216B and 226B Skid Steer Loaders

216B and 226B Skid Steer Loaders

216B and 226B Skid Steer Loaders

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

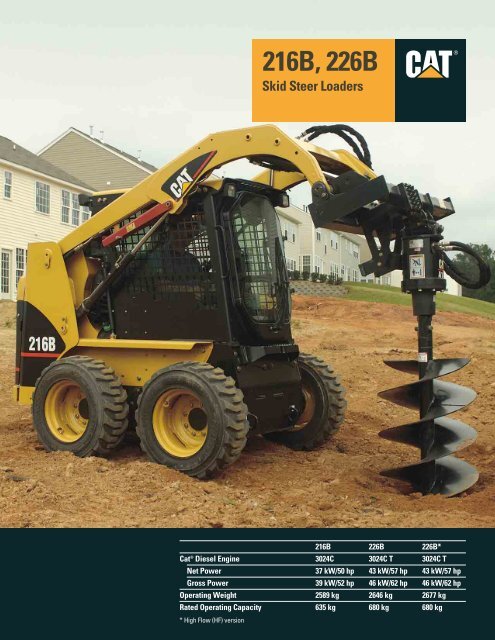

<strong>216B</strong>, <strong>226B</strong><strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong>®<strong>216B</strong> <strong>226B</strong> <strong>226B</strong>*Cat ® Diesel Engine 3024C 3024C T 3024C TNet Power 37 kW/50 hp 43 kW/57 hp 43 kW/57 hpGross Power 39 kW/52 hp 46 kW/62 hp 46 kW/62 hpOperating Weight 2589 kg 2646 kg 2677 kgRated Operating Capacity 635 kg 680 kg 680 kg* High Flow (HF) version

Caterpillar ® <strong>216B</strong> <strong>and</strong> <strong>226B</strong> <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong>Two versatile compact machines designed, built <strong>and</strong> backed by Caterpillar to deliverexceptional performance, ease of operation <strong>and</strong> simplified service.World-class Operator StationOperator comfort <strong>and</strong> ease of operationare designed into the operator’s stationfrom every aspect. Ergonomic featuressuch as low-effort joystick controls,comfortable padded armrest <strong>and</strong> anadjustable contoured seat reduceoperator fatigue. Excellent visibilityto the work tools helps enhanceproductivity. pg. 4-5✔High Performance Power TrainThe Cat ® 3024C engine provides highengine horsepower <strong>and</strong> torque.Exclusive anti-stall feature maximizespower to the drive train <strong>and</strong> work toolswithout stalling the engine, allowingpart-throttle operation for lower soundlevels <strong>and</strong> lower fuel consumption.pg. 6✔Advanced Hydraulic SystemThe hydraulic system in the Cat<strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong> is designed formaximum power <strong>and</strong> reliability.Increased hydraulic power enablesbetter overall performance.Reduced componentary translatesto fewer hydraulic connectionsthus reducing potential leak points.High Flow hydraulics are optionalon the <strong>226B</strong>. pg. 7Built for Versatility.The Caterpillar <strong>216B</strong> <strong>and</strong> <strong>226B</strong> <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong>are ideal for multiple applications including:construction, l<strong>and</strong>scaping <strong>and</strong> agriculture.They deliver traditional Cat reliability <strong>and</strong>durability with excellent productivity.✔ New feature2

✔Quick Coupler <strong>and</strong> Cat Work ToolsA universal work tool interface <strong>and</strong>quick coupler make the Cat <strong>Skid</strong> <strong>Steer</strong>Loader the most versatile machineon the jobsite. The wide range ofCaterpillar work tools optimisemachine performance for maximumutility <strong>and</strong> production. pg. 8-9✔ServiceabilityCat <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong> offer quick <strong>and</strong>easy routine maintenance <strong>and</strong> service.The rear door opens 90 degrees <strong>and</strong>the cooling package raises to provideindustry leading access to the enginecompartment. The cab also tilts up foreasy access. pg. 10Customer SupportCaterpillar Dealers offer unmatchedcustomer support, with excellentwarranty programs <strong>and</strong> fast partsavailability, resulting in maximumuptime <strong>and</strong> minimum repair costs.Equipment maintenance services helpoptimize machine performance <strong>and</strong>reliability. pg. 113

