You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

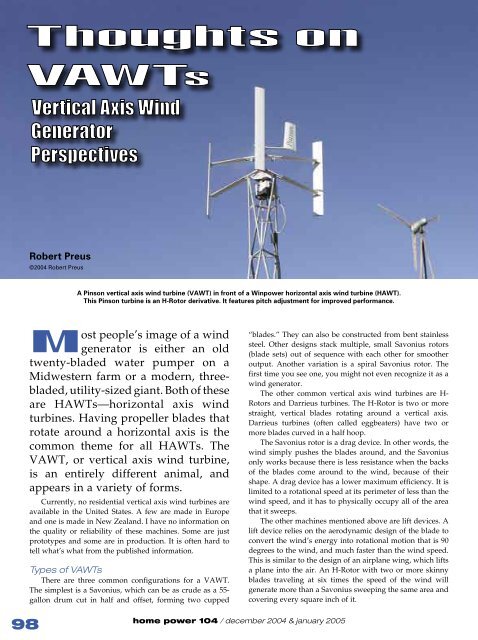

Robert Preus©2004 Robert PreusA Pins<strong>on</strong> vertical axis wind turbine (VAWT) in fr<strong>on</strong>t of a Winpower horiz<strong>on</strong>tal axis wind turbine (HAWT).This Pins<strong>on</strong> turbine is an H-Rotor derivative. It features pitch adjustment for improved performance.Most people’s image of a windgenerator is either an oldtwenty-bladed water pumper <strong>on</strong> aMidwestern farm or a modern, threebladed,utility-sized giant. Both of theseare HAWTs—horiz<strong>on</strong>tal axis windturbines. Having propeller blades thatrotate around a horiz<strong>on</strong>tal axis is thecomm<strong>on</strong> theme for all HAWTs. TheVAWT, or vertical axis wind turbine,is an entirely different animal, andappears in a variety of forms.Currently, no residential vertical axis wind turbines areavailable in the United States. A few are made in Europeand <strong>on</strong>e is made in New Zealand. I have no informati<strong>on</strong> <strong>on</strong>the quality or reliability of these machines. Some are justprototypes and some are in producti<strong>on</strong>. It is often hard totell what’s what from the published informati<strong>on</strong>.Types of <strong>VAWTs</strong>There are three comm<strong>on</strong> c<strong>on</strong>figurati<strong>on</strong>s for a VAWT.The simplest is a Sav<strong>on</strong>ius, which can be as crude as a 55-gall<strong>on</strong> drum cut in half and offset, forming two cupped“blades.” They can also be c<strong>on</strong>structed from bent stainlesssteel. Other designs stack multiple, small Sav<strong>on</strong>ius rotors(blade sets) out of sequence with each other for smootheroutput. Another variati<strong>on</strong> is a spiral Sav<strong>on</strong>ius rotor. Thefirst time you see <strong>on</strong>e, you might not even recognize it as awind generator.The other comm<strong>on</strong> vertical axis wind turbines are H-Rotors and Darrieus turbines. The H-Rotor is two or morestraight, vertical blades rotating around a vertical axis.Darrieus turbines (often called eggbeaters) have two ormore blades curved in a half hoop.The Sav<strong>on</strong>ius rotor is a drag device. In other words, thewind simply pushes the blades around, and the Sav<strong>on</strong>ius<strong>on</strong>ly works because there is less resistance when the backsof the blades come around to the wind, because of theirshape. A drag device has a lower maximum efficiency. It islimited to a rotati<strong>on</strong>al speed at its perimeter of less than thewind speed, and it has to physically occupy all of the areathat it sweeps.The other machines menti<strong>on</strong>ed above are lift devices. Alift device relies <strong>on</strong> the aerodynamic design of the blade toc<strong>on</strong>vert the wind’s energy into rotati<strong>on</strong>al moti<strong>on</strong> that is 90degrees to the wind, and much faster than the wind speed.This is similar to the design of an airplane wing, which liftsa plane into the air. An H-Rotor with two or more skinnyblades traveling at six times the speed of the wind willgenerate more than a Sav<strong>on</strong>ius sweeping the same area andcovering every square inch of it.98home power 104 / december 2004 & january 2005

