1 60 23 750<br />

N2000 ® Mechanically galvanised finish.<br />

FHSD (Flat Head Self Drilling)<br />

• Wood to steel applications<br />

• #2 Drill point with wings<br />

Item Reference<br />

FHSD64E 8 4.2 64 30 750<br />

Yellow Zinc Dichromate finish.<br />

1,000<br />

2,500<br />

1,000<br />

2,500<br />

1,000<br />

2,500<br />

1,000<br />

2,500<br />

1,000<br />

2,500<br />

1,000<br />

2,500<br />

WSee page 22 for details on how self drilling<br />

screws work.<br />

Please note: All dimensions in millimetres.<br />

QDHSD60<br />

QDHSD60/QDHSD75<br />

QDHSD75<br />

QDHSD60<br />

QDHSD60/QDHSD75<br />

QDHSD75<br />

31

32<br />

Quik Drive and Stainless Steel Fixings<br />

WOOD TO STEEL<br />

BIT3SE<br />

STEEL TO STEEL<br />

BIT2SE<br />

BIT2PE<br />

PPSD (Pilot Point Self Drilling)<br />

• Wood to steel applications<br />

• #2 Drill point<br />

Item Reference<br />

PPSD49E 8.2 4.0 49 30 2,000 2,500<br />

Yellow Zinc Dichromate finish.<br />

PHSD (Pan Head Self Drilling)<br />

• Steel to steel applications<br />

Item Reference<br />

QDPRO51/QDPRO64/<br />

QD76KE<br />

PHSD19E 8 4.1 19 23 2,500 2,500 QDPROPH<br />

Clear Zinc Finish.<br />

TRSD (Truss Self Drilling)<br />

• Steel to steel applications<br />

• #2 Drill point<br />

Item Reference<br />

TRSD19E1012 9.2 4.7 19 23 2,500 2,500 QDPROPH<br />

Clear Zinc Finish.<br />

WSee page 22 for details on how self drilling<br />

screws work.<br />

Please note: All dimensions in millimetres.

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

SPECIALITY SCREWS<br />

BIT2SUE<br />

BIT2PE<br />

BIT2SE<br />

CBSD (Cement Board Self Drilling)<br />

• Fibre cement siding to steel applications<br />

• #2 Drill point with wings<br />

Item Reference<br />

CBSDQ41E 8.4 4.2 41 30 1,500 2,500<br />

QDPRO51/QDPRO64/<br />

QD76KE<br />

CBSDQ55E 8.4 4.2 55 30 1,500 2,500 QDPRO64/QD76KE<br />

Quik Guard ® coating.<br />

BHSD (Bugle Head Self Drilling)<br />

• Drywall to steel applications<br />

• #2 Drill point with wings<br />

Item Reference<br />

BHSDZ41PE 8.2 4.2 41 30 1,500 2,500<br />

Clear zinc coating.<br />

MTH (Modified Trim Head)<br />

• Underlayment applications<br />

Item Reference<br />

QDPRO51/QDPRO64/<br />

QD76KE<br />

MTH32E * 6.9 3.8 32 30 2,500 2,500 QDPRO51/QD76KE<br />

MTHZ25E ** 6.9 3.8 25 30 2,500 2,500 QDPRO51/QD76KE<br />

* Grey Phosphate Finish<br />

** Yellow Zinc Dichromate Finish.<br />

Please note: All dimensions in millimetres.<br />

33

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Stainless Steel<br />

Fastenings<br />

The following guidance notes have been<br />

produced to assist the cladding installation<br />

professional. For more detailed technical<br />

assistance, please contact the<br />

<strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> ® technical support team on<br />

