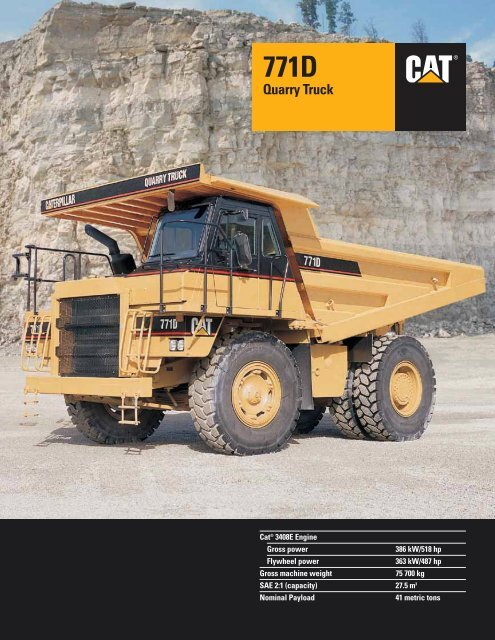

771D Quarry Truck

771D Quarry Truck

771D Quarry Truck

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>771D</strong><strong>Quarry</strong> <strong>Truck</strong>®Cat ® 3408E EngineGross power386 kW/518 hpFlywheel power363 kW/487 hpGross machine weight75 700 kgSAE 2:1 (capacity) 27.5 m 3Nominal Payload41 metric tons

<strong>771D</strong> <strong>Quarry</strong> <strong>Truck</strong>Engineered for performance, designed for comfort and built to last.Power Train – EngineThe power train features the Caterpillar ®3408E Diesel engine and AdvancedModular Cooling System for efficientoperation. pg. 4<strong>Truck</strong> Body – Flat FloorThe flat floor body incorporates boxbeam and full-length stringer design forextended life. The flat floor body designhelps quarry trucks achieve ratedpayload and provides an optimummatch with Caterpillar Loaders. pg. 11Power Train – TransmissionThe Cat ® 6-speed, power shifttransmission, matched with the directinjection3408E diesel engine providesconstant power over a wide range ofoperating speeds. pg. 6Operator StationControls and gauges are positioned tomaximize productivity and comfort.The cab includes air suspension seatand advanced electronic monitoringsystem. Adjustable telescoping steeringcolumn, electric wipers, window andbody controls reduce operator effortand simplify control. pg. 12Engine/Power Train IntegrationThe Caterpillar Data Link Systemelectronically combines engine,transmission, brake and operationalinformation to optimize overalltruck performance. The ElectronicTechnician (ET) accesses storeddiagnostic data, significantlyreducing downtime. pg. 7Top Performance.The <strong>771D</strong> is designed for high productionand low cost-per-ton hauling in quarry applications.Reliable, durable operationRugged construction and easy maintenancecan help extend life with low operating costs.2

Oil-Cooled, Rear Disc BrakesCaterpillar oil-cooled, multiple discbrakes offer exceptional, fade-resistantbraking and retarding. pg. 8Integrated Braking Control (IBC)IBC integrates the optional AutomaticRetarder Control and Traction ControlSystem (TCS) into one system toenhance truck performance andproductivity and improve operatorconfidence. pg. 9StructuresCaterpillar truck frames are built forsevere applications. Mild steel providesflexibility, durability and resistance toimpact loads. Castings and forgings inhigh stress areas of the frame providegreat structural strength. pg. 10✔Serviceability/Total Customer SupportEasy serviceability access, QuickEvac TMsystem, on- and off-board diagnostics,machine management service,worldwide parts availability andliterature support represents theCaterpillar commitment to customersupport. pg. 14Systems/ApplicationsNumerous options and a systemapproach to match the <strong>771D</strong> to themost appropriate loader meets customerneeds for various applications. pg. 16✔ New feature3