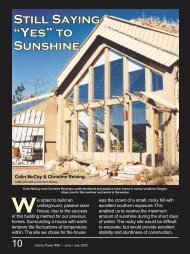

wind turbine c<strong>on</strong>figurati<strong>on</strong>sWind TurbineC<strong>on</strong>figurati<strong>on</strong>sRotorBladeRotorDiameterRotorDiameterGearboxGeneratorNacelleTowerFixedPitchRotorBladeRotorHeightGearboxGeneratorHoriz<strong>on</strong>tal AxisVertical AxisA drag device’s blades travel with the wind, and arelimited to traveling at the wind speed. A lift device’sblades travel through the wind, and are driven at muchhigher speeds. The H-Rotor weighs and costs a fracti<strong>on</strong> ofwhat the Sav<strong>on</strong>ius does. The higher costs for the Sav<strong>on</strong>iusdesign are due to the amount of raw materials requiredand some design issues, which I will describe in furtherdetail below. There is not likely to ever be a cost-effective,commercially produced Sav<strong>on</strong>ius variati<strong>on</strong>. The H-Rotorand Darrieus <strong>VAWTs</strong> are more efficient and more likely tobe commercially produced.Advantages & DisadvantagesSome VAWT enthusiasts make str<strong>on</strong>g claims ofsuperiority for these machines. Many feel that ignoring thistype of design is some kind of a c<strong>on</strong>spiracy. Let’s examinethe specific issues in more detail.Yawing. VAWT supporters are quick to point out that aVAWT is always pointing into the wind and does not needto reorient (or yaw) like a HAWT when the wind changesdirecti<strong>on</strong>. This point is valid, but the value of this advantageis often overstated.It is true that a VAWT does not need a tail and thatyawing in turbulent winds does create wear and tear<strong>on</strong> HAWTs, especially two-bladed <strong>on</strong>es. But under mostc<strong>on</strong>diti<strong>on</strong>s, properly sited wind generators do not see lotsof rapid wind directi<strong>on</strong> shifts (thirty-plus degrees). Winddirecti<strong>on</strong> usually shifts more slowly, and HAWTs willtypically follow the changes smoothly. If a site experiencesrapid and frequent changes in wind directi<strong>on</strong>, d<strong>on</strong>’t placeany wind generator there! Turbulent winds are very hard <strong>on</strong>any wind generator—HAWT or VAWT.Speed C<strong>on</strong>trol. Offsetting the VAWT advantage of notneeding to yaw is the fact that c<strong>on</strong>trolling the output of aVAWT is difficult. You can’t have it yaw out of the windto reduce output, like a side-furling HAWT. This can be aserious problem. A VAWT that makes 2 KW at 20 mph (9The Darrieus pictured here is a small utility-scale machine.Note the extruded aluminum blades and the guy wires,which are typical for a Darrieus.m/s) will want to make 16 KW at 40 mph (18 m/s). Youcannot let this happen.A 2 KW wind generator is not str<strong>on</strong>g enough to handlethe forces involved to generate 16 KW. If it were builtstr<strong>on</strong>gly enough, both the wind generator and the rest ofthe system comp<strong>on</strong>ents would be much more expensive.Yet most of the time, it would <strong>on</strong>ly generate as much asthe original 2 KW machine, because output is limited bythe wind and swept area, not by alternator capacity. (Analternator c<strong>on</strong>verts the mechanical rotati<strong>on</strong> of the bladesinto electricity.) There are ways to deal with the additi<strong>on</strong>alforces of generating at higher wind speeds, but all of themadd complexity and cost. This problem is easily handledwith a side-furling HAWT.Fatigue. Another equally serious disadvantage for<strong>VAWTs</strong> is fatigue. If fatigue is a problem for the HAWT,it is the archenemy of the VAWT. There are two reas<strong>on</strong>sfor this. One is that during part of its revoluti<strong>on</strong>, a VAWTblade has lift <strong>on</strong> <strong>on</strong>e side of the blade and then no lift, thenlift <strong>on</strong> the other side, then no lift. This cycle is repeated inevery revoluti<strong>on</strong> that the machine makes. The other sourcewww.homepower.com99

