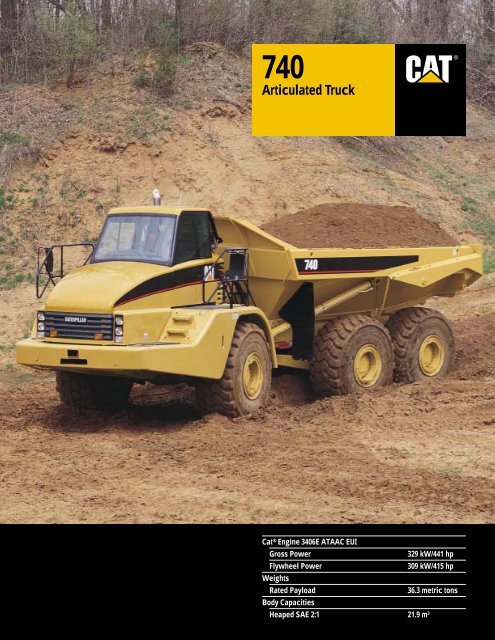

740 Articulated Truck

740 Articulated Truck

740 Articulated Truck

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>740</strong><strong>Articulated</strong> <strong>Truck</strong>®Cat ® Engine 3406E ATAAC EUIGross Power329 kW/441 hpFlywheel Power309 kW/415 hpWeightsRated Payload36.3 metric tonsBody CapacitiesHeaped SAE 2:1 21.9 m 3

Performance and Productivity – PowertrainIntegrated powertrain with more power, greater performance and lower fuel consumption –the power to do more work.3406E Electronic Engine. The electronicversion of this proven engine delivershigher power, durability and completesystem integration of the engine andtransmission for maximum efficiency.High Torque Rise. Provides unequaledlugging force during acceleration, onsteep grades and in tough underfootconditions.Turbocharged and ATAAC. Air-to-airaftercooling provides improved fueleconomy by packing cooler, denser airinto cylinders for more completecombustion of fuel and loweremissions.Electronic Control Module (ECM).Advanced Diesel EngineManagement III (ADEM III) providesimproved emissions, performance,advanced troubleshooting anddiagnostic capabilities.Fuel Efficiency. The electronicallycontrolled, computer actuated unitinjection fuel system has high injectionpressure for complete fuel combustion,greater fuel efficiency and reducedemissions.Controlled Throttle Shifting (CTS).CTS significantly reduces powertrainstress and clutch wear by controllingengine speed, torque converter lock upand transmission clutch engagements.Engine Construction. Since 1974,the 3406 engine has been the benchmarkfor heavy-duty reliability andperformance. The latest electronicversion incorporates major updates tokeep it ahead of the rest. Cylinder headwith overhead camshaft and a pendulumshock absorber improve efficiency andincrease reliability.Electronic Transmission. The sevenspeedelectronic transmission is basedon the proven design of the Cat769 Off-Highway <strong>Truck</strong>. It featuresIndividual Clutch Modulation (ICM)to ensure constant shift times evenwhen the oil is cold.Engine Compression Brake.The standard Jake Brake ® providesextra braking effort on downhill grades.It is an excellent match for the 3406Eengine, turning it into a powerabsorbingair compressor. It has veryfast response time and produces noadditional heat, so it can be usedcontinuously. Four modes of operationprovide an optimum match betweenoperating conditions and retardingpower.4

Performance and ProductivitySuspension systems and traction control – delivering power to the ground in all conditions.Front Suspension. New front suspensionoscillates ±6° to provide a smootherride, allowing the operator to travelfaster over rough terrain and softeningimpact loads on structures andcomponents.Rear Suspension. Features a walkingbeam geometry that provides a stableride for excellent load retention.Traction Control. The traction controlsystem is comprised of a wet clutchedinter-axle differential and wet clutchedcross-axle differentials. All differentialscan be engaged and disengaged on-thegofor maximum versatility. When usedtogether, the differentials provide100 percent driveline locking.Inter-Axle Differential Lock. Modifiestorque distribution to give a fixed 50/50torque split between tractor and trailerfor excellent traction in poor underfootconditions and on grades. It is operatedby a switch in the footrest.Cross-Axle Differential Locks. Providesfull driveline locking – all three axlesand all six wheels – for maximumperformance in the most adverseconditions. Acts in unison with theinter-axle differential lock when thefootswitch is actuated and the dashmountedswitch is selected.Oil-Immersed, Oil-Cooled Brakes.Multi-plate oil-immersed brakes arefitted to both front and center axles.These brakes provide outstandingstopping capability, while maintainingmaximum durability and low wearcharacteristics.Fastest Hoist Cycle Times. Carried overfrom the E Series II, fast body raise andlower times mean less time spent in thedump area.Load-Carrying Capacity. The <strong>740</strong> has alarge target area to provide consistentlyhigh load-carrying capacity.Its diverging flow design gives cleanload ejection, which maximizesproduction and avoids the waste ofmaterial carryback.Service brake detail5

