advanced coking technologies abstract key words introduction

advanced coking technologies abstract key words introduction

advanced coking technologies abstract key words introduction

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

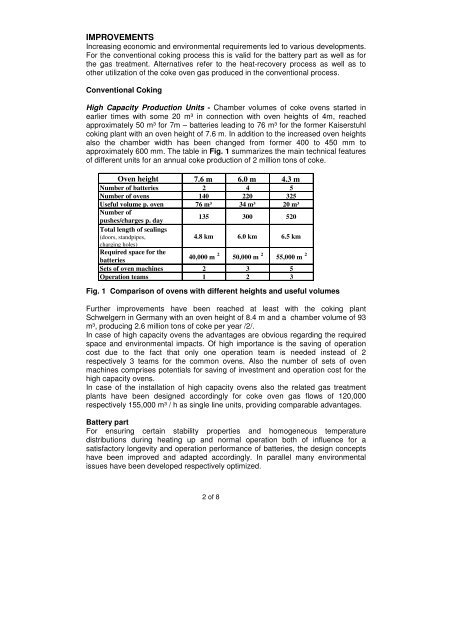

IMPROVEMENTSIncreasing economic and environmental requirements led to various developments.For the conventional <strong>coking</strong> process this is valid for the battery part as well as forthe gas treatment. Alternatives refer to the heat-recovery process as well as toother utilization of the coke oven gas produced in the conventional process.Conventional CokingHigh Capacity Production Units - Chamber volumes of coke ovens started inearlier times with some 20 m³ in connection with oven heights of 4m, reachedapproximately 50 m³ for 7m – batteries leading to 76 m³ for the former Kaiserstuhl<strong>coking</strong> plant with an oven height of 7.6 m. In addition to the increased oven heightsalso the chamber width has been changed from former 400 to 450 mm toapproximately 600 mm. The table in Fig. 1 summarizes the main technical featuresof different units for an annual coke production of 2 million tons of coke.Oven heightNumber of batteriesNumber of ovensUseful volume p. ovenNumber ofpushes/charges p. dayTotal length of sealings(doors, standpipes,charging holes)Required space for thebatteriesSets of oven machinesOperation teams7.6 m 6.0 m 4.3 m2 4 5140 220 32576 m³ 34 m³ 20 m³135 300 5204.8 km 6.0 km 6.5 km40,000 m 2 50,000 m 2213255,000 m 253Fig. 1 Comparison of ovens with different heights and useful volumesFurther improvements have been reached at least with the <strong>coking</strong> plantSchwelgern in Germany with an oven height of 8.4 m and a chamber volume of 93m³, producing 2.6 million tons of coke per year /2/.In case of high capacity ovens the advantages are obvious regarding the requiredspace and environmental impacts. Of high importance is the saving of operationcost due to the fact that only one operation team is needed instead of 2respectively 3 teams for the common ovens. Also the number of sets of ovenmachines comprises potentials for saving of investment and operation cost for thehigh capacity ovens.In case of the installation of high capacity ovens also the related gas treatmentplants have been designed accordingly for coke oven gas flows of 120,000respectively 155,000 m³ / h as single line units, providing comparable advantages.Battery partFor ensuring certain stability properties and homogeneous temperaturedistributions during heating up and normal operation both of influence for asatisfactory longevity and operation performance of batteries, the design conceptshave been improved and adapted accordingly. In parallel many environmentalissues have been developed respectively optimized.2 of 8