Operator StationWorld-class operator station provides exceptional working comfort withexcellent visibility, enhanced fingertip control <strong>and</strong> optimum instrumentation.Ergonomic Design. Cat <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong>feature an updated ergonomic cab designthat makes operation easier <strong>and</strong> morecomfortable. A choice of contoured,adjustable seats offer increased operatorcomfort. Careful placement of machinecontrols make them feel like a naturalextension of the operator h<strong>and</strong>s. A newcontoured armbar gives excellent support ofarms <strong>and</strong> wrists for easier machine control.The cab features a removable floor matwhich acts as a foot rest <strong>and</strong> offers excellentsound <strong>and</strong> heat insulation. The foot throttlecontrol is an ergonomically-designed pedalthat allows operation at variable enginespeeds for optimum performance whileminimizing fuel consumption. A st<strong>and</strong>ardh<strong>and</strong> throttle also allows operation at any setengine speed.Cab Features. The ergonomically designedcab provides the operator with easy to usepilot controls in a comfortable workingenvironment. The st<strong>and</strong>ard offerings ofthe Cat <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong> operator stationinclude: 12 volt power socket Removable, sliding side windows Enclosed cabs feature an automatic lockoutswitch which prevents accidentaldamage by disabling the loader functionswhen the door is open.Low-Effort Machine Controls.Ergonomic pilot-operated hydraulic controlsgive operators precision control of Cat <strong>Skid</strong><strong>Steer</strong> <strong>Loaders</strong> with minimal effort. The leftjoystick controls forward <strong>and</strong> reverse travelspeed plus direction <strong>and</strong> the right joystickcontrols loader up/down <strong>and</strong> tilt control.Both joysticks use an intuitive “S” controlpattern. Joysticks provide additionalauxiliary controls, using positive-actionbuttons to provide precision fingertip controlof many machine functions, including: One-touch continuous auxiliaryhydraulic flow Momentary auxiliary hydraulic flow Multiple auxiliary functions Horn Proportional auxiliary hydraulicfunctionality (optional)4

High-efficiency Climate Controls.Operating in extreme temperatures is nowmore comfortable with the optional cabair conditioner <strong>and</strong> heater installed.The air conditioner offers 14 250 kjcooling capacity <strong>and</strong> the heater output is18 690 kj. Six adjustable vents provideexcellent air flow throughout the cab <strong>and</strong>makes defrosting the optional front door<strong>and</strong> side windows easier. (Air conditioningavailable on the <strong>226B</strong> only.)Visibility. The Cat <strong>Skid</strong> <strong>Steer</strong> Loader hasa wide cab opening providing exceptionalview of the work tool enhancing ease ofoperation <strong>and</strong> productivity. The slopedangle of the engine compartment allowsexcellent visibility to the rear of themachine. A new convex rearview mirroroption gives the operator a panoramic viewof the rear <strong>and</strong> sides of the machine.For better visibility in low-light conditions,the st<strong>and</strong>ard forward lights are adjustable10 degrees in any direction.Instrumentation. Cat <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong>use instrument panels <strong>and</strong> gauges that aresimple, easy-to-use <strong>and</strong> reliable. Brightindicator lights <strong>and</strong> audible warning,signals any critical system situation.An engine air cleaner restriction indicatoris situated in the cab for easier reference.Access/Egress. The Cat <strong>Skid</strong> <strong>Steer</strong> Loadercab is designed to make machine operationsimple, productive <strong>and</strong> comfortable.Getting into <strong>and</strong> out of the cab is secure<strong>and</strong> easy through a wide opening withthree-point grab h<strong>and</strong>les <strong>and</strong> skid-resistantsteps. Tilt cylinders are neatly locatedunder the lift arms so not to interfere withoperator access <strong>and</strong> egress.Cab Packages. Several cab packages<strong>and</strong> options are available.The st<strong>and</strong>ard cab includes: ROPS/FOPS cab Contoured cushion seat with fore/aftadjustment Retractable seat belt Cushioned, contoured armbar Dual throttle controls - h<strong>and</strong> <strong>and</strong> foot Dome light Horn Rear wall liner Windows, top <strong>and</strong> rear Two overhead instrument panels Pilot-hydraulic joystick <strong>and</strong> fingertipauxiliary controls 12 Volt power socketThe deluxe cab package includes itemsin the st<strong>and</strong>ard cab, plus Deluxe suspension seat Headliner Additional working lightsA cold-weather cab package includesitems in the st<strong>and</strong>ard cab, plus: Removable, sliding side windows High-efficiency heater/defrost Engine coolant heater Heavy-duty 880 CCA starting battery Debris barrierOther cab options include: Cab door (either glass orpolycarbonate) with wiper/washer<strong>and</strong> loader arm lock-out Air conditioner with heater/defrost FOPS, Level II Insulated floor mat with foot rest Cup holder 76 mm seat belt Additional controls for– hydraulic quick coupler– proportional auxiliary hydraulics– work tool electrical requirements– high flow hydraulics5

