1511 Series - Maintenance Manual

1511 Series - Maintenance Manual

1511 Series - Maintenance Manual

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

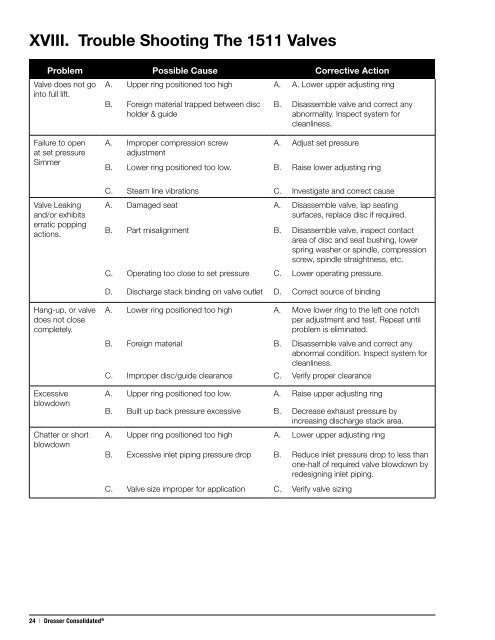

XVIII. Trouble Shooting The <strong>1511</strong> ValvesProblem Possible Cause Corrective ActionValve does not go A. Upper ring positioned too high A. A. Lower upper adjusting ringinto full lift.B. Foreign material trapped between discholder & guideB. Disassemble valve and correct anyabnormality. Inspect system forcleanliness.Failure to openat set pressureSimmerA. Improper compression screwadjustmentA. Adjust set pressureB. Lower ring positioned too low. B. Raise lower adjusting ringValve Leakingand/or exhibitserratic poppingactions.C. Steam line vibrations C. Investigate and correct causeA. Damaged seat A. Disassemble valve, lap seatingsurfaces, replace disc if required.B. Part misalignment B. Disassemble valve, inspect contactarea of disc and seat bushing, lowerspring washer or spindle, compressionscrew, spindle straightness, etc.C. Operating too close to set pressure C. Lower operating pressure.D. Discharge stack binding on valve outlet D. Correct source of bindingHang-up, or valvedoes not closecompletely.ExcessiveblowdownChatter or shortblowdownA. Lower ring positioned too high A. Move lower ring to the left one notchper adjustment and test. Repeat untilproblem is eliminated.B. Foreign material B. Disassemble valve and correct anyabnormal condition. Inspect system forcleanliness.C. Improper disc/guide clearance C. Verify proper clearanceA. Upper ring positioned too low. A. Raise upper adjusting ringB. Built up back pressure excessive B. Decrease exhaust pressure byincreasing discharge stack area.A. Upper ring positioned too high A. Lower upper adjusting ringB. Excessive inlet piping pressure drop B. Reduce inlet pressure drop to less thanone-half of required valve blowdown byredesigning inlet piping.C. Valve size improper for application C. Verify valve sizing24 | Dresser Consolidated ®