Articulated Truck

Articulated Truck

Articulated Truck

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

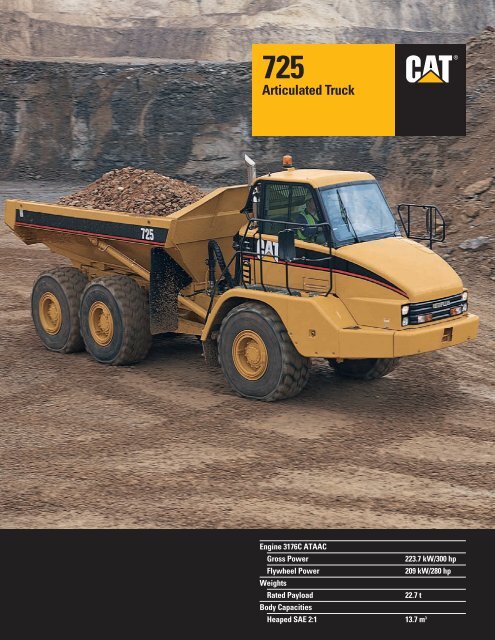

725<strong>Articulated</strong> <strong>Truck</strong>®Engine 3176C ATAACGross Power223.7 kW/300 hpFlywheel Power209 kW/280 hpWeightsRated Payload22.7 tBody CapacitiesHeaped SAE 2:1 13.7 m 3

725 <strong>Articulated</strong> <strong>Truck</strong>sThe 725 Caterpillar ® articulated truck is Simply The Best.Performance and Productivity -PowertrainHigh power Cat ® 3176C ATAACelectronic engine, electronicallycontrolled transmission, and a newfaster acting, more powerful retarderdeliver the performance needed to getthe job done. pg. 4Performance and ProductivityCross-axle differential locking systemprovides full driveline locking formaximum performance in adverseconditions. New front suspensionprovides a smoother ride allowingthe operator to travel faster overrough terrain. pg. 5Durability and ReliabilityThe 725 has built-in durability andreliability. Cat purpose-built, articulatedtruck drivetrain components, improvedfront frame and hitch assure topperformance in the toughestapplications. pg. 6Better than all the rest, the 725 offers provenreliability and durability, high performance,low fuel consumption, operator comfort andlow operating costs.2

Operator ComfortLarger center-mounted cab, newoscillating front axle, Cat Comfort seatand increased storage space provideexceptional operator comfort. pg. 7Ease of OperationErgonomically designed wrap-arounddash, tilt and telescoping steeringwheel, easy to reach controls and betterall around viewing promote fast,confident machine operation for topproductivity. pg. 8ServiceabilityLonger service intervals and easiermaintenance result in better machineavailability, lower owning andoperating costs. pg. 9Complete Customer SupportYour Cat dealer offers a wide range ofservices that can be set up under acustomer support agreement when youpurchase your equipment. The dealerwill help you choose a plan that cancover everything from machineconfiguration to eventual replacement.pg. 103

Performance and Productivity – PowertrainIntegrated Powertrain – More Power, Greater Performance and Lower Fuel Consumption.3176C Electronic Engine. The 3176Celectronic engine offers highhorsepower and complete systemintegration of the engine andtransmission for maximum efficiency.High Torque Rise. Provides unequaledlugging force during acceleration, onsteep grades and in tough underfootconditions.Turbocharged and Air-to-AirAftercooled. Provides improved fueleconomy by packing cooler, denser airinto cylinders for more completecombustion of fuel and loweremissions.Electronic Control Module. ECM-Advanced Diesel Engine Management2000 provides improved emissions,performance, advanced trouble shootingand diagnostic capabilities.Fuel Efficiency. The electronicallycontrolled, computer-actuated unitinjection fuel system has high injectionpressure for complete fuel combustion,greater fuel efficiency and reducedemissions.Engine Construction. Caterpillardesigned one-piece cast iron blockprovides strength and maximumdurability. Two-piece articulatedpistons with forged steel crownswithstand higher cylinder pressure.Electronic Transmission. The newelectronically controlled transmission isdesigned specifically for the articulatedtruck and its applications.Electronic Clutch Pressure Control.The ECPC technology works with thepatented Controlled Throttle Shifting(CTS) to manage shift torque andprovide exceptional shift smoothness.Controlled Throttle Shifting. CTSsignificantly reduces powertrain stressand clutch wear by controlling enginespeed, torque converter lock up andtransmission clutch engagements.Retarder. The 725 features an integralretarder with a new high-power densitydesign. Due to its compact size, the unitquickly fills with oil, providing faster,fuller response.Retarder Power. Increased powercapability gives operators greatercontrol on short, steep grades andminimizes the need to apply the brakes,resulting in extended service brake life.4