01827 255600 or visit www.strongtie.co.uk.<br />

• Cladding fixings should preferably be of stainless steel due<br />

to their inherent corrosion protection and the fact that the<br />

colour of the head will weather to a similar colour to untreated<br />

cladding.<br />

• Galvanised or coated steel screws are not preferred as the<br />

coating on the head can be damaged during driving which can<br />

result in subsequent rust staining. This is especially important<br />

for unfinished cladding boards as there is no possibility of<br />

replacement of the protection during coating of the boards.<br />

• Exceptions to the above would be when cladding is fixed<br />

to galvanised steel members. In this case it is necessary to<br />

avoid galvanic corrosion due to dissimilar metals. This can be<br />

avoided by fixing battens to the steel members using coated<br />

steel screws, then fixing the cladding to the battens using<br />

stainless steel screws.<br />

• Fasteners should be driven slightly below the surface to allow<br />

for shrinkage in board thickness thus preventing the nail heads<br />

from standing proud.<br />

• Nail penetration into battens should be twice the thickness of<br />

the board for ring shank nails.<br />

• Proprietary clips are available to connect the cladding to the<br />

battens.<br />

• Angle brackets are available to connect the vertical battens<br />

directly to the wall without the need for horizontal battens.<br />

This system creates a zone for insulation and/or ventilation<br />

between the wall and the cladding. An example of this system<br />

is <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>’s ABC Cladding Bracket.<br />