Power TrainCaterpillar Hystat power train delivers aggressive performance <strong>and</strong> easy operation.Cat Diesel Power.The heart of the Cat <strong>Skid</strong> <strong>Steer</strong> Loaderpower train is the Caterpillar 3024Cdiesel engine, which is turbocharged inthe <strong>226B</strong> model. This rugged, reliablefour-cylinder Stage II compliant Catengine offers aggressive performance<strong>and</strong> a fast torque curve for quickresponse.Throttle Control.Dual engine throttle controls allowthe operator to match engine speed tothe task. The h<strong>and</strong> throttle is ideal forjobs requiring consistent engine speed -such as cold planing or trenching.The foot throttle enables the operatorto vary engine speed <strong>and</strong> minimize fuelconsumption for other tasks such asload <strong>and</strong> carry, truck loading, grading<strong>and</strong> dozing.Anti-Stall System. An exclusive antistallsystem on the Cat <strong>Skid</strong> <strong>Steer</strong><strong>Loaders</strong> allows maximum power tothe wheels while minimizing enginestalling. This exclusive system helpsmaximize productivity for experiencedoperators <strong>and</strong> makes it easier for noviceoperators to become productive.Axial Piston Pumps. Dual, variabledisplacementaxial piston pumps aredriven directly off the engine <strong>and</strong>provide hydraulic flow to the drivemotors via a closed loop system.Drive motors transfer mechanical powerto the wheels via two high-strength,pre-stressed chains per machine side.Chains run in an oil bath for constantlubrication <strong>and</strong> long life. Chains areadjustable through slots in the axlehousings.Drive Axles. Drive axles are forged <strong>and</strong>induction hardened for maximum life.They include a unique labyrinth sealwhich consist of lip <strong>and</strong> outer seal tohelp prevent debris such as wire <strong>and</strong>twine from wrapping around the axle<strong>and</strong> destroying the seal. An inner sealis used for permanent lubrication ofaxle bearings - no daily axle serviceis required.6

