THE HISTORY OF TUNGSRAM 1896-1945 - MEK

THE HISTORY OF TUNGSRAM 1896-1945 - MEK

THE HISTORY OF TUNGSRAM 1896-1945 - MEK

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

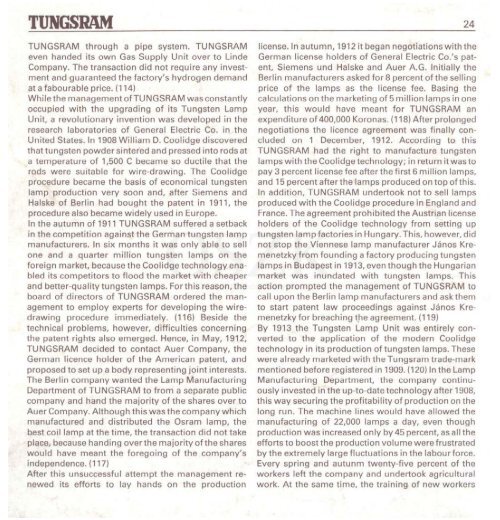

<strong>TUNGSRAM</strong>.^.•:-i-'24<strong>TUNGSRAM</strong> through a pipe system. <strong>TUNGSRAM</strong>even handed its own Gas Supply Unit over to LindeCompany. The transaction did not require any investmentand guaranteed the factory's hydrogen demandat a fabourable price. (114)While the management of <strong>TUNGSRAM</strong> was constantlyoccupied with the upgrading of its Tungsten LampUnit, a revolutionary invention was developed in theresearch laboratories of General Electric Co. in theUnited States. In 1908 William D. Coolidge discoveredthat tungsten powder sintered and pressed into rods ata temperature of 1,500 C became so ductile that therods were suitable for wire-drawing. The Coolidgeprocedure became the basis of economical tungstenlamp production very soon and, after Siemens andHalske of Berlin had bought the patent in 1911, theprocedure also became widely used in Europe.In the autumn of 1911 <strong>TUNGSRAM</strong> suffered a setbackin the competition against the German tungsten lampmanufacturers. In six months it was only able to sellone and a quarter million tungsten lamps on theforeign market, because the Coolidge technology enabledits competitors to flood the market with cheaperand better-quality tungsten lamps. For this reason, theboard of directors of <strong>TUNGSRAM</strong> ordered the managementto employ experts for developing the wiredrawingprocedure immediately. (116) Beside thetechnical problems, however, difficulties concerningthe patent rights also emerged. Hence, in May, 1912,<strong>TUNGSRAM</strong> decided to contact Auer Company, theGerman licence holder of the American patent, andproposed to set up a body representing joint interests.The Berlin company wanted the Lamp ManufacturingDepartment of <strong>TUNGSRAM</strong> to from a separate publiccompany and hand the majority of the shares over toAuer Company. Although this was thecompany whichmanufactured and distributed the Osram lamp, thebest coil lamp at the time, the transaction did not takeplace, because handing overthe majority of the shareswould have meant the foregoing of the company'sindependence. (117)After this unsuccessful attempt the management renewedits efforts to lay hands on the productionlicense. In autumn, 1912 it began negotiations with theGerman license holders of General Electric Co.'s patent,Siemens und Halske and Auer A.G. Initially theBerlin manufacturers asked for 8 percent of the sellingprice of the lamps as the license fee. Basing thecalculations on the marketing of 5 million lamps in oneyear, this would have meant for <strong>TUNGSRAM</strong> anexpenditure of 400,000 Koronas. (118) After prolongednegotiations the licence agreement was finally concludedon 1 December, 1912. According to this<strong>TUNGSRAM</strong> had the right to manufacture tungstenlamps with the Coolidge technology; in return it was topay 3 percent license fee after the first 6 million lamps,and 15 percent afterthe lamps produced on top of this.In addition, <strong>TUNGSRAM</strong> undertook not to sell lampsproduced with the Coolidge procedure in England andFrance. The agreement prohibited the Austrian licenseholders of the Coolidge technology from setting uptungsten lamp factories in Hungary. This, however, didnot stop the Viennese lamp manufacturer Janos Kremenetzkyfrom founding a factory producing tungstenlamps in Budapest in 1913, even though the Hungarianmarket was inundated with tungsten lamps. Thisaction prompted the management of <strong>TUNGSRAM</strong> tocall upon the Berlin lamp manufacturers and ask themto start patent law proceedings against Janos Kremenetzkyfor breaching the agreement. (119)By 1913 the Tungsten Lamp Unit was entirely convertedto the application of the modern Coolidgetechnology in its production of tungsten lamps. Thesewere already marketed with the Tungsram trade-markmentioned before registered in 1909. (120) In the LampManufacturing Department, the company continuouslyinvested in the up-to-date technology after 1908,this way securing the profitability of production on thelong run. The machine lines would have allowed themanufacturing of 22,000 lamps a day, even thoughproduction was increased only by 45 percent, as all theefforts to boost the production volume were frustratedby the extremely large fluctuations in the labourforce.Every spring and autunm twenty-five percent of theworkers left the company and undertook agriculturalwork. At the same time, the training of new workers• * .

![Letöltés egy fájlban [4.3 MB - PDF]](https://img.yumpu.com/50159926/1/180x260/letaltacs-egy-fajlban-43-mb-pdf.jpg?quality=85)