Product Manual - Blue Phoenix Mechanical

Product Manual - Blue Phoenix Mechanical

Product Manual - Blue Phoenix Mechanical

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

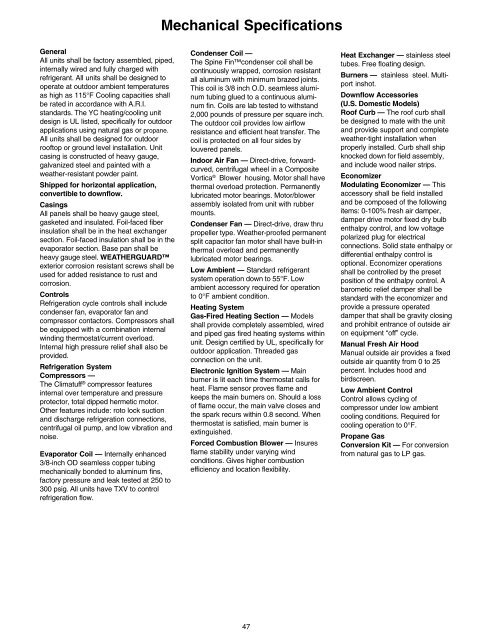

<strong>Mechanical</strong> SpecificationsGeneralAll units shall be factory assembled, piped,internally wired and fully charged withrefrigerant. All units shall be designed tooperate at outdoor ambient temperaturesas high as 115°F Cooling capacities shallbe rated in accordance with A.R.I.standards. The YC heating/cooling unitdesign is UL listed, specifically for outdoorapplications using natural gas or propane.All units shall be designed for outdoorrooftop or ground level installation. Unitcasing is constructed of heavy gauge,galvanized steel and painted with aweather-resistant powder paint.Shipped for horizontal application,convertible to downflow.CasingsAll panels shall be heavy gauge steel,gasketed and insulated. Foil-faced fiberinsulation shall be in the heat exchangersection. Foil-faced insulation shall be in theevaporator section. Base pan shall beheavy gauge steel. WEATHERGUARDexterior corrosion resistant screws shall beused for added resistance to rust andcorrosion.ControlsRefrigeration cycle controls shall includecondenser fan, evaporator fan andcompressor contactors. Compressors shallbe equipped with a combination internalwinding thermostat/current overload.Internal high pressure relief shall also beprovided.Refrigeration SystemCompressors —The Climatuff ® compressor featuresinternal over temperature and pressureprotector, total dipped hermetic motor.Other features include: roto lock suctionand discharge refrigeration connections,centrifugal oil pump, and low vibration andnoise.Evaporator Coil — Internally enhanced3/8-inch OD seamless copper tubingmechanically bonded to aluminum fins,factory pressure and leak tested at 250 to300 psig. All units have TXV to controlrefrigeration flow.Condenser Coil —The Spine Fincondenser coil shall becontinuously wrapped, corrosion resistantall aluminum with minimum brazed joints.This coil is 3/8 inch O.D. seamless aluminumtubing glued to a continuous aluminumfin. Coils are lab tested to withstand2,000 pounds of pressure per square inch.The outdoor coil provides low airflowresistance and efficient heat transfer. Thecoil is protected on all four sides bylouvered panels.Indoor Air Fan — Direct-drive, forwardcurved,centrifugal wheel in a CompositeVortica ® Blower housing. Motor shall havethermal overload protection. Permanentlylubricated motor bearings. Motor/blowerassembly isolated from unit with rubbermounts.Condenser Fan — Direct-drive, draw thrupropeller type. Weather-proofed permanentsplit capacitor fan motor shall have built-inthermal overload and permanentlylubricated motor bearings.Low Ambient — Standard refrigerantsystem operation down to 55°F. Lowambient accessory required for operationto 0°F ambient condition.Heating SystemGas-Fired Heating Section — Modelsshall provide completely assembled, wiredand piped gas fired heating systems withinunit. Design certified by UL, specifically foroutdoor application. Threaded gasconnection on the unit.Electronic Ignition System — Mainburner is lit each time thermostat calls forheat. Flame sensor proves flame andkeeps the main burners on. Should a lossof flame occur, the main valve closes andthe spark recurs within 0.8 second. Whenthermostat is satisfied, main burner isextinguished.Forced Combustion Blower — Insuresflame stability under varying windconditions. Gives higher combustionefficiency and location flexibility.Heat Exchanger — stainless steeltubes. Free floating design.Burners — stainless steel. Multiportinshot.Downflow Accessories(U.S. Domestic Models)Roof Curb — The roof curb shallbe designed to mate with the unitand provide support and completeweather-tight installation whenproperly installed. Curb shall shipknocked down for field assembly,and include wood nailer strips.EconomizerModulating Economizer — Thisaccessory shall be field installedand be composed of the followingitems: 0-100% fresh air damper,damper drive motor fixed dry bulbenthalpy control, and low voltagepolarized plug for electricalconnections. Solid state enthalpy ordifferential enthalpy control isoptional. Economizer operationsshall be controlled by the presetposition of the enthalpy control. Abarometic relief damper shall bestandard with the economizer andprovide a pressure operateddamper that shall be gravity closingand prohibit entrance of outside airon equipment “off” cycle.<strong>Manual</strong> Fresh Air Hood<strong>Manual</strong> outside air provides a fixedoutside air quantity from 0 to 25percent. Includes hood andbirdscreen.Low Ambient ControlControl allows cycling ofcompressor under low ambientcooling conditions. Required forcooling operation to 0°F.Propane GasConversion Kit — For conversionfrom natural gas to LP gas.47