• A Structural Engineer should be involved in the design of the<br />

cladding to ensure the correct type and number of fasteners<br />

and brackets are used to adequately support the loads from<br />

self weight and wind.<br />

35

36<br />

Quik Drive and Stainless Steel Fixings<br />

ANNULAR RING SHANK NAILS<br />

Item<br />

Reference<br />

Ring Shank Nail<br />

Annular Ring Shank : 305 (A2) or 316 (A4) Stainless Steel<br />

Penny Size<br />

Diamond patterned head blends with wood texture,<br />

diffracts sunlight and accepts surface finishes.<br />

Annular ring threads resist cupping of cladding<br />

boards and prevent nail-head popping.<br />

Slender gauge and diamond point prevents splitting.<br />

Can be driven flush or counter-sunk without crushing<br />

the surrounding wood.<br />

Choose 316 marine grade stainless for seaside<br />

applications and for superior corrosion resistance.<br />

Length<br />

(mm)<br />

Gauge<br />

Weight<br />

Per Pack (kg)<br />

Approx.<br />

Count per Pack<br />

Item Code in<br />

316 Marine Grade<br />

Stainless Steel<br />

S6SND1 6d 51 13 0.45 245 T6SND1<br />

S6SND5 6d 51 13 2.27 1,225 T6SND5<br />

S8SND1 8d 64 13 0.45 196 T8SND1<br />

S8SND5 8d 64 13 2.27 980 T8SND5<br />

S10SND1 10d 76 12 0.45 120 T10SND1<br />

S10SND5 10d 76 12 2.27 600 T10SND5<br />

S16SND5 12d 90 11 2.27 440 T16SND5

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

SWANEZE ® SCREWS<br />

Swaneze® Bugle Head Screw<br />

High ‘Pull-Out’ Resistance<br />

Bugle head sits flush with the timber.<br />

Square drive for improved driving torque.<br />

Coarse thread along 2/3 of it’s #8 shank.<br />

Draws timber tighter to the joist.<br />

Type 17 point provides a faster, straighter start.<br />

Item Code<br />

Length<br />

(mm)<br />

Shank ø<br />

(mm)<br />

Head ø<br />

(mm)<br />

Quantity Per<br />

Pack<br />

Approx. Area Coverage<br />

per Pack<br />

S08200DB1 51 4.17 8.74 128 2.6m 2<br />

S08200DB5 51 4.17 8.74 640 13.3m 2<br />

S08250DB1 64 4.17 8.74 102 2.1m 2<br />

S08250DB5 64 4.17 8.74 510 10.6m 2<br />

S08300DB1 76 4.17 8.74 82 1.7m 2<br />

S08300DB5 76 4.17 8.74 410 8.5m 2<br />

Swaneze Trim Head Screw<br />

For a Neat Finish<br />

Trim head provides a neat, professional finish.<br />

Square drive for improved driving torque.<br />

Coarse thread along 2/3 of it’s #7 shank.<br />

Draws timber tighter to the joist.<br />

Type 17 point provides a faster, straighter start.<br />

Item Code<br />

Length<br />

(mm)<br />

Shank ø<br />

(mm)<br />

Head ø<br />

(mm)<br />

Quantity Per<br />

Pack<br />

Approx. Area Coverage<br />

per Pack<br />

S07200FB1 51 3.81 5.84 154 3.2m 2<br />

S07200FB5 51 3.81 5.84 770 16.0m 2<br />

S07200FBB 51 3.81 5.84 4,000 83.3m 2<br />

S07250FB1 64 3.81 5.84 126 2.6m 2<br />

S07250FB5 64 3.81 5.84 630 13.1m 2<br />

S07250FBB 64 3.81 5.84 2,500 52.1m 2<br />

S07300FB1 76 3.81 5.84 98 2.0m 2<br />

S07300FB5 76 3.81 5.84 490 10.2m 2<br />

S07300FBB 76 3.81 5.84 1,750 36.4m 2<br />

37

38<br />

Quik Drive and Stainless Steel Fixings<br />

FIBRE CEMENT BOARD SCREWS<br />

FY-CEM Wood Screw<br />

Fibre Cement to Wooden Studding Screw<br />

Self counter-sinking nibs keep head flush with the surface.<br />

Square drive for improved driving torque.<br />

Threaded along full length of the screw.<br />

Type 17 point provides a faster, straighter start.<br />

Superior corrosion resistance (316 marine grade).<br />

Item Reference Size<br />

Length<br />

(mm)<br />

Shank ø<br />

(mm)<br />

Head ø<br />

(mm)<br />

Approx.<br />

Count per Pack<br />

T08C162WQC #8 41 4.17 10 100<br />

T08C162WQM #8 41 4.17 10 1,000<br />

T08C225WQM #8 57 4.17 10 1,000<br />

FY-CEM Metal Screw<br />

Self Drilling Fibre Cement to Metal Studding Screw<br />

Self counter-sinking nibs keep head flush with the surface.<br />

Square drive for improved driving torque.<br />

Threaded along full length of the screw.<br />

Use 53mm long screws to attach fibre cement to stress skin panels.<br />

410 stainless steel can be hardened through heat treatment, giving it<br />

the ability to drill through metal.*<br />

Fasten fibre cement through furring strips to steel studs.<br />

Item Reference Size<br />

Length<br />

(mm)<br />

Shank ø<br />

(mm)<br />

Head ø<br />

(mm)<br />

Approx.<br />

Count per Pack<br />

F08T162WDC #8 41 4.17 10 100<br />

* 410 Stainless does not offer the same corrosion resistance as 305 or 316 stainless steel.

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

SHAKE AND SHINGLE NAILS<br />

Item Reference Penny Size<br />

Annular Ring Shank Nail<br />

Firmly Secure Shakes and Shingles of All Types<br />

Diamond patterned head blends with wood texture,<br />

diffracts sunlight and accepts surface finishes.<br />

Ample bearing surface firmly secures shakes and<br />

shingles of all types.<br />

Annular ring threads resist cupping of cladding<br />

boards and prevent nail-head popping.<br />

Slender gauge and diamond point prevents splitting.<br />

Can be driven flush or counter-sunk without crushing<br />

the surrounding wood.<br />

Length<br />

(mm)<br />

Gauge<br />

Weight<br />

Per Pack (kg)<br />

Approx.<br />

Count per Pack<br />

Item Code in<br />

316 Marine Grade<br />

Stainless Steel<br />

S6SN71 6d 51 13 0.45 237 T6SN71<br />

S6SN75 6d 51 13 2.27 1,185 T6SN75<br />

39

40<br />

Quik Drive and Stainless Steel Fixings<br />

DECKING SCREW<br />

Woodpecker Woodpecker Decking Screw<br />

Decking Screw<br />

Trim Head 6 Lobe Drive : Hardwood<br />

Superior screw for penetrating the hardest of woods.<br />

6 Lobe drive prevents the screw head from stripping.<br />

Unique ‘box’ thread allows fast and easy installation, reducing driving torque.<br />