Power Train – EngineThe eight cylinder, turbocharged and air-to-air aftercooled HEUI TM engine is built for power,reliability and economy with reduced sound levels and low emissions.2345671891011Engine.1 Turbocharger2 Electronic Control Module (ECM)3 Valve Rotators4 Stellite-Faced Valves5 Steel-Backed, Copper-BondedBearings6 Oil Cooler7 Forged Crankshaft8 Adjustment-Free Fuel InjectionPump9 Hydraulic Electronic Unit Injectors10 Forged Steel Pistons11 Full-Length, Water-Cooled CylinderLinersCat 3408E Diesel Engine. The fourstrokedesign uses long power strokesfor more complete fuel combustion andoptimum efficiency. Large displacementand a low speed rating can helpextend engine life. This engine meetsU.S. Environmental Protection AgencyTier II emissions regulations and Stage IIEU Emissions Directive 97/68/EC.Torque Rise. The 27 percent torquerise provides high lugging force duringacceleration on grade or in high rimpullconditions. The torque rise effectivelymatches the transmission shift points toprovide maximum efficiency and fastercycle times.Engine Features. Contributing to the3408E power and reliability are:■ High pressure injection.■ Full electronic control■ One piece forged steel pistons withthree rings cooled by oil spray.■ Copper-bonded crankshaft bearings■ Hardened crankshaft journals.■ Dry-type radial seal air cleaners withprimary and secondary elements andprecleaner.■ Direct-electric, 24-volt startingsystem with 50-amp alternator andfour 172-amp-hour, low maintenance,high output, 12-volt batteries.Hydraulic Electronic Unit Injector(HEUI TM ). The HEUI is a proven highpressure,direct injection fuel system.This system electronically monitorsoperator and machine inputs to optimizeengine performance. HEUI is unique inits ability to independently controlinjection pressure over the entire engineoperating range. This allows completecontrol over injection timing, duration,performance and efficiency. Rateshaping technology modifies the heatrelease characteristics of thecombustion process for significantdecreases in sound and emission levels.Exhaust smoke is significantly reducedthrough precise, electronic control offueling limits and injection timing ofthe HEUI.4

Electronic Control Module (ECM).The ECM monitors key functions andlogs critical indicators. The ElectronicTechnician can access this diagnosticinformation for easier maintenanceand repair.Advanced Modular Cooling System(AMOCS). Is a Caterpillar exclusivetechnology which improves serviceabilityand reduces downtime. It utilizes anexclusive two pass cooling systemand increased cooling surface area toprovide significantly more coolingcapacity than conventional systems.System Operation. The two pass systemcirculates coolant from the sectionedbottom tank up through one side of thecooling element and down through theother side returning it to the bottom tank.AMOCS Design. The cooling elementsare individual core modules, with brasstube construction within each core, thatare connected to a sectioned bottomtank. There is no top tank to remove.Each core module can be replacedindividually (without removing theentire radiator), saving considerablecost and repair time. And with ninesteel fins per inch, fin bendingresistance is improved.5

Power Train – TransmissionThe Cat 6-speed, power shift transmission gets the job done smoothly and quickly.■ Economy shift mode. gears match Cat engine design for1324Transmission. The Cat 6-speed,power shift transmission, matchedwith the direct-injection 3408E dieselengine provides constant power over1 Lock-up Torque Converter. Combinesthe maximum rimpull and cushionedshifting of torque converter drivewith the efficiency and performanceAxles. Full floating axles are shotpeenedto relieve internal stresses andincrease durability. Rolled splines alsoprovide increased service life.a wide range of operating speeds. of direct drive.Wheels and Rims. Cast rear wheels■ Engages at approximately 6.9 km/h,Transmission Features.and Cat center-mount rims aredelivering more power to the wheels.■ 6 speeds forward, one reverse.mounted using studs and nuts to■■Lock-up clutch quickly releases andTorque converter driven reverse.minimize maintenance and maximizere-engages during shifts, maintaining■ 1st gear has both torque converterdurability.power wind-up, improvingdrive and direct drive.transmission life and increasingTransmission Chassis Controller■ 2nd through 6th gears are directoperator comfort.(TCC). TCC uses electronicallydrive.transferred engine rpm data to execute■ Single-lever shift control provides 2 Planetary Power Shift Transmission.shifts at preset points for optimumautomatic shifting in all gears up to Utilizes a modulating pressure valve toperformance and efficiency.the one selected by the control lever. regulate clutch pressure rise and fall toThis integration allows:■ Each shift is individually modulated ease clutch engagement. This reduces■ Programmable top gear limit.for maximum smoothness.shock loads on power train components.■■Control throttle shifting.Separate hydraulic circuit withFeatures include:■■Directional shift management.cooler.Large diameter clutches and robust■■Neutral coast inhibitor.Electronic control has built-inplanetary gears and bearings.■■Economy shift mode.diagnostics and fault code memory, Patented rotating clutch pressure sealsevent memory and programmablefeatures.minimize drag losses and improvereliability.Integration. The Caterpillar powertrain integration provides increased■ Control throttle shifting.■ 35 percent gear splits between all component life and operator comfort.optimum use of engine power withminimized shifting and torqueconverter use.3 Final Drive. Final drive and differentialtorque multiplication of 13.15:1 furtherreduces stress on the drive train.4 Sump. Transmission and torqueconverter share a common sump.The combined sump offers an easilyaccessible fill tube and sight gauges.6

