advanced coking technologies abstract key words introduction

advanced coking technologies abstract key words introduction

advanced coking technologies abstract key words introduction

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

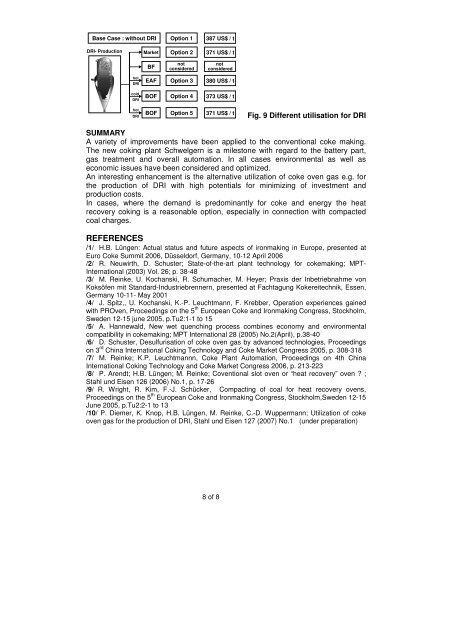

Base Case : without DRI Option 1387 US$ / tDRI- ProductionMarketOption 2371 US$ / tBFnotconsiderednotconsideredhotDRIEAFOption 3380 US$ / tcoldDRIBOFOption 4373 US$ / thotDRIBOFOption 5371 US$ / tFig. 9 Different utilisation for DRISUMMARYA variety of improvements have been applied to the conventional coke making.The new <strong>coking</strong> plant Schwelgern is a milestone with regard to the battery part,gas treatment and overall automation. In all cases environmental as well aseconomic issues have been considered and optimized.An interesting enhancement is the alternative utilization of coke oven gas e.g. forthe production of DRI with high potentials for minimizing of investment andproduction costs.In cases, where the demand is predominantly for coke and energy the heatrecovery <strong>coking</strong> is a reasonable option, especially in connection with compactedcoal charges.REFERENCES/1/ H.B. Lüngen: Actual status and future aspects of ironmaking in Europe, presented atEuro Coke Summit 2006, Düsseldorf, Germany, 10-12 April 2006/2/ R. Neuwirth, D. Schuster; State-of-the-art plant technology for cokemaking; MPT-International (2003) Vol. 26; p. 38-48/3/ M. Reinke, U. Kochanski, R. Schumacher, M. Heyer; Praxis der Inbetriebnahme vonKoksöfen mit Standard-Industriebrennern, presented at Fachtagung Kokereitechnik, Essen,Germany 10-11- May 2001/4/ J. Spitz,, U. Kochanski, K.-P. Leuchtmann, F. Krebber, Operation experiences gainedwith PROven, Proceedings on the 5 th European Coke and Ironmaking Congress, Stockholm,Sweden 12-15 june 2005, p.Tu2:1-1 to 15/5/ A. Hannewald, New wet quenching process combines economy and environmentalcompatibility in cokemaking; MPT International 28 (2005) No.2(April), p.38-40/6/ D. Schuster, Desulfurisation of coke oven gas by <strong>advanced</strong> <strong>technologies</strong>, Proceedingson 3 rd China International Coking Technology and Coke Market Congress 2005, p. 308-318/7/ M. Reinke; K.P. Leuchtmannn, Coke Plant Automation, Proceedings on 4th ChinaInternational Coking Technology and Coke Market Congress 2006, p. 213-223/8/ P. Arendt; H.B. Lüngen; M. Reinke; Coventional slot oven or “heat recovery” oven ? ;Stahl und Eisen 126 (2006) No.1, p. 17-26/9/ R. Wright, R. Kim, F.-J. Schücker, Compacting of coal for heat recovery ovens,Proceedings on the 5 th European Coke and Ironmaking Congress, Stockholm,Sweden 12-15June 2005, p.Tu2:2-1 to 13/10/ P. Diemer, K. Knop, H.B. Lüngen, M. Reinke, C.-D. Wuppermann; Utilization of cokeoven gas for the production of DRI, Stahl und Eisen 127 (2007) No.1 (under preparation)8 of 8