Superior corrosion resistance (316 marine grade).<br />

Item Code<br />

Length<br />

(mm)<br />

Shank ø<br />

(mm)<br />

Woodpecker Woodpecker Pack Information<br />

Head ø<br />

(mm)<br />

Quantity Per Pack<br />

Approx. Area Coverage<br />

per Pack<br />

T07225WPP 57mm 3.81 5.84 350 7.3m 2<br />

T07225WPP 57mm 3.81 5.84 350 7.3m 2<br />

T07300WPP 76mm 3.81 5.84 350 7.3m 2<br />

T07225WPB 57mm 3.81 5.84 1750 36.5m 2<br />

T07300WPP 76mm 3.81 5.84 350 7.3m 2<br />

T07300WPB 76mm 3.81 5.84 1750 36.5m 2<br />

Hardwood to Hardwood Decking Screw<br />

Loose variant of the collate SSDHSD<br />

305 (A2) Stainless Steel<br />

Item Code<br />

Length<br />

(mm)<br />

SSDHSD Pack Information<br />

Shank ø<br />

(mm)<br />

Head ø<br />

(mm)<br />

Quantity Per Pack<br />

SSDHSD50ER100 50 5.3 7.2 100<br />

SSDHSD50ER350 50 5.3 7.2 350<br />

SSDHSD50ER1000 50 5.3 7.2 1000<br />

SSDHSD60ER100 60 5.3 7.2 100<br />

SSDHSD60ER350 60 5.3 7.2 350<br />

SSDHSD60ER100 60 5.3 7.2 1000

Catalogue C-FASTENERS12 © 2012 SIMPSON STRONG-TIE COMPANY INC.<br />

Quik Drive and Stainless Steel Fixings<br />

TIMBER TAMER<br />

Timber Tamer ®<br />

Hex Washer Head : Timber Framing<br />

Ideal for outdoor projects which need a longer screw, such as: timber framing, barn construction, oak<br />

sleepers and many more timber uses.<br />

Available in lengths up to 20cm.<br />

Unique ‘box’ thread allows fast and easy installation, reducing driving torque.<br />

