THE HISTORY OF TUNGSRAM 1896-1945 - MEK

THE HISTORY OF TUNGSRAM 1896-1945 - MEK

THE HISTORY OF TUNGSRAM 1896-1945 - MEK

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

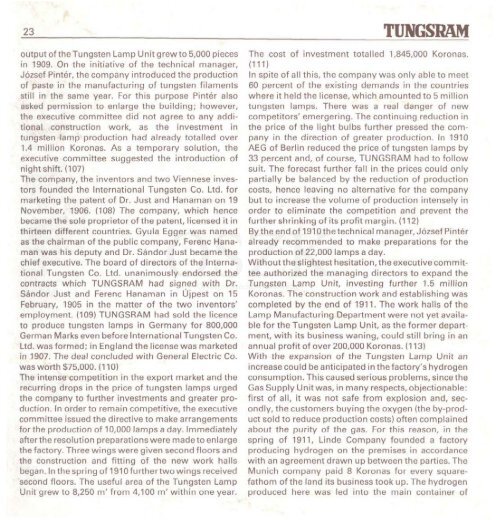

23 <strong>TUNGSRAM</strong>output of the Tungsten Lamp Unit grew to 5,000 piecesin 1909. On the initiative of the technical manager,Jozsef Pinter, the company introduced the productionof paste in the manufacturing of tungsten filamentsstill in the same year. For this purpose Pinter alsoasked permission to enlarge the building; however,the executive committee did not agree to any additionalconstruction work, as the investment intungsten lamp production had already totalled over1.4 million Koronas. As a temporary solution, theexecutive committee suggested the introduction ofnight shift. (107)The company, the inventors and two Viennese investorsfounded the International Tungsten Co. Ltd. formarketing the patent of Dr. Just and Hanaman on 19November, 1906. (108) The company, which hencebecame the sole proprietor of the patent, licensed it inthirteen different countries. Gyula Egger was namedas the chairman of the public company, Ferenc Hanamanwas his deputy and Dr. Sandor Just became thechief executive. The board of directors of the InternationalTungsten Co. Ltd. unanimously endorsed thecontracts which <strong>TUNGSRAM</strong> had signed with Dr.Sandor Just and Ferenc Hanaman in Ujpest on 15February, 1905 in the matter of the two inventors'employment. (109) <strong>TUNGSRAM</strong> had sold the licenceto produce tungsten lamps in Germany for 800,000German Marks even before International Tungsten Co.Ltd. was formed; in England the license was marketedin 1907. The deal concluded with General Electric Co.was worth $75,000. (110)The intense competition in the export market and therecurring drops in the price of tungsten lamps urgedthe company to further investments and greater production.In order to remain competitive, the executivecommittee issued the directive to make arrangementsfor the production of 10,000 lamps a day. Immediatelyafter the resolution preparationswere made to enlargethe factory. Three wings were given second floors andthe construction and fitting of the new work hallsbegan. In the spring of 1910 further two wings receivedsecond floors. The useful area of the Tungsten LampUnit grew to 8,250 m' from 4,100 m' within one year.The cost of investment totalled 1,845,000 Koronas.(Ill)In spite of all this, the company was only able to meet60 percent of the existing demands in the countrieswhere it held the license, which amounted to 5 milliontungsten lamps. There was a real danger of newcompetitors' emergering. The continuing reduction inthe price of the light bulbs further pressed the companyin the direction of greater production. In 1910AEG of Berlin reduced the price of tungsten lamps by33 percent and, of course, <strong>TUNGSRAM</strong> had to followsuit. The forecast further fall in the prices could onlypartially be balanced by the reduction of productioncosts, hence leaving no alternative for the companybut to increase the volume of production intensely inorder to eliminate the competition and prevent thefurther shrinking of its profit margin. (112)Bythe end of 1910 the technical manager, Jozsef Pinteralready recommended to make preparations for theproduction of 22,000 lamps a day.Without the slightest hesitation, the executive committeeauthorized the managing directors to expand theTungsten Lamp Unit, investing further 1.5 millionKoronas. The construction work and establishing wascompleted by the end of 1911. The work halls of theLamp Manufacturing Department were not yet availablefor the Tungsten Lamp Unit, as the former department,with its business waning, could still bring in anannual profit of over 200,000 Koronas. (113)With the expansion of the Tungsten Lamp Unit anincrease could be anticipated in the factory's hydrogenconsumption. This caused serious problems, since theGas Supply Unit was, in many respects, objectionable:first of all, it was not safe from explosion and, secondly,the customers buying the oxygen (the by-productsold to reduce production costs) often complainedabout the purity of the gas. For this reason, in thespring of 1911, Linde Company founded a factoryproducing hydrogen on the premises in accordancewith an agreement drawn up between the parties. TheMunich company paid 8 Koronas for every squarefathomof the land its business took up. The hydrogenproduced here was led into the main container of

![Letöltés egy fájlban [4.3 MB - PDF]](https://img.yumpu.com/50159926/1/180x260/letaltacs-egy-fajlban-43-mb-pdf.jpg?quality=85)