Engine/Power Train IntegrationCombining the electronic Engine Control Module (ECM) with the Caterpillar TransmissionChassis Controller (TCC) allows critical power train components to work more intelligently.Integration.1 Electronic Technician2 Cat Data Link System3 Engine Control Module174 Engine5 Transmission Chassis Control6 Automatic Retarder Control,Traction Control System andIntegrated Brake Controller7 Caterpillar ElectronicMonitoring System8 Transmission234 56899 Oil-cooled BrakesCat Data Link. The Cat Data Linkelectronically integrates the machine’scomputer systems, which allowscommunications and provides thefollowing benefits:■ Controlled Throttle Shifting. Enginerpm is regulated during a shift toreduce driveline stress for smoothershifts and longer component life.■ Economy Shift Mode. Modifiesengine maps, resulting in improvedfuel consumption.■ Directional Shift Management.Regulates engine speed duringdirectional shifts to prevent damagecaused by high speed directionalchanges.Elevated Idle Neutral Coast Inhibitor.Helps prevent the transmission fromshifting to neutral at speeds above6.5 km/h.Body-up Shift Inhibitor. Helps preventthe transmission from shifting above apre-programmed gear without the bodyfully lowered.Event Memory. Records machine managementdata that can be accessed using the ElectronicTechnician. Recorded information includes:■ Shift histograms.■ Operator-induced events.■ Lock-up clutch counter.■ Machine overspeed.■ Transmission overspeed.Electronic Technician (ET). The electronicengine and transmission controls provideexhaustive diagnostic capability for servicetechnicians. The ability to store both activeand intermittent indicators will simplifyproblem diagnosis and total repair time,resulting in improved mechanical availabilityand lower operating cost.■ ET accesses data stored in the engineand transmission controls via the CatData Link System.■ ET displays the status of all engineparameters including throttle position,timing and fuel flow.■ ET replaces 13 mechanical tools toperform functions like cylinder cutoutchecks, injector solenoid tests and timingcalibration.Caterpillar Electronic MonitoringSystem (CEMS). CEMS allows theoperator to view requestedinformation and utilizes a threecategorywarning system to alert theoperator to abnormal machineconditions.Optional Attachments. Caterpillaroffers optional attachments thatintegrate with the Cat Data LinkSystem.■ Automatic Retarder Control (ARC).Works with other electroniccomponents to automatically controlretarding on grade, maintainingapproximately 2,230 rpm.■ Traction Control System (TCS).Improves performance in poorunderfoot conditions byelectronically monitoring andcontrolling wheel slippage.■ Integrated Brake Controller (IBC).Combines ARC and TCS, reducingthe number of electroniccomponents and electrical lines.7

Oil-Cooled, Rear Disc BrakesRear braking lets the operator concentrate on the haul road.21Brakes.1 Parking/Secondary Piston2 Service/Retarding Piston3 Friction Discs4 Steel Plates5 Actuating Springs6 Cooling Oil In7 Cooling Oil Out37456Multiple Disc Brakes. Caterpillar forcedoil-cooled, multiple disc brakes arecontinuously cooled for exceptional,fade-resistant braking and retarding.The optional ARC and TCS utilize theoil-cooled rear brakes to enhance truckperformance and increase productivity.Oil Cooled Disc Brakes. Are designedand built for reliable, adjustment-freeoperation providing superiorperformance and service life incomparison to shoe-type and dry-discsystems.Oil Film. An oil film prevents directcontact between the discs. Absorbingthe braking forces by shearing oil andcarrying heat away, this design extendsbrake life.Secondary Braking. Spring applied,hydraulically released, oil-cooled discbrakes are located on the rear axle.The front brakes will activate as partof the secondary system, even ifswitched out of service.Parking Brakes. Spring applied,hydraulically released parking brakesuse wet disc brakes in service system.A toggle switch activates theparking brakes.Pistons. A Caterpillar patented, twopistondesign combines the service,secondary and parking brakes, alongwith retarding functions.The primary piston hydraulicallyactuates both service and retardingfunctions. The secondary piston isspring-applied and held in thedisengaged position by hydraulicpressure. If hydraulic system pressuredrops below a certain level, the springappliedsecondary piston automaticallyapplies the brakes.8