Performance and ProductivityProductivity in All Conditions – All Terrain All the Time.Traction Control. Inter-axle differentiallock and cross-axle differential locksprovide 100% driveline locking. Alldifferentials are hydraulically actuated,oil-immersed, multi-plate clutch typethat can be engaged and disengaged onthe-gofor maximum versatility.Inter-axle Differential Lock. Locks allthree axles together for excellenttraction in poor underfoot conditions.It is operated by a switch incorporatedinto the footrest.Cross-axle Differential Locks. Providesfull driveline locking – all three axlesand all six wheels for maximumperformance in the most adverseconditions. Acts in unison with theinter-axle differential lock when thefootswitch is actuated and is selectedvia the dash-mounted switch.Front Suspension. The 725's new frontsuspension oscillates ±6° to provide asmoother ride allowing the operator totravel faster over rough terrain andsoftening impact loads on structures andcomponents.Front Suspensions Cylinders. Frontsuspension cylinders are designed fortough applications and offer a soft andsmooth ride.Construction. The front suspension usesan oscillating A-frame with a lateral tierod to control axle sideways movement.<strong>Truck</strong> Transport. The new suspensionsystem eliminates the need to lower thesuspension when transporting the truck,reducing maintenance and downtime.Mounting Points. Suspension mountingpoints are integrated into the axlehousing, increasing reliability.Rear Suspension. The rear suspensionfeatures a mechanical walking beamgeometry that extends component lifeand provides a stable ride for excellentload retention.5

Durability and ReliabilityHigh Availability Leads to High Productivity.Front Frame. An all new design withlarge box-section, wide and stiff framebeams to handle torque loads.The divergent frame design decreasesstress in the hitch area and optimizessuspension geometry. The frame hasbeen designed to make maximum use ofrobotic welding for increased durability.Rear Frame. Twin-box constructionminimizes stress concentration andprovides low weight with long servicelife.Castings. The front and rear framesmake extensive use of heavy-duty steelcastings to handle stress concentrations.Articulating/Oscillating Hitch.The articulating hitch provides thetruck with steering articulation and theoscillation ensures the truck maintainsall wheel ground contact in roughterrain.Hitch Construction. A new two-piececonstruction featuring a strong anddurable cast steel head bolted to a hardwearing forged steel tube. The hitchtube features larger, hardened bearingareas and a hardened thrust face forreduced maintenance and longer life.Caterpillar Powertrain Components.The 725 features Purpose DesignedEarthmoving Components from theengine through to the final drives.Proven in articulated trucks and otherCaterpillar equipment, these ruggedbuilding blocks ensure long life andreliability.6

Operator ComfortThe Operator's Office, High Productivity from a Comfortable, Motivated Operator.Ride Comfort. The new front suspensionwith its oscillating axle and lowpressure ride struts, combined withthe new center-mounted cab, offerunrivaled levels of ride comfort forthe operator in all driving conditions.Sound Levels. Cab mounts are designedto reduce noise and vibration in the cab.All connections to the cab are resilientlymounted and the cab itself makesextensive use of sound absorbing andbarrier materials to keep sound levelslow.Spacious Cab. The 725 features moreinterior space than the E Series II,giving it one of the roomiest operatorstations in the industry.Heating/Ventilation/Air Conditioning.Stay warm or cool in all environments.Twelve vents provide air distribution tokeep the operator comfortable and togive rapid defrosting of all windows.Heating and air conditioning arestandard and the recirculation filter ispositioned for easy servicing.Storage Space. More storage space tocreate a secure and uncluttered workingenvironment.Steering Column. Offers telescopingand tilting features to provide acomfortable driving position.Suspended Pedals. Are easier to reachand create more leg and foot room.They also make for easier cleaning ofthe cab floor.Cat Comfort Seat. The new Cat Comfort airsuspension seat enhances operator comfortwith a dual-sided support recliner andthicker cushions. It is fully adjustable toprovide an optimal driving position.Trainer Seat. The full-size trainer seatfeatures a fully padded seat with a backrestand a seatbelt for a comfortable, secure ride.7