Hydraulic SystemHydraulic system has built-in reliability <strong>and</strong> provides exceptional wheel torque plus lift,breakout <strong>and</strong> auxiliary power to work tools.High-Flow Hydraulics. Optional highflowhydraulics provide increasedhydraulic horse power for high-speed,high-power work tools such as coldplaners, l<strong>and</strong>scape rakes, stump grinders<strong>and</strong> trenchers. This system can beordered on new Cat <strong>226B</strong> machinesor can be installed later by your localCat Dealer.Front Hydraulics. St<strong>and</strong>ard ON/OFFfront hydraulics are featured on the<strong>216B</strong> <strong>and</strong> <strong>226B</strong>. Optional proportionalfront auxiliary hydraulics are alsoavailable on these models.Power <strong>and</strong> Reliability. Maximum power<strong>and</strong> reliability are built into the Cat<strong>Skid</strong> <strong>Steer</strong> Loader hydraulic system.In addition to providing power to drivethe wheels, this system also providesthe loader lift <strong>and</strong> tilt functions, powersthe auxiliary circuit to drive work tools<strong>and</strong> drives the engine cooling fan.Hydraulic Pumps. Hydraulic pumpsare driven directly off the engine formaximum hydraulic performance <strong>and</strong>reliability - no belts are used. Pumps areopen center, fixed-displacement <strong>and</strong>provide flow to the loader <strong>and</strong> auxiliaryhydraulic circuits.Control of the loader lift <strong>and</strong> tiltfunctions by hydraulically-operatedpilot controls enable low-effort <strong>and</strong>precise operation.Auxiliary Hydraulics. St<strong>and</strong>ard auxiliaryhydraulics to power work tools isavailable through quick-connecthydraulic couplings that are rigidlymounted to the loader arm. Cat XT hose<strong>and</strong> O-Ring Face Seals help ensurea leak-free system.Reliability <strong>and</strong> Cleanliness.Reduced potential leak points improvereliability <strong>and</strong> result in a cleanermachine. In addition, hydraulic oilflows through a 4-micron spin-on filter.A filter restriction indicator is located atthe operator station. A 74-micron screenin the hydraulic tank prevents largerdebris from entering the system <strong>and</strong>causing damage to the hydrauliccomponents.Hydraulic Oil Cooler.A high-efficiency hydraulic oil coolerenables the Cat <strong>Skid</strong> <strong>Steer</strong> Loaderto work longer <strong>and</strong> harder in higherambient temperatures, even when usingcontinuous high flow work tools.The high-capacity hydraulic oilreservoir maintains lower operatingtemperatures.7

Quick Coupler <strong>and</strong> Caterpillar Work ToolsChoose from a wide variety of tools that are performance matched to Cat <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong>.Quick Coupler. Work tools can bechanged quickly <strong>and</strong> easily with theCat <strong>Skid</strong> <strong>Steer</strong>’s quick coupler system.The universal coupler interfacefeatures: Low profile side plates are designedfor the optimum match to work tools<strong>and</strong> minimal material packing Opposing wedges ensure a tighttool fit Rugged design <strong>and</strong> large contact areaabsorbs loads <strong>and</strong> minimizes stress Tool engagement <strong>and</strong> release arequick <strong>and</strong> easy Vertical pins are chrome-plated <strong>and</strong>lubricated for smooth engagement<strong>and</strong> prevention of corrosion Coupler allows excellent visibilityto work tools <strong>and</strong> unobstructed entry<strong>and</strong> exit to the cab.The st<strong>and</strong>ard quick coupler featuresmanual engagement <strong>and</strong> disengagementof work tools using two high-leverageh<strong>and</strong>les. An optional hydraulic quickcoupler is also available <strong>and</strong> allowsengagement <strong>and</strong> disengagementof work tools without the need forthe operator to exit the machine.Control of the coupler by use ofa rocker switch inside the cab,making work tool changes quicker<strong>and</strong> easier.Cat Work Tools. They extend the versatilityof the Cat <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong>. Designed <strong>and</strong>built for optimum performance <strong>and</strong> durability,these tools deliver high productivity,long service life <strong>and</strong> excellent value: Angle blades Augers Backhoes Brooms Buckets:– general purpose– grapple– light material– multi purpose– utility Cold planers Compactor vibratory Hammers L<strong>and</strong>scape rakes L<strong>and</strong>scape tillers Material h<strong>and</strong>ling arm Pallet forks Stump grinders Trenchers Wheel Saws8