Superior corrosion resistance (316 marine grade).<br />

Timber Tamer Pack Information<br />

Item Code Size<br />

Thread Length<br />

(mm)<br />

Quantity Per Pack<br />

T14400TP 6 x 102mm 57 20<br />

T14400TTB 6 x 102mm 57 100<br />

T14600TP 6 x 152mm 57 10<br />

T14600TTB 6 x 152mm 57 100<br />

T14800TTB 6 x 203mm 57 50<br />

41

42<br />

Quik Drive and Stainless Steel Fixings<br />

EB-TY HIDDEN DECK FASTENER<br />

The EB-TY provides a unique method of fastening<br />

deck boards that makes the fasteners virtually invisible.<br />

Fastening is done into the side of the board, leaving a<br />

fastener-free deck surface.<br />

The EB-TY is a polypropylene biscuit fastener that fits into<br />

a slot the builder cuts into the edge of the deck boards<br />

with a standard biscuit joiner.<br />

The EB-TY fasteners are inserted and fastened with<br />

a screw driven into the joist. Nesting each successive<br />

board against the EB-TY automatically ensures consistent<br />

spacing and uniform height.<br />

• Easy to install since all fastening is done from the top<br />

side<br />

• Affords easier deck resurfacing since nail heads are<br />

eliminated from the deck surface<br />

• Formed from long lasting polypropylene to last<br />

the life of the deck<br />

• Stainless-steel #7 trim-head screws included<br />

• Each EB-TY package includes installation instructions<br />

and enough<br />

EB-TY fasteners, screws and tapered Ipê wood plugs<br />

to install 100 square feet of decking (175-Pack quantity<br />

assumes 6" wide boards, installed perpendicular to<br />

joists spaced 16" on center)<br />

Working from left to right, compare the information in the<br />

columns to your application to select the correct EB-TY for the job.<br />

Decking Material<br />

IPÊ<br />

Redwood<br />

Cedar<br />

PVC<br />

Kiln-dried<br />

Composites<br />

Natural Woods<br />

Decking<br />

Thickness<br />

(mm)<br />

Spacing<br />

Requirement<br />

(mm)<br />

Special<br />

Application<br />

Information<br />

Biscuit<br />

Model No.<br />

17.46 2.38 N/A EBE007MINI<br />

17.46 6.35<br />

Model EBE007MINI<br />

“Live Cylinder”<br />

design for<br />

expansive<br />

material<br />

EBE006JR<br />

Tapered Ipê<br />

Wood Plugs -<br />

see next page<br />

Ordering Information<br />

Pack<br />

Quantity<br />

Pack<br />

Model No.<br />

Screw Type<br />

175 175-EBTYMT 316 Stainless<br />

175 175-EBTYMW<br />

316 Stainless<br />

(Woodpecker)<br />

175 175-EBTYJR 305 Stainless<br />

175 175-EBTYJT 316 Stainless<br />

175 175-EBTYJW<br />

Model EBE006JR<br />

316 Stainless<br />

(Woodpecker)

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

EB-TY HIDDEN DECK FASTENER<br />

Installation Information<br />

• As with all decking materials, please<br />

consult manufacturer’s installation instructions<br />

for deck height requirements and deck board<br />

spacing.<br />

• All slots for the EB-TY’s (except for the 316TT)<br />

can be cut using a #20 setting with<br />

a biscuit cutter/plate jointer or router with 5 ⁄32"<br />

slot cutter. Decking can be grooved the entire<br />

length of the board.<br />

• Always butt boards over a joist. One method<br />

for installing butt ends is to cut the keel off the<br />

bottom of an EB-TY, slot the board ends, and<br />

insert the EB-TY. Another, more reliable method<br />

is to face-screw and plug.<br />

If you have questions about which EB-TY<br />

to use, contact <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>.<br />

Installation Process<br />

EB-TY<br />

biscuit fastener<br />

#7x 2 1 ⁄4" trim<br />

head screw<br />

angled at 45°<br />

Second deck board<br />

fastened with EB-TY<br />

and construction<br />

adhesive applied to<br />

top of floor joist<br />

1. Fasten the first board using construction adhesive and screws, then cut<br />

slots where the board intersects joists using a 5 ⁄32" router bit or plate joiner<br />

(biscuit cutter #20) and install the first EB-TY fasteners. Do not use<br />

construction adhesive with composite decking (see note on the right).<br />

2. Cut slots in the next board where it intersects the joists.<br />

3. Apply a bead of construction adhesive to the top of each joist and install the new<br />

board so that the slots fit over the EB-TY fasteners installed in the first board.<br />

4. Insert EB-TY fasteners into each slot in the exposed<br />

edge of the board and fasten with screws.<br />

5. Repeat the process until all boards are installed.<br />

Refer to the installation instructions (included) for more<br />

information. Consult composite decking manufacturer’s or<br />

wood supplier’s installation instructions for deck height<br />

requirements and deck board spacing.<br />

Pre-grooving the entire length of the deck board is a<br />

time-saving alternative to individual grooves made with<br />

a router or plate joiner. Some types of composite lumber<br />

are available with grooves as an added feature. Have your<br />

lumber yard use the schematic on the right to pregroove<br />

boards to accept EB-TY fasteners.<br />

*For model numbers TP015 and 316TT screws are to be driven at a 90° angle to the board face.<br />