Ease of OperationDesigned for Simple, Easy Operation, the 725 Allows the Operator to Focus on Production.Ergonomic Layout. The controls andlayout of the 725's cab are designed tomake it as easy to operate as your car.Quick and easy to read and simple tooperate, the controls on the 725 allowthe operator to concentrate onproduction.Dash. All controls are within easy reachof the operator and the non-metallicmaterials give an automotive feel.Viewing Area. The low sloping hoodand placement of the engine coolingpackage behind the cab give the 725 thebest all-round viewing of any truck inthe industry. This increases operatorconfidence and speeds up cycle times.Diff Lock Controls. The switch for theinter-axle differential lock has beenpositioned in the operator's footrest forease of operation. A dash-mountedswitch is all that is required to selectfull driveline lock-up. Disengaging thefoot switch disengages all differentiallocks immediately.Transmission and Hoist Levers.The hoist lever has been redesignedand relocated to provide easy andcomfortable operation. The transmissionlever continues to offerexcellent comfort along with controlsfor top gear limit, transmission holdand neutral lock.Electronic Monitoring System (EMS II).Constantly monitors critical machinefunctions and alerts operators topotentially damaging problems beforefailures occur. It also indicates whencertain functions are in use.8

ServiceabilityMore time on production, less time and less money, spent on servicing.Extended Service Intervals. Increasedengine oil change and hydraulic oilchange intervals and wheel-bearingadjustment completely eliminated.Test and Lube Points. Test points aregrouped together behind the cab andaccessible from the ground. Lube pointsare grouped at the rear of the frontframe and the front of the rear frame.Radiator. The radiator package islocated behind the cab, which providesimproved protection from frontalimpacts and offers improved access toboth inlet and outlet sides of theradiator.Extended Life Coolant. Extends thechange interval as well as improvingwater pump life by reducing aluminumcorrosion.Hood. The hood is raised and loweredelectrically requiring minimal operatoreffort when servicing. A manualoverride is also provided.Electrical Service Center. Locatedinside the cab this provides a powerport, diagnostic connector and the Catdata link connector.Cat Data Link Connector. The Cat datalink connector provides a plug-in usinga laptop computer with ElectronicTechnician (ET) software. The Cat datalink port performs programmingfunctions on all electronic controls.Service Points. Engine and transmissiondipstick and fill caps, air and fuel filtersand the fuel priming pump are allmounted on the left side of the engineunder the hood. Coolant level indicatorand fill caps are outside the cab.9

Complete Customer SupportCat dealer services help you operate longer with lower costs.Selection. Make detailed comparisonsof the machines you are consideringbefore you buy. What are the jobrequirements, machine attachments andoperating hours? What is your need formachine availability and do you need orhave the proper loading tool match?Your Cat dealer can help.Purchase. Look past initial price, lookat the value the 725 offers. Consider theresale value, compare productivity andday-to-day operating costs and fuelconsumption. Consult your local Catdealer for financing options.Operation. For the best operatingtechniques to increase productivity andyour profit turn to your Cat dealer forthe latest training literature and trainedstaff.Maintenance. Repair option programsguarantee the cost of repairs up front.Diagnostic programs such as S•O•S SMand Technical Analysis help you avoidunscheduled repairs.Replacement. Repair or rebuild?Caterpillar <strong>Articulated</strong> <strong>Truck</strong>s aredesigned for a longer life withrebuildable components. Your Catdealer can help you evaluate the costinvolved so you can make the rightchoice.Product Support. The 725 offers easymaintenance with combined servicepoints and extended service intervals tokeep the machine running longer. Yourlocal Cat dealership will be with youevery step of the way with itsunsurpassed worldwide parts support,trained technicians and customersupport agreements.Warranty. Your local Cat dealer is thereto support and protect you. Extendedwarranty options are also available.10

EngineCat 3176C ATAACRatingGross PowerFlywheel PowerISO 9249EEC 80/1269BoreStrokeDisplacement2200 rpm223.7 kW/300 hp209 kW/280 hp209 kW/280 hp125 mm140 mm10.3 liters■ The 725 meets TierII/Stage 2emission specifications for theU.S. and Europe.■ No engine derating required below4572 m.TransmissionForwardkm/h1 7.12 13.43 20.44 31.25 43.56 51.3Reverse1 7.9WeightsRated Payload22.7 tBody CapacitiesHeaped SAE 2:1 13.7 m 3Struck 10.4 m 3Heaped SAE 1:1 16.8 m 3Body HoistTwo flex-free, single-stage, doubleactinghoist cylinders.■ cylinders positioned within bodyprofile for maximum protection■ 70° hoist angle with power up anddown for clean load ejection and fastdump cycles■ power up, 10 seconds; power down,7 secondsOperating WeightsEmptykgFront axle 12 250Center axle 4 630Rear axle 4 840Total 21 720Rated LoadFront axle 1 840Center axle 10 420Rear axle 10 420Total 22 680LoadedFront axle 14 090Center axle 15 050Rear axle 15 260Total 44 400Body Plate ThicknessFrontScowSideBase8 mm14 mm12 mm14 mmService Refill CapacitiesLitersFuel Tank 310Cooling System 85Hydraulic System 150Engine Crankcase 31Transmission 36Final Drives/Differential 132Output Transfer Gear 20Sound LevelsInterior CabStandards76 dB(A)Brakes ISO 3450-1998Cab/FOPS ISO 3449-1992 Level IICab/ROPS ISO 3471-1994725 <strong>Articulated</strong> <strong>Truck</strong> specifications11