Augers. Caterpillar Augers are designedfor drilling holes for footings, fencing,signs, trees <strong>and</strong> shrubs in construction,agricultural <strong>and</strong> l<strong>and</strong>scapingapplications. Backhoes. The compact CaterpillarBackhoe transforms the <strong>Skid</strong> <strong>Steer</strong>Loader into a dedicated excavator fordigging our trenches, hammer use orgeneral excavating tasks. Brooms. Caterpillar Angle Broomsare ideal work tools for removing rock,dirt <strong>and</strong> other debris from streets,carparks, driveways, pavements <strong>and</strong>factory floors. Buckets - multi purpose.Caterpillar Multi Purpose Buckets aredesigned to optimize the versatility ofCat <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong> when digging,dozing, clamping, scraping, backdragging, grading <strong>and</strong> levelling ina wide range of applications. Cold planers. Caterpillar Cold Planersare designed for milling tarmac, asphalt,concrete surfaces, prior to repair <strong>and</strong>reinstatement. Grapple Forks. Caterpillar IndustrialGrapple Forks are designed to easilyh<strong>and</strong>le a wide array of bulky, loose,objects encountered in demolition,industrial, construction <strong>and</strong> otheraggressive applications. Trenchers. Caterpillar Trenchersare designed for cutting narrow straighttrenches in soil prior to laying electrical,telephone lines, cable lines, water orgas pipes. Wheel Saws. Caterpillar Wheelsaws areused to cut trenches in tarmac, asphalt,concrete <strong>and</strong> permafrost surfaces priorto laying cable, electrical, gas <strong>and</strong> waterpipes. (<strong>226B</strong> High Flow only)9

ServiceabilityQuick access <strong>and</strong> superior design make the Cat <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong> easy to maintain.Service Access. The rear service door opens90 degrees for easy access to both sides ofthe in-line mounted engine.Filters. All filters are spin-on <strong>and</strong> easilyaccessible, which makes routine servicequicker <strong>and</strong> virtually spill-free.Cooling System. The radiator, hydraulic oilcooler <strong>and</strong> grill tilt up to increase access tothe cooling system during maintenance <strong>and</strong>allows easier cleaning of debris from betweenthe grill <strong>and</strong> cooling package. The cooling fanis hydraulically driven for quieter operation<strong>and</strong> to eliminate the service <strong>and</strong> maintenancethat comes with belt-driven fans.Easy Tilting Cab. The machine cab can nowbe tilted rearward by a single person usinga single tool, <strong>and</strong> is held in place by a selflatchingmechanism. When the cab is tiltedback, all hydraulic pumps, motors, valves,lines <strong>and</strong> the fuel tank are accessible for quick,easier service.Removable Belly Pan. A removable belly pansection on the floor of the machine’s lowerframe provides excellent access for periodiccleaning.Electrical <strong>and</strong> Hydraulic Lines.Clean routings of electrical <strong>and</strong> hydraulic linesimproves reliability <strong>and</strong> simplifies service.Maintenance Points. They are groupedin easily accessible locations.S•O•S SM Valves. Scheduled Oil SamplingS•O•S valves are st<strong>and</strong>ard to allow regularmonitoring of the engine <strong>and</strong> hydraulic oilquality.Other St<strong>and</strong>ard Service Features Easy access to battery, air filter <strong>and</strong> singleengine belt Sight glass on hydraulic tank <strong>and</strong> radiatorallow quick, easy level checks Air filter restriction indicators are locatedinside the operator station <strong>and</strong> at the air filter Ecology drains simplify changing engine<strong>and</strong> hydraulic oils Grease fittings are countersunk to preventdamage Extended life coolant <strong>and</strong> 250-hour engineoil change intervals10