Ipê Wood Plugs<br />

FEATURES:<br />

• Made of high quality Ipê and tapered for ease of use<br />

• For use on decks using the EB-TY ® system (first boards, aprons, etc.); also stairs, railings<br />

Plug Diameter<br />

(in.)<br />

3 ⁄8<br />

Plug Length<br />

(in.)<br />

Count<br />

Quantity<br />

Model No.<br />

7 ⁄16 100 WDPLUG-100<br />

0.163"<br />

Fasten one side of first deck<br />

board using screws and plugs<br />

Floor joist<br />

Deck boards<br />

Slots cut with<br />

biscuit joiner<br />

Bring the schematic below to your lumber yard. They will use it<br />

to pre-groove your decking material to accept EB-TY fasteners.<br />

0.500"<br />

Cut groove at center of material thickness<br />

!<br />

Construction adhesive is not<br />

recommended when installing<br />

composite deck boards as some<br />

adhesives will have an adverse<br />

reaction upon contact with<br />

certain plastics.<br />

43

44<br />

Collated Quik Drive and and Corrosion Stainless Resistant Steel Fixings Fastenings<br />

IMPORTANT INFORMATION<br />

IMPORTANT INFORMATION & GENERAL NOTES<br />

These notes are provided to ensure proper installation of <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> Company Inc. products and must be followed fully.<br />

a. <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> Company Inc. reserves the right to change specifications, designs, and models without notice or liability for such<br />

changes.<br />

b. Unless otherwise noted, dimensions are in millimetres, loads are in kilograms, and shear loads are applied perpendicular to edge.<br />

This catalogue includes all information available as of the effective date of publication. Please consult our website www.strongtie.eu for<br />

current information.<br />

WARRANTIES<br />

QD & QDPRO Kits and attachments<br />

The kits and attachments in the QD and QDPRO series sold by <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>® are covered by a one-year part and labour guarantee<br />

after the date of purchase. <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>® will repair or replace any defective tool on sight of the purchase invoice and the completed<br />

guarantee card. This guarantee will apply to uses of the attachment that are normal and compliant with the instructions of the tool<br />

manual. Screwdriver motors that may be supplied with the Products are manufactured by others and are warranted by their respective<br />

manufacturers.<br />

Guarantee extension to 3 years for QD & QDPRO<br />

<strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>® offers a guarantee extension to 3 years after the purchase date. The guarantee extension covers the foreseen tools<br />

for parts and labour. The guarantee extension will be considered as effective on receipt of the duly completed warranty form sent to<br />

<strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>® within one year after the purchase of the kit or attachment. Our guarantee form can also be filled in on our web site<br />

www.strongtie.eu.<br />

Guarantee limitation:<br />

The guarantee of the foreseen tool will not apply in the following cases:<br />

• Use of the attachment with other screws than the ones sold by <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>®, the tool has been designed with specific characteristics,<br />

• Mandrel and bits are defined as wear parts, they are not covered by the guarantee,<br />

• Any change made to the tools will exclude them from the guarantee,<br />

• The screw driver motor is covered by the manufacturer’s guarantee.<br />

The <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>® company declines any liability for damageable consequences resulting from the immobilisation of equipment which would be under<br />

the guarantee. The <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>® company declines any responsibility for direct, consequential or accidental damageable consequences resulting from<br />

a use breaching professional rules and the instructions contained in the manual.<br />

INSTRUCTIONS FOR THE DESIGNER<br />

1. There are many choices of fasteners, tools and other products. It is often difficult to determine which type of product is best suited<br />

for your application. In some cases, there may be more than one type of product that will work well. The information in this catalogue is<br />

intended to guide the Designer toward the product best suited for the specific application, use and environment. The choice of which product<br />

to use should be made by a qualified Designer.<br />

2. Select fasteners of a type, size, length, thread, head, finish, material, tip and other characteristics suitable for your application, use and<br />

environment. Incorrect fastener selection may cause the connection to fail.<br />