DimensionsAll dimensions are approximate.5785 mm3028 mm*6386 mm70°5396 mm**2664 mm2750 mm7253436 mm495 mm575 mm1680 mm 1700 mm3819 mm2721 mm2218 mm9920 mm2820 mm* if equipped with a scissor tailgate** Inside of bodyTurning CircleDimensions are for machines equipped with 23.5R25 tires.Turning dimensionsSteer angle – left/right 45°SAE turning radius7225 mmClearing radius7590 mmInside radius3745 mmAisle width4942 mm12 725 <strong>Articulated</strong> <strong>Truck</strong> specifications

Gradeability/Speed/RimpullTo determine performance,read from Gross Weightdown to % Total Resistance.Total Resistance equalsactual % grade plus 1% foreach 10 kg/metric ton ofRolling Resistance.From this point, readhorizontally to the curvewith the highest attainablespeed range. Then, go downto Maximum Speed.Usable Rimpull dependson traction available.kg x 1000504030Rimpull20105321151E23Gross Weight20 25 30 40 50 60 70 80 10045L6kg x 100 0-40%-30%-25%-20%-15%-12%-10%-8%-6%-5%-4%-3%-2%Total Resistance (Grade and Rolling Resistance)0.50.30 5 10 15 20 25 30 35 40 45 50 55 60Speedkm/hE – Empty 21 720 kgL – Loaded 44 400 kg1 – 1st Gear2 – 2nd Gear3 – 3rd Gear4 – 4th Gear5 – 5th Gear6 – 6th Gear725 <strong>Articulated</strong> <strong>Truck</strong> specifications 13

Standard EquipmentStandard and optional equipment may vary. Consult your Caterpillar dealer for specifics.Air conditioning with R134ArefrigerantAir vents, adjustableBack up alarmBody, adapted for exhaust heatDifferentials, clutched cross-axle for allaxlesElectrical system, 24-voltEther starting aidGlass windows, toughened and tinted,front and rear.Guards: rear window and radiator,crankcase and axleHeadlights, four with dimmer switchHeater and defroster with three speedfanHorn, electricLights: cab interior, front, side, rear,two reversing/working lights,two stop/tail lightsMirrors, left and rightMud flaps, body mountedRadio readyRetarderROPS/FOPS cab, with fullinstrumentation, including:Electronic Monitoring System panel:alternatorcoolant temperaturebrake oil pressureengine oil pressurelow fuel indicatorGauges:fuel (in cab)torque convertor temperatureIndicator lights:direction, hazardheadlights, high beam onlycross axle differential lock-upparking braketransmission/torque convertorlock-upMetersservice hour meterspeedometertachometerSeat, Caterpillar comfort seat with AirSuspensionSeat, padded companion/trainerTwo retractable seat beltsSun visorStorage – thermos holder, under seatstorage, door pocket, behind seatstorage, coat hook.S•O•S SM sampling valvesSpill guard, front, integral part offabricated bodySupplemental steeringTires, six 23.5R25, radialTool box, lockableTow pins front and rearVandalism protection: lockable capsfor fuel tank, hydraulic oil tank andradiatorWindows opening side, tintedWindshield wiper and washer,intermittent14 725 <strong>Articulated</strong> <strong>Truck</strong> specifications

Optional EquipmentStandard and optional equipment may vary. Consult your Caterpillar dealer for specifics.Body connection for exhaust heatBody linersEther starting aidSound suppression spectatorStarting receptacle, electric, remoteTailgates:scissor-typeunderslungTires, low profile, 660/65R25Tool kitWiper/washer, rear window intermittentHeated rearview mirrorsCustom ProductsThe 725 is compatible with a widerange of Caterpillar and auxiliaryequipment manufacturers' specializedproducts. This multi-purpose haulingsystem was designed for use with acommon tractor and a variety of traileroptions to suit different marketsegments such as: waste, forestry,tunneling, earthmoving and agriculture.For more information, contact yourlocal Cat dealer.725 <strong>Articulated</strong> <strong>Truck</strong> specifications 15