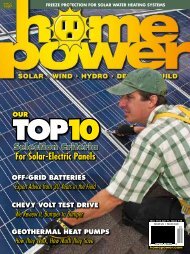

wind turbine c<strong>on</strong>figurati<strong>on</strong>sleast 30 feet (9 m) above anything within 500 feet (150 m)holds true for <strong>VAWTs</strong>, and installing <strong>VAWTs</strong> <strong>on</strong> tall towerswhere they bel<strong>on</strong>g has its own set of design problems.The H-Rotor and Darrieus turbines have at least as muchpotential for safety issues (such as throwing blades) as aHAWT. All wind generators are by nature rotating machinery.If they fail, they can lose parts. In a residential-size system, thisis usually no more dangerous than a tree limb blowing down.This small Sav<strong>on</strong>ius rotor was formed from stainless steel.Metal covers the whole swept area.of fatigue occurs because for part of each rotati<strong>on</strong>, the bladeis operating in the turbulence downwind created by theupwind blade(s), and usually a tube or tower in the center.Does this mean that a VAWT cannot be built to last? No,it <strong>on</strong>ly means that designing a VAWT blade and mountingstructure is more challenging than designing a HAWT.Urban Use. Some people say that a VAWT is bettersuited or safer for use in the city and a HAWT is notsuitable or can even be dangerous in the city. The issuesfor urban siting of wind generators are appearance, noise,performance in turbulence, height, and safety.Appearance is an aesthetics issue and is highly subjective.I like the appearance of both HAWTs and <strong>VAWTs</strong>. I havenever c<strong>on</strong>ducted a poll to determine if there are significantdifferences in the general public’s resp<strong>on</strong>se to the differentwind generator c<strong>on</strong>figurati<strong>on</strong>s. The challenge of minimizingnoise is fairly well understood in HAWTs today and wouldbe a similar challenge for VAWT designs.The VAWT does have an advantage in dealing withwind directi<strong>on</strong> shifts, but general turbulence will increasefatigue <strong>on</strong> a VAWT just like a HAWT. Often VAWTprop<strong>on</strong>ents point out that a VAWT can be installed <strong>on</strong> a roofor <strong>on</strong> the ground, while HAWTS must be <strong>on</strong> tall, expensivetowers. But roofs and the ground are poor sites for any typeof wind turbine. Turbulence and drag from the ground,trees, and buildings rob much of the energy available in thewind, and turbulent winds are hard <strong>on</strong> all types of windgenerators. Vibrati<strong>on</strong> from wind generators <strong>on</strong> buildingscan be an irritant at least, and a structural problem at worst.The standard guideline of installing a wind generator atNo Magic BulletThere is an all-too-comm<strong>on</strong> belief that a VAWT approachwill revoluti<strong>on</strong>ize the small wind industry. This seems to bea lot of wishful thinking by people who d<strong>on</strong>’t understandphysics. It is fed by the seemingly endless string ofcompanies promoting roof-mounted, high-tech variati<strong>on</strong>s <strong>on</strong>the Sav<strong>on</strong>ius rotor. Most of these inventi<strong>on</strong>s claim to capturemore than 100 percent of the energy in the wind at lowspeeds. The maximum they can actually capture is around 30percent. If they claim more than that, be very suspicious.Some of you, especially VAWT enthusiasts, may thinkthat I am opposed to <strong>VAWTs</strong>. I am not. In fact, I wouldlike to see some models <strong>on</strong> the U.S. market. I even lookedat developing a 500-watt VAWT several years ago. Whatstopped me was simply limited resources, not the technicalproblems that come with <strong>VAWTs</strong>.There is no magic here. High-quality, detailedengineering, design, and manufacture can produce a goodwind generator—HAWT or VAWT. Some special problemsmust be overcome in designing a VAWT. We need a goodsoluti<strong>on</strong> for power c<strong>on</strong>trol in high winds and better designfor fatigue than is used in the best HAWTs.If you want to have a wind generator installed or install<strong>on</strong>e yourself, it will be a HAWT. That is what is available <strong>on</strong>the market today. If you want to build <strong>on</strong>e yourself, there ismore informati<strong>on</strong> <strong>on</strong> building HAWTs, and it is a less riskyopti<strong>on</strong>. If you are a brave experimenter and have a suitableplace to put it, you can try a VAWT.So far, no <strong>VAWTs</strong> are produced commercially in theUnited States for several reas<strong>on</strong>s. The most important is thatthere is no easy way to provide power c<strong>on</strong>trol in high windscompared to the ease of side-furling a HAWT. <strong>VAWTs</strong> arealso less efficient and tend to be more expensive. The highfatigue cycles inherent in a VAWT make successful designmore difficult. The advantage for the VAWT of having no tailor yawing system does not seem to be enough to counter thedisadvantages.AccessRobert W. Preus, PE, Abundant Renewable Energy, 22700NE Mountain Top Rd., Newberg, OR 97132 • 503-538-8298 •Fax: 503-538-8792 • robert@abundantre.com •www.abundantre.comAmerican Wind Energy Associati<strong>on</strong> (AWEA), 122 C St.NW Ste. 380, Washingt<strong>on</strong>, DC 20001 • 202-383-2500 •Fax: 202-383-2505 • windmail@awea.org • www.awea.orgPhotos by Mick Sagrillo, Sagrillo <strong>Power</strong> & Light100home power 104 / december 2004 & january 2005