Complete Customer SupportCat dealer services help you operate longer with lower costs.Machine Selection. With nine differentCat <strong>Skid</strong> <strong>Steer</strong> Loader <strong>and</strong> four Cat MultiTerrain Loader to choose from, selectingthe right machine is even easier when youconsult your Caterpillar dealer. Yourdealer helps you make detailed machinecomparisons before you purchase.Purchase Options. Available to let youlook beyond just the initial machine price.With your Cat dealer, you can reviewavailable financing options plus look atday-to-day operating costs. You can alsolook at dealer services that can be includedin the cost of the machine to yield lowerequipment owning <strong>and</strong> operating costsover the life of the machine.Customer Support Agreements.These agreements offer you a variety ofservice <strong>and</strong> maintenance options that canbe customized to best fit your specificrequirements. These can cover the entiremachine <strong>and</strong> include work tools to helpprotect your investment.Machine Support. It is one of your Catdealer’s primary goals. You will find highavailability of parts at our Dealer partscounter. Cat Dealers utilize a worldwidecomputer network to find in-stock partsto minimize machine downtime.Your Cat dealer can also save you moneyby suggesting Cat Remanufactured partsthat carry the same warranty as new,but with savings of 40 to 70 percent.Maintenance Service Plans.Help manage machine maintenance,by choosing from a wide range ofmaintenance plans <strong>and</strong> services at the timeyou purchase a machine. Repair optionplans guarantee the cost of repairs up front.Diagnostics programs such as ScheduledOil Sampling, Coolant Sampling <strong>and</strong>Technical Analysis help you avoiddowntime <strong>and</strong> unscheduled repairs.Operator Training. Cat dealers canimprove your operator’s techniques <strong>and</strong>help boost your profits.Cat Machine Security System.Secure your investment with Caterpillar’sMachine Security System (MSS),a programmable key system that providesmaximum machine security for Cat<strong>Skid</strong> <strong>Steer</strong> Loader owners. MSS disables machine by interactingwith the machine’s Electronic ControlModules (ECM) Keys fit all existing Cat machines(including machines without MSS) Each machine can store up to 50 keyidentifications Each key can be configured tooperate a certain range of machinesor enable operation for a certainperiod of timeRepair, Rebuild or Replace.Choices become even more evidentwhen you consult your Caterpillardealer. Your Cat dealer can helpevaluate the costs involvedso you can make the right choiceevery time.11

Engine 3024C<strong>216B</strong> <strong>226B</strong>Ratings at 2600 rpm kW/hp kW/hpNet power 37/50 43/57Gross power 39/52 46/62DimensionsBore 84 mm 84 mmStroke 100 mm 100 mm Caterpillar 3024C (<strong>216B</strong>) <strong>and</strong> 3024C T turbocharged (<strong>226B</strong>),water-cooled, four-stroke cycle, four-cylinder diesel Net power rating per ISO 9249 or EEC 80/1269 Meets EU directive 97/68/EC Stage II emissionrequirementsHydraulic System<strong>216B</strong> <strong>226B</strong> *<strong>226B</strong>Hydraulic Flow Std Std HFLoaderHydraulic pressure (kPa) 21 400 23 000 23 000Hydraulic Flow (l/min) 60 60 100Features Single, hydraulically-operated joystick controls lift,lower <strong>and</strong> tilt functions Open center, fixed displacement* High Flow (HF) versionOperating SpecificationsThe specification for the <strong>216B</strong> <strong>and</strong> <strong>226B</strong> <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong>are with 10 x 16.5 6 PR tires, 1525 mm dirt bucket,full fuel 65 kg <strong>and</strong> a 75 kg operator.<strong>216B</strong> <strong>226B</strong> *<strong>226B</strong>kg kg kgRated operating capacity** 635 680 680Rated operating capacity withoptional counterweight** 680 726 726Operating weight 2589 2646 2677Tipping load 1270 1360 1360Breakout forcelift cylinder 1386 1515 1499tilt cylinder 1717 1852 1852* High Flow (HF) version** ISO 5998:1986Power Train <strong>and</strong> BrakesDual, closed-loop, axial piston hydrostatic pumps drivendirectly off engine. Pumps provide pressure <strong>and</strong> flow to twofixed displacement motors.Travel speed <strong>216B</strong> <strong>226B</strong> *<strong>226B</strong>km/h km/h km/hForward 12.5 12.7 12.7Reverse 12.5 12.7 12.7Features Single hydraulically-operated joystick, controls speed<strong>and</strong> direction Hydrostatic service brakes Multi-disc, spring-applied hydraulically releasedparking brake Anti-stall system maximizes torque to the wheelswithout stalling engine* High Flow (HF) versionROPS/FOPSRollover Protective Structure (ROPS) <strong>and</strong> Falling ObjectsProtective Structure (FOPS). ROPS meets ISO 3471:1994 FOPS meets ISO 3449:1998 Level I FOPS Level II (optional) meets ISO 3449:1998 Level IISoundOperator Sound The operator sound level measured according tothe procedures specified in ISO 6396 is 89 dB(A).Exterior Sound The labeled spectator sound power level measuredaccording to the test procedures <strong>and</strong> conditions specifiedin 2000/14/EC is 104 dB(A).12<strong>216B</strong> <strong>and</strong> <strong>226B</strong> <strong>Skid</strong> <strong>Steer</strong> Loader specifications

