Oil & Gas | Filtration - Filtration News

Oil & Gas | Filtration - Filtration News

Oil & Gas | Filtration - Filtration News

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

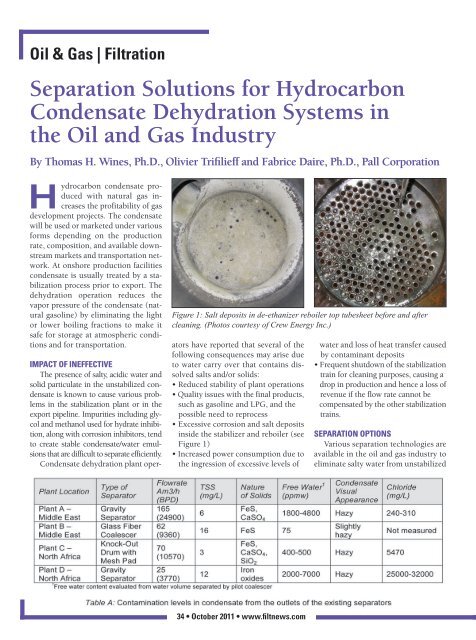

<strong>Oil</strong> & <strong>Gas</strong> | <strong>Filtration</strong>Separation Solutions for HydrocarbonCondensate Dehydration Systems inthe <strong>Oil</strong> and <strong>Gas</strong> IndustryBy Thomas H. Wines, Ph.D., Olivier Trifilieff and Fabrice Daire, Ph.D., Pall CorporationHydrocarbon condensate producedwith natural gas increasesthe profitability of gasdevelopment projects. The condensatewill be used or marketed under variousforms depending on the productionrate, composition, and available downstreammarkets and transportation network.At onshore production facilitiescondensate is usually treated by a stabilizationprocess prior to export. Thedehydration operation reduces thevapor pressure of the condensate (naturalgasoline) by eliminating the lightor lower boiling fractions to make itsafe for storage at atmospheric conditionsand for transportation.Figure 1: Salt deposits in de-ethanizer reboiler top tubesheet before and aftercleaning. (Photos courtesy of Crew Energy Inc.)IMPACT OF INEFFECTIVEThe presence of salty, acidic water andsolid particulate in the unstabilized condensateis known to cause various problemsin the stabilization plant or in theexport pipeline. Impurities including glycoland methanol used for hydrate inhibition,along with corrosion inhibitors, tendto create stable condensate/water emulsionsthat are difficult to separate efficiently.Condensate dehydration plant operatorshave reported that several of thefollowing consequences may arise dueto water carry over that contains dissolvedsalts and/or solids:• Reduced stability of plant operations• Quality issues with the final products,such as gasoline and LPG, and thepossible need to reprocess• Excessive corrosion and salt depositsinside the stabilizer and reboiler (seeFigure 1)• Increased power consumption due tothe ingression of excessive levels ofwater and loss of heat transfer causedby contaminant deposits• Frequent shutdown of the stabilizationtrain for cleaning purposes, causing adrop in production and hence a loss ofrevenue if the flow rate cannot becompensated by the other stabilizationtrains.S EPARATION OPTIONSVarious separation technologies areavailable in the oil and gas industry toeliminate salty water from unstabilized34 • October 2011 • www.filtnews.com