Operator ComfortThe operator’s office – high productivity from a comfortable, motivated operator.Ride Comfort. The new front suspensionwith its oscillating axle and lowpressure ride struts, combined withthe new center-mounted cab, offersunrivaled levels of ride comfort forthe operator in all driving conditions.Operators remain comfortable andproductive throughout the day.Spacious Two-Person Cab.The <strong>740</strong> features a large two-person cab– 41 percent larger than the E Series II –offering comfortable working space forboth the operator and trainer or trainee.All 700 Family articulated trucks usethe same spacious cab design.Cat Comfort Seat. The new Cat Comfortair suspension seat enhances operatorcomfort with a dual-sided supportrecliner and thicker cushions. It is fullyadjustable to provide an optimal drivingposition.Trainer Seat. Full-size trainer seatfeatures a fully padded seat with abackrest and a wide seatbelt for a secureand comfortable ride. The trainer seat ispositioned next to the operator seat,giving both the operator and trainer aclear view of the instrument panel,controls and the road.Storage Space. More storage space tocreate a safe, secure and unclutteredworking environment.Heating/Ventilation/Air Conditioning.Twelve vents provide air distribution tokeep the operator comfortable and toprovide rapid defrosting of all windows.Heating, air conditioning and defrostingare standard. The recirculation filter ispositioned for easy servicing.Sound Levels. Cab mounts are designedto reduce noise and vibration in the cab.All connections to the cab are resilientlymounted. The operator’s station makesextensive use of sound-absorbing andbarrier materials to keep sound levelslow.Steering Column. Offers telescopingand tilting features to provide acomfortable driving position.6

ServiceabilityMore time on production, less time and money spent on servicing.Extended Service Intervals. Increasedengine oil change and hydraulic oilchange intervals.Test and Lube Points. Test points aregrouped together behind the cab and areaccessible from the ground. Lube pointsare grouped at the rear of the frontframe and the front of the rear frame.Service Points. Engine and transmissiondipstick and fill caps, air and fuel filtersand the fuel-priming pump are allmounted on the left side of the engineunder the hood. Coolant level indicatorand fill cap are outside the cab.Radiator. The radiator package islocated behind the cab, which providesimproved access to both inlet and outletsides of the radiator. The ATAACradiator is located at the front of thetruck.Extended Life Coolant. Extends thechange interval and improvescomponent life by reducing aluminumcorrosion.Hood. The hood is raised and loweredelectrically, minimizing operator effortwhen servicing the machine. A manualoverride is also provided.Electrical Service Center. Locatedinside the cab, this service centerprovides a power port, diagnosticconnector and Cat Data Link connector.Cat Data Link Connector. The Cat DataLink connector provides a plug-in usinga laptop computer with ElectronicTechnician (ET) software. The Cat DataLink port performs programmingfunctions on all electronic controls.Service Access. The cab tilts to the sideto provide easier access underneath,which simplifies servicing of thetransmission, drive shafts and hydraulicpumps. Accessibility to machineelectrical and hydraulic interfaces hasalso been improved. They are locatedon the right side of the cab, behind aremovable cab body panel.<strong>Truck</strong> Transport. The new suspensionsystem eliminates the need to lower thesuspension when transporting the truck,reducing maintenance and downtime.Output Transfer Gear. The OTGprovides lubrication of all bearings andclutches using a distributed-pressurelubricated and filtered system, whichreplaces the previous splash-lubricatedsystem on the E Series II. Betterlubrication and filtration reduce serviceand repair. In addition, improved lipseals on output yokes decrease thechance of leaks.9