Integrated Braking Control (IBC)Electronically combines Automatic Retarding Control (ARC) and the Traction ControlSystem (TCS) into one integrated control system.ARC Operating Efficiency AdvantagesEngine Speed (rpm)*01020 30 40 50 60Time (Seconds)Automatic Retarder Control(Maintains Engine rpm between 2160-2300)Manual Retarder Control(Wide Variation in Engine rpm)* Optimum Engine rpmCat Retarding System. When retarding,the engine runs against compression ondownhill hauls, resulting in no fuel burn.Retarding forces and heat are absorbedthrough the oil. The retarding systemgenerates lower drive line stresses thandrive line retarding systems.70Automatic Retarder Control (Optional).The ARC electronically controls brakingon grade to maintain approximately2230 engine rpm (engine rpm isadjustable from 2160-2300 rpmin increments of 10 rpm). ARC isdeactivated when the operator appliesthe brakes or throttle.Engine Overspeed Protection. With theaccelerator depressed and/or ARCturned off, ARC will automaticallyactivate at 2475 rpm to help avoidpotentially destructive and often costlyengine overspeeds.ARC Benefits.■ Increased operating efficiency withfaster downhill speeds. Bymaintaining consistently higherengine speeds, average truck speedwill be higher than a manuallycontrolled truck.■ Excellent controllability and reducedoperator effort. Automatic brakemodulation provides a smoother rideover manual modulation, allowingthe operator to focus more on truckoperation down the haul road.■ Improved component life, optimizedsystem cooling capability andreduced torque fluctuations resultfrom ARC’s precision.■ Faster troubleshooting and diagnosiswith self-diagnostic capability andthe ability to communicate with ETthrough the Cat Data Link System.■ Operator awareness throughelectronic integration and CEMS,alerting the operator to overspeedconditions and critical machinefunctions.Traction Control System (Optional).Monitors wheel slip so if it exceedsthe set limit, the oil-cooled disc brakesare automatically applied to slow thespinning wheel.Operator Awareness. An on-dashindicator shows the operator that TCSis engaged.Differential Action. Utilizes normaldifferential action to provide superiormaneuvering in poor underfootconditions. Also reduces tire scuffing ascompared to positive lock differentialsused on other systems.Torque. TCS divides torque equallyto reduce stress created on final drivesand axles when torque is transferredto one side.System Back-up. Should sensors fail,the normal differential action is stillavailable to maintain control andsteering.9

StructuresThe backbone of the Cat <strong>Quarry</strong> <strong>Truck</strong>.Box-Section Design. The <strong>771D</strong>frame uses a box section design,incorporating 17 castings in highstress areas with deep penetratingand continuous wrap-aroundwelding. Mild steel, which providesflexibility, durability and resistanceto impact loads even in cold climatesis used throughout.Castings. Castings have large radiiwith internal reinforcing ribs todissipate stress. Castings move weldsto lower stress areas and provide twoto three times the strength ofequivalent sized fabricatedstructures.Frame Features.■ Integral front bumper.■ Front box beams for suspensioncylinder and ROPS support.■ Box-section rear crossmember forbody and ROPS support withattachment points for maintenanceplatform and rear engine hoodhinge support.■ Castings are used to provideadditional strength in critical stressareas.■ Mild steel plates (290 MPaminimum yield strength) andcastings (241 MPa minimum yieldstrength) provide flexibility,durability and easy fieldmaintenance.Frame Serviceability. The box-section frameallows simple access to power traincomponents. This open design reduces overallremoval and installation time, lowering repaircosts. Transmission access is excellent underthe raised and pinned body. Repairs can bemade without preheating in ambienttemperatures 16°C using readily availablewelding supplies.Rollover Protection Structure (ROPS).The ROPS attaches securely to four castingswelded into the frame.Suspension System. Designed to dissipatehaul road and loading impacts for extendedframe life. Four, independent, self-contained,oil pneumatic, variable-rebound, suspensioncylinders absorb shocks. Rear cylinders allowaxle oscillation and absorb the bending andtwisting stresses. Front cylinders, mountedto the frame, serve as steering kingpins,providing excellent maneuverability andreduced maintenance. Caster and camberare preset.10

<strong>Truck</strong> Body – Flat FloorCaterpillar offers excellent wear characteristics in a flat floor design.Design. <strong>771D</strong> bodies are designed tohandle a variety of material densities.Maximum payload is reached in threeto five passes from a matched Cat loaderin 1620 kg/m 3 material and higher.Sidewall and Floor Junctions. Are joinedby five-sided beams to resist impactloading and sustained hauling stresses.Box-Section Beams. Offer increaseddurability in the floor, sidewalls, top rail,corner and cab canopy areas.Hardox 400 Steel. Wear surfaces provideexcellent wear resistance and are easilywelded without preheating procedures.Two-Stage Hoist Cylinders. Providefast dump cycle times of 7.5 secondsfor Raise and 8.3 seconds for Lower.Standard Body. Comes exhaust heatedwith options including a full-timemuffler or exhaust diverter.Body Floor Construction. Uses a12 degree single slope, offeringexcellent wear characteristics anduniform dumping into hoppers,crushers and feeders.Flat Floor <strong>Quarry</strong> Body. Offersexcellent load retention on grades upto 12 percent and on smoother haulroad conditions.11

Operator StationControl ease and comfort maximizes productivity.15653101713114128142912

