VISA Steel Limited Annual Report 2007-08

VISA Steel Limited Annual Report 2007-08

VISA Steel Limited Annual Report 2007-08

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

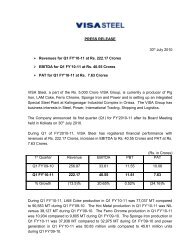

integrating the value chainWith Ferro Chrome production in placeFerro chrome production is apower-intensive process, as is theentire steel manufacturing chain.<strong>VISA</strong> <strong>Steel</strong> is in the process ofsetting up a 75 MW captive powerplant, in two phases.Captive power supplyis the next stepDuring the year <strong>2007</strong>-<strong>08</strong>, <strong>VISA</strong> <strong>Steel</strong> commissioned its50,000 TPA Ferro Chrome Plant. The plant is equipped withtwo electric submerged arc furnaces of 16.5 MVA each.These state-of-the-art machines produce High CarbonFerro Chrome. <strong>VISA</strong> <strong>Steel</strong> has actualised its strategy of“getting the metallics in place”. The Ferro Chrome Planthas enabled the Company enter the league of majormanufacturers of this critical alloy. This is a key elementin the integration of the steel value chain. Moreover, <strong>VISA</strong><strong>Steel</strong>’s proximity to the Sukinda Valley chrome ore reservesreduces logistics costs and allows for a steady supply ofraw material. Production of Ferro Chrome during the yearwas 18,014 onnes.Ferro chrome production is a power-intensive process,as is the entire steel manufacturing chain. <strong>VISA</strong> <strong>Steel</strong>is in the process of setting up a 75 MW captive powerplant, in two phases. The first phase of this project is thecommissioning of a 50 MW Power Plant by utilising wasteheat generated by the Coke Oven, Blast Furnace and DRIPlant, further capturing value. An additional 25 MW PowerPlant using coal and char shall follow. <strong>VISA</strong> <strong>Steel</strong> hasalso commissioned the 220 kv power transmission line tofacilitate stable supply of power at the Kalinganagar facility.With a current power requirement of around 35 MW,these steps will offer the twin benefits of assured powersupply and steady cash flow by using captive power. TheCompany will bolster its profit margins by leveraging asubstantial cost saving compared to existing costs.The Captive Power Plant will help <strong>VISA</strong> <strong>Steel</strong>in the years ahead to establish itself as a lowcost producer of Ferro Chrome.<strong>Annual</strong> <strong>Report</strong> <strong>2007</strong>-<strong>08</strong>17