Wilo NL Base Mount End Suction Pumps - Wilo Canada Inc.

Wilo NL Base Mount End Suction Pumps - Wilo Canada Inc.

Wilo NL Base Mount End Suction Pumps - Wilo Canada Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

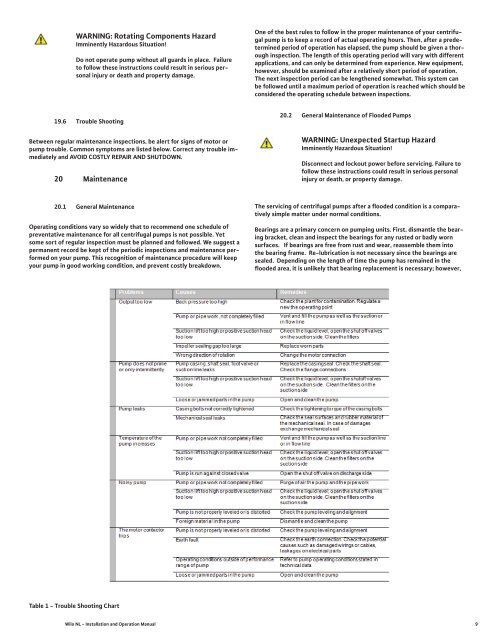

WARNING: Rotating Components HazardImminently Hazardous Situation!Do not operate pump without all guards in place. Failureto follow these instructions could result in serious personalinjury or death and property damage.One of the best rules to follow in the proper maintenance of your centrifugalpump is to keep a record of actual operating hours. Then, after a predeterminedperiod of operation has elapsed, the pump should be given a thoroughinspection. The length of this operating period will vary with differentapplications, and can only be determined from experience. New equipment,however, should be examined after a relatively short period of operation.The next inspection period can be lengthened somewhat. This system canbe followed until a maximum period of operation is reached which should beconsidered the operating schedule between inspections.19.6 Trouble ShootingBetween regular maintenance inspections, be alert for signs of motor orpump trouble. Common symptoms are listed below. Correct any trouble immediatelyand AVOID COSTLY REPAIR AND SHUTDOWN.20 Maintenance20.2 General Maintenance of Flooded <strong>Pumps</strong>WARNING: Unexpected Startup HazardImminently Hazardous Situation!Disconnect and lockout power before servicing. Failure tofollow these instructions could result in serious personalinjury or death, or property damage.20.1 General MaintenanceOperating conditions vary so widely that to recommend one schedule ofpreventative maintenance for all centrifugal pumps is not possible. Yetsome sort of regular inspection must be planned and followed. We suggest apermanent record be kept of the periodic inspections and maintenance performedon your pump. This recognition of maintenance procedure will keepyour pump in good working condition, and prevent costly breakdown.The servicing of centrifugal pumps after a flooded condition is a comparativelysimple matter under normal conditions.Bearings are a primary concern on pumping units. First, dismantle the bearingbracket, clean and inspect the bearings for any rusted or badly wornsurfaces. If bearings are free from rust and wear, reassemble them intothe bearing frame. Re-lubrication is not necessary since the bearings aresealed. Depending on the length of time the pump has remained in theflooded area, it is unlikely that bearing replacement is necessary; however,Table 1 - Trouble Shooting Chart<strong>Wilo</strong> <strong>NL</strong> - Installation and Operation Manual9