<strong>771D</strong> Operator Station. Rated highlyby operators. Everything needed fortop performance is at the operator’sfingertips.1 Wraparound Dash Panel. Offers aneasy line-of-sight arrangement, usingLED backlit rocker switches.2 Caterpillar Contour Series AirSuspension Seat. Standard and fullyadjustable, including an adjustableright-hand armrest.3 Tilt/Telescoping Steering Wheel.With ergonomic grip improvescomfort and control. Low effortsteering system and ergonomicallydesigned retarder lever reducesoperator fatigue. Also includes anenhanced turn signal lever with highbeam actuator and electric windshieldwiper controls.4 Transmission Console. Has LEDbacklit gear numbers and ergonomicshift knob.5 Visibility. Exceptional all-aroundviewing area reduces fatigue andimproves productivity.6 Integral, Sound-SuppressedROPS/FOPS Cab. Is resilientlymounted providing a quiet,protected work environment.Radio-Ready. The cab is radio-readywith speakers, wiring harness,antenna and mounting bracket.7 Front Brake Cut-Out Switch.Increases front brake componentlife.8 Large Storage Compartment. 0.10 m 3of space is located under thetrainer’s seat.9 Trainer’s Seat. Includes back restand retractable seat belt.10 Caterpillar Electronic MonitoringSystem (CEMS). Provides criticaldata. The system features threeseparate displays:■ Four-gauge cluster with coolanttemperature, oil temperature,brake air pressure, fuel level.■ Tachometer, digital speedometer/actual gear indicator.■ Message center module.11 Standard Heater and Optional AirConditioner. Includes four-speed fanand nine vents.12 Foot Pedals. Ergonomicallydesigned for increased operatorcomfort.13 Electric Power Window.For simplified operation.15 <strong>Truck</strong> Production ManagementSystem (TPMS) (Optional).Provides payload and cycletime data.■ Cat developed technology utilizesstrut pressure sensors and anon-board microprocessor todetermine payload weight.■ Accurate under normal loadingto within ± five percent over anormal operating shift.■ Delivers consistent accuratepayloads and improves efficiencyby minimizing overloading andunderloading.– On-board computer stores1400 cycles for further analysisof payload weight, cyclesegment times, cycle segmentdistances and actual clock timeand date of each cycle.– External lights signal loadingtool operator when payload isreached.– Internal troubleshooting andfault recording for easiermaintenance.14 Electrohydraulic Hoist Lever.Is fingertip actuated and provideslow impact body-down snubbing.13

Serviceability/Total Customer SupportPurchase of a Caterpillar machine includes a total commitment to customer support.2131 QuickEvac Check Valve2 Oil Flow3 QuickEvac Bracket4 QuickEvac/Prelube motor5 QuickEvac Service Tool Assembly(available separately)6 To Waste Oil Drain7 Line to Oil Filter74652Cat QuickEvac TM System.An exclusive Caterpillar on-board engineoil evacuation and prelubrication system.Automated Engine Oil Change.A new, state of the art on-board systemevacuates engine sump in less than oneminute and allows for purge of oilfilters prior to removal, minimizing oilspills. It delivers new oil throughprimary filters for filtered protectionand ensures new filters are correctlyfilled following routine oil change.Contamination Control.Environmentally efficient, clean oilchanges are ensured since engine sumpis evacuated directly into PM trucks orwaste containers with flush faced, quickdisconnects for fast evacuation and fill.This eliminates handling of waste oil,minimizes chances of oil spillage andenhances Contamination Control effortsby ensuring complete filtration of newoil on engine refill.Complete Engine Prelubrication.Provides engine oil pressure prior toengine cranking. Reduces engine drystart wear and risk of cold starts forincreased protection of key enginecomponents. Also provides expandedlow temperature range for 15W40motor oils.Improved Serviceability and MachineAvailability. Reduces time to completeengine service (changing engine oil, oilfilters, fuel filter, air cleaner) by asmuch as 30 to 50 percent. Improves theability to schedule engine services atprescribed hours, allows for servicingduring normal working hours andintegrates easily with PM trucks tofurther reduce total cycle time of engineservice.Machine Platform. Provides access toair tanks, brake master cylinder andmake-up tank; engine oil level; airfilters; steering hydraulic tank; andbattery compartment.14