Complete Customer SupportCat dealer services help you operate longer with lower costs.Selection. Make detailed comparisonsof the machines you are consideringbefore you buy. What are the jobrequirements, machine attachments andoperating hours? What is your need formachine availability and do you havethe proper loading tool match? YourCat dealer can help.Custom Products. The <strong>740</strong> is compatiblewith a wide range of Caterpillar andauxiliary equipment manufacturers’specialized products. This multipurposehauling system was designedfor use with a common tractor and avariety of trailer options to suit differentmarket segments such as waste,forestry, tunneling, earthmovingand agriculture.Purchase. Look past the initial price,look at the value the <strong>740</strong> offers.Consider the resale value, compareproductivity and day-to-day operatingcosts and fuel consumption. Consultyour local Cat dealer for financingoptions.Operation. For the best operatingtechniques to increase productivity andyour profit, turn to your Cat dealer forthe latest training literature and trainedstaff.Maintenance. Repair option programsguarantee the cost of repairs up front.Diagnostic programs such as S•O•S smand Technical Analysis help you avoidunscheduled repairs.Replacement. Repair or rebuild?Caterpillar trucks are designedfor longer life with rebuildablecomponents. Your Cat dealer canhelp you evaluate the cost involvedso you can make the right choice.Product Support. The <strong>740</strong> offers easymaintenance with combined servicepoints and extended service intervalsto keep the machine running longer.Your local Cat dealership will be withyou every step of the way with itsunsurpassed worldwide parts support,trained technicians and customersupport agreements.Warranty. Your local Cat dealer is thereto support and protect you. Extendedwarranty options are also available.10

EngineCat 3406E ATAAC EUIRatingGross PowerFlywheel PowerISO 9249EEC 80/1269BoreStrokeDisplacement■■1900 rpm329 kW/441 hp309 kW/415 hp309 kW/415 hp137 mm165 mm14.64 litersThe <strong>740</strong> meets Stage II emissionspecifications for Europe through2005.No engine derating required below2438 m.WeightsRated PayloadTransmission36.3 metric tonsForwardkm/h1 9.32 12.83 17.04 22.55 30.56 40.67 55.1Reverse 13.4Body CapacitiesHeaped SAE 2:1 21.9 m 3Struck 16.5 m 3Heaped SAE 1:1 27.3 m 3Body HoistRaise timeLower timeOperating Weights12 Seconds7 SecondsEmptykgFront axle 19 060Center axle 7075Rear axle 6415Total 32 550Rated LoadFront axle 4541Center axle 15 878Rear axle 15 878Total 36 287LoadedFront axle 23 592Center axle 22 953Rear axle 22 293Total 68 838Body Plate ThicknessFrontScowSideBase8 mm16 mm12 mm16 mmService Refill CapacitiesLitersFuel Tank 560Cooling System 80Hydraulic System 233Engine Crankcase 38Transmission 72Final Drives/Differential 80Output Transfer Gear 21Sound LevelsInterior CabStandards77 dB(A)Brakes ISO 3450-1998Cab/FOPS ISO 3449-1992 Level IICab/ROPS ISO 3471-1994Optimal Loader/<strong>Truck</strong> Pass MatchingHydraulic Excavators 375 L ME 365B L ME 345B L MELoader Capacity (metric tons) – 50 min/h 900-1125 750-1100 665-805Passes 4 5 6Wheel Loaders 988G 980G 972G 966GLoader Capacity (metric tons) – 50 min/h 565-790 590-650 490-565 400-535Passes 3-4 4 5 5-6An optimum system match gives you a major productivity advantage. The <strong>740</strong> is an excellent match for the Cat 345B L, 365B L and 375 L Hydraulic Excavators;and 972G, 980G and 988G Wheel Loaders. Thus results in increased production and lower system costs per unit of volume moved.<strong>740</strong> <strong>Articulated</strong> <strong>Truck</strong> specifications11

Gradeability/Speed/RimpullTo determine performance,read from Gross Weight downto % Total Resistance.Total Resistance equalsactual % grade plus 1% for each10 kg/metric ton of RollingResistance. From this point,read horizontally to the curvewith the highest attainablespeed range. Then, go downto Maximum Speed.Usable Rimpull dependson traction available.Rimpullkg x 1000504030201053210.512345EGross Weight15 20 25 30 40 50 60 70 80 100 kg x 10006L<strong>740</strong>%30%25%20%15%12%10%8%6%5%4%3%2%Total Resistance % (Grade plus Rolling Resistance)0.30 5 10 15 20 25 30 35 40 45 50 55 60km/hSpeedE – Empty 32 550 kgL – Loaded 68 838 kg1 – 1st Gear2 – 2nd Gear3 – 3rd Gear4 – 4th Gear5 – 5th Gear6 – 6th Gear7 – 7th Gear12 <strong>740</strong> <strong>Articulated</strong> <strong>Truck</strong> specifications

