LOKRING TOOL - MSAWorld.com

LOKRING TOOL - MSAWorld.com

LOKRING TOOL - MSAWorld.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

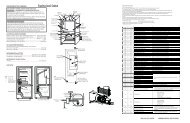

Lokring Tube Connectors Strong and elastic metal/metal sealing High reliability No notch effect or restriction Easy and fast assembly Handy assembly tools No special preparation No welding or soldering Working pressure 725 psi Maximum temp ‐58 F to 302FService ConnectorOEM Connectors

Function of LOKPREPLOKPREP is an Anaerobic Sealer usedto fill surface blemishes and scratches.(LOKPREP is NOT a bonding agent)

Lokring How‐ToSet‐up1. Plan your cuts2. Clean the tube withemery cloth orabrasive mat.3. Cut tube with achipless wheel typecutter

Lokring How‐ToApplication4. Apply LOKPREP5. Rotate the<strong>LOKRING</strong>6. Use the hand tool to<strong>com</strong>plete theconnection.

Finished ConnectionsAluminum to Copper, Copper to Copper, Capillary Tube, Schraders, Reducersand Unions.

Lokring as a Field Repair Optionfor Appliance Repair• Open flame‐torch prohibited in High Rises• No need to disarm fire alarm• Health reasons and presence of medical gas• No possible torch damage to product or home• Lokring process is the same regardless of tube• Ideal for tough installs requiring elevator breakdown• Easier installs of remote <strong>com</strong>pressor / condenser units• Major sealed system repairs seem less intrusive

Lokring The Cold Clean ConnectionInternal Cleanliness <strong>com</strong>parison of a LokringConnection and a Brazed Connection.

Current Lokring CustomersWhirlpoolBosche SiemensDaimler ChryslerDaimler ChryslerValeoBehr BehrGM ServiceTecumsehTecumsehElectroluxVisteon VisteonHaier HaierMieleComet CometZanussi ZanussiMerloniViking VikingGeneral DomesticAppliancesGE ServiceGE Service

Lokring Assembly Tool•There are 2 different style Lokring manual assembly tools availabledepending on the applications they are used on.• The MZ and HMRKL style tools have one ratcheting handle and onefixed straight handle. The other style tools the MZV and HMRKV haveone ratcheting handle and the option to position the fixed handle inmultiple fixed positions for added clearance.• The HMRKL and HMRKV are re<strong>com</strong>mended for refrigerated applianceand automotive type applications where tube O.D. sizes range from .063inch to ¾ inch.•The MZV is used for all connection sizes thru 1 3/8 inch O.D.

Lokring Assembly ToolRemovable JawsJaw PinsFixed handlerelease level if soequippedRatchet releaselever

Lokring Assembly ToolRight handed with release levers onback side of toolLeft handed with release levers onfront side of toolIf you are using your right hand pull down on the ratchet release lever using yourright index finger or left thumb if using your left hand.

Lokring Assembly ToolRight handed Left handedUsing a pushing motion as shown by arrows open tool the tool until jaws are fullyopened.

Lokring Assembly ToolRight handedLeft handedOnce the tool is fully open fold the ratcheting handle back against the fixed handle asshown and place your thumb against the handle to hold the tool open.

Lokring Assembly ToolRight handedLeft HandedNext place your other handover the fixed handle andratcheting handle as showngrabbing both handles.

Lokring Assembly ToolYour other hand is now free to move up and hold the tubes and connector.

Methods for holding the tool•Always try and preload tubes so they seat againstinternal stop.•Push loose tube against fixed tube such asmounted evaporator or <strong>com</strong>pressor.

Making a Lokring Connection1. If aluminum tube is one of the tubes tobe joined always use an aluminumLokring connector. For all other tube<strong>com</strong>binations use a brass Lokringconnector.2. Clean both of the tubes with an abrasivepad or emery cloth in a radial motion.3. With the connector placed over thetubes approximately ½ way to theinternal stop.4. Apply the Lokprep to area where thetube meets the end of the connector.The Lokprep will be drawn into theconnection by capillary action.5. Then push the tubes in until seatedagainst internal stop.

Making a Lokring Connection6. Rotate the connector 360 degrees to help disperse the Lokprep.7. Place the assembly tool with the appropriate size jaws over the connectorends.8. Slowly ratchet the handle closing the connector while making sure the tubesare fully inserted to the internal stop.

Making a Lokring Connection9. Continue to ratchet the tool until the connection is <strong>com</strong>pletely closed,both Lokrings seated should be against center stop.10. Once the connect is <strong>com</strong>plete wait at least 3 minutes before applyingvacuum, pressure or radial force.

Lokring Capillary Tube Connectors• Lokring reducers for capillary connections such as those used atthe evaporator inlet or drier outlet and various otherapplications do not have a internal stop at the capillary side ofthe connector.• As with all Lokring service connectors if an aluminum tube ison either side of the intended connection an aluminumLokring connector should be used.• For all other connections of tubing such as copper, steel,stainless steel, or titanium in any <strong>com</strong>bination a brass Lokringconnector should be used.• The following steps are a guide to making a Lokring reducerconnection on capillary tubing.