Ground Level Battery DisconnectSwitch. Facilitates safe, convenientservicing and maintenance.On-Board Diagnostics. With CEMS,provides the machine operator witha three-category warning system andquick access to stored diagnostic data.Off-Board Diagnostics. With ET, allowsservice technicians access to storeddiagnostics data reducing downtimeand lowering operating costs. ET storesengine parameter information such astiming, throttle position and fuel flow.Transmission data is available throughET via access to the Cat Data LinkSystem.Radial Seal Filters. Are easy to change,reducing air filter maintenance times.Vertical, Spin-on Oil Filters. Provide forsimplified servicing.Quick Coupler Pressure Taps. Locatedin all hydraulic systems provide clear,quick pressure checks. S•O•S SM oilanalysis points make oil samplingquick, clean and easy.Sealed Electrical Connectors. Lockoutdust and moisture. Color-coded wiringis standard for the entire Cat productline.Machine Management Service.Cat Dealers help manage equipmentinvestments with:■ Vehicle systems analysis to helpmatch the right machine to the job.■ Preventative maintenance programs.■ S·O·S oil analysis and technicalanalysis programs.■ Repair option analysis.■ Training for operators and mechanics.■ TPMS data analysis.Parts Availability. The Caterpillarworldwide computer network locatesparts instantly to minimize machinedowntime.Literature Support. Caterpillar manualsare easy to use and help provide the fullvalue of an equipment investment.15

Systems/ApplicationsThe <strong>771D</strong> is designed for versatility.Machine Configuration Options.System Approach. The CaterpillarCaterpillar offers a variety of machine system approach means increasedconfiguration options to help meet efficiencies through common design.customer needs.Haul trucks, loaders, excavators,tractors, engines for generator sets andBody Options. Include a full line ofpumps – all designed by Caterpillar –standard and custom designs based onuse common components, parts andspecific customer preference, materialdesign. Commonality reduces customerdensity, loading tool and site conditions.parts stock, improves parts availability,Tire Options. A full line of tire options, reduces training/maintenance andrepresenting various manufacturers, is improves diagnostics. This systemoffered by Caterpillar to maximize approach adds up to lower cost-per-ton.performance and life for specific Dealer support is available to addressapplications.customer needs regardless of thecomponent.Attachments. Give the customer optionsto tailor trucks for specific applicationrequirements, including:■ <strong>Truck</strong> Production ManagementSystem.■ Automatic Retarder Control.■ Traction Control System.■ Custom product offerings.■ Muffler/exhaust diverter.Caterpillar Product Analysis Team(PAT). Combined with Caterpillarsoftware programs can assist customerswith detailed, application evaluation.Loader Match. Designed to work as partof a system, the <strong>771D</strong> is best matched tothe following Caterpillar loaders:■ 980G – 5 pass/match.■ 988G – 4 pass/match.■ 5080/5090B – 5 pass/match.■ 375/385B ME – 4 to 5 pass/match.16

EngineBrakesBody HoistsCat 3408EGross Power 386 kW/518 hpFlywheel Power 363 kW/487 hpNet PowerISO 9249363 kW/487 hpEEC 80/1269 363 kW/487 hpMax. Torque2186 NmTorque rise 27%Bore137 mmStroke152 mmDisplacement18 Liters■■■■■These ratings apply at 2000 rpmwhen tested under the specifiedstandard conditions for the specifiedstandard.Net power advertised is the poweravailable at the flywheel when theengine is equipped with fan, aircleaner, muffler and alternator.No derating required up to 3050 maltitude.Complies with U.S. EnvironmentalProtection Agency Tier II emissionsregulations.Complies with Stage II EU EmissionsDirective 97/68/EC.Brake surfacefront 1395 cm 2rear 54 999 cm 2■ Brakes meet ISO 3450:1996standards up to 75 700 kg grossoperating weight.■ Retarding system continuous rating433 kW intermittent rating 895 kW.Final DrivesPlanetary, full-floating.RatioDifferential 2.74:1Planetary 4.80:1Total reduction 13.15:1Pump flowhigh idleRelief valve settingraiselowerBody raise timehigh idleBody lower time floatBody power downhigh idle■■417 L/min17 225 kPa3445 kPa7.5 Seconds8.3 Seconds8.3 SecondsTwin, two-stage, hydraulic cylindersmounted inside the main frame,double acting in second stage.Power raise in both stages and powerdown in second stage.SuspensionEffective cylinder strokefront234 mmrear149 mmRear axle oscillation ±8.5°Service Refill CapacitiesLitersFuel Tank 530Cooling System 113.5Crankcase 45Differentials and final drives 83SteeringTank 34System (includes tank) 56Brake/HoistHydraulic tank 133System (includes tank) 277Torque converter/transmissionSump 53System (includes sump) 72TransmissionMaximum travel speeds(standard 18.00-R33).Forwardkm/h1 12.62 17.23 23.34 31.45 42.56 57.3Reverse 16.6SteeringMeets ISO 5010-1992■ Turning diameter per ISO 7457-1997is 17 m.■ Machine clearance diameter perISO 7457-1997 (E) is 20.3 m.■ Steering angle (left or right) is39 degrees.■ Separate hydraulic system preventscross contamination.■ Steering wheel effort is low and cycletimes are reduced with dynamic, loadsensing, variable displacement pistontypesteering pump.<strong>771D</strong> <strong>Quarry</strong> <strong>Truck</strong> specifications17