Retarding PerformanceTo determine performance,read from Gross Weight downto % Effective Grade. EffectiveGrade equals actual % favorablegrade plus 1% for each10 kg/metric ton of RollingResistance. From this point,read horizontally to the curvewith the highest attainablespeed range. Then, go down toMaximum Speed. Retardingeffect on these curves representsfull application of the retarder.Gross Weight0 10 20 30 40 50 60 70 80 kg X 100050% 40% 35% 30% 25%EL120%Rimpull23415%10%% Effective Grade (Favorable)56 75%0 10 20 30 40 50 60 70 km/hSpeedE – Empty 32 550 kgL – Loaded 68 838 kg1 – 1st Gear2 – 2nd Gear3 – 3rd Gear4 – 4th Gear5 – 5th Gear6 – 6th Gear7 – 7th Gear<strong>740</strong> <strong>Articulated</strong> <strong>Truck</strong> specifications 13

DimensionsAll dimensions are approximate.6271 mm3418 mm7068 mm70 ∞5670 mmInside of Body3100 mm3745 mm577 mm697 mm 1458 mm1966 mm 4244 mm10 889 mm3221 mm2687 mm3430 mmTurning CircleDimensions are for machines equipped with 29.5R25 tires.Turning dimensionsSteer angle – left/right 45°SAE turning radius8138 mmClearance radius8595 mmInside radius4101 mmAisle width5694 mm14 <strong>740</strong> <strong>Articulated</strong> <strong>Truck</strong> specifications

Standard EquipmentStandard equipment may vary. Consult your Caterpillar dealer for specifics.Air conditioning with R134ArefrigerantAir vents, adjustableBack up alarmBody, includes exhaust heat routingDifferentials, clutched cross-axle forall axlesElectrical system: 24 volt,2.5A 24 to 12 volt converterEngine compression brakeEther start readyGlass windows, toughened and tinted,front and rearGuards: rear window and radiator,crankcase and axleHeadlights, four with dimmer switchHeater and defroster with three-speedfanHorn, electricLights: cab interior, front, side, rear,two reversing/working lights,two stop/tail lightsMirrors, left and rightMud flaps, body mountedRadio readyROPS/FOPS cab with fullinstrumentation including:– Electronic Monitoring Systempanel: alternator, coolanttemperature, brake oil pressure,engine oil pressure, low fuelindicator– Gauges: fuel (in cab), torqueconverter temperature.– Indicator lights: direction, hazard,headlights, high beam only, crossaxle differential lock-up, parkingbrake, transmission/torqueconverter lock-up– Meters: service hour meter,speedometer, tachometerSeat, Caterpillar Comfort seat with airsuspensionSeat, padded companion/trainerSeatbelts, two retractableS•O•S sm sampling valvesSpillguard: front, integral part offabricated bodyStarting receptacle, electric, remoteStorage – two cup holders, under seatstorage, door pocket, behind seatstorage, coat hook.Sun visorSupplemental steeringTires, 29.5R25, radial, Michelin XADNand Goodyear RL2+Toolbox, lockableTow pins front and rearVandalism protection: lockable caps forfuel tank, hydraulic oil tank andradiatorWindows opening side, tintedWindshield wiper and washer,intermittent (front)Optional EquipmentOptional equipment may vary. Consult your Caterpillar dealer for specifics.Body connection for exhaust heatBody linersEther start canisterSound suppression spectatorTailgates:– Scissor-type– UnderslungTires, low profileTool kitWiper/washer, rear window intermittentHeated rearview mirrors<strong>740</strong> <strong>Articulated</strong> <strong>Truck</strong> specifications 15

<strong>740</strong> <strong>Articulated</strong> <strong>Truck</strong>HEHM5436 (07/2001) hrMaterials and specifications are subject to change without notice.Featured machines in photos may include additional equipment.See your Caterpillar dealer for available options.www.CAT.com© 2001 Caterpillar®