3. Some hardened fasteners may have premature failure if exposed to moisture. These fasteners are recommended to be used in dry interior<br />

applications.<br />

4. Select a fastener only after reading the corrosion information in this catalogue.<br />

5. If using a Quik Drive® product with any other <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong>® product, consult the <strong>Simpson</strong> catalogue or www.strongtie.eu for<br />

detailed information concerning such other product.<br />

INSTRUCTIONS FOR THE INSTALLER<br />

1. Use Quik Drive® tools only with authentic Quik Drive® fasteners. Other fasteners may cause the tool to malfunction and become<br />

damaged.<br />

2. If a Quik Drive® product is compatible with a specified tool, do not use the product with any other tool.<br />

3. Choose the proper tool to suit your needs.<br />

4. Use products only in accordance with all instructions.<br />

5. All specified fasteners must be installed according to the instructions in this catalogue.<br />

6. Use proper safety equipment and follow all safety instructions. Always wear protective eyewear.

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

IMPORTANT INFORMATION<br />

SAFETY WARNINGS<br />

Safe Work Area<br />

a. Keep work area clean and well lit.<br />

b. Do not operate Quik Drive ® tools in dangerous environments. Do<br />

not expose tools to rain, or use them in damp or wet locations. Do<br />

not use Quik Drive tools in the presence of flammable liquids, dust<br />

or gases, as they can create sparks.<br />

c. Keep bystanders, children and visitors away while operating a Quik<br />

Drive tool. Distractions can cause accidents and serious bodily injury.<br />

Reduce Risk of Electrical-Related Accidents<br />

a. Guard against electrical shock. Prevent body contact with grounded<br />

surfaces.<br />

b. Never modify the Quik Drive tool power plug in any way. Always<br />

use a plug with a matching outlet. Use of proper, unmodified plugs<br />

and outlets reduces the risk of electric shock.<br />

c. Do not abuse the power cord. Never carry a Quik Drive tool by its<br />

cord or yank it to disconnect from an outlet or other receptacle.<br />

Keep cord away from heat, oil, sharp edges, or moving parts.<br />

Replace damaged cord immediately. Damaged cords increase the<br />

risk of electrical shock.<br />

d. When operating a Quik Drive tool outside, use extension cords<br />

suitable for outdoor use.<br />

Personal Safety<br />

a. Stay alert. Do not use a Quik Drive tool while tired or under the<br />

influence of drugs, alcohol, or medication. Use common sense<br />

when operating the tool. Inattention while operating Quik Drive<br />

tools may result in serious bodily injury.<br />

b. Dress appropriately when using a Quik Drive tool. Do not wear<br />

FASTENER CORROSION INFORMATION<br />

Understanding the Issues<br />

loose clothing or jewellery. Keep your hair, clothing, and gloves<br />

away from moving parts. Loose clothes, long hair, or jewellery can<br />

be caught in moving parts and result in serious bodily injury.<br />

c. Be sure the power switch on a Quik Drive tool is in the off position<br />

before plugging in the tool. Do not carry tools with your finger on<br />

the switch.<br />

d. Keep proper footing and balance at all times.<br />

e. Always use safety equipment such as wearing protective glasses,<br />

dust masks, non-skid safety shoes, hard hats, and/or earplugs.<br />

Quik Drive Tool Use and Care<br />

a. Do not force the Quik Drive tool. Use the correct tool for the<br />

application.<br />

b. When not in use, Quik Drive tools should be stored in a dry place<br />

and out of the reach of children and other untrained persons.<br />

c. Disconnect the plug from power source before making<br />

adjustments, changing accessories, or storing tool.<br />

d. Maintain Quik Drive tools with care. Follow instructions for<br />

lubricating and changing accessories.<br />

e. Regularly check for misalignment or binding of moving parts, and<br />

other conditions that may affect operation.<br />

f. Use only accessories recommended by <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong><br />