Flat FloorApproximate Weights.Gross vehicle75 700 kgChassis23 000 kgBody10 350 kgFront axleempty 46.3%loaded 32.9%Rear axleempty 53.7%loaded 67.1%Capacity – 100% fill factorStruck 20.2 m 3Heaped 3:1 25.1 m 3Heaped 2:1 (SAE) 27.5 m 3Heaped 1:1 34.3 m 3 ROPSROPS meets ISO 3741:1994Rollover Protective Structure (ROPS)is offered by Caterpillar as standardequipment.SoundExterior SoundWhen the optional attachment soundsuppression package is properlyinstalled and maintained, this machinecomplies with the European Directivefor Equipment Used Outdoors –2000/14/EC.Operator SoundThe operator sound pressure levelmeasured according to the proceduresspecified in ISO 6394:1998 is less than74 dB(A) for the cab offered byCaterpillar when properly installed,maintained and tested with doors andwindows closed.TiresStandard: 18.00-R33 (E4)WeightsOperating Specifications■■Productive capabilities of the <strong>771D</strong>are such that, under certain jobconditions, Tkm/h capabilities ofstandard or optional tires could beexceeded and, therefore, limitproduction.Caterpillar recommends the userevaluate all job conditions andconsult the tire manufacturer to makeproper tire selection.Gross Machine Weight75 700 kgSAE (2:1) Capacity 27.5 m 3Nominal Payload Capacity 41 tonnes18 <strong>771D</strong> <strong>Quarry</strong> <strong>Truck</strong> specifications

DimensionsAll dimensions are approximate.emptyloadedemptyemptyemptyloaded1 7628 mm2 1527 mm3 5519 mm4 7735 mm5 3398 mm6 464 mm7 364 mm8 2541 mm9 4018 mm10 3943 mmemptyloadedemptyWeights/Payload CalculationFlat FloorkgEmpty Chassis Weight 23 000Fuel Correction 400Optional Attachments WeightDebris Allowance (4% of chassis) +920Chassis Weight 24 320* Operating width to r.h. mirrorBody Weight 10 430Body Attachments Weight +0Total Empty Operating Weight 34 750Target Payload +40 950Gross Machine Operating Weight 75 700<strong>771D</strong> <strong>Quarry</strong> <strong>Truck</strong> specifications19

Retarding PerformanceThe brake performance retarding curves shown in this sectionare for general guidance only. As each site has many uniqueenvironmental and operating conditions that will impactretarding performance, actual site performance could varyconsiderably from predicted performance. Users should usethe retarding speed (gear) recommendations from these tablesas a starting point for determining retarding performance andthen adjust retarding speeds to their site-specific conditions.In adjusting retarding performance to continuously changingenvironmental and site-specific conditions, users need toexercise care to maintain brake cooling and machinecontrollability at all times.To determine brake retarding performance fromretarding tables:1. Determine the total distance of all downhill gradescombined for a given haul profile. This total distancedetermines the appropriate retarding table (continuousor one of the grade distance tables) applicable to yourhaul profile.2. Read from the appropriate gross weight down to percentfavorable effective grade. (For these retarding charts,effective grade equals the maximum grade of all downhillhaul segments minus rolling resistance – do not use anaverage grade value.)E – Empty WeightL – Gross Machine Weight – 75 700 kgGross Weight1 – 1st Gear2 – 2nd Gear3 – 3rd Gear4 – 4th Gear5 – 5th Gear6 – 6th Gear0 10 20 30 40 50 60 70 80 kg x 100030% 25%20%EL115%2310%Effective Grade (Favorable)45%560 10 20 30 40 50 60 70 80 km/hSpeedContinuous Grade Length20 <strong>771D</strong> <strong>Quarry</strong> <strong>Truck</strong> specifications