Lokring Capillary Tube Connectors1. Both tubes to be joined should becleaned with an abrasive pad oremery cloth using a radial motion.2. The capillary tube is thenpassed all the way thru theproper sized Lokringconnector as shown.

Lokring Capillary Tube Connectors3. A slight bent is placed in thecapillary tube to create a stop.Notice the capillary tube is justthru the other end of theconnector.4. The other larger cleaned tube tobe joined is then inserted into theappropriate size Lokringconnector about half to theinternal stop.

Lokring Capillary Tube ConnectorsAB5. Apply Lokprep to the larger tube first at the point where the Lokringconnector meets the tube point “A”6. Pull the capillary tube back just slightly, approximately an 1/8 inch,from the bend stop and apply one drop of Lokprep at the point wherethe capillary tube meets the tube point “B”. Do not over applyLokprep to the capillary connection as doing so may block thecapillary tube. Use one drop!

Lokring Capillary Tube Connectors7. Turn the connector 360 degrees to helpdisperse the Lokprep.8. Then start closing the connection usingthe Lokring assembly tool andappropriate sized jaws making sure bothtubes are fully inserted their stop, thebend in the capillary tube and internalstop on the larger tube. Also make surethe connector is fully seated into theassembly jaws while closing theconnection.

Lokring Capillary Tube Connectors9. Continue to ratchet the tool until the connection is <strong>com</strong>pletelyclosed, both Lokrings should be seated against center stop.10. Once the connect is <strong>com</strong>plete wait at least 3 minutes beforeapplying vacuum, pressure or radial force.

Selecting the Correct Lokring ConnectorSize and Material for Service Applications

Lokring Connector Size and Material•Lokring service connectors are a permanent, secure and leak free methodfor joining all <strong>com</strong>binations of tube material used for refrigeratedproducts when sized and <strong>com</strong>pleted correctly.•It is very important that the correct size and material Lokring connectoris used. Failure to use the correct connector may cause leaks and alsoelectrolysis attacking the tubing.•Lokring connectors are sized and marked using the metric system inmillimeters.•Lokring connectors current size range from the smallest cap tube O.D. of1.6 mm or .063 inch thru 35mm or 1 3/8 inches O.D. tubing.•They are designed to join both size to size and reducer sizes.

Lokring Connector Size and Material•Lokring connectors <strong>com</strong>e in 2 base material versions brass oraluminum.•Brass Lokring connector <strong>com</strong>e <strong>com</strong>plete with either steel or brassrings depending on size.•Aluminum Lokring connectors <strong>com</strong>e <strong>com</strong>plete with aluminum rings.

Selecting the Correct LokringMaterial for Your Connection•If the tube material is aluminumon either side of the intendedconnection an aluminum Lokringconnector should be used.•For all other connections a brassconnector should be used.

Measuring Tubes and ComponentsABCDEFTubes should be measured using a digital caliper set to the millimeter mode.A. in/mm button. B. Lock screw. C. Outside measuring blades.D. On / Off switch E. Zero button. F. Thumb wheel.Button locations may vary by model and manufacturer.

Lokring Connector Size and Material• Press the on / off switch once to turn the caliper on.• When the caliper is on, the screen will display numbers and zeros orall zeros.• If the display flashes off and on or shows low battery, change batterybefore use.• Make sure outside measuring surfaces are clean and free of debris atcontact surfaces.• Roll thumb wheel until caliper is fully closed.• If caliper does not read zero on screen when fully closed, press zerobutton to recalibrate zero.• Caliper should now read zero and be in the metric mode. It shouldread 0.00 and display mm.• If it reads in inches 0.0000 in. press the in/mm button once.• Caliper is now ready for use.

Lokring Connector Size and Material• When measuring tubes larger thancapillary tube use the very end aspictured of the caliper outsidemeasuring blades.•Most tubes are somewhat oval so tubesshould be measured twice at 180degrees and the average should be used.•In the example shown the tube averageis 7.89mm. The tube would use an 8mmLokring connector.•If the tube is to oval to fit in theLokring connector. Use a pair of pliersto gently make it round.

Lokring Connector Size and MaterialThe tolerance fit generally built into Lokring connectors is as follows.•Lokring capillary tube connectors have a tube O.D. tolerance of plus or minus0.1 mm & <strong>com</strong>e in sizes 1.6, 1.8, 2, 2.2 and 2.5mm.•The most popular sizes for US appliances are 1.8 and 2mm.•If the O.D. measurement of the capillary tube falls between 2 sizes try thesmaller size connector 1 st . “fit doesn’t fit”. Then use the smaller connector if itfits over the tubing.•The tolerance for connector sizes 3mm thru 11 mm is plus or minus 0.2 mm•Example 7.8 to 8.2 O.D. uses a 8mm Lokring connector 8.3 to 8.7 uses a 8.5.•Lokring connectors for appliance repairs <strong>com</strong>e in <strong>com</strong>mon sizes 3mm and largerevery 0.5mm including reducer type connectors.

Lokring Connector Size and MaterialLokring Size Description8 NK MS 00Tube size straight connector material connector typeLokring Reducer8/2 NR MS 00Tube sizes reducing connector material connector typeAluminum = ALBrass = MS

Questions?