DimensionsDimensions shown are based on st<strong>and</strong>ard machine equipped with optional 10 x 16.5 6 PR tires <strong>and</strong> 1525 mm dirt bucket.The specification for the <strong>216B</strong> <strong>and</strong> <strong>226B</strong> <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong> are static <strong>and</strong> conform to ISO 5998:1986.All dimensions are approximate.198135 15176418914111071612132mmmm1 Wheelbase2 Length with bucket on ground3 Length without bucket4 Height to top of cab5 Max overall height6 Hinge pin height at max lift7 Hinge pin height at carry position8 Reach at max lift <strong>and</strong> dump9 Clearance at max lift <strong>and</strong> dump98632332519195037092854239505216910 Ground clearance11 Departure angle12 Bumper overhang behind rear axle13 Maximum dump angle14 Maximum width over tiresTurning radius from center15 left16 right17 full18 Reach with level arms <strong>and</strong> bucket19 Rack back angle at max height19526°96740°1525148511991940128097°Service Refill CapacitiesLitersChain box, each side 6Cooling system 10Engine crankcase 8Fuel tank 65Hydraulic system 55Hydraulic tank 35<strong>216B</strong> <strong>and</strong> <strong>226B</strong> <strong>Skid</strong> <strong>Steer</strong> Loader specifications13

St<strong>and</strong>ard EquipmentSt<strong>and</strong>ard equipment may vary. Consult your Caterpillar dealer for specifics.Air cleaner, dual element, radial sealAlternator<strong>216B</strong>: 65-amp<strong>226B</strong>: 85-ampArmrest, pull downBattery, 12-volt, 850 CCABrake, parking, SAHRCleanout, belly panControls, pilot-operated, hydraulicCoupler, mechanical, quickEcology drains: engine, hydraulic oil<strong>and</strong> coolantElectric Socket, 12-voltEngine, diesel:<strong>216B</strong>: Cat 3024C naturally-aspirated<strong>226B</strong>: Cat 3024C T turbochargedFalling Object Protective Structure, Level IFan, hydraulically-drivenFilterfuel, bayonet-typehydraulic, spin-on, 4 micronFuel/water separator, spin-onHydraulics, auxiliary, front, ON/OFFHydraulics, continuous flowInstrumentation:Audible:– engine coolant temperature– engine oil pressure– hydraulic oil temperatureGauges:– fuel level– hour meter, digitalIndicators:– air filter restriction– alternator output– armrest raised/operator out of seat– engine coolant temperature– engine oil pressure– hydraulic filter restriction– hydraulic oil temperature– parking brake engagedMufflerPrecleaner, self-unloadingPump, hydraulic implementPump, hystat charge <strong>and</strong> hydraulic fanRear view mirror, internalSafety control interlock systemScheduled Oil Sampling (S•O•S) valvesSeat, staticSeat belt, retractable, 50 mmSight gauge, coolant <strong>and</strong> hydraulic oilStarting aid, glow plugsSupport, lift armSwitch, ignitionTail lightsThrottle controls, h<strong>and</strong> <strong>and</strong> footTie-downs, front <strong>and</strong> rearValve, hydraulic, three-sectionWindows, top <strong>and</strong> rearLow Side Wall.The Cat LSW offers exceptionalpuncture resistance <strong>and</strong> run-flatcapability. Ideal for generalconstruction <strong>and</strong> heavy-dutyapplications.Premium Conventional.The Cat Premium Conventionaltyre are equipped with the industry’sdeepest tread depth, thickestsidewall <strong>and</strong> heaviest rim guard.Provides optimum performance ina variety of applications.14 <strong>216B</strong> <strong>and</strong> <strong>226B</strong> <strong>Skid</strong> <strong>Steer</strong> Loader specifications