Company, Inc.<br />

g. Any repairs to electric tools should be performed by qualified<br />

personnel. Use only authorised parts.<br />

Metal fasteners will corrode and may lose load-carrying capacity when installed in corrosive environments or exposed to corrosive<br />

materials. There are many environments and materials which may cause corrosion including ocean salt air, fire-retardants, fumes, fertilizers,<br />

preservative-treated wood, dissimilar metals, and other corrosive elements.<br />

The many variables make it impossible to accurately predict if, or when, significant corrosion will begin or reach a critical level. This relative<br />

uncertainty makes it crucial that specifiers and users be knowledgeable of the potential risks and select a product coating or metal suitable<br />

for the intended use.<br />

It is also important that regular maintenance and periodic inspections are performed, especially for outdoor applications. When outdoor, it is<br />

common to see some corrosion, even stainless steel can corrode. If significant corrosion is apparent or suspected, then wood, fasteners and<br />

connectors should be inspected by a professional engineer or contractor and may need to be replaced.<br />

Recently, pressure-treated wood formulations have changed. Due to the many different pressure treatment formulations, retention levels,<br />

moisture content, and because the formulations may vary, understanding which connectors and fasteners to use with these materials is<br />

a complex task. It is important to educate yourself by reviewing technical literature on the topic and to get the latest information by the<br />

manufacturer.<br />

Stainless Steel is always the most effective solution to corrosion risk. To best serve our customers, <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> is evaluating the<br />

options to identify the safest and most cost-effective solutions. Based on our testing and experience there are some specific applications that<br />

are appropriate for N2000®, XtremeCoat, Quik Guard® and TufCote® coated fasteners.<br />

Free Quik Drive ® Demonstration DVD<br />

Get the most out of your Quik Drive ® system: Contact <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> on 01827 255600 or<br />

visit www.strongtie.co.uk/qd to request a free copy of the Quik Drive demonstration video on DVD.<br />

The sequence shows you how to assemble the kit, load screws, change bits and put the the tool to use. It<br />

perfectly illustrates the benefits of the system and serves as the ideal point of sale tool.<br />

45

Quik Drive and Stainless Steel Fixings<br />

SALES SUPPORT<br />

Point of Sale Support for Distributors<br />

Our range of stainless steel fastenings is designed to look good on the shelf as well<br />

as installed.<br />

Our network of distributors are supported with excellent product packaging, point of<br />

sale display panels, external banners and much more.<br />

Call our sales team on 01827 255600 if you would like to join our network.

Catalogue C-FIXINGS-12 © 2012 SIMPSON STRONG-TIE ®<br />

Quik Drive and Stainless Steel Fixings<br />

TECHNICAL SUPPORT<br />

We stock a large selection of high quality, stainless steel fasteners<br />

for cladding, decking and other applications which offer the<br />

combined benefits of strength, durability and corrosion resistance.<br />

You can count on <strong>Simpson</strong> <strong>Strong</strong>-<strong>Tie</strong> ® products to endure the<br />

challenges of harsh environmental elements and time - in most<br />

cases outlasting the cladding itself.<br />

Fast Technical Support<br />

For the best technical support and practical advice, contact our Technical<br />

Support Team.<br />

Call +44(0)1827 255600 or Fax +44(0)1827 255629 or<br />

Email: uktechnical@strongtie.com<br />

For sales enquiries call:<br />

01827 255600 or visit: www.strongtie.co.uk<br />

47

Collated and<br />

Corrosion Resistant<br />

Fastenings<br />

Applications include:<br />

Decking<br />

Cladding<br />

Drywall<br />

Flooring<br />

Ceilings<br />

Truck Beds<br />

Marine Installations<br />

Oak Framing<br />

Modular Housing<br />

C-FIXINGS-12<br />

SIMPSON STRONG-TIE ®<br />

Winchester Road<br />

Cardinal Point<br />

Tamworth<br />

Staffordshire<br />

B78 3HG<br />

United Kingdom<br />

Tel: +44 1827 255 600<br />

Fax: +44 1827 255 616<br />

www.strongtie.co.uk