3. From the intersection of the gross weight and effectivegrade line point, read horizontally to the appropriate gearcurve. the horizontal line intersects two gear curves, choosethe first gear curve that the horizontal line intersects(reading from right to left) and read the retarding speedperformance immediately below this point. If theintersection point falls on a vertical line between two gears,choose the lowest of the two gears to allow for higherengine rpm thus maximizing brake cooling capability.4. Adjust recommended retarding speeds to site specific(environmental and operational) conditions. If the brakesystem overheats or specific site conditions dictate(tight turns, short steep grades, manual braking, etc.),reduce ground speed to allow the transmission to shiftto the next lower speed range.Gross Weight0 10 20 30 40 50 60 70 80 kg x 100030%125%20%Gross Weight0 10 20 30 40 50 60 70 80 kg x 100030%25%120%2345615%10%5%Effective Grade (Favorable)2345615%0%5%Effective Grade (Favorable)0 10 20 30 40 50 60 70 80 km/hSpeedGrade Distance – 450 m0 10 20 30 40 50 60 70 80 km/hSpeedGrade Distance – 600 mGross Weight0 10 20 30 40 50 60 70 80 kg x 1000Gross Weight0 10 20 30 40 50 60 70 80 kg x 100030%25%20%30%25%20%12345615%10%5%Effective Grade (Favorable)12345615%10%5%Effective Grade (Favorable)0 10 20 30 40 50 60 70 80 km/hSpeedGrade Distance – 900 m0 10 20 30 40 50 60 70 80 km/hSpeedGrade Distance – 1500 m<strong>771D</strong> <strong>Quarry</strong> <strong>Truck</strong> specifications21

Gradeability/Speed/RimpullTo determine gradeability performance:Read from gross weight down to the percentof total resistance. Total resistance equalsactual percent grade plus 1% for each10 kg/metric ton of rolling resistance.From this weight-resistance point, readhorizontally to the curve with the highestobtainable gear, then down to maximumspeed. Usable rimpull will depend upontraction available and weight on drive wheels.E – Empty WeightL – Gross Machine Weight – 75 700 kgGross Weightkg x100028240 10 20 30 40 50 60 70 80 90 100 kg x 100030%EL25%Rimpull201612841Torque Converter Drive1Direct Drive2345620%15%10%5%Effective Grade (Favorable)00 10 20 30 40 50 60 70 80km/h1 – 1st Gear2 – 2nd Gear3 – 3rd Gear4 – 4th Gear5 – 5th Gear6 – 6th GearSpeed22 <strong>771D</strong> <strong>Quarry</strong> <strong>Truck</strong> specifications

Standard EquipmentStandard and optional equipment may vary. Consult a Caterpillar Dealer for specifics.Air horn, electricAir line dryerAlternator, 50-ampAuxiliary jump start receptacleBackup alarmBattery disconnect switch, ground levelBody mounting groupBrakesCaliper disc (front)Oil disc (rear)ParkingSecondaryBrake (front) disconnect switchBrake heat exchangerBrake release motor for towingCab, ROPSCaterpillar Contour Series airsuspension seatCoat hookInsulated and sound-suppressedRadio-readyStorage compartmentSun visorTinted glassCrankcase guardDiagnostic connection port, 24-voltDriveline guardElectrical system, 24-voltElectronic Monitoring SystemFilters, spin-onGaugesActual Gear IndicatorAir pressureBrake oil temperatureCoolant temperatureFuelHour meter, electricOdometerSpeedometerTachometerHeater/defroster 11 070 kCalHoist lever, fingertip-actuatedLighting systemBackup lightDome/courtesy lightHazard and directional signals, LEDHeadlights, halogen, with dimmerStop/tail lights, LEDMirrors, right and leftPower port, 24-voltPrecleanerQuickEvac TM System with PrelubeReservoirs (separate)Brake/hoistSteeringTransmission/torque converterRetarderRock ejectorsSeat belts, retractableSeat, passengerService platform, bolt-onStarting, electricSteering, automatic supplemental,electricSteering wheel, padded, tilt, telescopicTires, 18.00-33, radialTow hooks, frontTow pin, rearTransmission, electronically controlledautomatic power shift withdownshift/reverse shift inhibitor,neutralizer during dumping, neutralstart switch, engine overspeedprotection, directional shiftmanagement, programmable top gear,body-up shift limiter, economy shiftmode and control throttle shiftingVandalism protection locksWindow, electric power (operator)Windshield wipers and washer, electricintermittentOptional EquipmentWith approximate changes in operating weights.Air conditioning 90Automatic lube system 60Automatic Retarder Control (ARC) 6Clustered grease fittings 20Engine coolant heater – 120-volt 3Engine coolant heater – 240-volt 4Ether starting aid 5Exhaust diverter/muffler 75Flexxaire fan 110Fuel heater kit 5kgIntegrated brake control 55Muffler 55Sound suppression package(2000/14/EC compliant) 136Spare rim 330 mm 360Traction Control System (TCS) 50<strong>Truck</strong> Production Management System (TPMS) 45Wheel chocks 25Wiggins fast fuel change 2Wiggins high-speed oil change 1kg<strong>771D</strong> <strong>Quarry</strong> <strong>Truck</strong> specifications23

<strong>771D</strong> <strong>Quarry</strong> <strong>Truck</strong>HEHM5441 (05/2002) hrFeatured photos of machines may not always include standard equipment.See your Caterpillar Dealer for available options.Materials and specifications are subject to change without notice.www.CAT.com© 2002 Caterpillar®