Optional EquipmentOptional equipment may vary. Consult your Caterpillar dealer for specificsAir conditioning with heater/defrost (<strong>226B</strong> only)Alarm, back upBattery, 12-volt, 880 CCAControl, work tool, electricalCounterweight, adds 45 kg to ROCCoupler, hydraulicCup holderDebris barrier for cabDoor, frontlaminated glass with wiper/washerpolycarbonate with wiper/washer, for demolition useFalling Object Protective Structure, Level II,attaches to existing FOPSFloor matHeadlinerHeater/Defrost, cabHeater, engine coolantHornHydraulics, auxiliary, front, proportionalHydraulics, auxiliary, front, proportional,High Flow (<strong>226B</strong> only)Hydraulics, self leveling, liftLifting provisions:– four-point, or– single-pointLights, front <strong>and</strong> rear, workingLight, warning beaconMachine Security System (MSS)Seat, suspensionSeat belt, 76 mmfor static seatfor suspension seatSynthetic hydraulic oil for cold weather operationWindows, side, sliding, removableTires:7 x 15 6 PR 1372 mm (54 in) Caterpillar (<strong>216B</strong> only)10 x 16.5 8 PR 1524 mm (60 in)Caterpillar Premium Conventional*265-521 8 PR 1524 mm (60 in) Caterpillar Low Side Wall*10 x 16.5 6 PR 1524 mm (60 in) GY SGL10 x 16.5 8 PR 1524 mm (60 in) GY IT323*10 x 16.5 8 PR 1524 mm (60 in) GALAXY*10 x 16.5 10 PR 1524 mm (60 in) MICHELIN10 x 16.5 8 PR 1676 mm (66 in)Caterpillar Premium Conventional*265-521 8 PR 1676 mm (66 in) Caterpillar Low Side Wall*10 x 16.5 6 PR 1676 mm (66 in) GY SGL10 x 16.5 8 PR 1676 mm (66 in) GY IT32310 x 16.5 8 PR 1676 mm (66 in) GALAXY10 x 16.5 10 PR 1676 mm (66 in) MICHELIN* Denotes spare tire option available with supplement.Premium ConventionalFlotation.The Cat PremiumConventional Flotationtyre is most efficient onsoft terrain.Extreme Duty Solid.The Cat Solid tyre performs onthe toughest applications.Profitability is improved throughthe elimination of downtime <strong>and</strong>repair costs. Ideal for foundary<strong>and</strong> demolition job-sites.<strong>216B</strong> <strong>and</strong> <strong>226B</strong> <strong>Skid</strong> <strong>Steer</strong> Loader specifications15

<strong>216B</strong> <strong>and</strong> <strong>226B</strong> <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong>HEHL3004 (12/2003) hrMaterials <strong>and</strong> specifications are subject to change without notice.Featured machines may include additional equipment.See your Caterpillar dealer for available options.www.CAT.com© 2004 Caterpillar®